A material turning device for female row

A turning device and material passing technology, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems that the workpiece posture cannot be changed, difficult to operate, etc., and achieve the effects of small inertia, reduced mass, and avoiding rigid impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

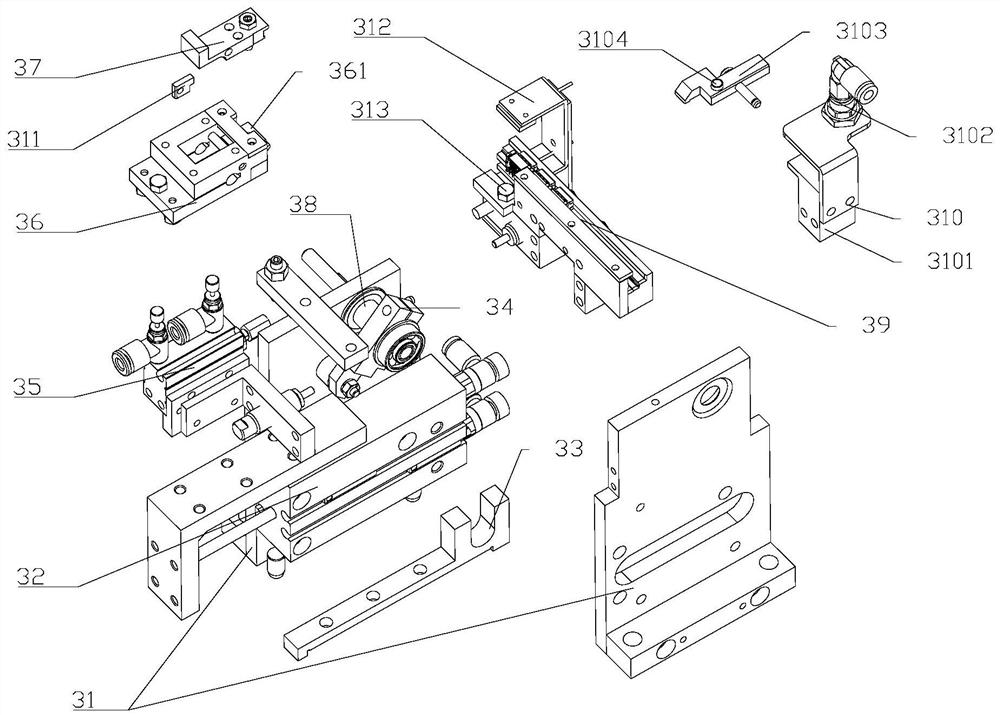

[0017] like figure 1 As shown, a kind of overturning device for female row includes a frame and a fixed base 31 installed on the frame, a horizontal cylinder 32, a groove block 33, a swing rod 34, an unlocking cylinder 35, a rotating material seat 36, a pressing Block 37, rotating shaft 38, feed track 39, pressing assembly 310, end stopper 311, optical fiber sensor 312 and positioning nail 313; Fixed base 31 is fixedly arranged on the frame, horizontal cylinder 32 is installed on the fixed base 31, horizontal Slotted block 33 is installed on the telescoping end of cylinder 32, and described trough-shaped block 33 upper ends are provided with vertical groove, and fork 34 is fixedly arranged on the rotating shaft 38, and is hinged on the fixed base 31 on the rotating shaft 38, and fork The end of 34 is provided with ball, and this ball and trough-shaped block 33 form groove pairs to cooperate; The side of fixed base 31 is provided with unlocking cylinder 35, and unlocking cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com