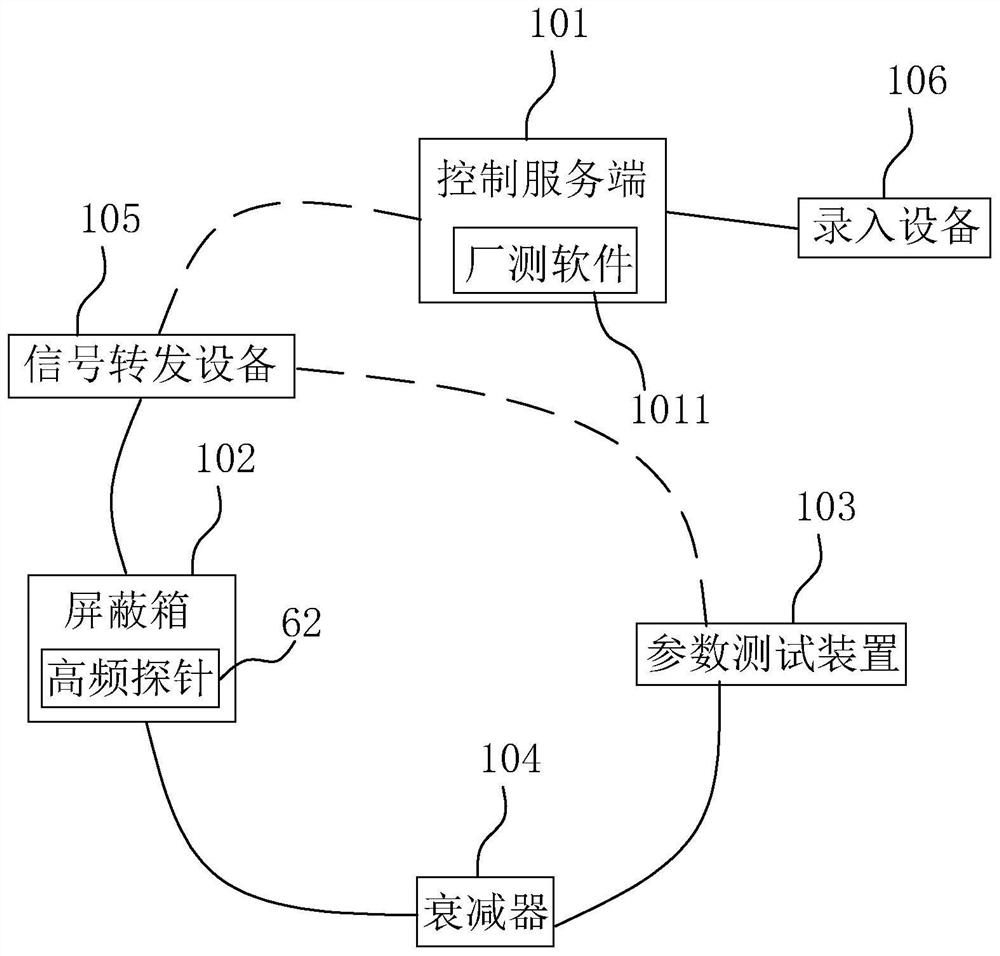

WIFI radio frequency test system and method

A radio frequency test system and parametric test technology, applied in transmitter monitoring, receiver monitoring and other directions, can solve the problems of low test efficiency, low cost, poor test stability and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

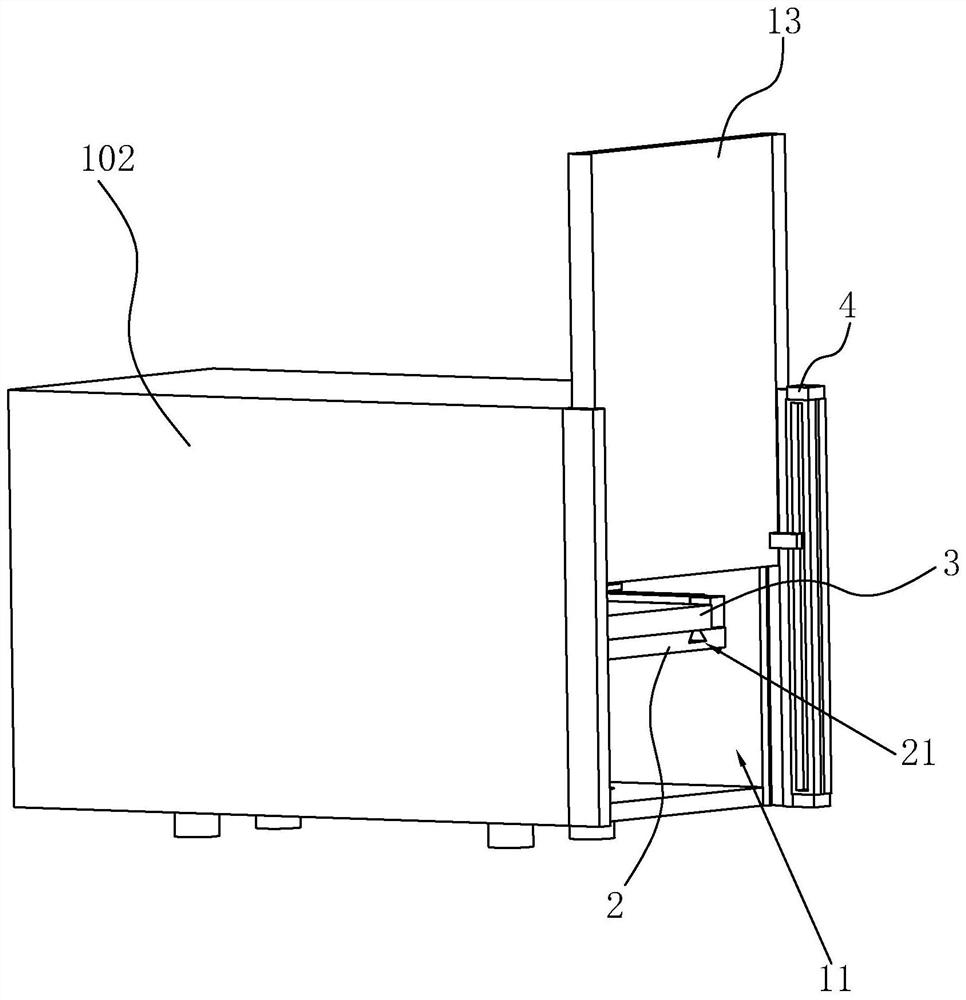

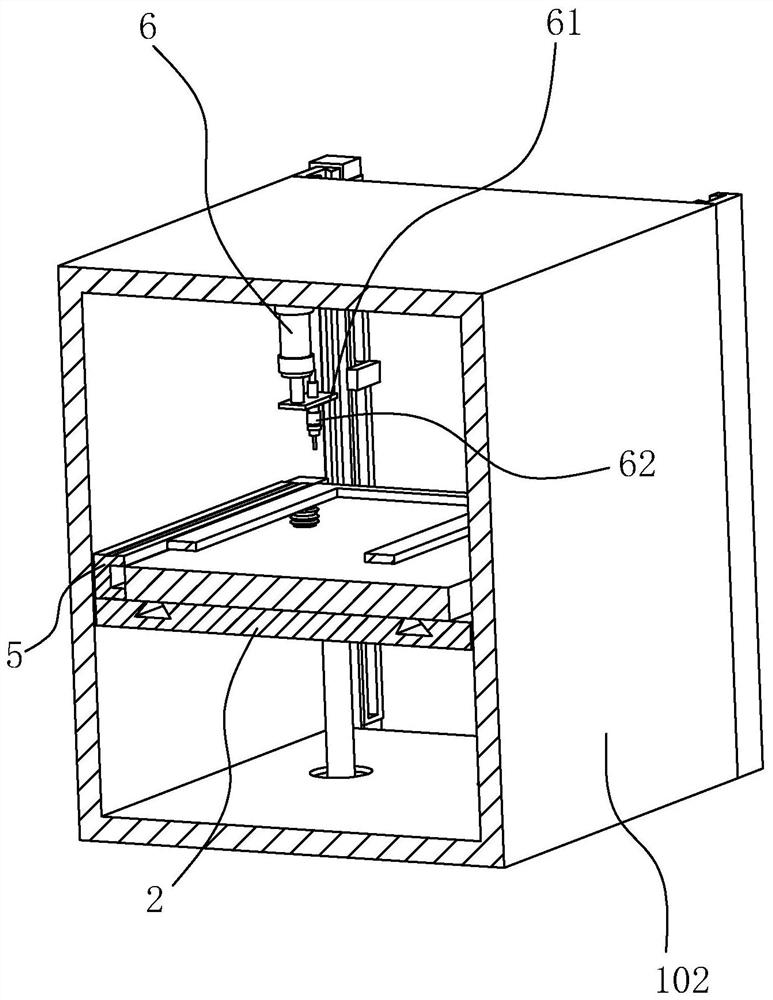

[0090] refer to Figure 7 , as an implementation of the test access wiring 202, including the following steps:

[0091] 2021. Connect one end of the serial cable to the input and output interface of the product under test, and connect the other end to the input and output port of the signal forwarding device.

[0092] 2022. Connect one end of the attenuator to the high-frequency probe through a radio frequency cable, and connect the other end of the attenuator to an output end of the parameter testing device through a radio frequency cable.

[0093] 2023. Start the third cylinder to make the high-frequency probe approach and connect to the RF head of the product under test.

[0094] refer to Figure 8 , as an implementation of launch indicator debugging 203, including the following steps:

[0095] 2031. In the first step of updating the calibration file, the calibration file is updated and placed in the project directory of the factory test software at the control server. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com