Method and device for extracting defect area on board surface

An extraction method and an extraction device technology, which are applied in the field of extraction of defect areas on board surfaces, can solve problems such as the inability to meet the running speed of a production line, increase in missed detection rate and false detection rate, and long calculation time, so as to save the time required for detection, The effect of reducing time and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

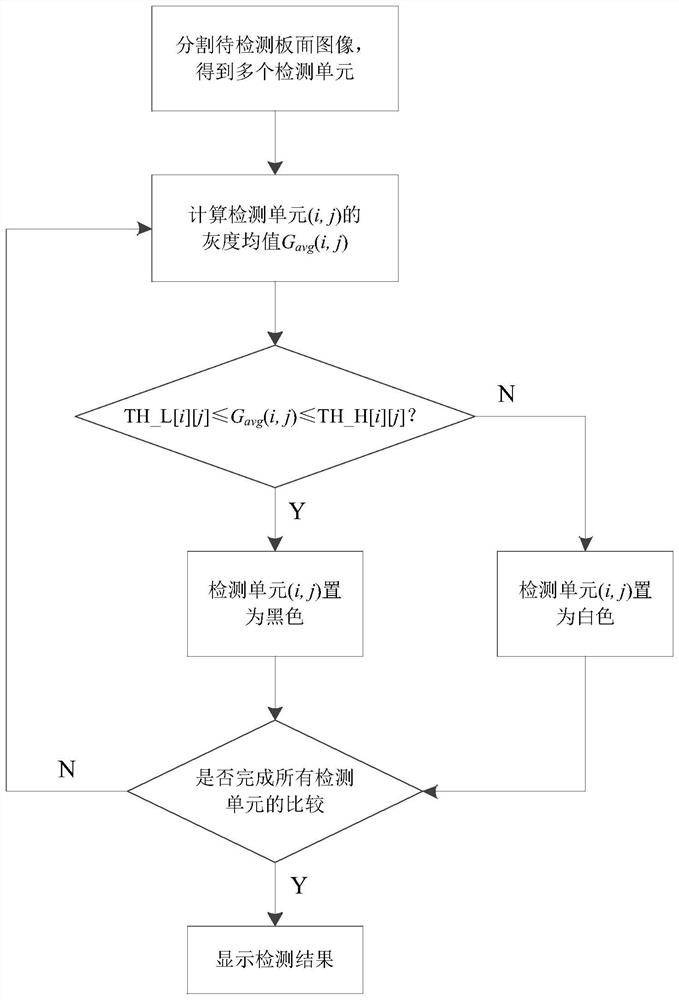

[0057] like figure 1 As shown, this embodiment provides a method for extracting a defect area on a board surface, including:

[0058] Obtain and segment the image of the board to be detected to obtain multiple detection units;

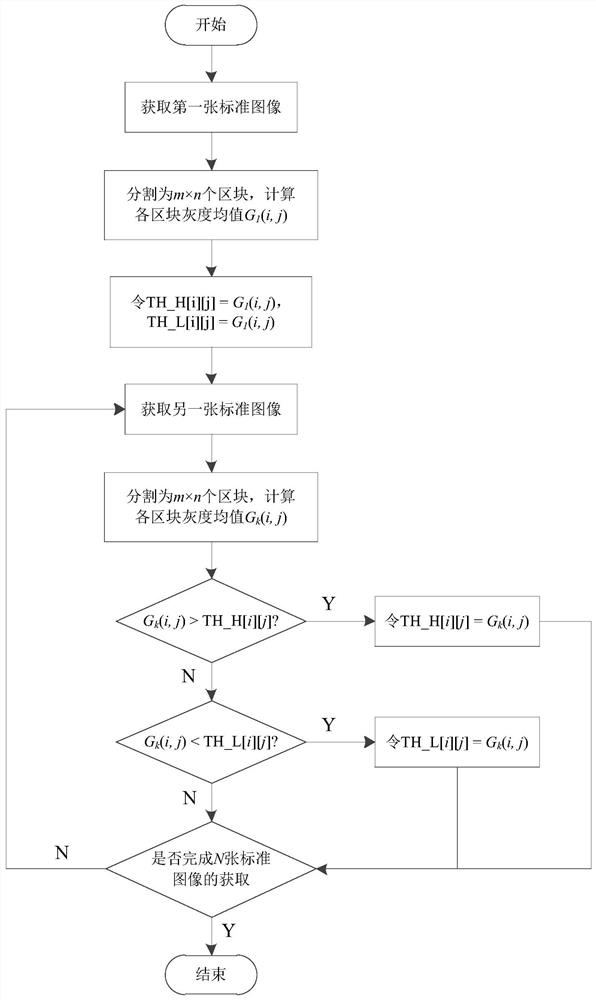

[0059] Obtain the grayscale thresholds corresponding to the multiple detection units one-to-one;

[0060] Calculate the average gray level of the detection unit and compare it with the corresponding gray level threshold to determine whether the detection unit contains a defect.

[0061] In the above solution, by dividing the image of the board surface to be inspected into a plurality of inspection units, for each inspection unit, there is a corresponding grayscale threshold for judging whether a defect is contained therein, which improves the accuracy of the judgment result. . At the same time, all the detection units containing defects together form the defect area on the board surface. When further identification of defects is performed, only the ...

Embodiment 2

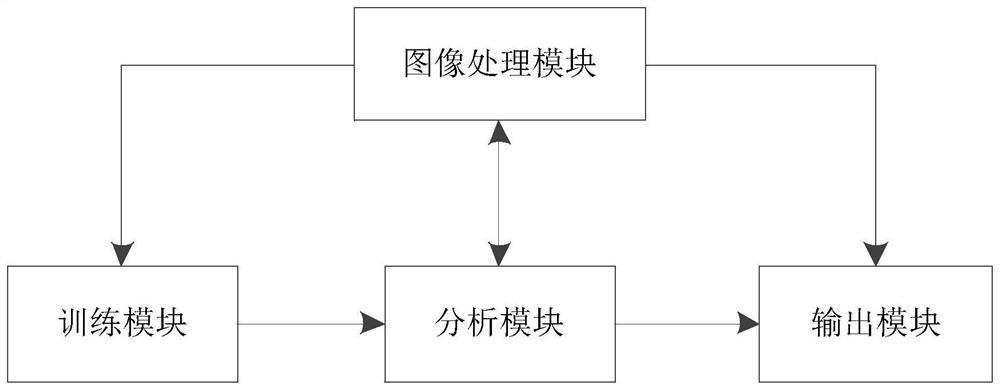

[0096] like image 3 As shown, this embodiment provides a device for extracting a defect area on a board surface, which is used to implement the method for extracting a defect area on a board surface described in the first embodiment. The extraction device for the defect area of the board surface includes:

[0097] The image processing module is used to segment the image of the panel to be detected to obtain a plurality of detection units;

[0098] The analysis module is connected with the image processing module, and is used for calculating the grayscale mean value of the detection unit and comparing it with the obtained grayscale threshold value to judge whether the detection unit contains defects.

[0099] Further, the grayscale threshold includes a high threshold and a low threshold, and the device for extracting the defect area on the board surface further includes a training module.

[0100] The training module is connected with the analysis module, and is used to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com