Thread pair capable of preventing automatic rolling movement in loosening direction

A thread pair, automatic technology, applied in the field of thread pair, can solve the problem that it is difficult to control the clamping force of the workpiece, and achieve the effect of easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

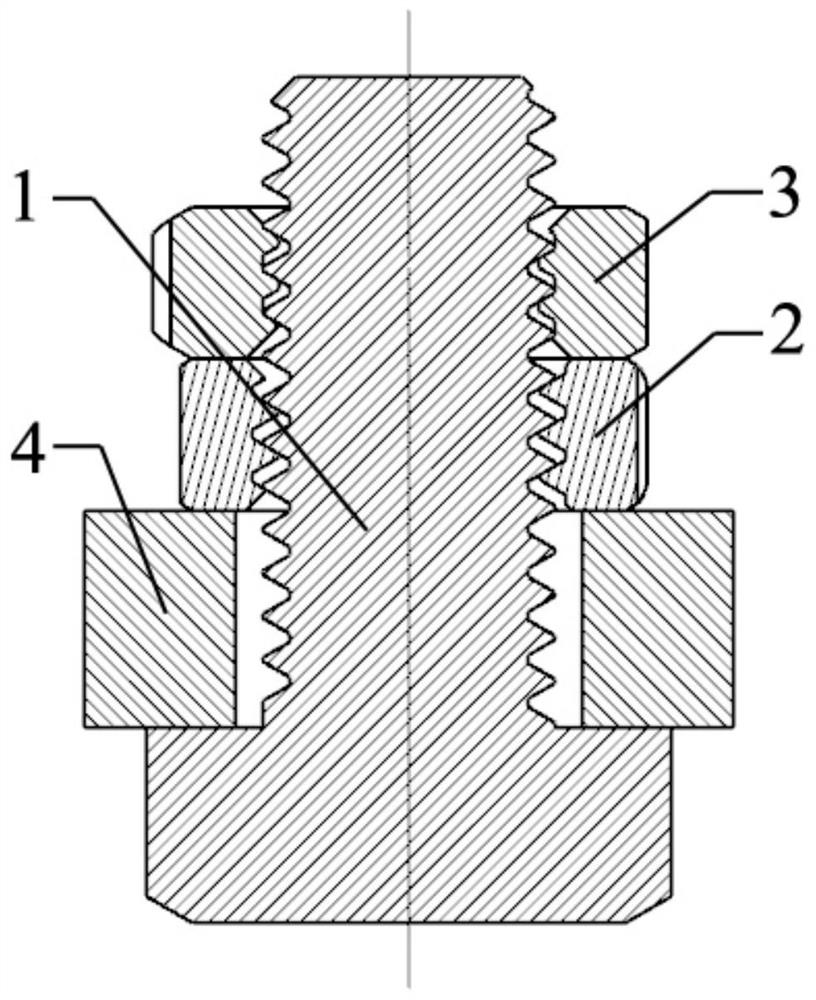

[0033] Such as figure 1 As shown, the thread pair that prevents the automatic rolling movement in the loosening direction includes a bolt 1, a first nut 2 and a second nut 3, and the major diameter of the internal thread of the second nut 3 is smaller than the major diameter of the external thread of the bolt 1. After the bolt 1, the first nut 2 and the second nut 3 are installed and tightened on the workpiece 4, the bottom of the first nut 2 is in contact with the workpiece 4, and the bottom of the second nut 3 is in contact with the first The top of the nut 2 is in contact with each other. The bottom of the internal thread of the second nut 3 and the crest of the external thread of the bolt 1 are in a mutual laterally locked contact structure. The upper flank of the internal thread of the first nut 2 is in contact with the The structure in which the lower flanks of the external thread of the bolt 1 are in contact with each other, the structure in which the upper flank of the...

Embodiment 2

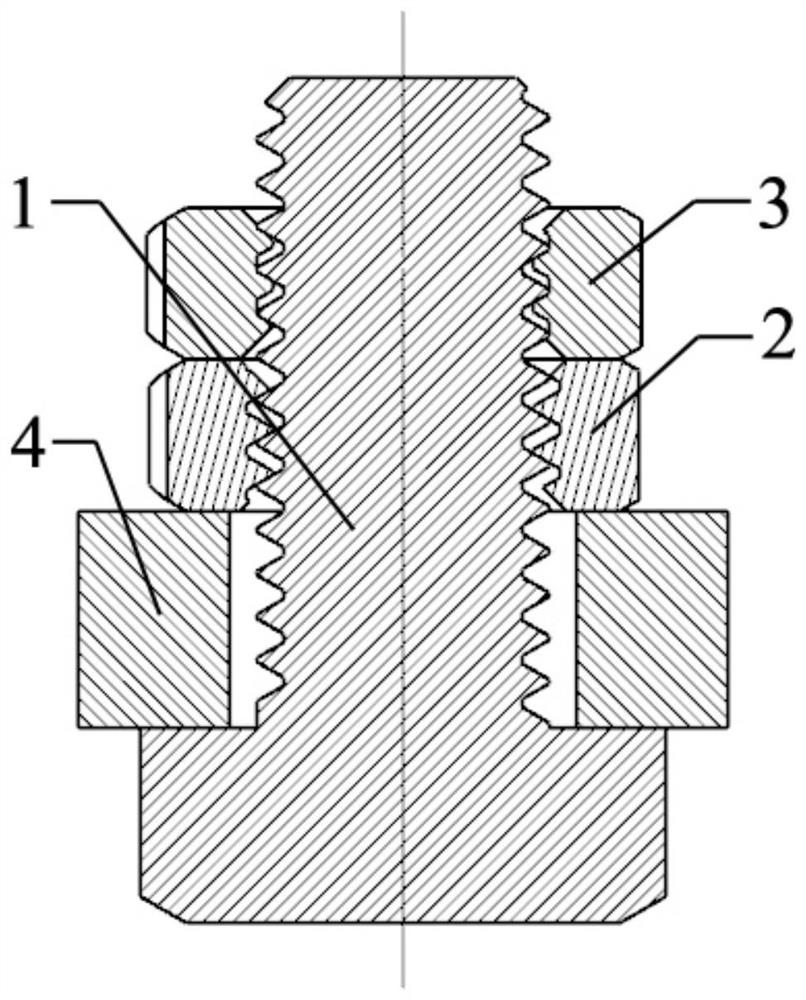

[0037] Such as figure 2 As shown, the thread pair that prevents the automatic rolling movement in the loosening direction includes a bolt 1, a first nut 2 and a second nut 3, and the major diameter of the internal thread of the second nut 3 is smaller than the major diameter of the external thread of the bolt 1. After the bolt 1, the first nut 2 and the second nut 3 are installed and tightened on the workpiece 4, the bottom of the first nut 2 is in contact with the workpiece 4, and the bottom of the second nut 3 is in contact with the first The top of the nut 2 is in contact, the bottom of the internal thread of the second nut 3 and the crest of the external thread of the bolt 1 are mutually locked in a contact structure, the lower flank of the internal thread of the first nut 2 is in contact with the crest of the external thread of the bolt 1 The structure in which the upper flanks of the external thread of the bolt 1 are in contact with each other, the structure in which th...

Embodiment 3

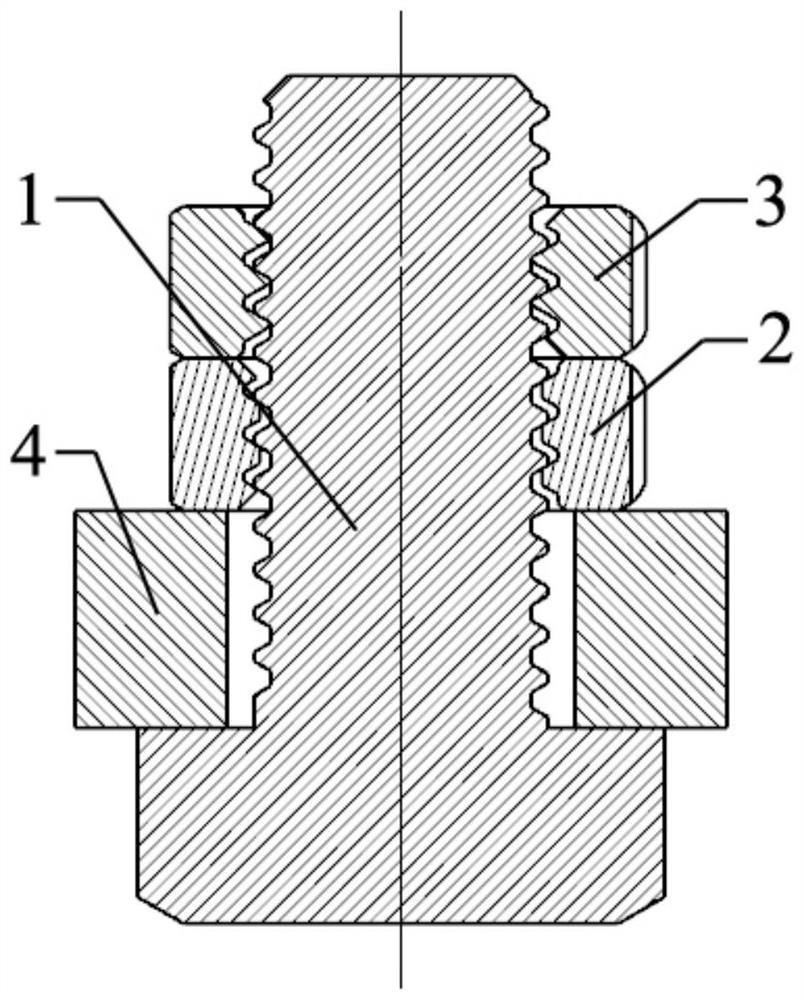

[0041] Such as image 3 As shown, the thread pair that prevents the automatic rolling movement in the loosening direction includes a bolt 1, a first nut 2 and a second nut 3, the inner thread minor diameter of the second nut 3 is smaller than the outer thread minor diameter of the bolt 1, and the After the bolt 1, the first nut 2 and the second nut 3 are installed and tightened on the workpiece 4, the bottom of the first nut 2 is in contact with the workpiece 4, and the bottom of the second nut 3 is in contact with the first nut 2. The crest of the internal thread of the second nut 3 and the bottom of the external thread of the bolt 1 are mutually locked in a contact structure, and the upper flank of the internal thread of the first nut 2 is in contact with the bottom of the external thread of the bolt 1. The structure in which the lower flanks of the external thread of the bolt 1 are in contact with each other, the structure in which the upper flank of the internal thread of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com