Fastener capable of preventing automatic rolling movement in loosening direction

A fastener, automatic technology, applied in the direction of threaded fasteners, locking fasteners, connecting components, etc., can solve the problem that it is difficult to control the clamping force of the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

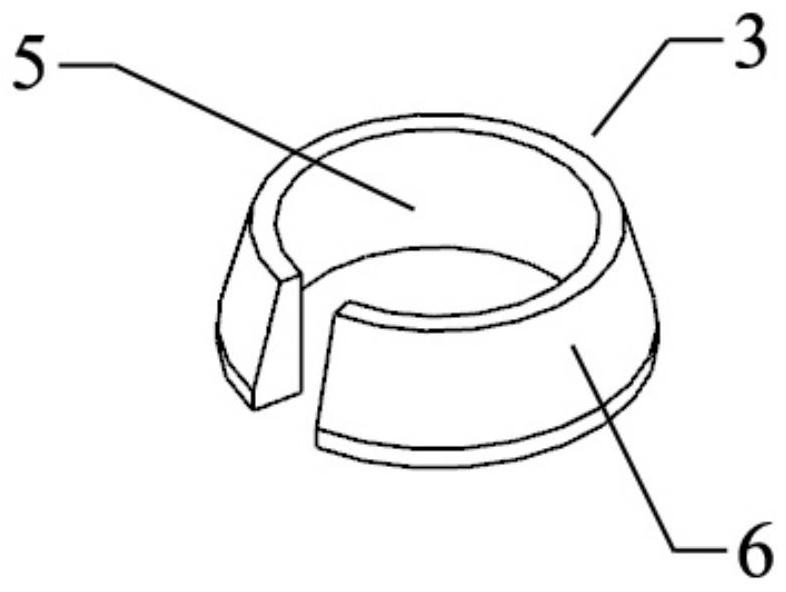

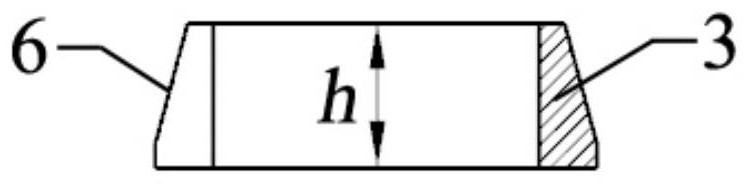

[0042]Such asfigure 1 ,figure 2 ,Figure 5 ,Figure 6,Figure 7 As shown, the fastener for automatically rolling motion in the loose direction, including bolts 1, first nut 2, washer 3, and second nut 4, the center of the gasket 3 is provided with a screw for the bolt 1. No closed through hole 5, the perimeter of the through hole 5 is smaller than the outer thread peripheral length of the bolt 1, the pore size of the through hole 5 is larger than the outer thread of the bolt 1, the through hole 5 The height H is larger than the outer thread riser of the bolt 1, and the top of the gasket 3 is provided with a conical convex surface 6; one end of the second nut 4 is provided with a conical concave surface 7, and the angle θ of the tapered concave surface 7 is smaller than the first The internal thread angle α of the second nut 4 is β with the outer thread angle β of the bolt 1; the bolt 1, the first nut 2, the gasket 3, and the second nut 4 are mounted on the workpiece 8, the first nut 2 ...

Embodiment 2

[0051]Such asfigure 1 ,figure 2 ,Figure 5 ,Figure 6,Figure 8 As shown, the fastener for automatically rolling motion in the loose direction, including bolts 1, first nut 2, washer 3, and second nut 4, the center of the gasket 3 is provided with a screw for the bolt 1. No closed through hole 5, the perimeter of the through hole 5 is smaller than the outer thread peripheral length of the bolt 1, the pore size of the through hole 5 is larger than the outer thread of the bolt 1, the through hole 5 The height H is larger than the outer thread riser of the bolt 1, and the top of the gasket 3 is provided with a conical convex surface 6; one end of the second nut 4 is provided with a conical concave surface 7, and the angle θ of the tapered concave surface 7 is smaller than the first The internal thread angle α of the second nut 4 is β with the outer thread angle β of the bolt 1; the bolt 1, the first nut 2, the gasket 3, and the second nut 4 are mounted on the workpiece 8, the first nut 2 ...

Embodiment 3

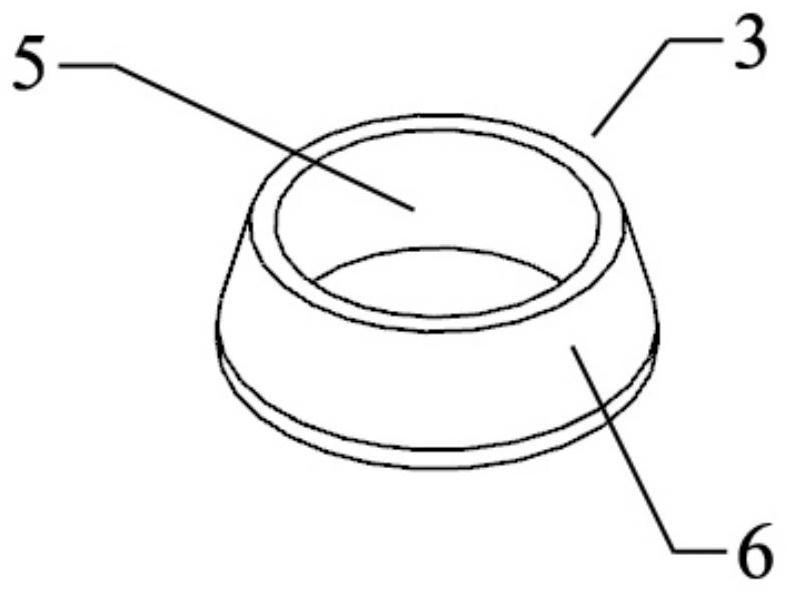

[0059]Such asimage 3 ,Figure 4 ,Figure 5 ,Figure 6,Figure 7 As shown, the fastener for automatically rolling motion in the loose direction, including bolts 1, first nut 2, washer 3, and second nut 4, the center of the gasket 3 is provided with a screw for the bolt 1. The closed through hole 5, the pore size of the through hole 5 is larger than the outer thread of the bolt 1, and the height H of the through hole 5 is larger than the outer thread riser of the bolt 1, and the top of the gasket 3 is provided Conical convex surface 6; one end of the second nut 4 is provided with a conical concave surface 7, and the angle θ of the cone 7 is smaller than the internal thread angle α of the second nut 4 and the outer thread angle β of the bolt 1; The bolt 1, the first nut 2, the washer 3, and the second nut 4 are tightened on the workpiece 8, and the bottom of the first nut 2 is in contact with the workpiece 8; the bottom of the gasket 3 and the first The top of the nut 2 is in contact; afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com