Steel rail supporting frame for urban rail transit integral building construction

A technology for urban rail transit and building construction. It is applied in the field of rail support frames for the overall construction of urban rail transit. It can solve problems such as inability to assist cleaning, affect normal adjustment, and vibrating cleaning, so as to save adjustment time and reduce the probability of residue Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] as attached figure 1 To attach Figure 8 Shown:

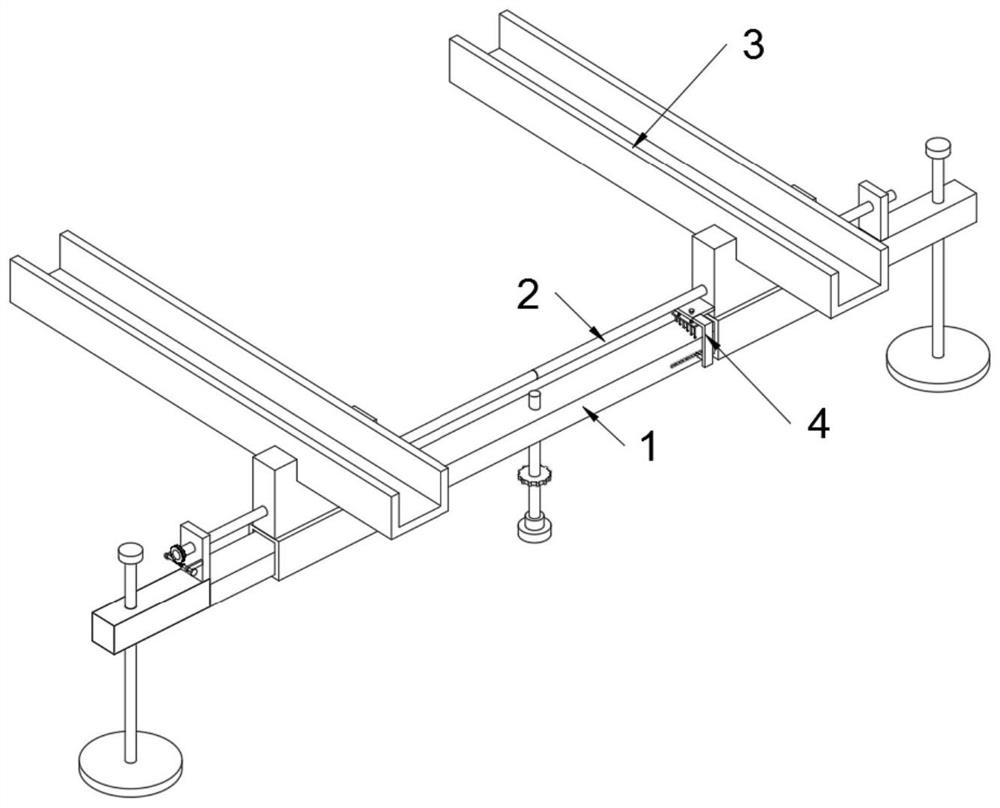

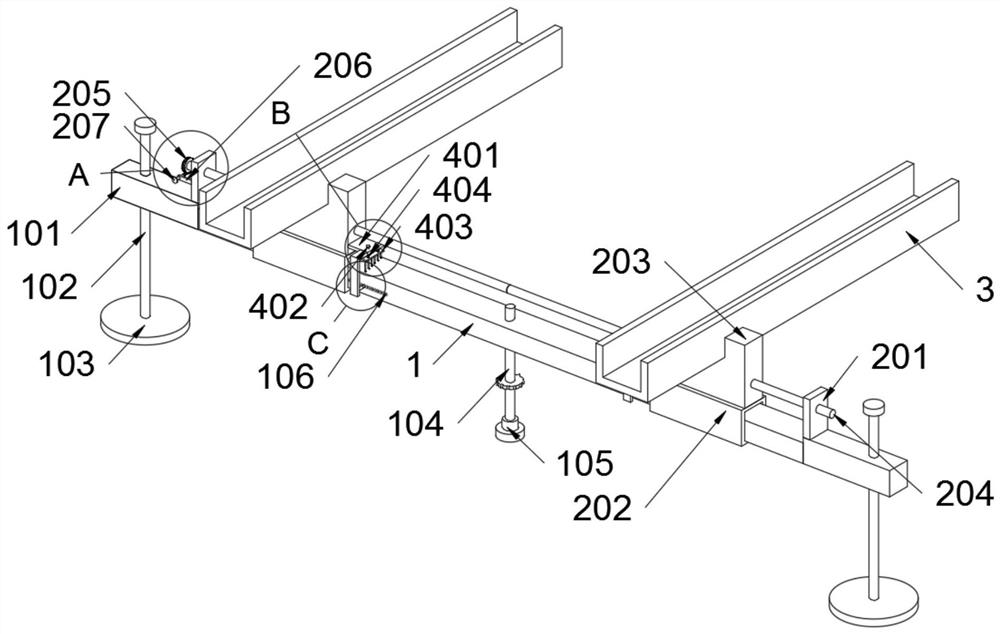

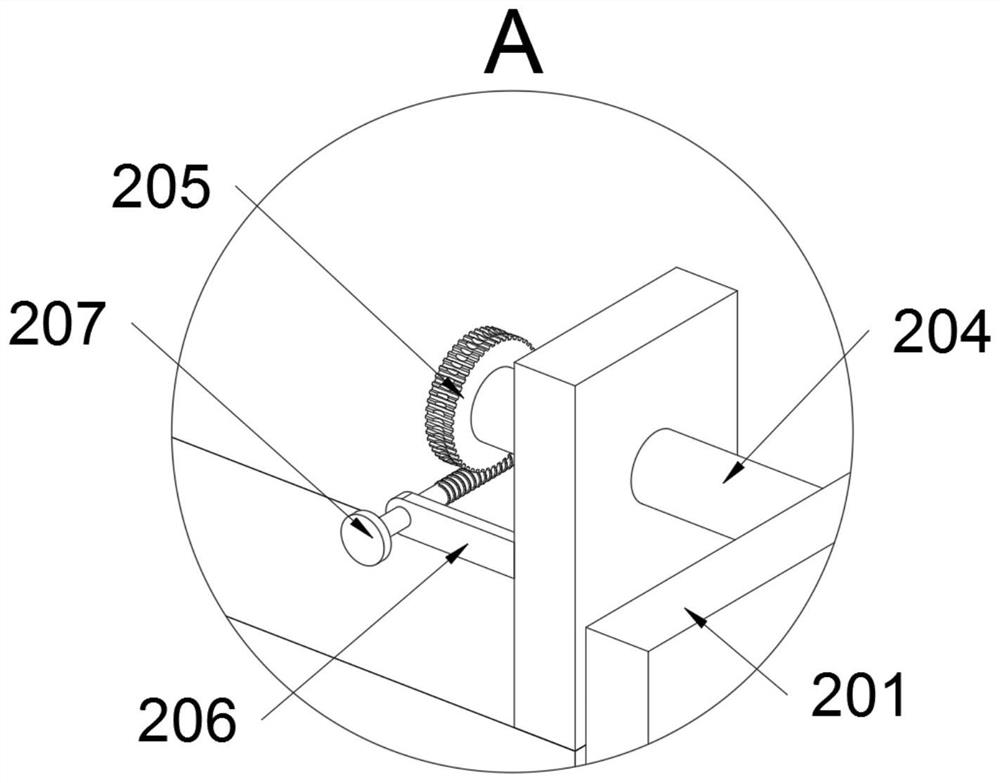

[0035]The present invention provides a steel rail support frame for urban rail transit integral building construction, comprising a main body rod 1; an adjustment structure 2 is installed on the main body rod 1, and two rails 3 are placed on the adjustment structure 2, and the There are also two auxiliary structures 4 installed; see e.g. figure 2 and Figure 5 The main body rod 1 includes a draw-in groove 106, and the main body rod 1 is provided with a draw-in groove 106 in a rectangular array, and the draw-in groove 106 is a semicircular groove-shaped structure; the auxiliary structure 4 includes an elastic telescopic rod 405, and the elastic telescopic rod 405 is welded on the seat body 401, and the head end of the elastic telescopic rod 405 is a hemispherical structure; Type structure, so that when the sliding seat 202 moves, the dust and residue on the main body rod 1 can be shaken off through the continuous eng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com