Curve fiber composite structure design multi-level optimization method

A fiber composite and structural design technology, applied in design optimization/simulation, special data processing applications, etc., can solve the problem of high computational cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

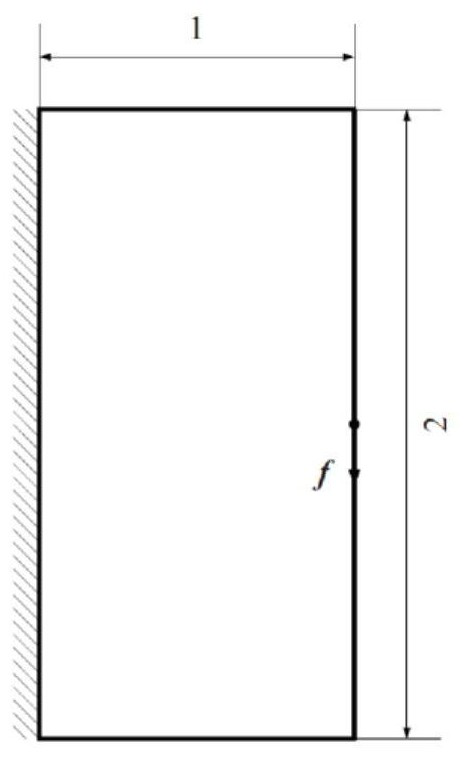

Embodiment 1

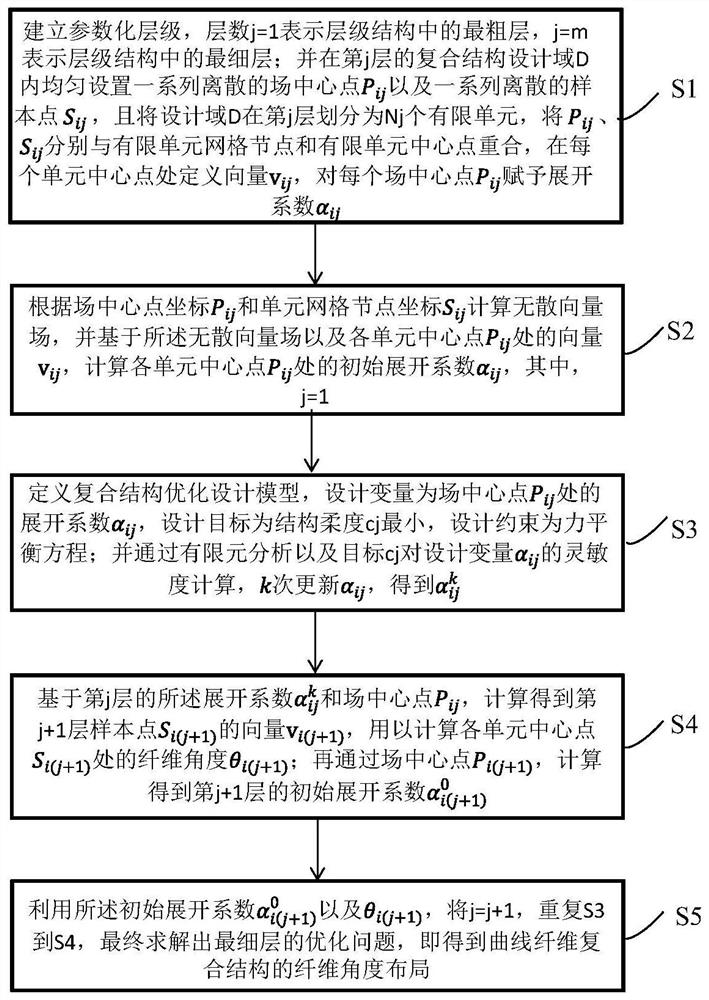

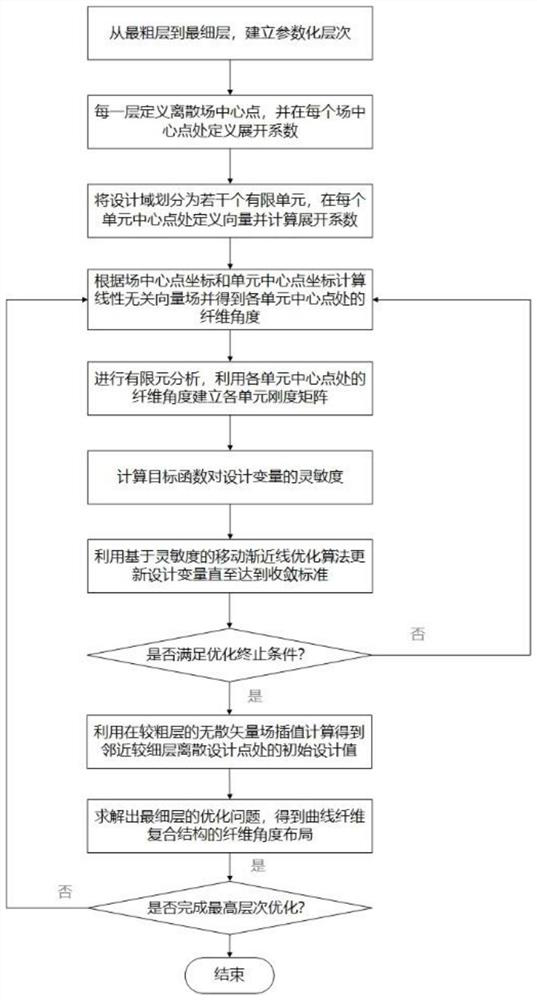

[0040] A multilevel optimization method for the design of curved fiber composite structures based on vector field interpolation without divergence, such as figure 1 As shown, it includes the following steps:

[0041] (1) Establish a parameterized hierarchy, the number of layers is m, and solve the optimization problem of the jth layer, where j=1, 2,...m. j=1 represents the coarsest layer in the hierarchical structure, and j=m represents the thinnest layer in the hierarchical structure.

[0042] (2) Evenly set a series of discrete field center points P in the composite structure design domain D of the jth layer ij (i=1,2,3,...,n j ) and a series of discrete sample points S ij (i=1,2,3,...,l j ). For each field center point P ij Assign expansion coefficient α ij , and divide the design domain D into N at layer j j finite elements (where n, l and N are positive integers). Among them, the P ij , S ij coincide with the finite element grid nodes and finite element center ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com