Patents

Literature

31results about How to "Clear and intuitive understanding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

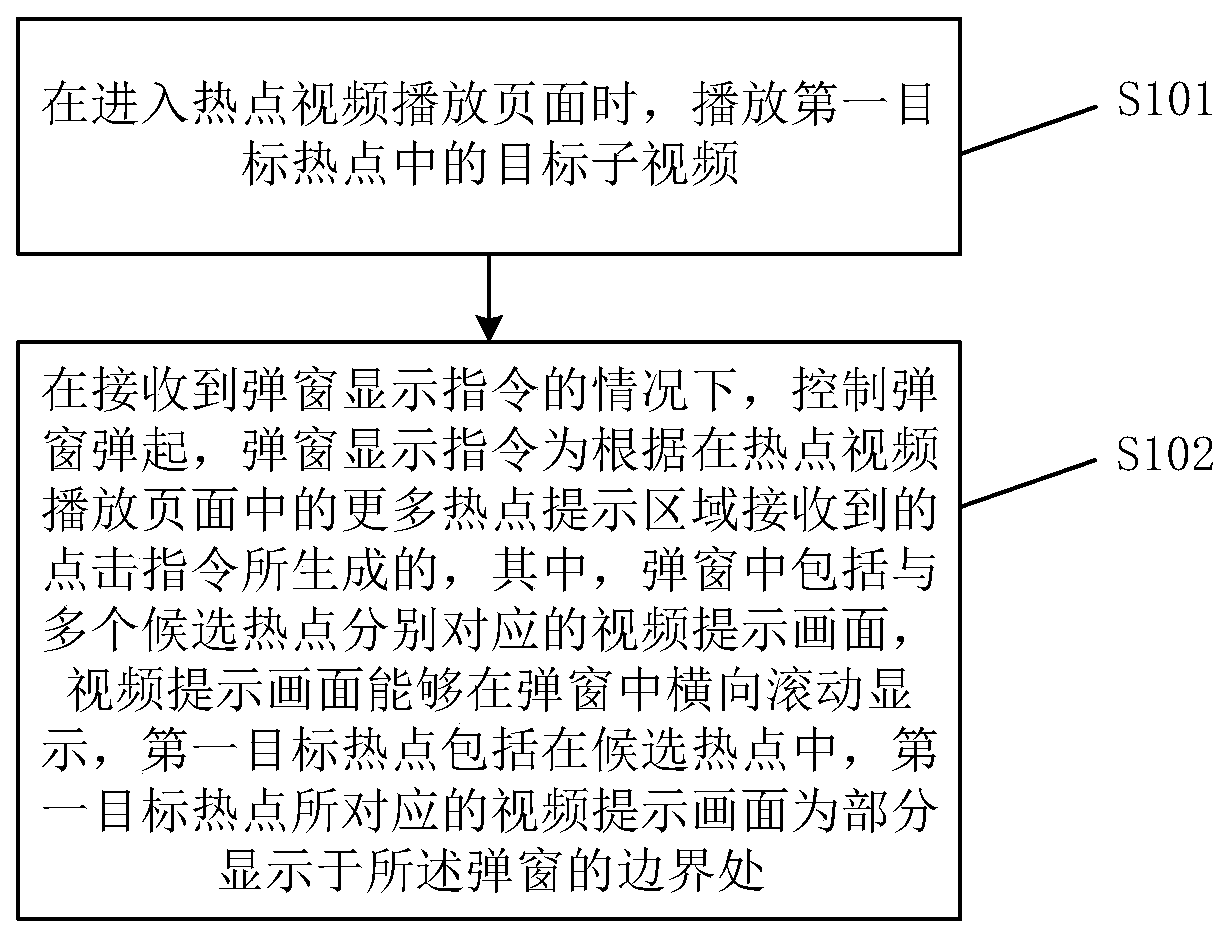

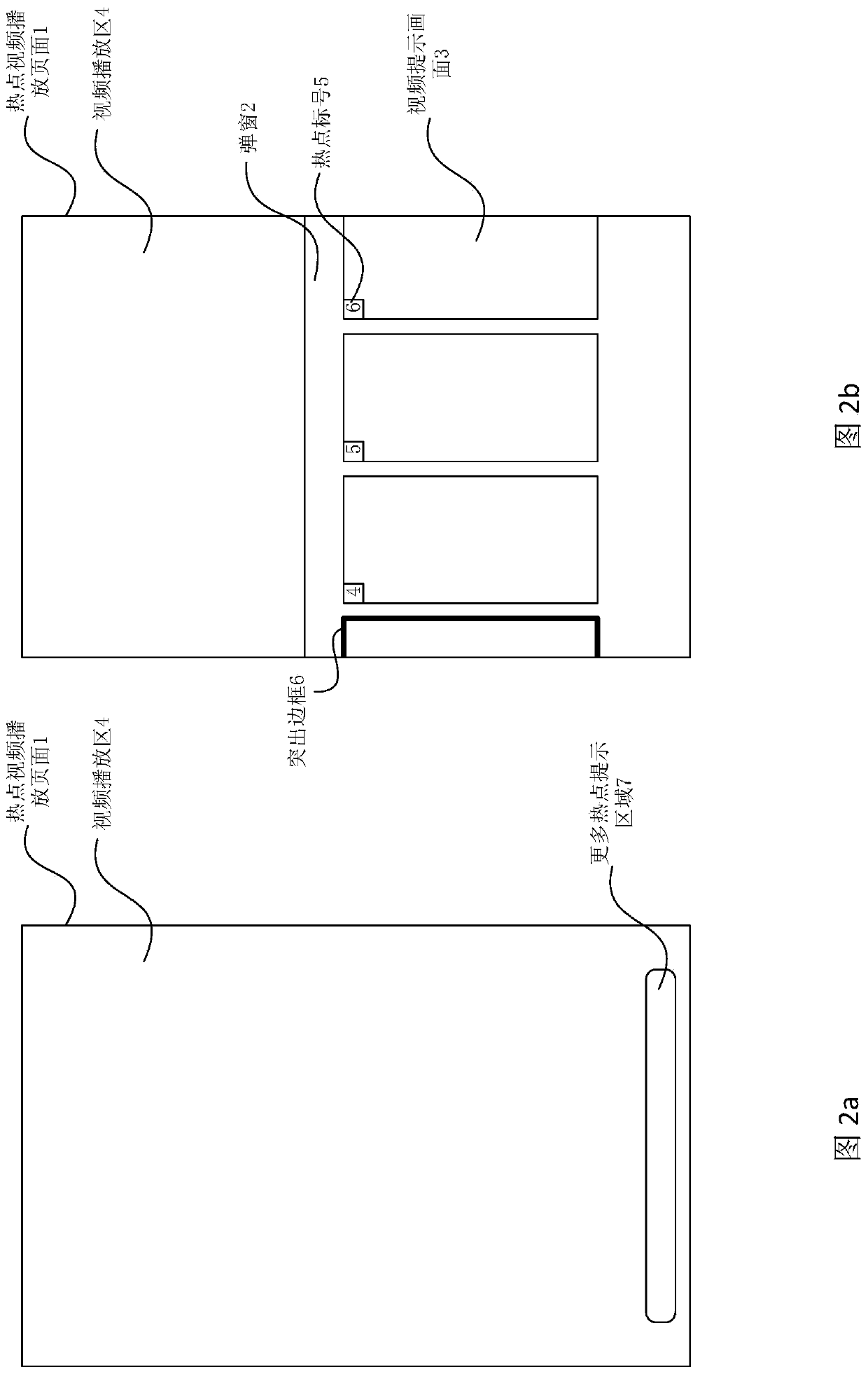

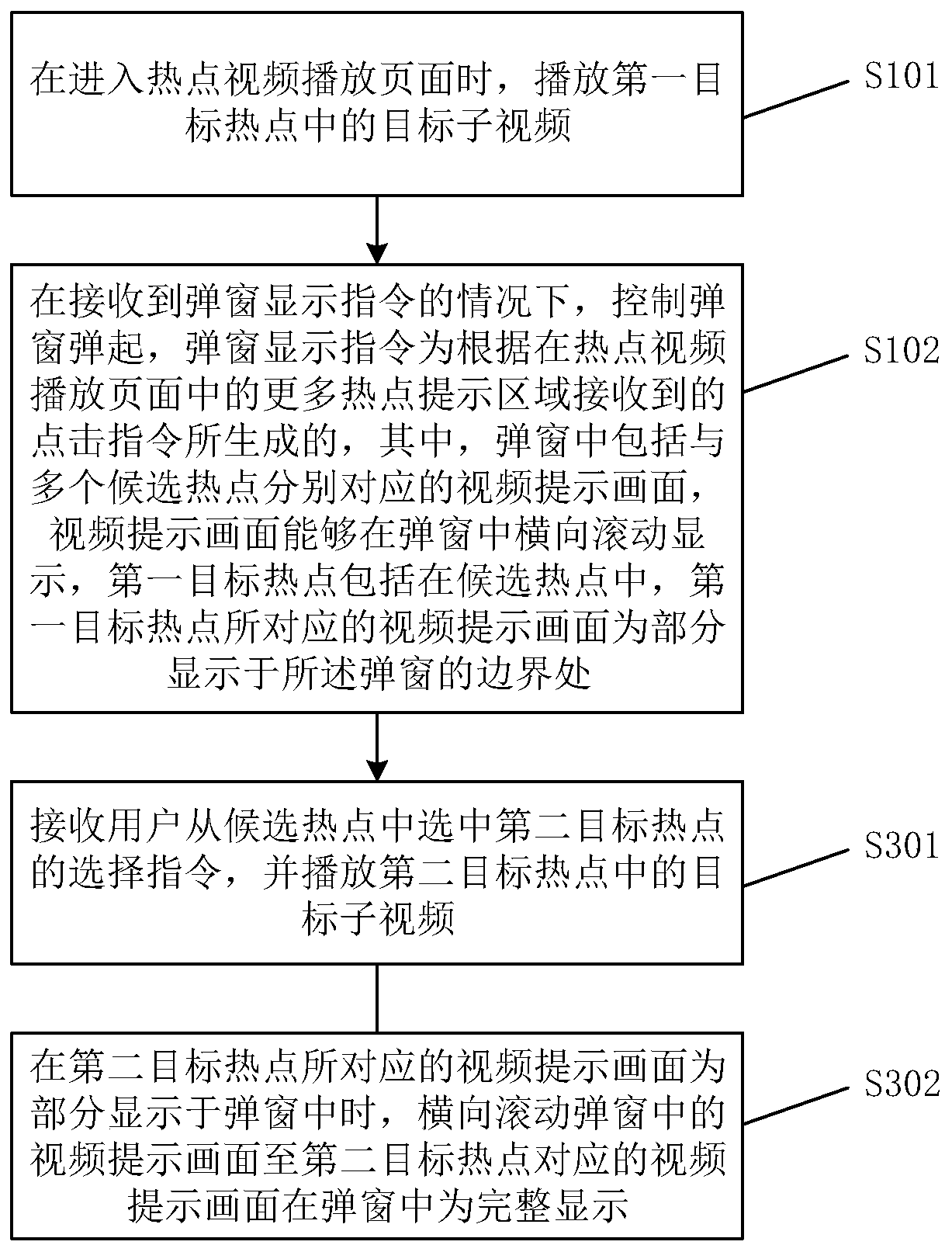

Popup window control method and device, medium and electronic equipment

ActiveCN110572705AClear and intuitive understandingSelective content distributionInput/output processes for data processingComputer hardwareOperating system

The invention relates to a pop-up window control method and device, a medium and electronic equipment, and the method comprises the steps: a target sub-video is played in a first target hotspot when ahotspot video playing page is entered; under the condition that a popup window display instruction is received, the popup window is controlled to pop up, and the popup window display instruction is generated according to click instructions received in more hotspot prompt areas in the hotspot video playing page, wherein the popup window comprises video prompt pictures corresponding to the candidate hotspots respectively, the video prompt pictures can be displayed in the popup window in a transverse rolling mode, the first target hotspot is included in the candidate hotspots, and the video prompt picture corresponding to the first target hotspot is partially displayed at the boundary of the popup window. Thus, when the user enters the hotspot video playing page to check the hotspot content,other hotspots can be checked through the popup window under the condition that the user does not exit from the hotspot video playing page, and the user can clearly and visually know the specific content of the hotspots in the popup window.

Owner:BEIJING BYTEDANCE NETWORK TECH CO LTD

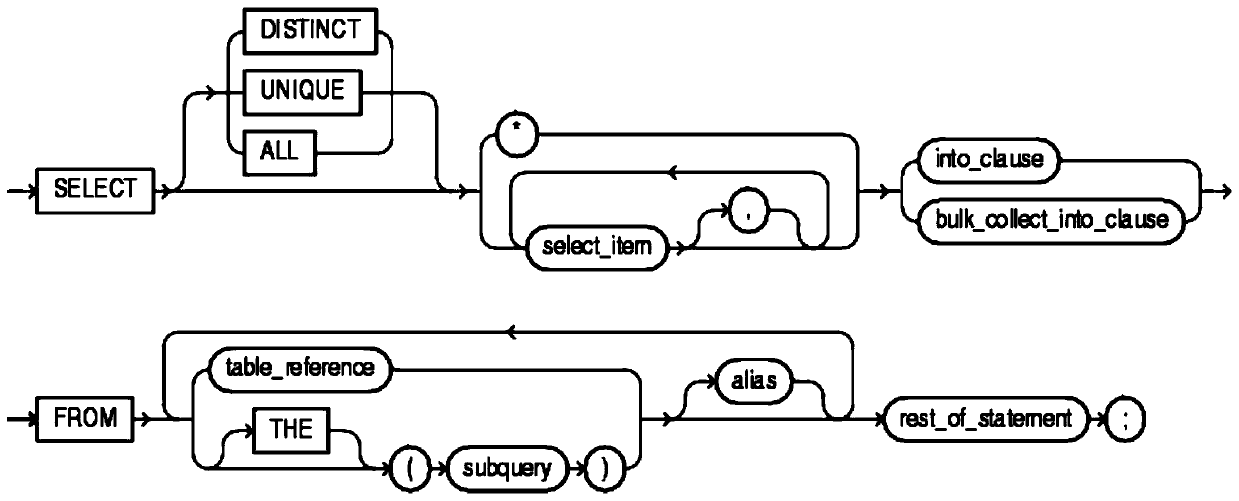

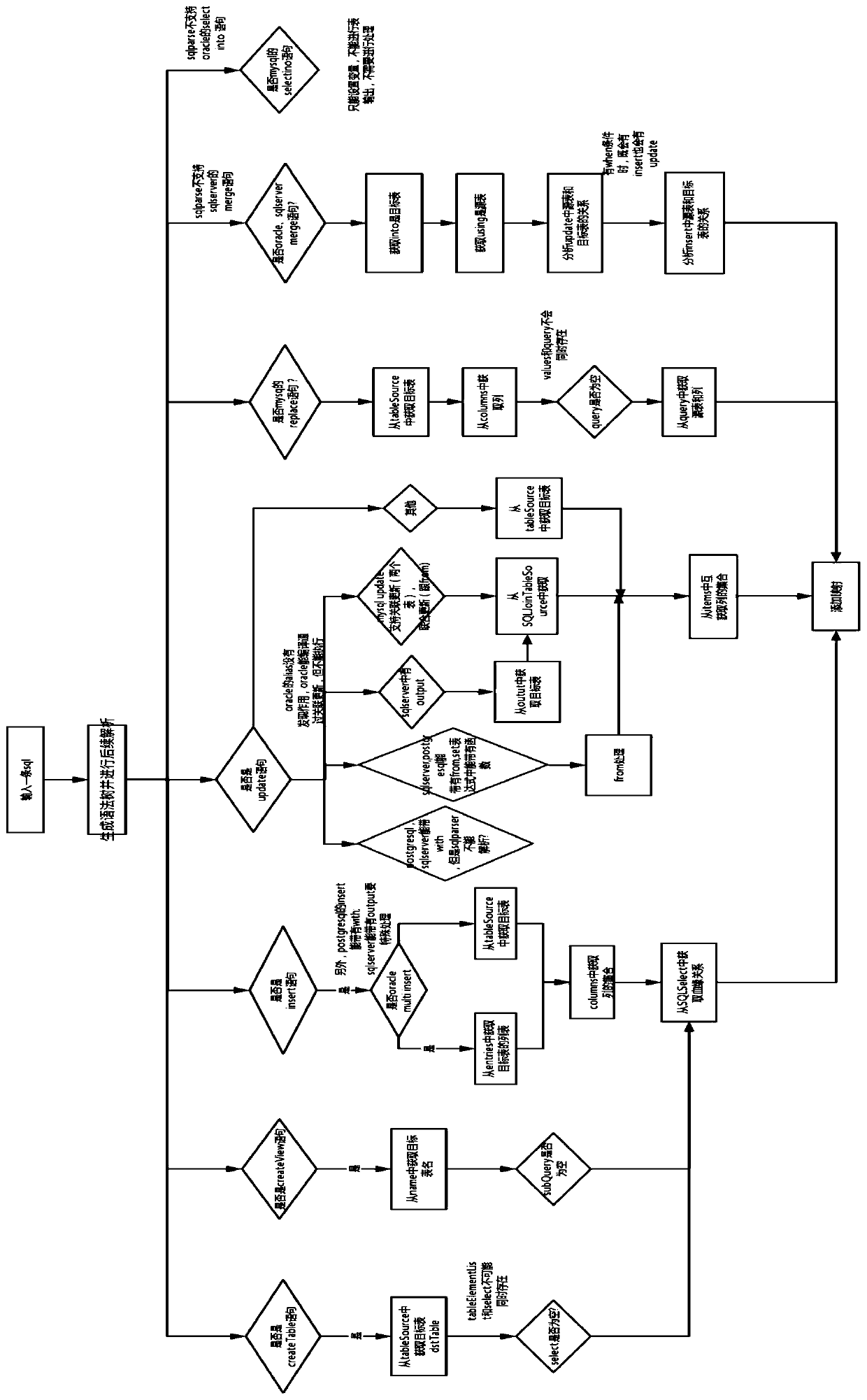

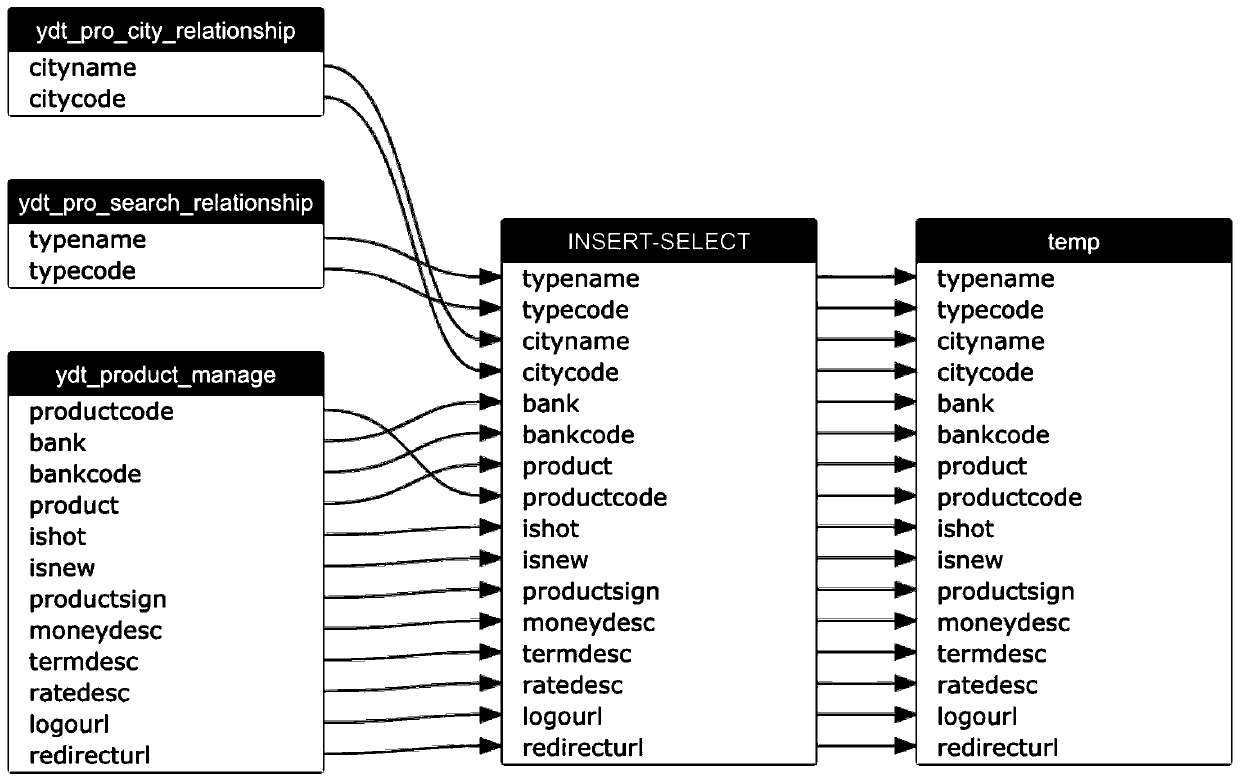

AST-based relational database SQL table relation analysis and display method

PendingCN110674229AReduce complexityImprove compatibilityDatabase management systemsVisual data miningTable (database)Relation (database)

The invention provides an AST-based relational database SQL table relation analysis and display method, and belongs to the technical field of web, java and databases. According to the method, an abstract syntax tree AST of sql is generated through syntax and lexical analysis of sql, and then the generated abstract syntax tree AST is accessed and traversed to extract tables and fields, so that analysis of table relationships of sql statements of the relational database and analysis of subordinate field relationships are realized. The table relationship and the field relationship are visually displayed in a drawing form through Mxgraph. And the complexity of association analysis is further reduced, and the compatibility of the system is improved.

Owner:山东爱城市网信息技术有限公司

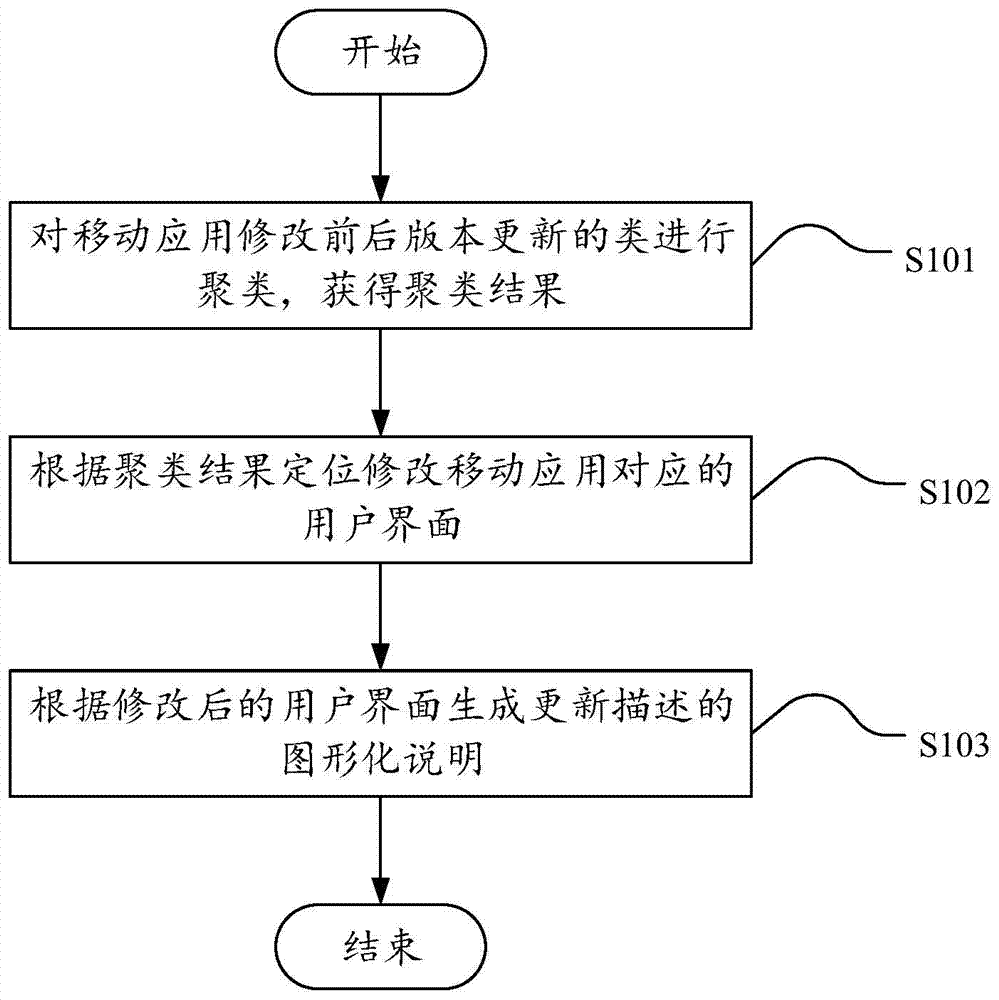

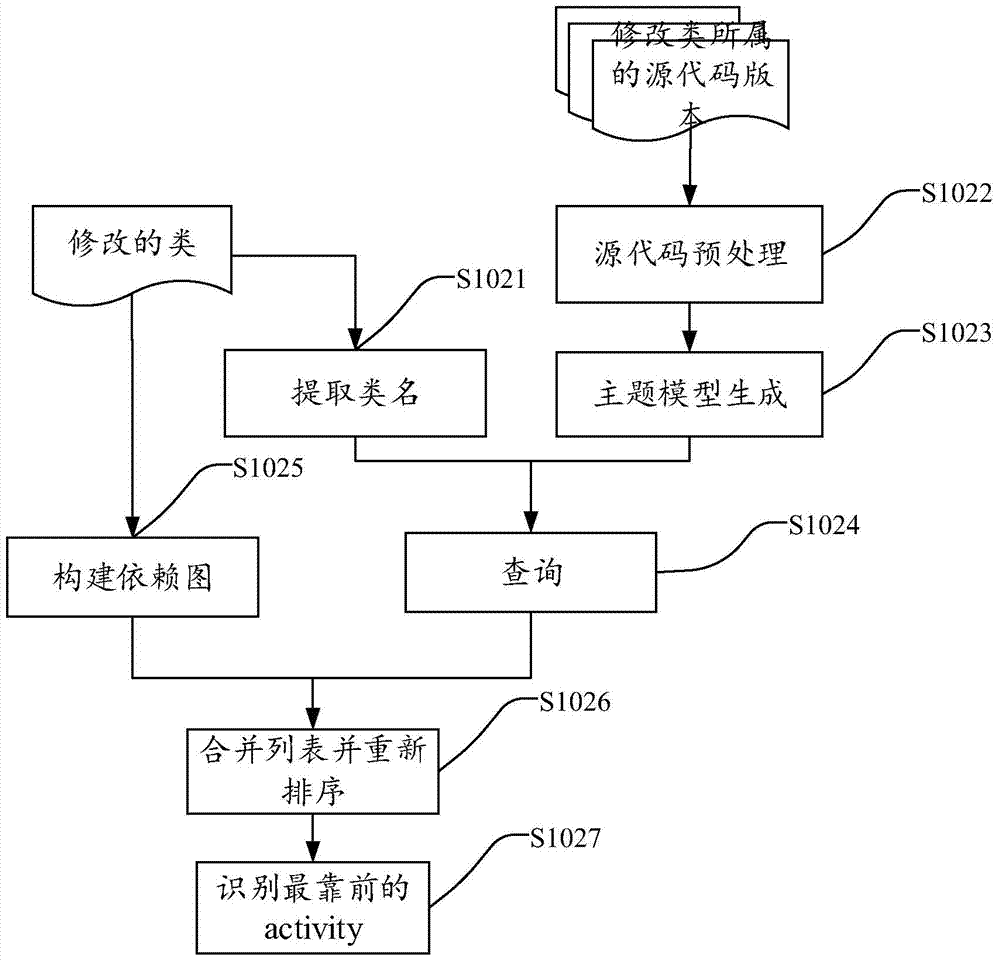

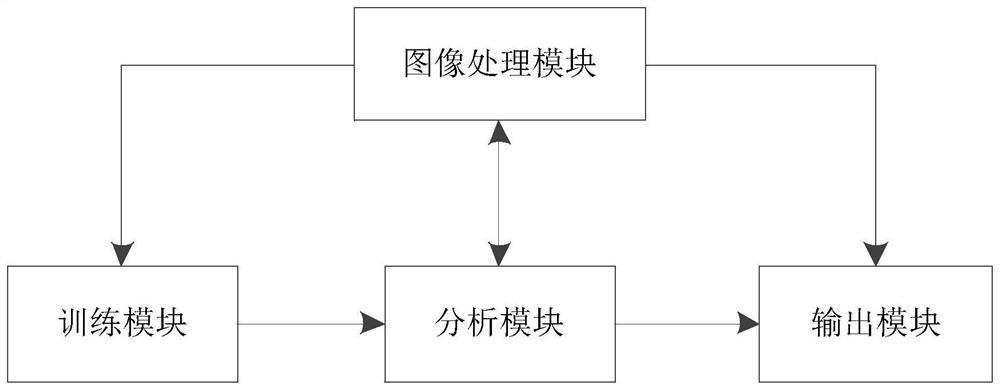

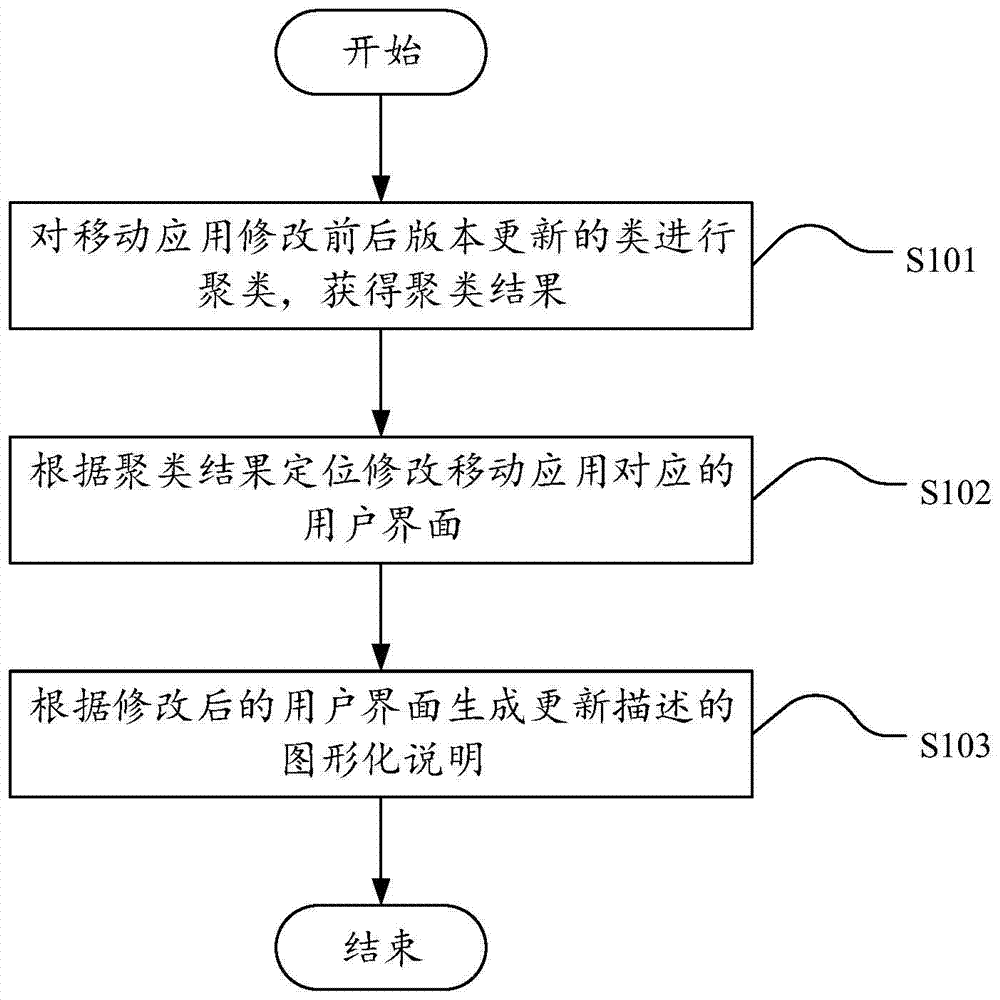

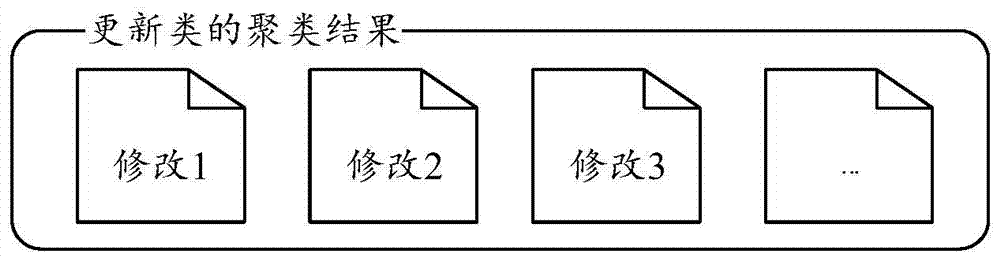

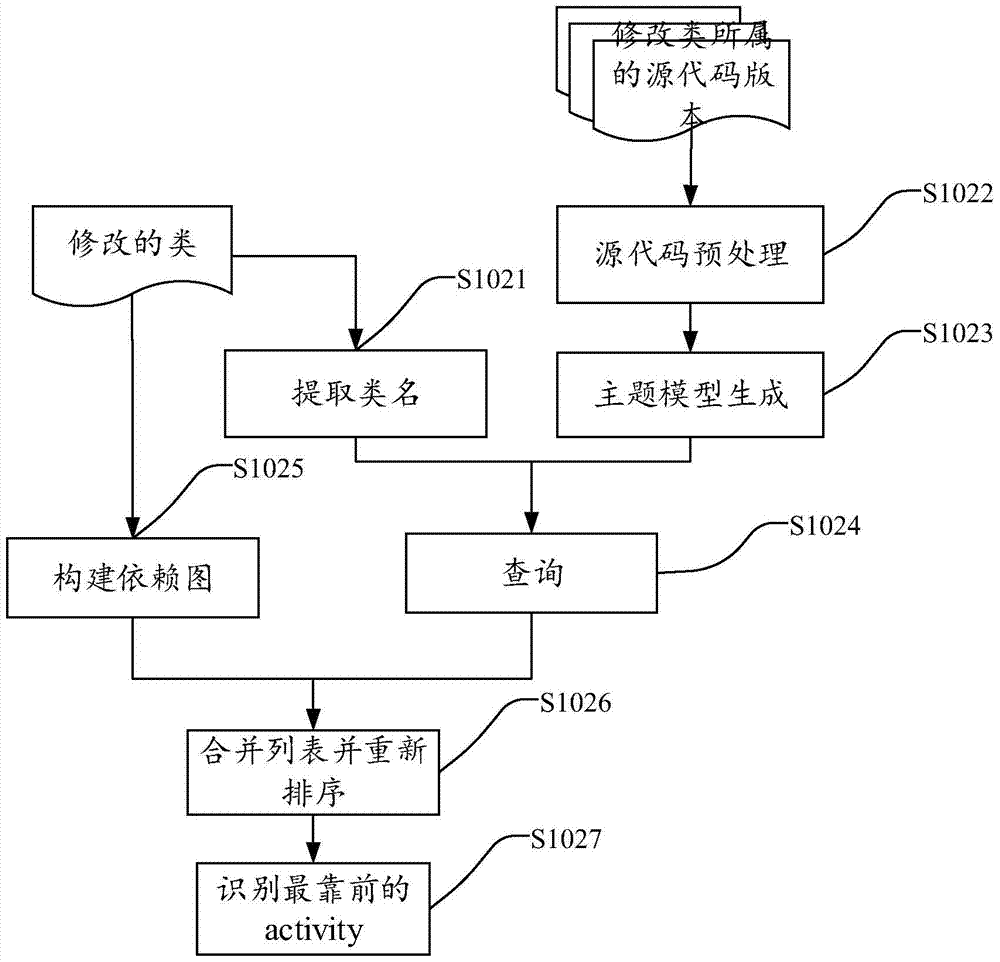

Generation method and system of graphical descriptions of version updates of mobile applications

ActiveCN104850311AImprove experienceClear and intuitive understandingInput/output processes for data processingSoftware engineeringZoom

An embodiment of the invention discloses a generation method and system of graphical descriptions of version updates of mobile applications. The method includes: clustering classes of version updates before and after modification of a mobile application so as to obtain clustering results; according to the clustering results, positioning and modifying a corresponding user interface of the mobile application; according to the modified user interface, generating a graphical description of updates. The generation method and system has the advantages that by generating graphical update descriptions, the corresponding user interfaces for software updating can be displayed to users, the users can be helped more visually know the changes of software, better services are provided for the users, and user experience is evidently improved.

Owner:SUN YAT SEN UNIV

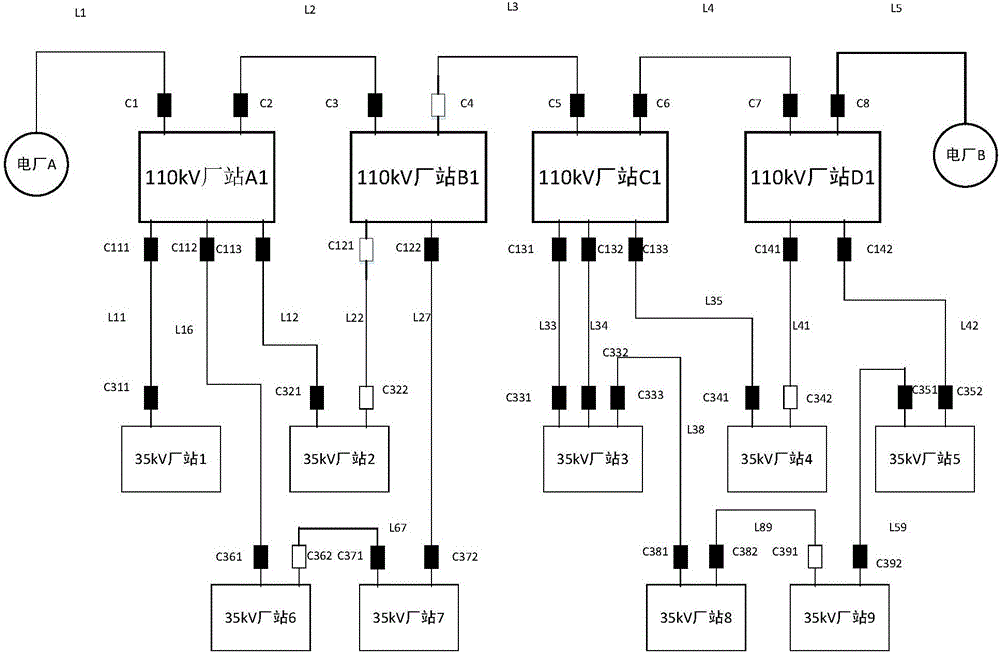

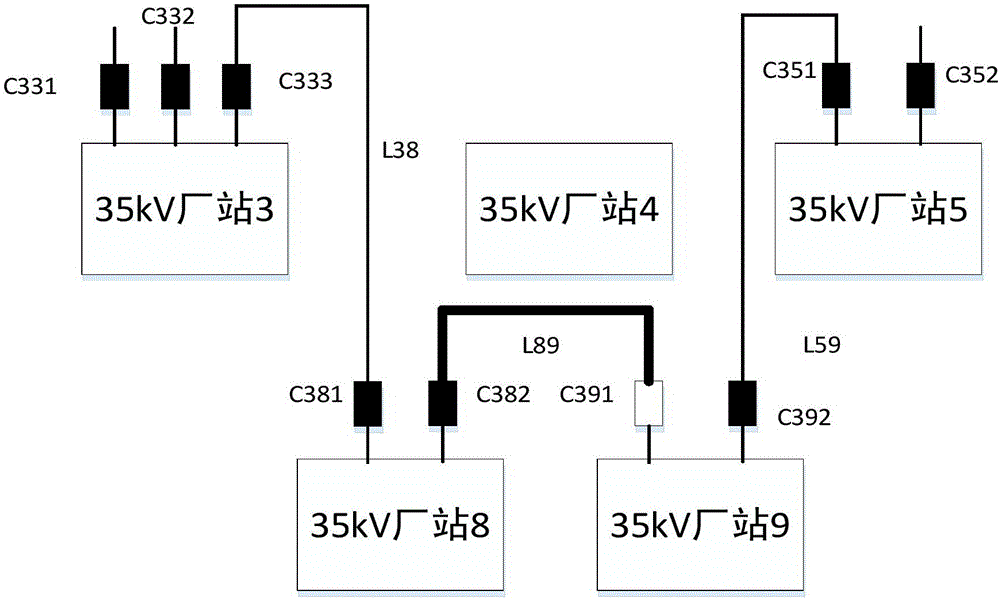

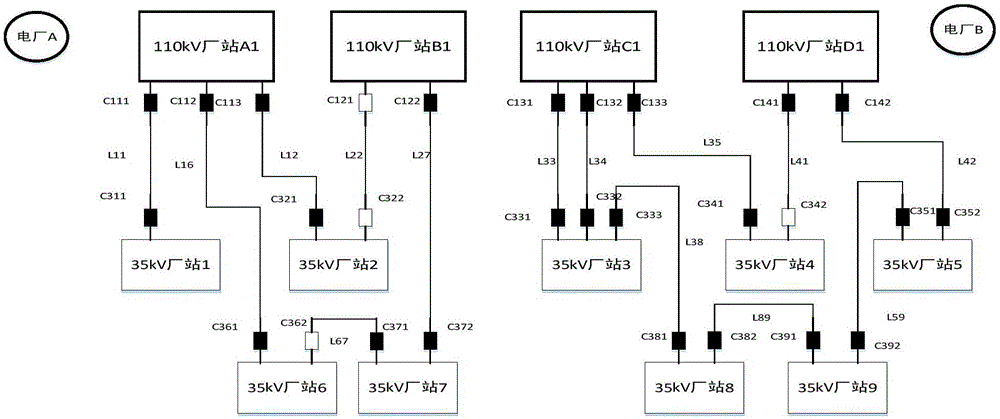

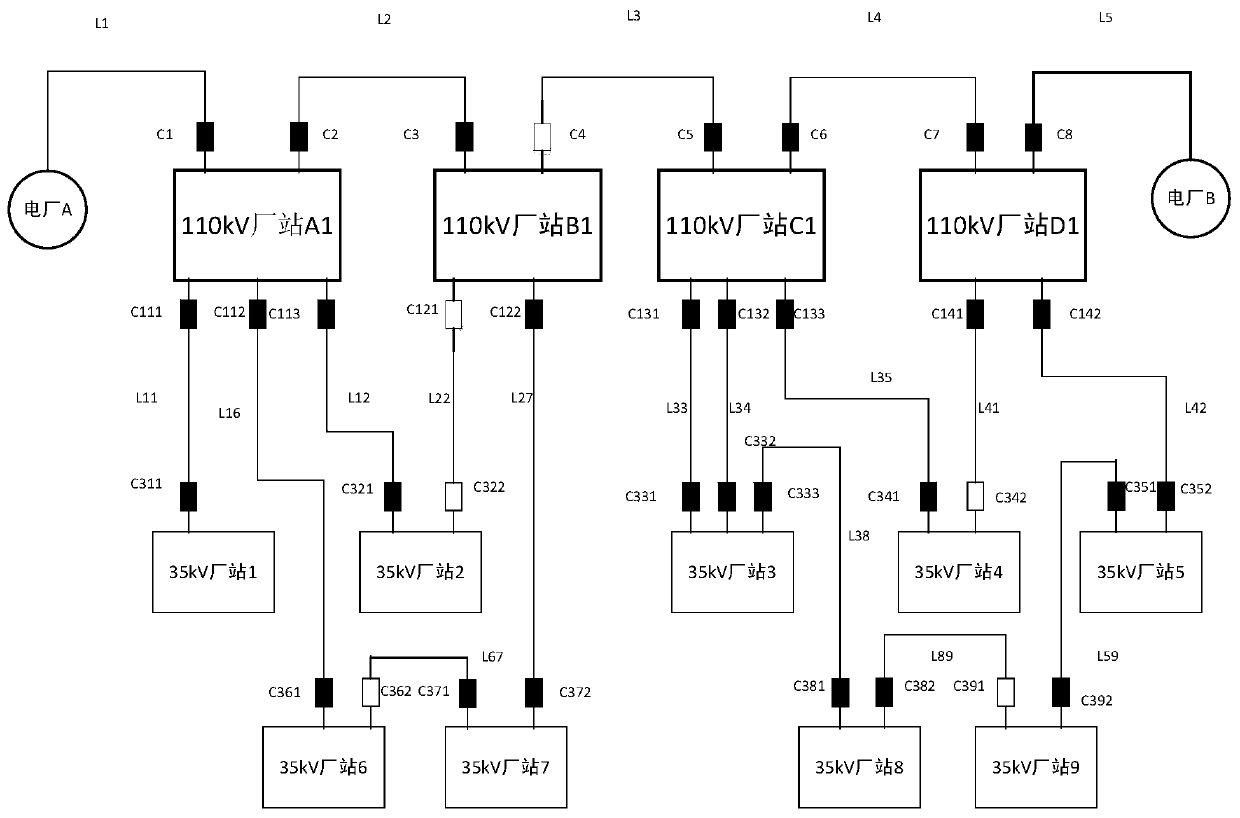

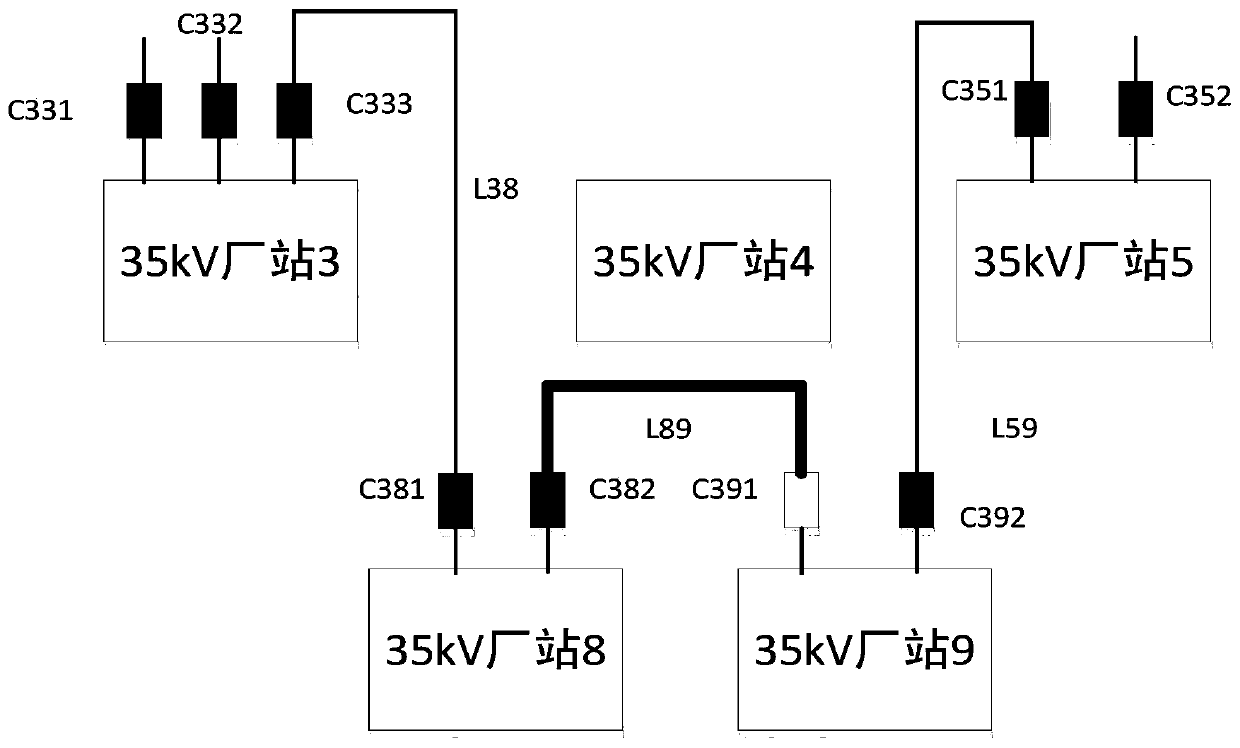

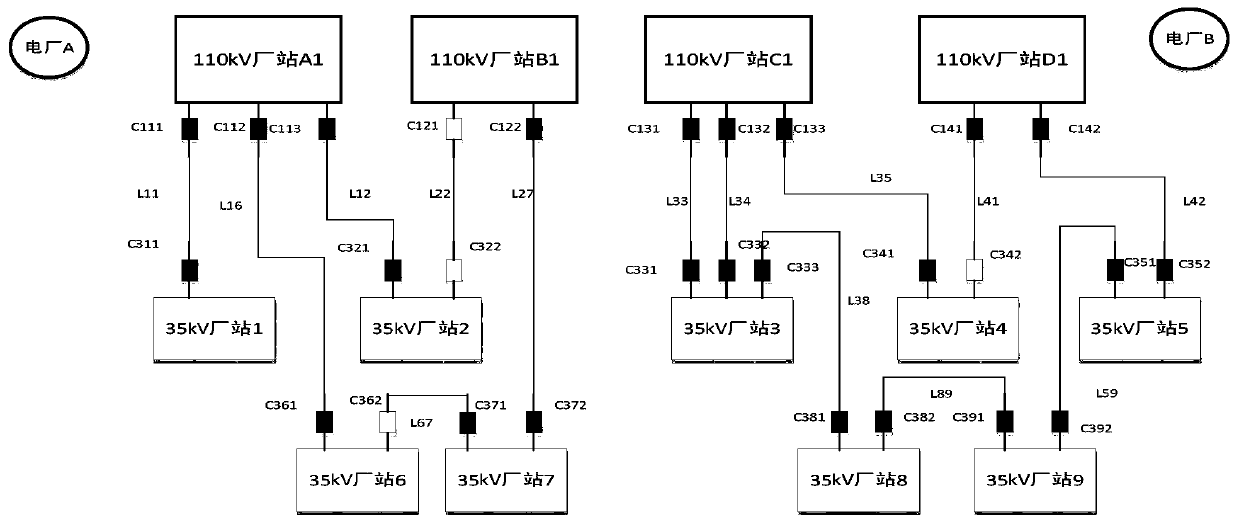

Generating method of association picture of power grid dispatching operation order

ActiveCN106844955AClear and intuitive understandingStrong technical supportSpecial data processing applicationsElectric power systemPower grid

The invention relates to a generating method of an association picture of a power grid dispatching operation order, and belongs to the technical field of a power system. The method includes steps of firstly, performing topological search on a related device to be operated according to an operation task, generating operation order tidal current charts of a factory station and a device that the operation task involve in; at last, adjusting the positions of the device and the factory station in operation, dynamically laying out and forming the association picture involved by the operation order. After generating the association picture, a dispatcher shall clearly and directly learn about the device to be operated, and provide a powerful technical support and decision-making bias for the power grid dispatching command operation.

Owner:LUDONG UNIVERSITY +2

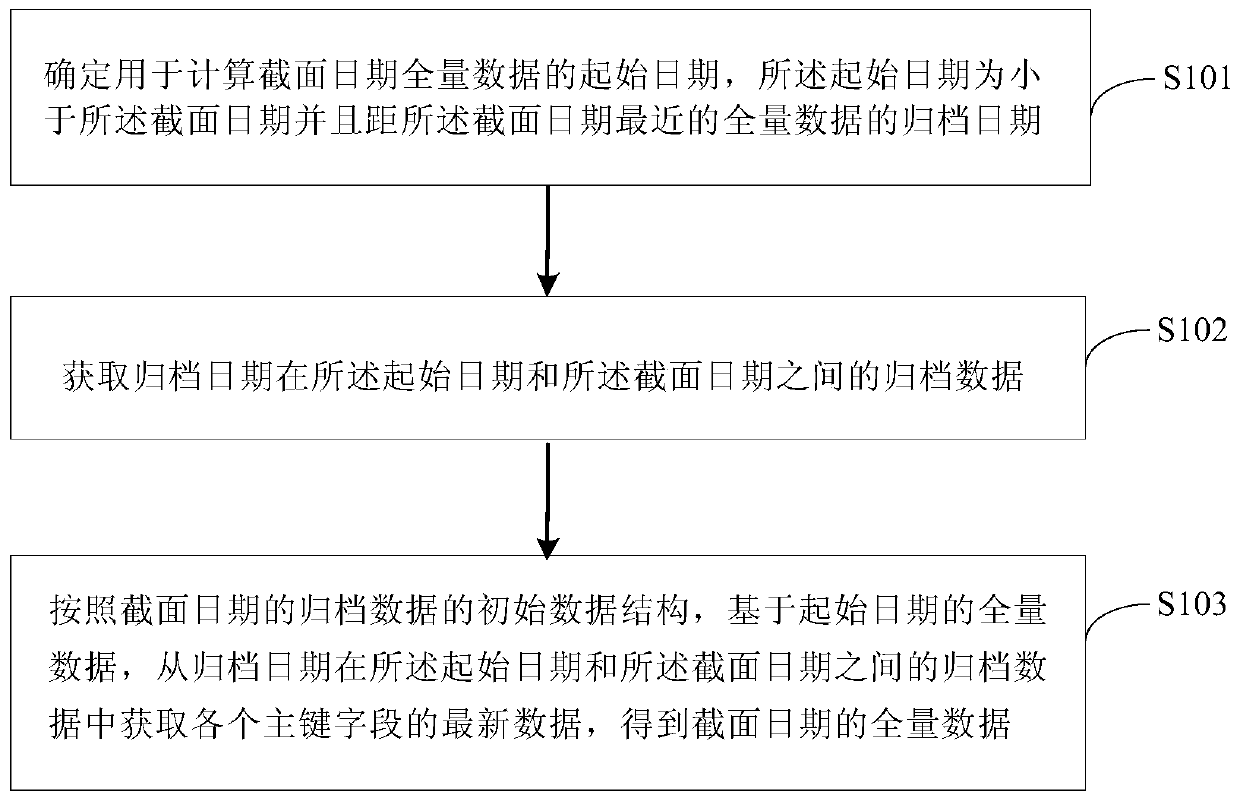

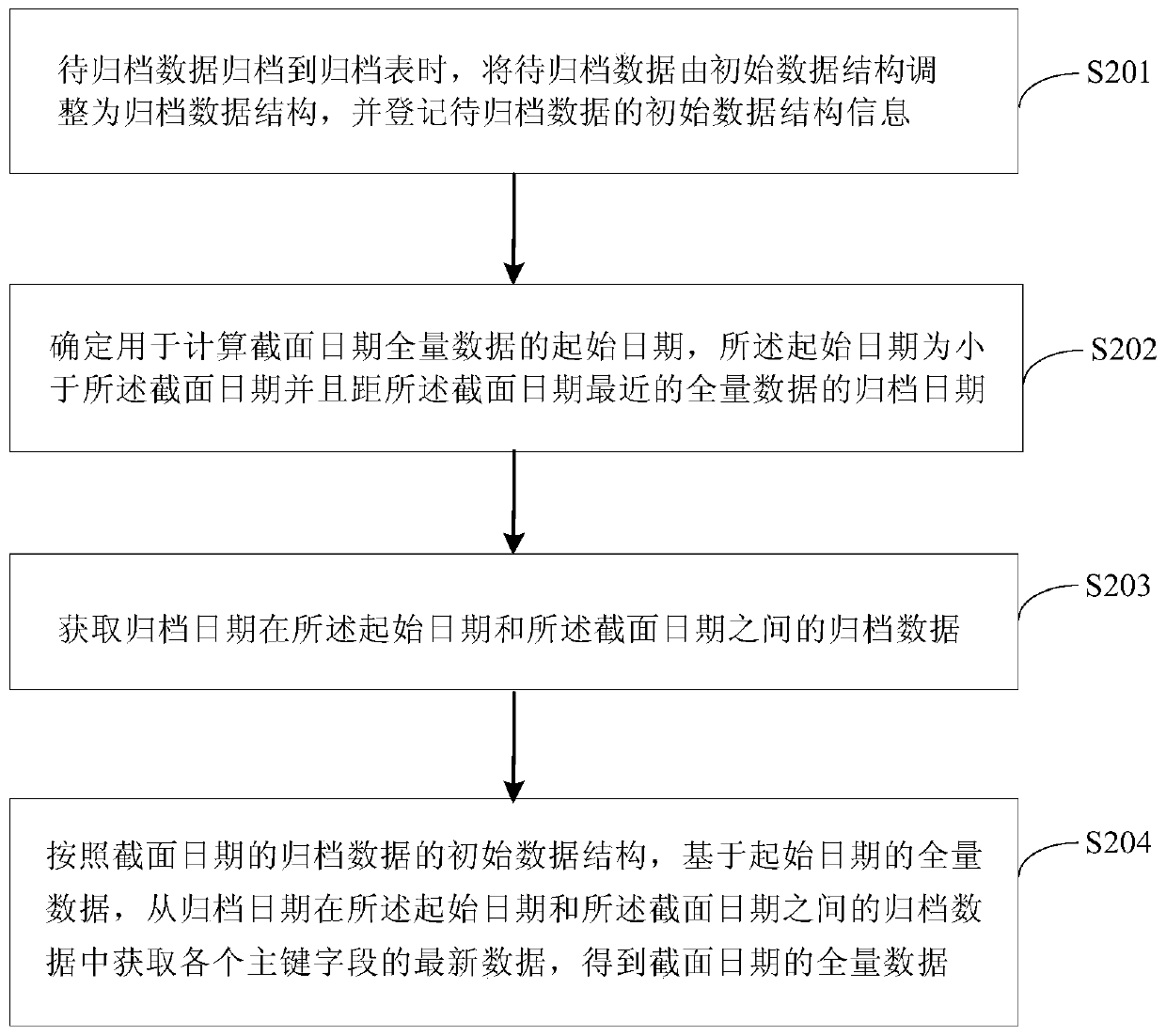

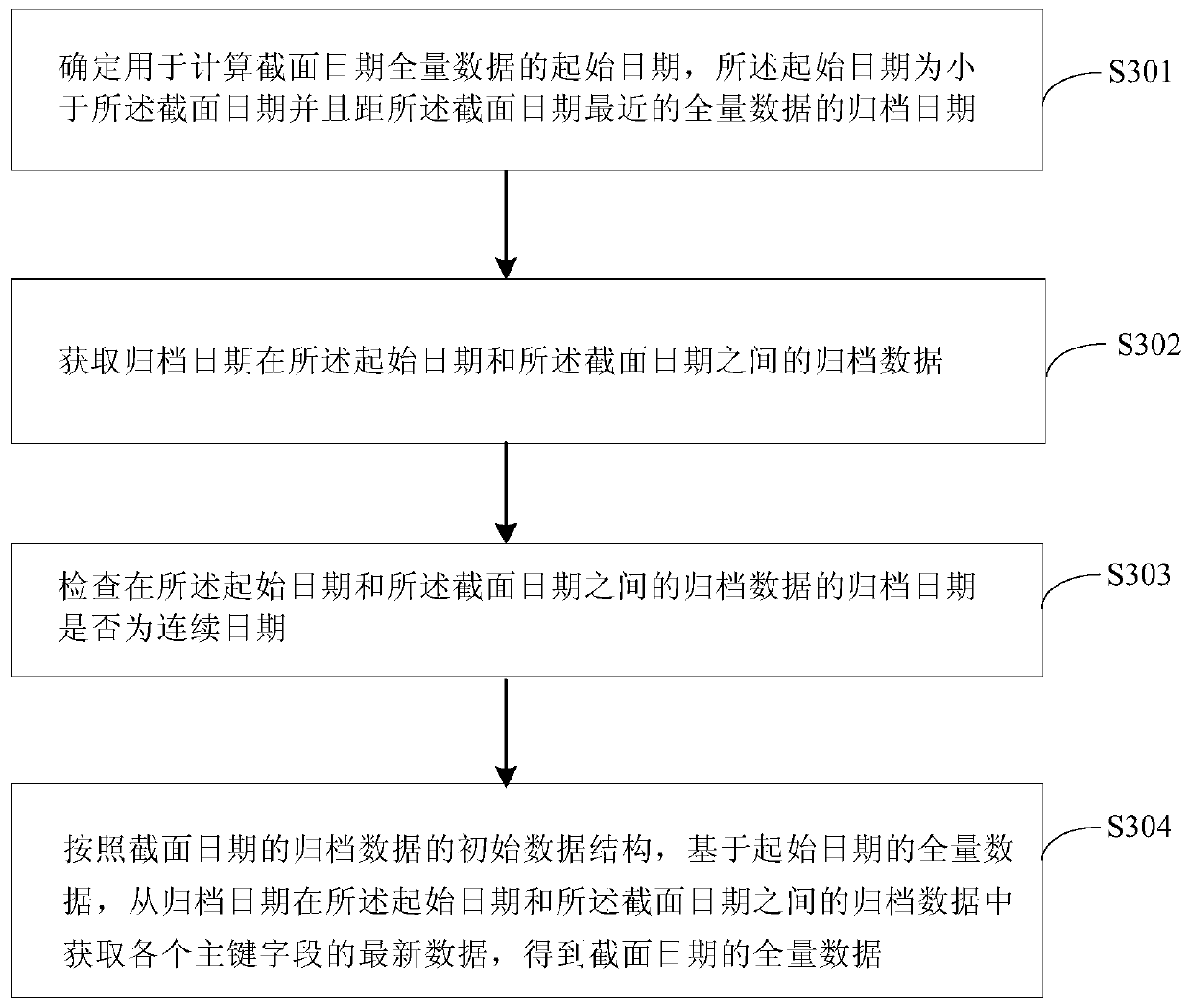

Method and device for acquiring total data of section date, electronic equipment and storage medium

PendingCN111400304AEasy to understandEasy to understand clearly and intuitivelySpecial data processing applicationsDatabase indexingEngineeringData mining

The invention discloses a method and a device for obtaining total data of a section date, electronic equipment and a storage medium, and relates to the technical field of computers. A specific embodiment of the method comprises the steps of determining a starting date for calculating total data of a section date, wherein the starting date is an archiving date of the total data which is smaller than the section date and closest to the section date; obtaining archiving data of an archiving date between the starting date and the section date; and according to the initial data structure of the archived data of the section date, based on the total data of the starting date, obtaining latest data of each main key field from the archived data of the archived date between the starting date and thesection date, and obtaining the total data of the section date. According to the embodiment, the storage space is saved; the data query and calculation efficiency is improved, and the total data of the section date can be clearly and visually known.

Owner:CHINA CONSTRUCTION BANK

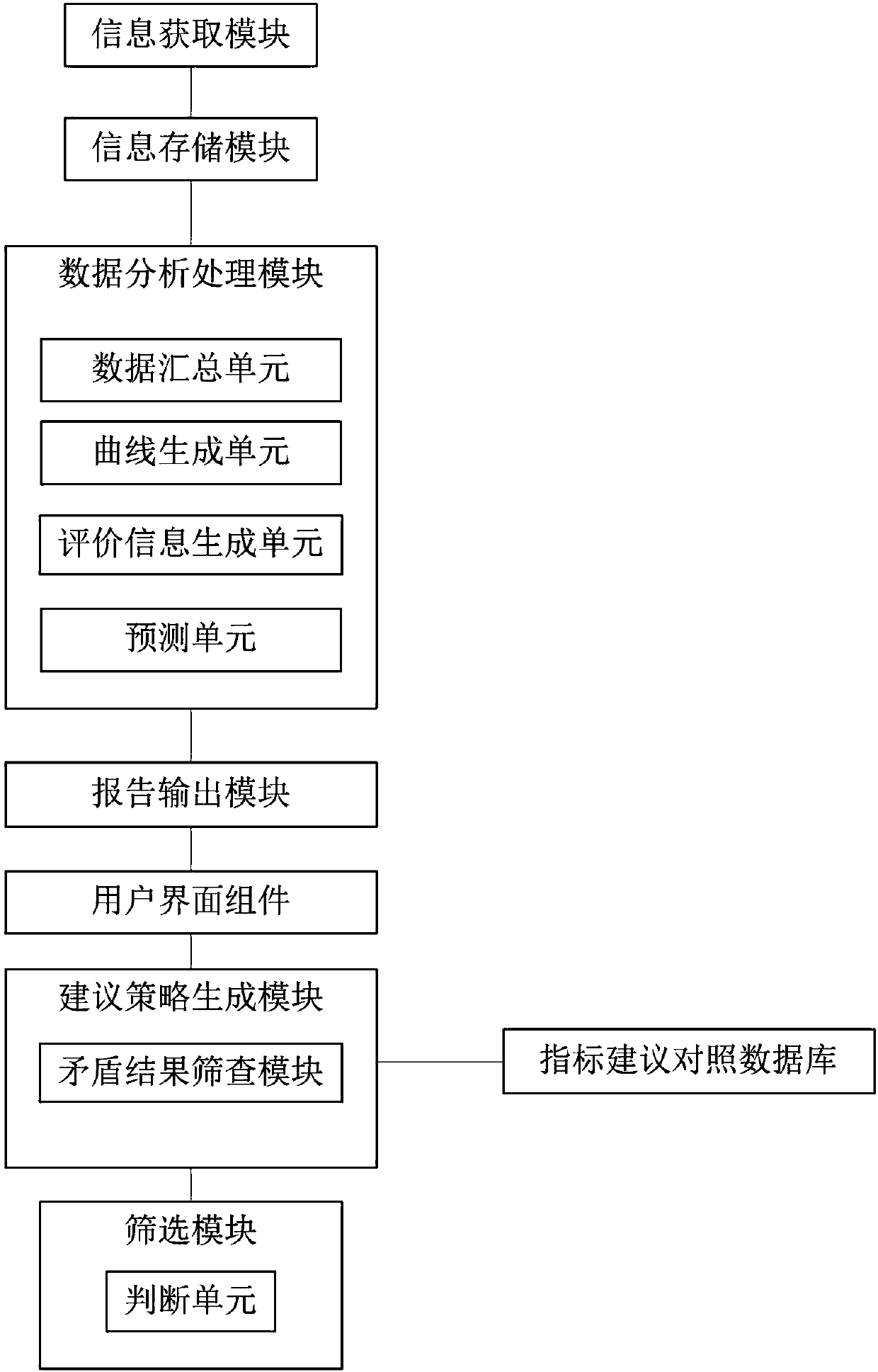

Information management system based on health care information

InactiveCN107767925AUnderstand comprehensivelyEasy to analyzeHealth-index calculationPatient-specific dataInformation analysisUser interface

The invention discloses an information management system based on health care information, including: an information acquisition module, used to receive health care information from one or more health care information sources; an information storage module; and a data analysis and processing module, used for one or more Analyze the health care information obtained from multiple health care information sources, and generate a health care information analysis report; the health care information analysis report contains at least one health index over time curve, and the evaluation information of the health index; report Output modules; user interface components. The data analysis and processing module of the present invention can generate a health care information analysis report. The health care information analysis report includes a graph of at least one health index changing over time, and the evaluation information of the health index, so that the user has a clear and intuitive view of the health trajectory. The understanding of monitoring indicators and the evaluation information of monitoring indicators can be obtained.

Owner:HAINAN VOCATIONAL TECHN COLLEGE

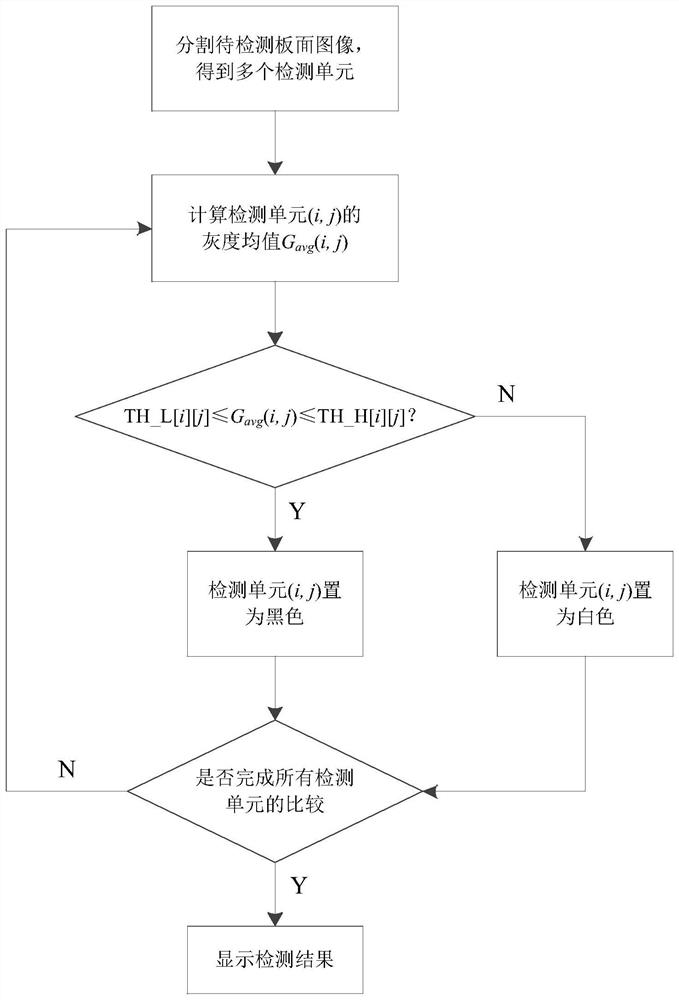

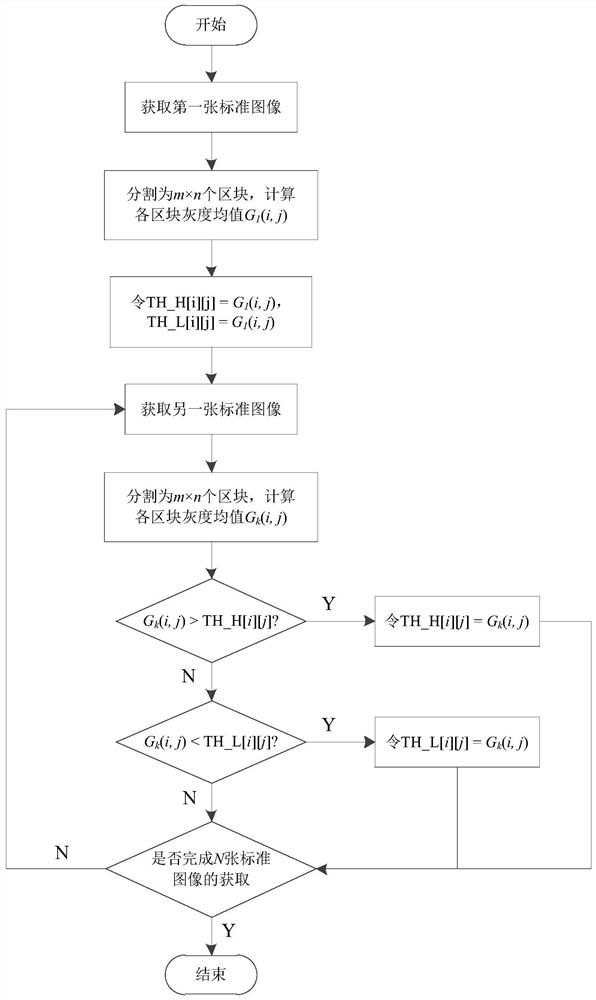

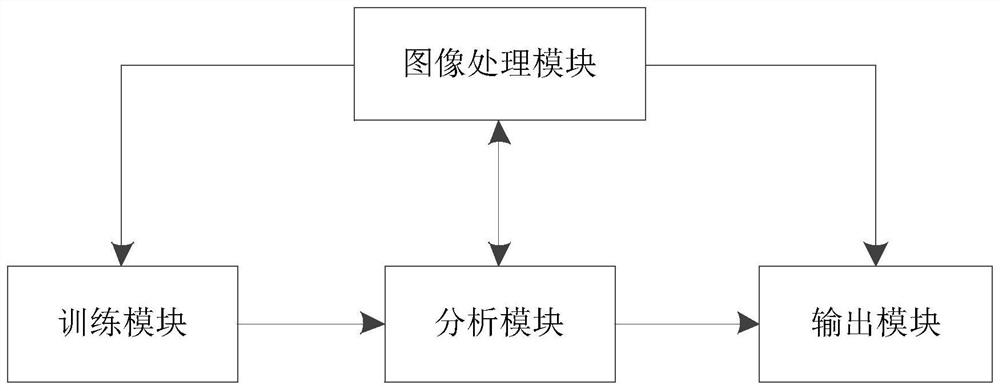

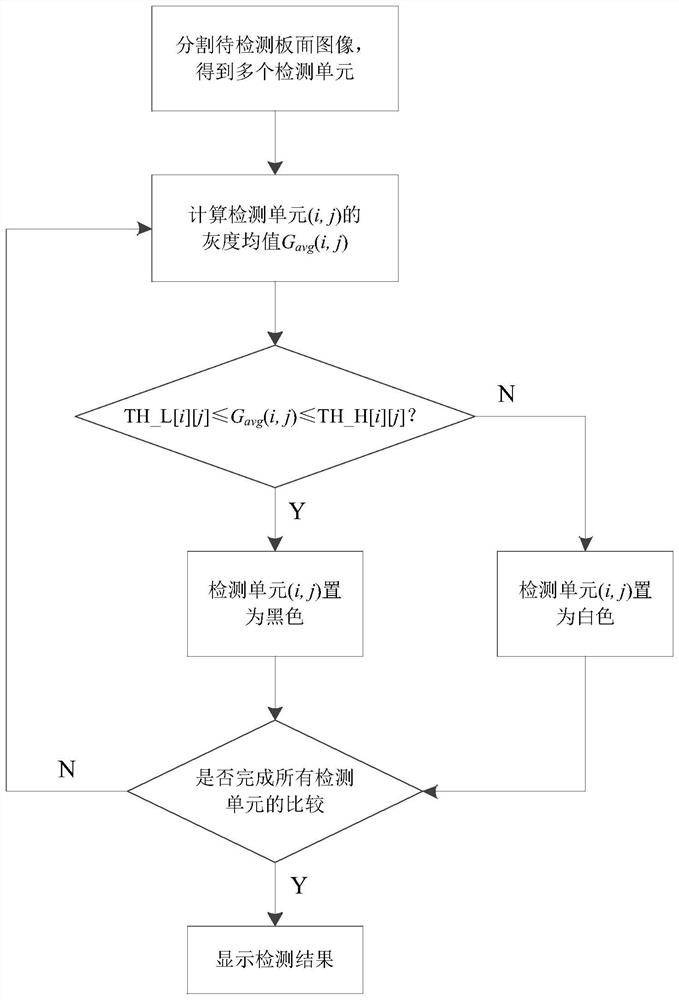

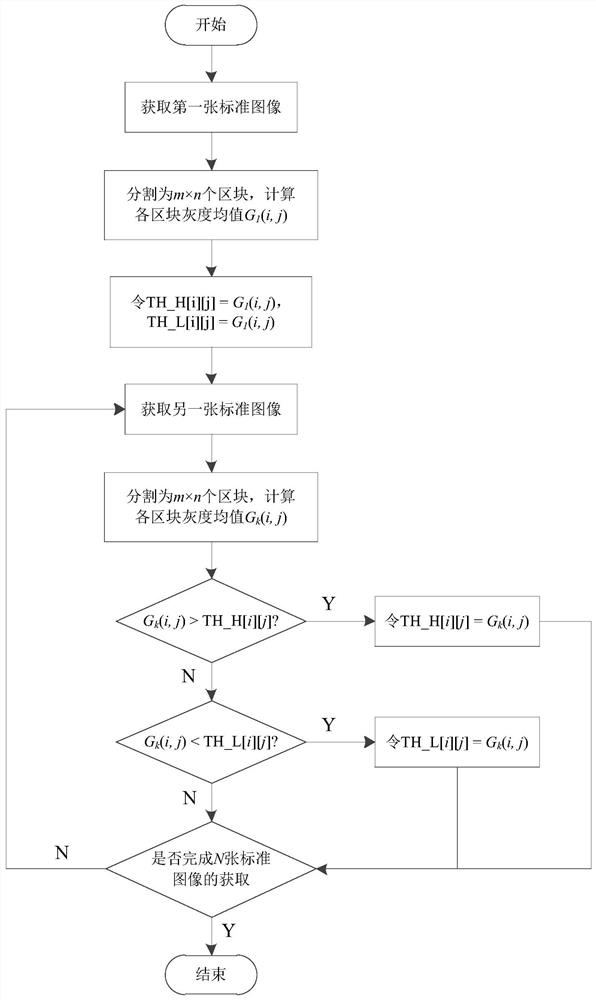

A board defect area extraction method and device

ActiveCN112837287AShorten the timeImprove accuracyImage enhancementImage analysisAlgorithmImage segmentation

Owner:SHANDONG JIANZHU UNIV +1

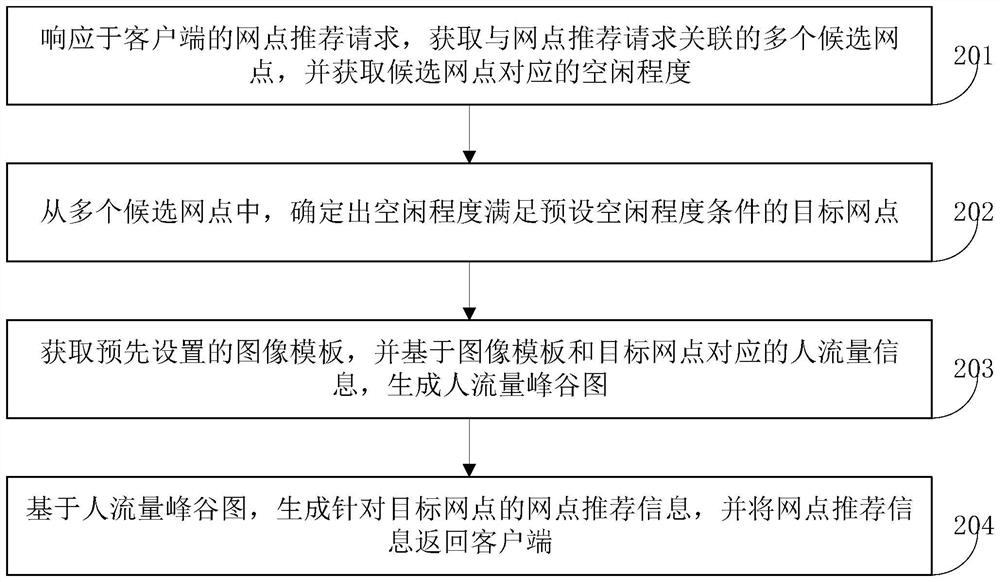

Branch recommendation method and device, computer equipment and storage medium

PendingCN114417190AClear and intuitive understandingImprove the efficiency of understanding target network informationDigital data information retrievalDrawing from basic elementsGraph generationData mining

The invention relates to a website recommendation method and device, computer equipment, a storage medium and a computer program product. The website recommendation method can be applied to the financial field or other fields. The method comprises the following steps: in response to a website recommendation request of a client, obtaining a plurality of candidate websites associated with the website recommendation request, and obtaining idle degrees corresponding to the candidate websites; determining a target network point of which the idle degree meets a preset idle degree condition from the plurality of candidate network points; obtaining an image template, and generating a pedestrian flow peak-valley map based on the image template and the pedestrian flow information corresponding to the target network point; and generating website recommendation information for the target website based on the pedestrian flow peak-valley graph, and returning the website recommendation information to the client. The target website recommendation can be performed according to the website idle degree, the waiting time is reduced, the passenger flow condition of the target website is reflected through the passenger flow peak-valley graph, the efficiency of the user for knowing the target website information is improved, and the cost of using the website service is reduced.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

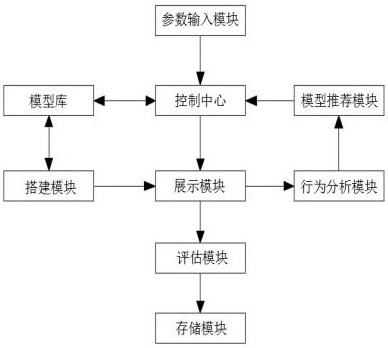

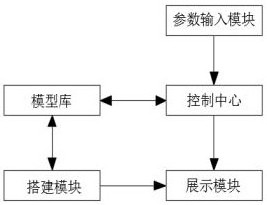

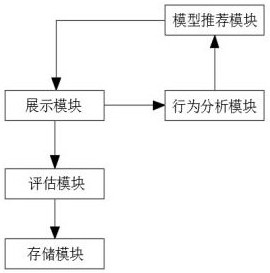

Product full-life-cycle display system supporting 3D display

ActiveCN113379517AMeet individual needsIncrease authenticityBuying/selling/leasing transactions3D modellingSoftware engineeringE-commerce

The invention discloses a product full-life-cycle display system supporting 3D display, relates to the technical field of electronic commerce, and solves the technical problem that at present, most three-dimensional models are displayed according to set parameters before display, and a user cannot change and check the parameters by himself / herself. Comprising a model library, a building module, a parameter input module, a control center, a display module, a behavior analysis module, a model recommendation module, an evaluation module and a storage module. The parameter input module is used for a user to select display parameters of a product and upload the display parameters to the control center; the control center is used for carrying out matching analysis on the display parameters selected by the user and the display parameters of the three-dimensional model information pre-stored in the model library, and then transmitting the corresponding three-dimensional model information to the display module, so that the individual requirements of the user are met, and clearer and more intuitive understanding is provided for the user; and the model recommendation module is used for selecting matched three-dimensional model information according to a preset rule and pushing the information to the user, so that the display effect of the system is improved.

Owner:NANCAL ENERGY SAVING TECH

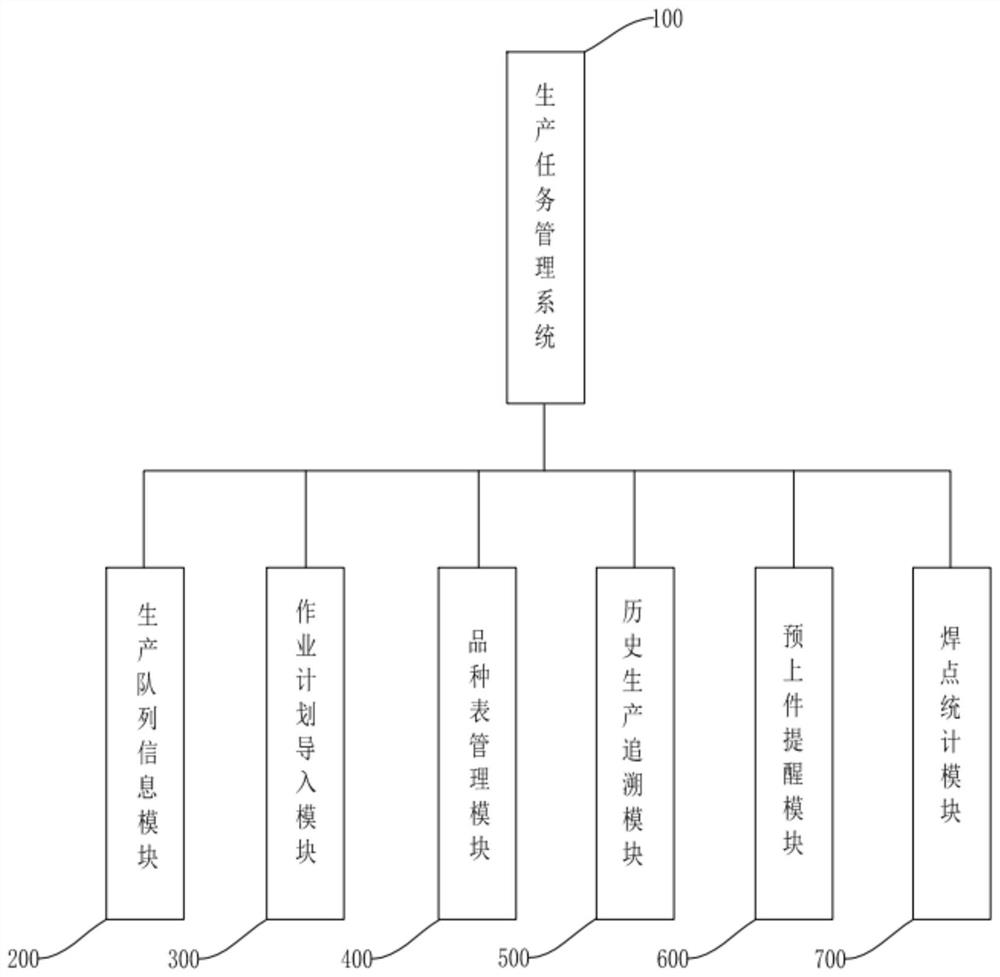

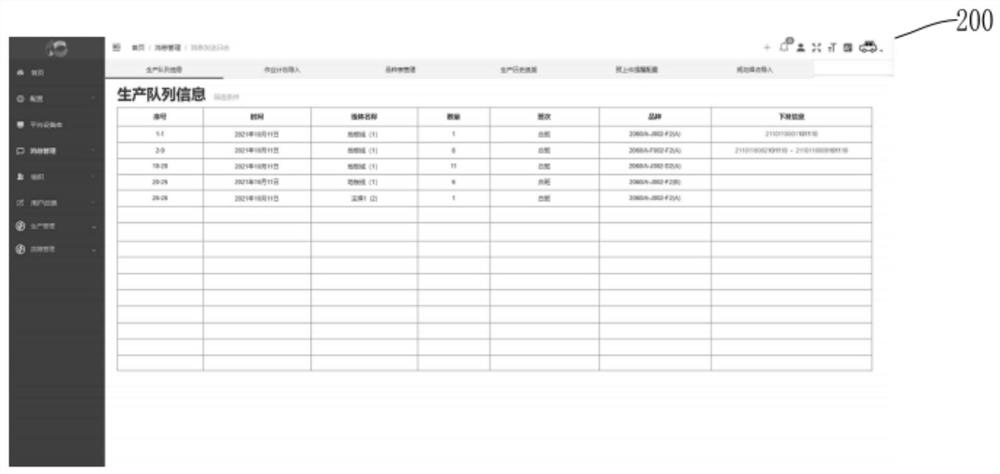

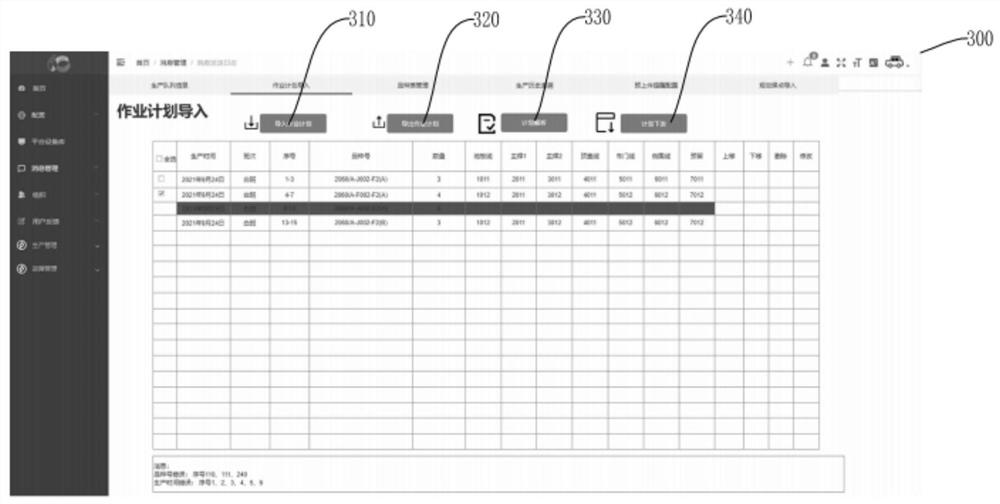

Production task management system, electronic equipment and computer medium

PendingCN114693124AClear and intuitive understandingEasy to modifyOffice automationResourcesTask managementSerial code

The invention provides a production task management system, an electronic device and a computer storage medium, the production task management system comprises a production queue information module, an operation plan import module, a variety table management module, a historical production tracing module, a pre-loading reminding module and a process statistics module, the production queue information module is used for displaying on-duty production queue information; the operation plan import module is used for displaying specific operation plan information; the variety table management module is used for displaying variety information of products; the historical production tracing module has a query function and is used for querying production information of products; and the pre-loading reminding module has a reminding function and is used for enabling field operators to predict serial numbers, vehicle model numbers and variety numbers of current and later product loading in advance, and a plurality of pre-loading reminding modules can be displayed by setting preset values. According to the invention, by setting each module, the functions of daily production scheduling, order issuing, order tracing, large-screen monitoring, product management, pre-loading reminding and the like are realized.

Owner:GUANGZHOU MINO AUTOMOTIVE EQUIP CO LTD

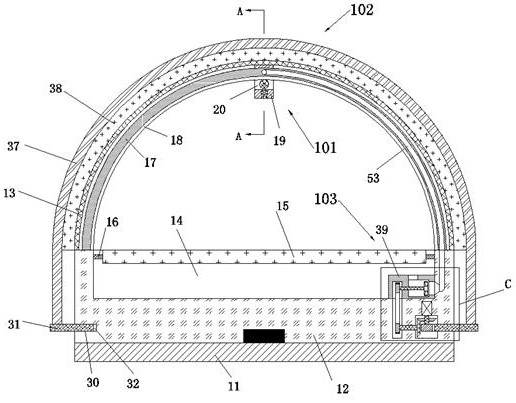

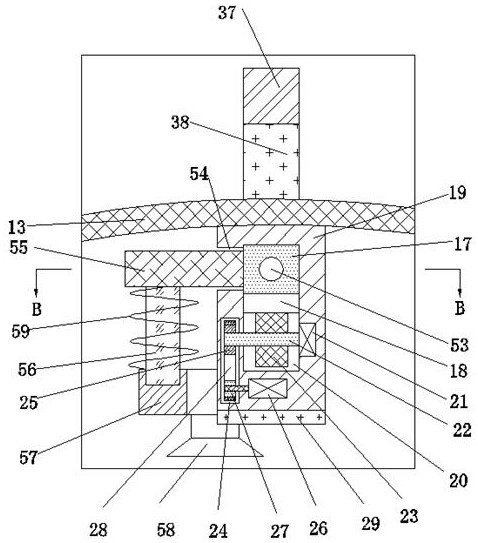

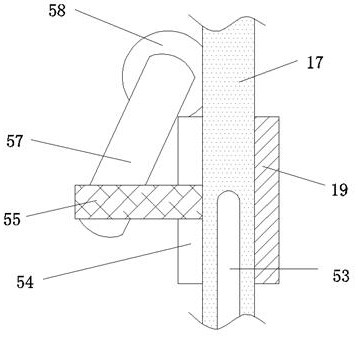

A self-cleaning architectural model display stand

ActiveCN110599889BClear and intuitive understandingEasy to observe from all anglesCleaning using toolsEducational modelsGlass coverDisplay device

The present invention discloses an automatically cleanable architectural model display stand, comprising a base, an exhibition stand is rotatably arranged in the center of the end surface on the upper end surface of the base, a display device is provided on the upper end surface of the exhibition stand, and the display device includes a fixed device The glass cover on the upper end surface of the booth, the upper end surface of the booth is provided with a water tank with an upward opening, the outer surface of the booth is provided with an external dust removal device, and the water tank is provided with an internal cleaning device. The lighting conditions at the location can display more information for the situation of the building, so that people can understand it more clearly and intuitively. The booth can be rotated manually to facilitate observation from various angles. At the same time, it can automatically remove dust inside and outside when not in use, making the booth and The internal architectural model is clean and new, giving people a better look and feel.

Owner:浏阳天艺广告装饰工程有限公司

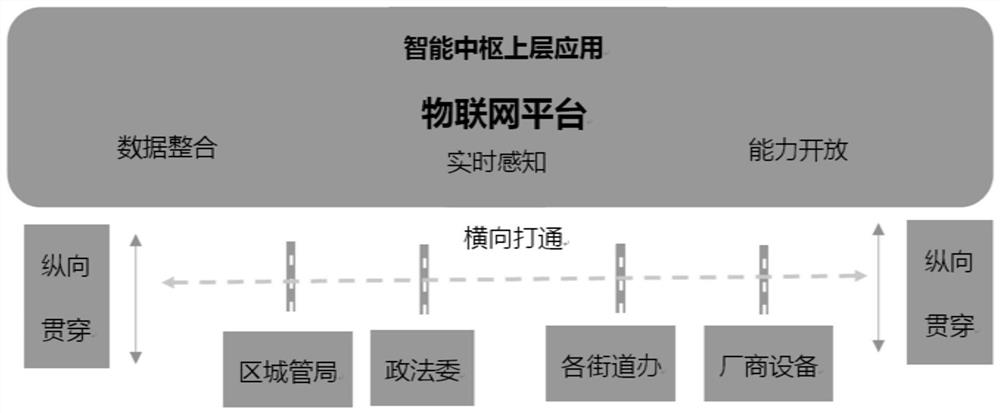

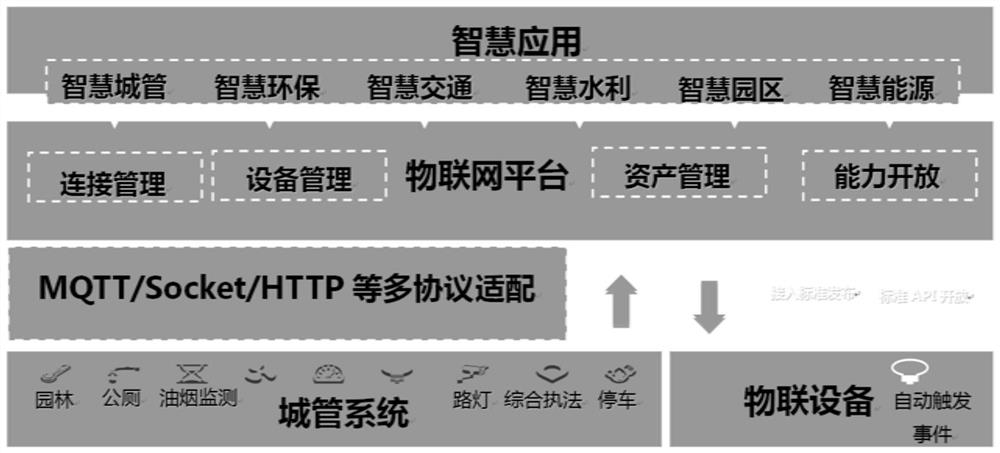

Internet of Things equipment and data standardized access and summary presentation method

PendingCN113778983AUnderstand staticUnderstanding Dynamic DataDatabase distribution/replicationRelational databasesData streamRemote control

The invention discloses Internet of Things equipment and a data standardized access and summary presentation method, belongs to the field of Internet of Things, and aims to solve the technical problem of how to summarize and fuse data of various Internet of Things equipment and equipment platforms. In order to improve the flexibility, usability and practicability of comprehensive presentation systems of smart cities, smart communities, Internet of Vehicles and the like, the adopted technical scheme is as follows: the method provides a connection communication capability for equipment, realizes standardized access and output of Internet of Things equipment and data, is downwards connected with massive equipment, and supports equipment data acquisition and cloud loading; a cloud API is provided upwards, and a server side issues an instruction to the equipment side by calling the cloud API, so that remote control is realized; the method specifically comprises the following steps: constructing a framework; performing data access; carrying out data circulation; supporting the smart application; analyzing an object model; and performing scene linkage.

Owner:济南浪潮智投智能科技有限公司

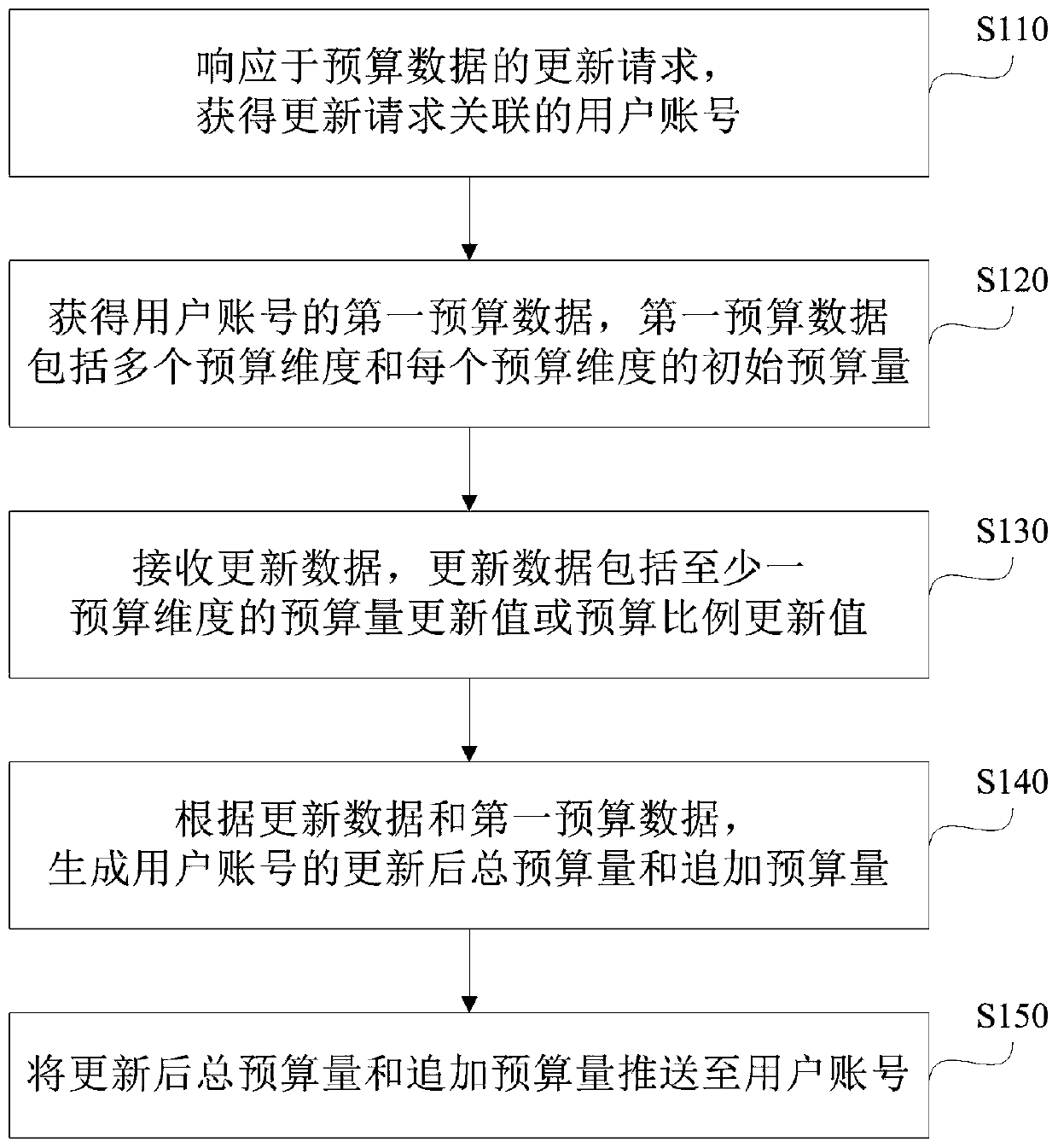

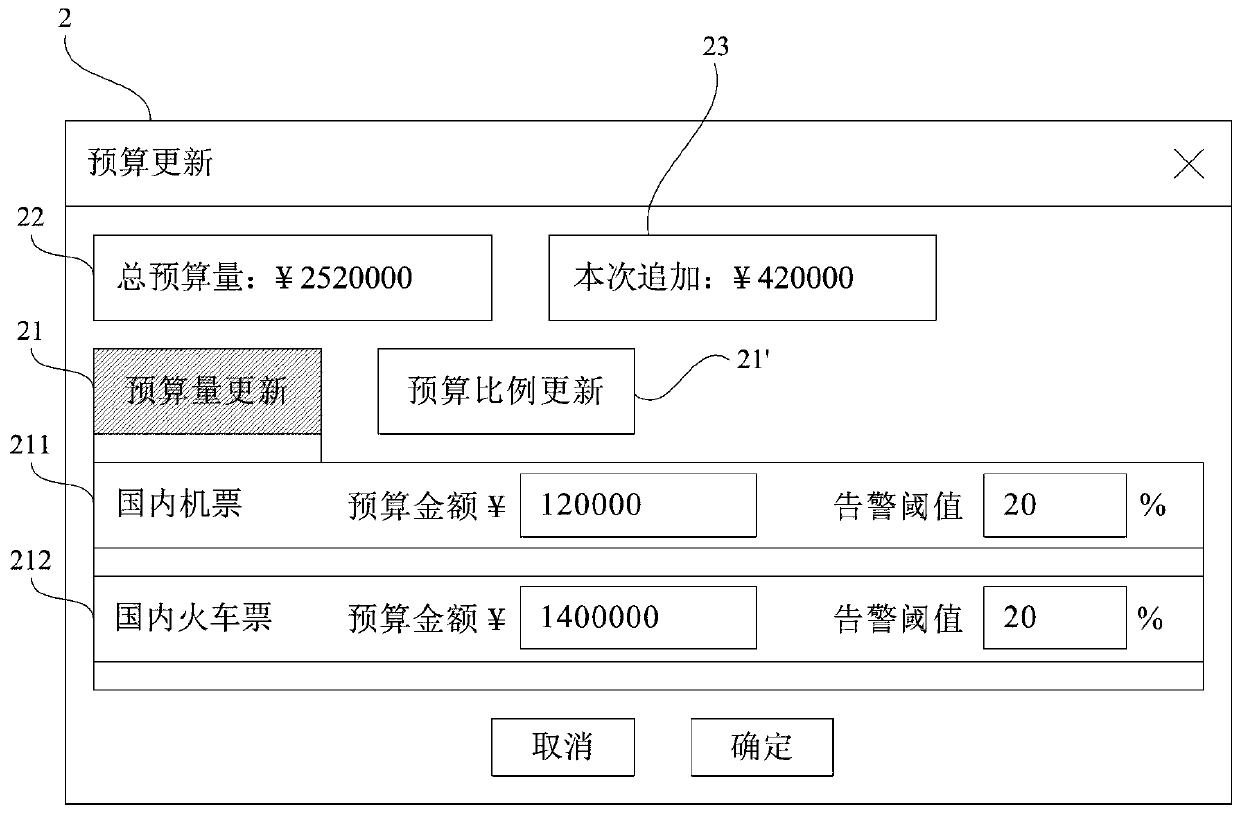

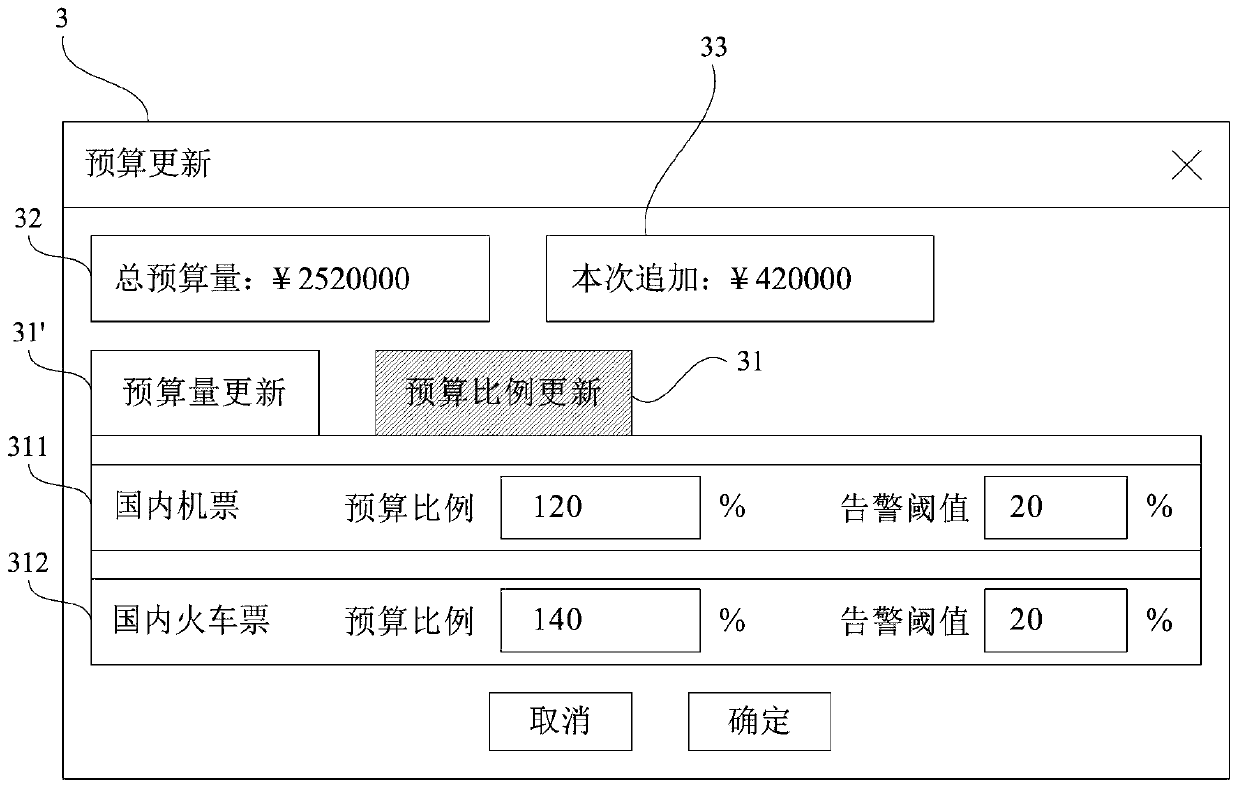

Budget data updating processing method and system, electronic equipment and storage medium

The invention relates to the technical field of data processing, and provides a budget data updating processing method and system, electronic equipment and a storage medium. The budget data updating processing method comprises the steps of obtaining a user account associated with an updating request in response to the budget data updating request; obtaining first budget data of the user account, wherein the first budget data comprises a plurality of budget dimensions and an initial budget amount of each budget dimension; receiving update data, wherein the update data comprises a budget amountupdate value or a budget proportion update value of at least one budget dimension; generating an updated total budget amount and an additional budget amount of the user account according to the updatedata and the first budget data; and pushing the updated total budget amount and the additional budget amount to the user account. In a budget data updating scene, the updated total budget amount andthe updated additional budget amount are automatically generated according to the updated data for a user to visually understand; and through adjustment of the alarm threshold, high efficiency, pertinence and safety of budget data monitoring are realized.

Owner:携程商旅信息服务(上海)有限公司

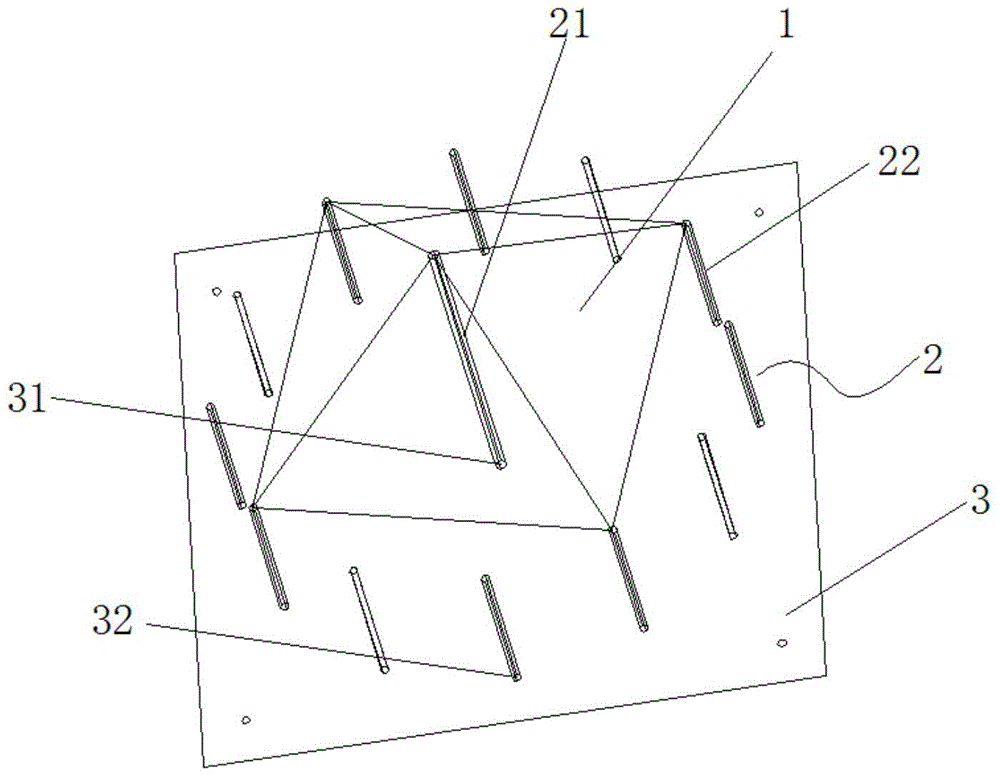

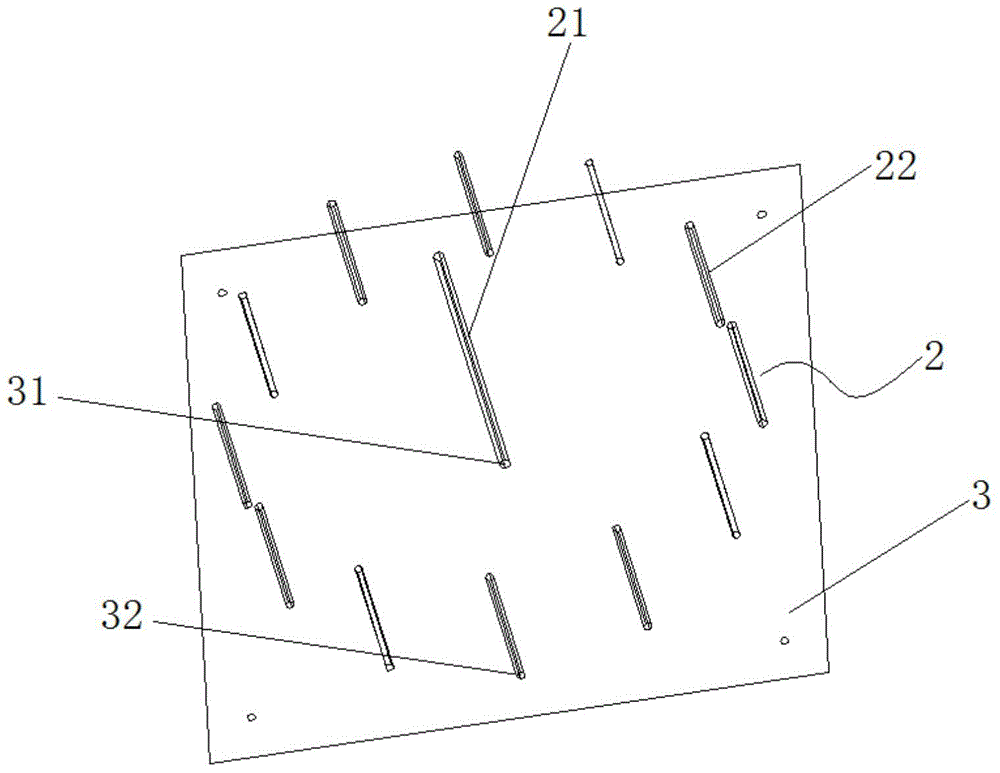

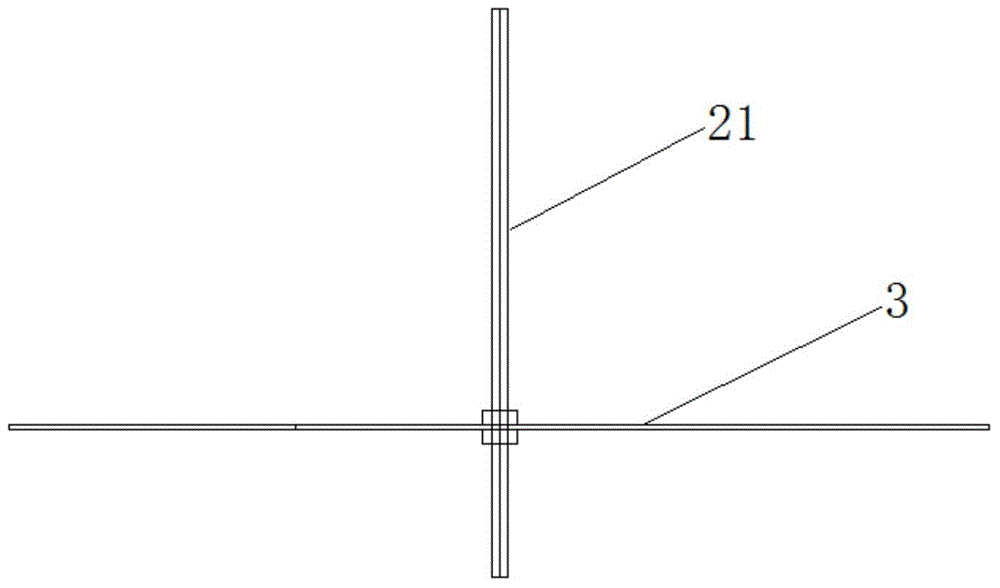

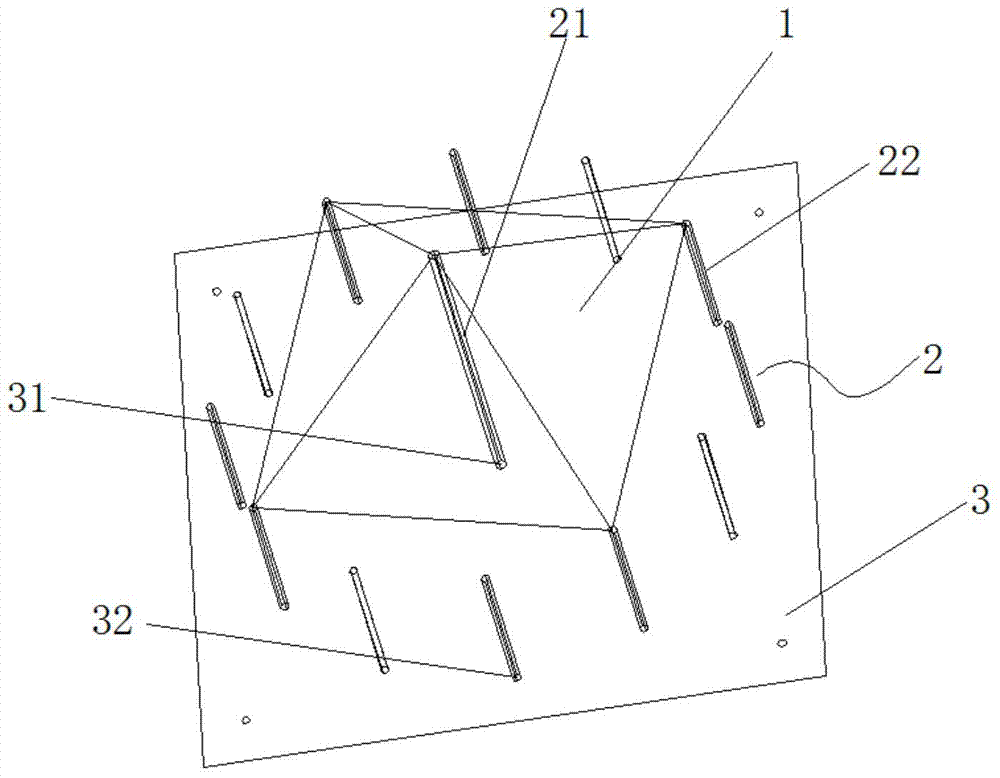

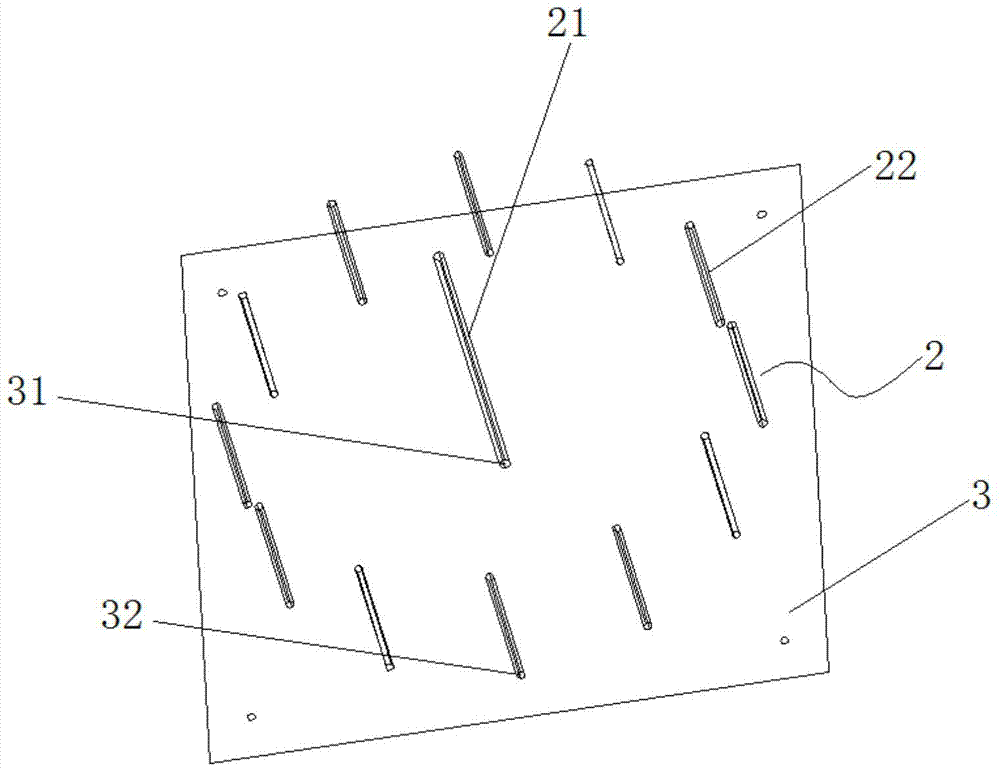

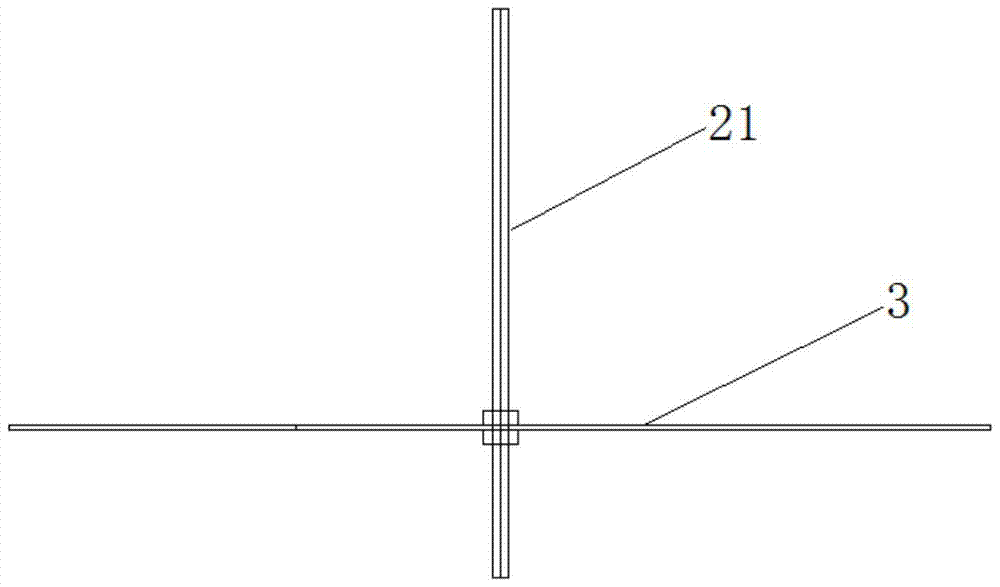

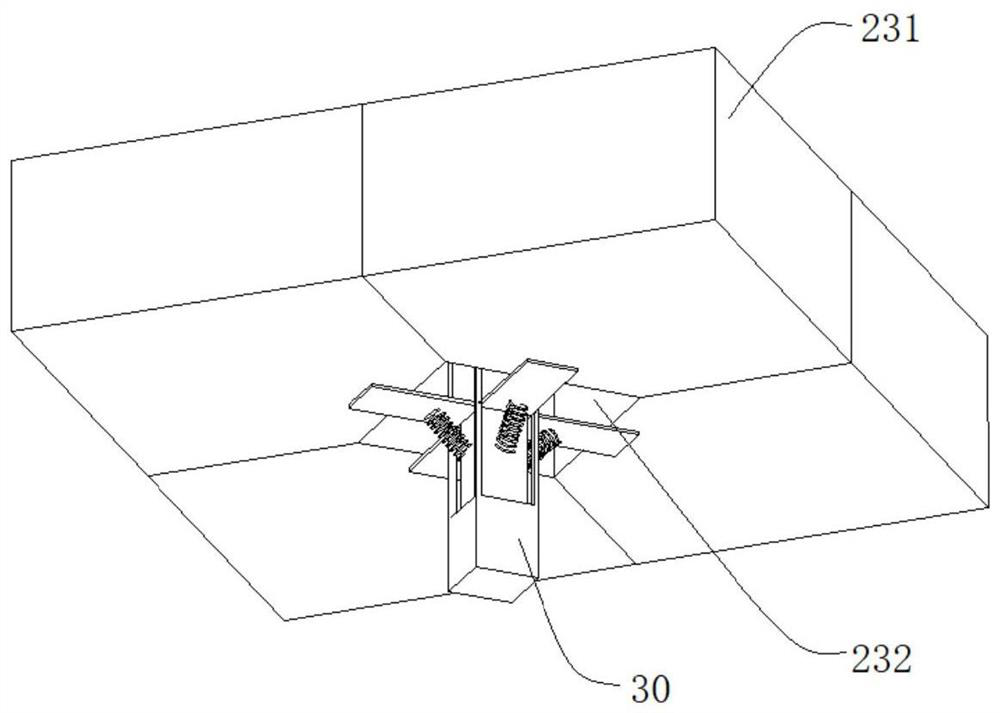

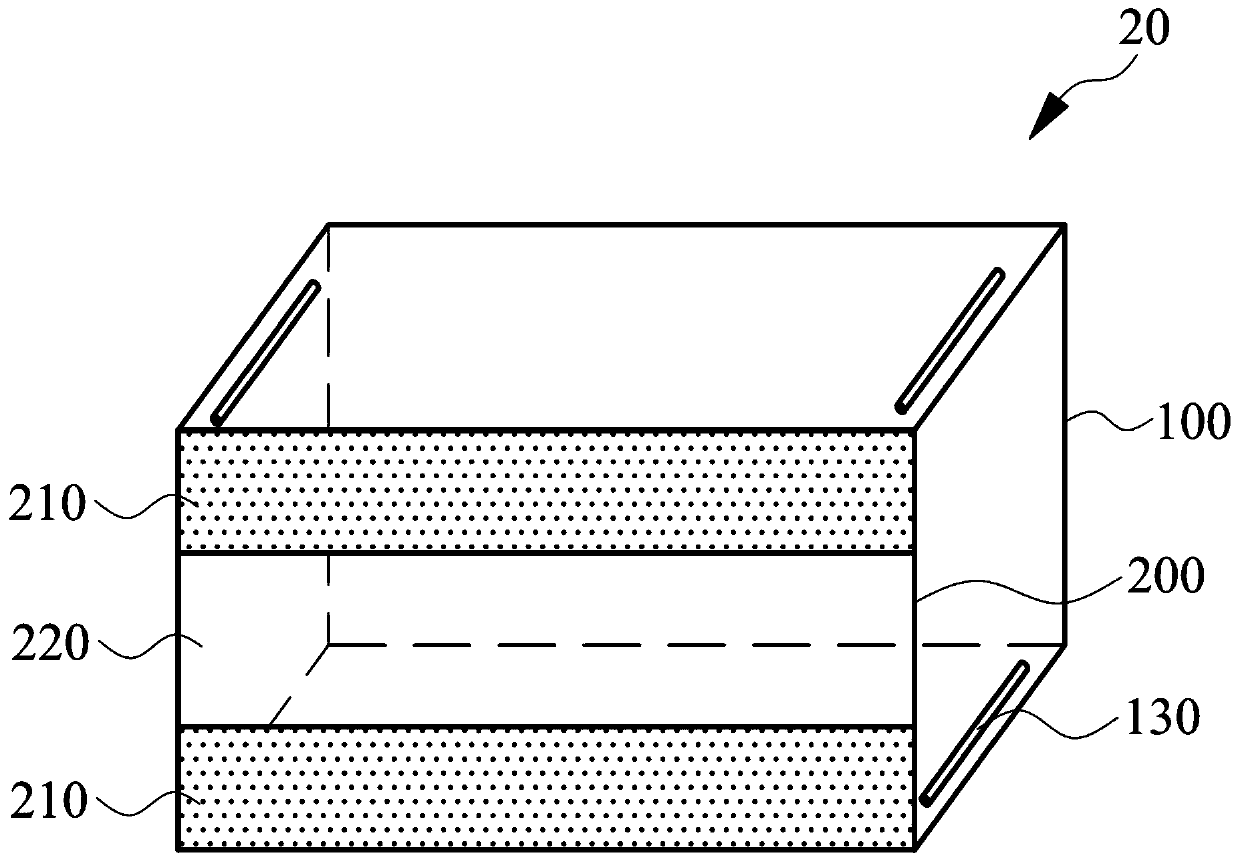

Tensile membrane structure teaching model

ActiveCN104900129ALow production costEasy to makeEducational modelsMembrane surfaceMembrane structure

The invention discloses a tensile membrane structure teaching model, comprising a working platform (3), a supporting structure (2) and at least one layer of membrane surface (1), wherein the supporting structure (2) is fixed on the working platform (3); and the membrane surface (1) is fixed on the supporting structure (2). A first hole (31) penetrating the upper and lower parts is formed in the center of the working platform (3). The supporting structure (2) comprises a first supporting rod (21) and at least three second supporting rods (22). The teaching model is low in manufacturing cost and simple in manufacturing, and a student can independently complete all operation, so the teaching model is favorable for teaching popularization.

Owner:TONGJI UNIV

Method and device for extracting defect area on board surface

ActiveCN112837287BShorten the timeImprove accuracyImage enhancementImage analysisOn boardEngineering

Owner:SHANDONG JIANZHU UNIV +1

Method and system for generating graphical description of mobile application version update

ActiveCN104850311BImprove experienceClear and intuitive understandingInput/output processes for data processingSoftware updateUser interface

The embodiment of the present invention discloses a method and system for generating a graphical description of a mobile application version update, wherein the method includes: clustering the classes of the mobile application version update before and after the modification, and obtaining the clustering result; according to the clustering As a result, the user interface corresponding to the mobile application is modified; and a graphical description of the updated description is generated according to the modified user interface. In the embodiment of the present invention, by generating a graphical update description, the user interface corresponding to the software update can be displayed for the user, which can help the user understand the software changes more clearly and intuitively, provide better services for the user, and significantly improve the user experience .

Owner:SUN YAT SEN UNIV

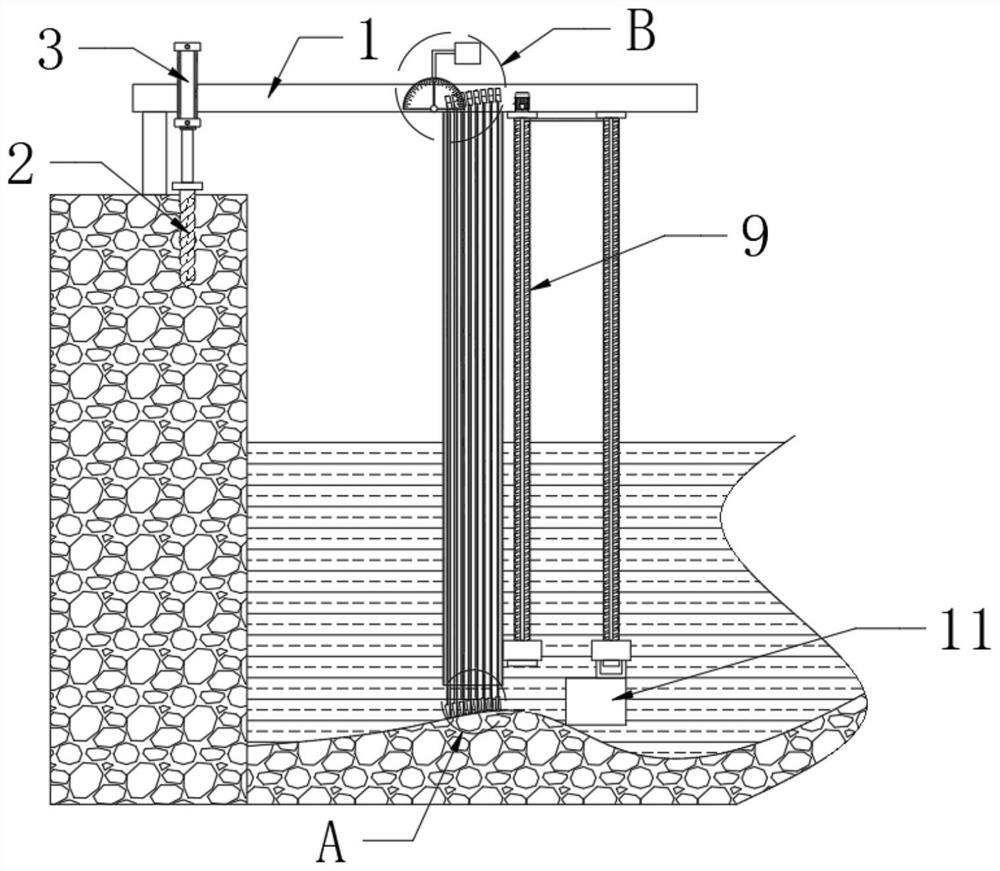

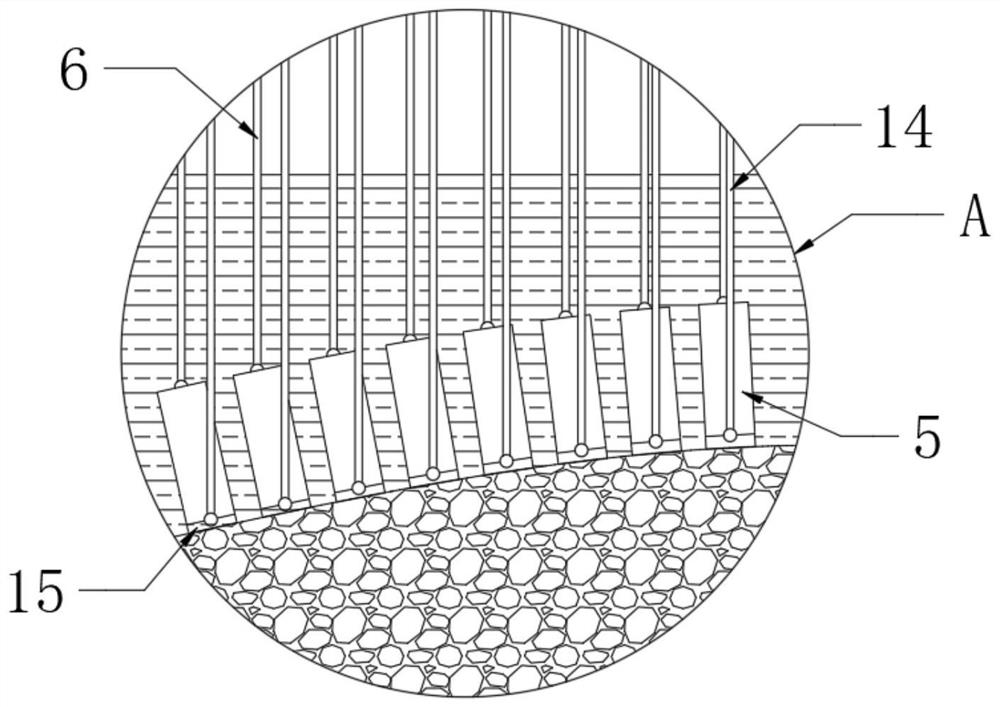

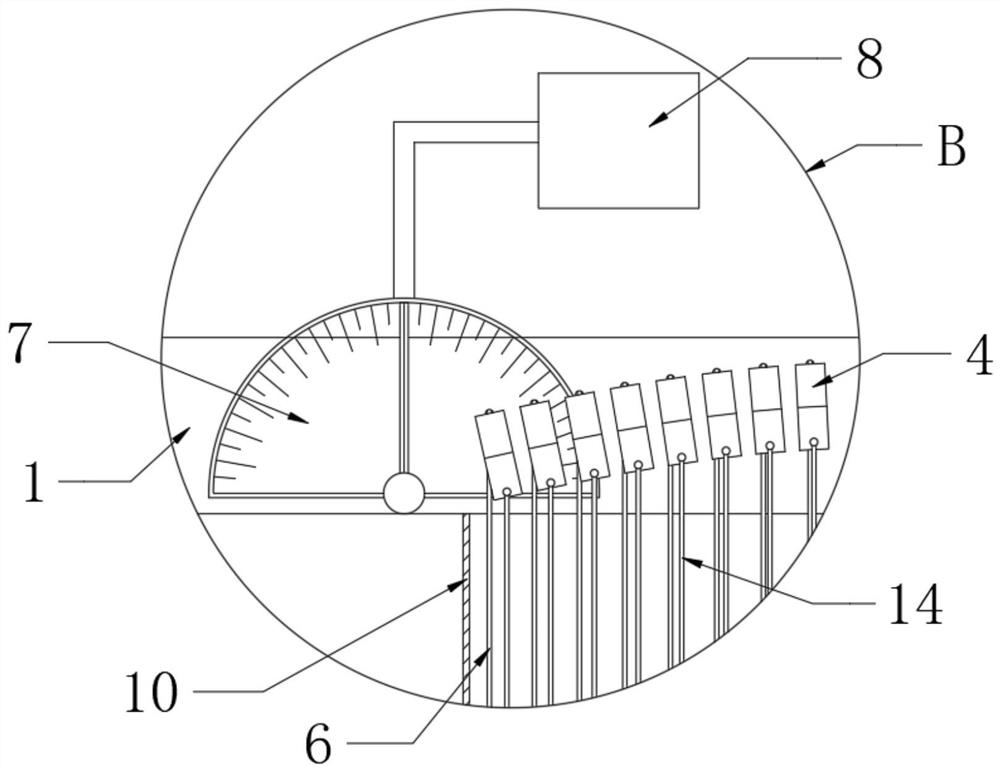

River slope testing device

InactiveCN114234923AClear and intuitive understandingIncline measurementRiver routingMeasuring instrument

The invention is suitable for the technical field of river channel testing, and provides a river channel gradient testing device, which comprises a fixed rod, a demonstration part; a test unit; a first link; a second connecting rod; a transmission assembly; and a measuring instrument; the transmission assembly drives the testing part to descend into a river to a river channel, the multiple testing blocks can be attached to the river channel along the trend of the slope of the river channel, the testing blocks can drive the demonstration blocks to incline through the second connecting rods, the inclination angles of the demonstration blocks are the same as the inclination angles of the testing blocks, and the inclination angles of the demonstration blocks can be measured through the measuring instrument. Meanwhile, the video camera can shoot the demonstration part to form a river slope demonstration diagram, so that the river slope can be clearly and intuitively known, the problems that an existing river slope testing device cannot clearly display the slope trend of a tested position and needs multi-point testing are effectively solved, and the river slope testing efficiency is improved.

Owner:新疆金业建筑安装有限责任公司

A teaching model of tensile membrane structure

ActiveCN104900129BReduce manufacturing costEasy to makeEducational modelsMembrane surfacePetroleum engineering

The invention discloses a tensile membrane structure teaching model, comprising a working platform (3), a supporting structure (2) and at least one layer of membrane surface (1), wherein the supporting structure (2) is fixed on the working platform (3); and the membrane surface (1) is fixed on the supporting structure (2). A first hole (31) penetrating the upper and lower parts is formed in the center of the working platform (3). The supporting structure (2) comprises a first supporting rod (21) and at least three second supporting rods (22). The teaching model is low in manufacturing cost and simple in manufacturing, and a student can independently complete all operation, so the teaching model is favorable for teaching popularization.

Owner:TONGJI UNIV

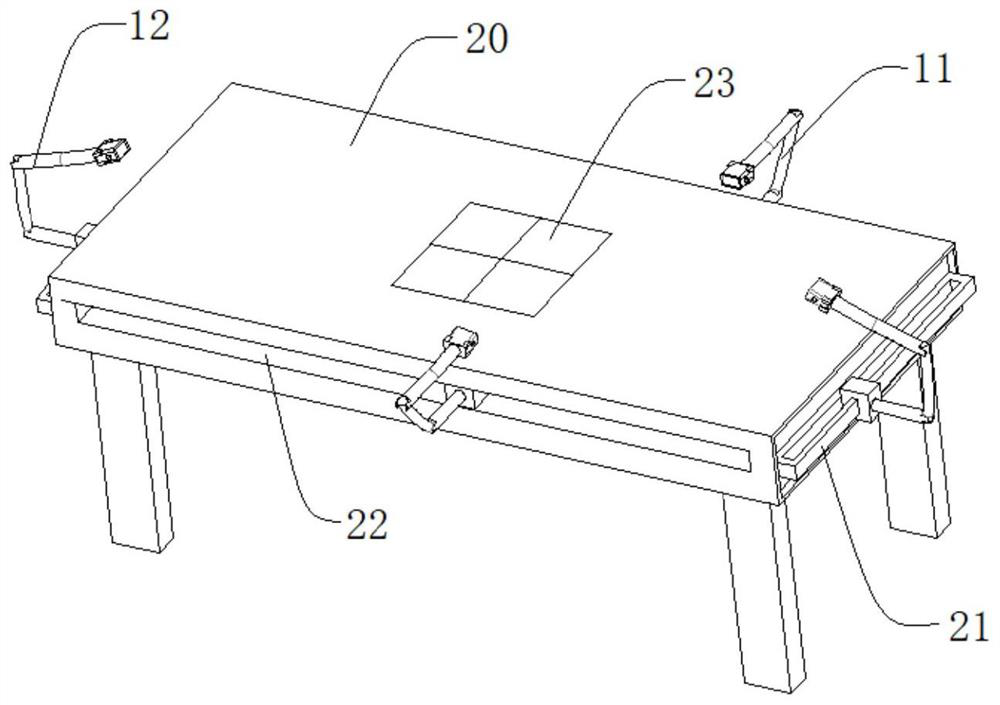

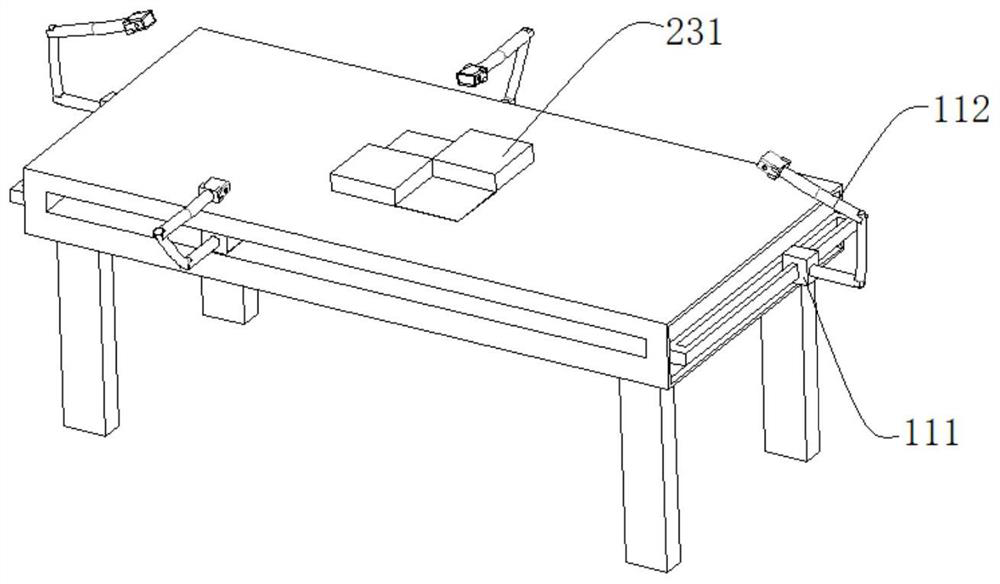

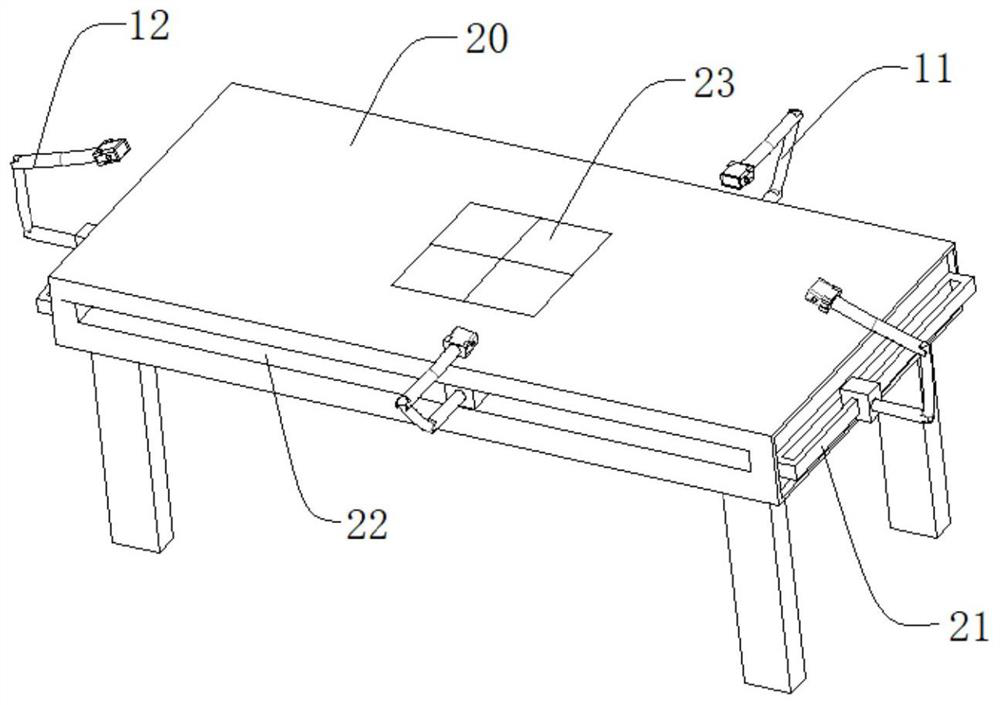

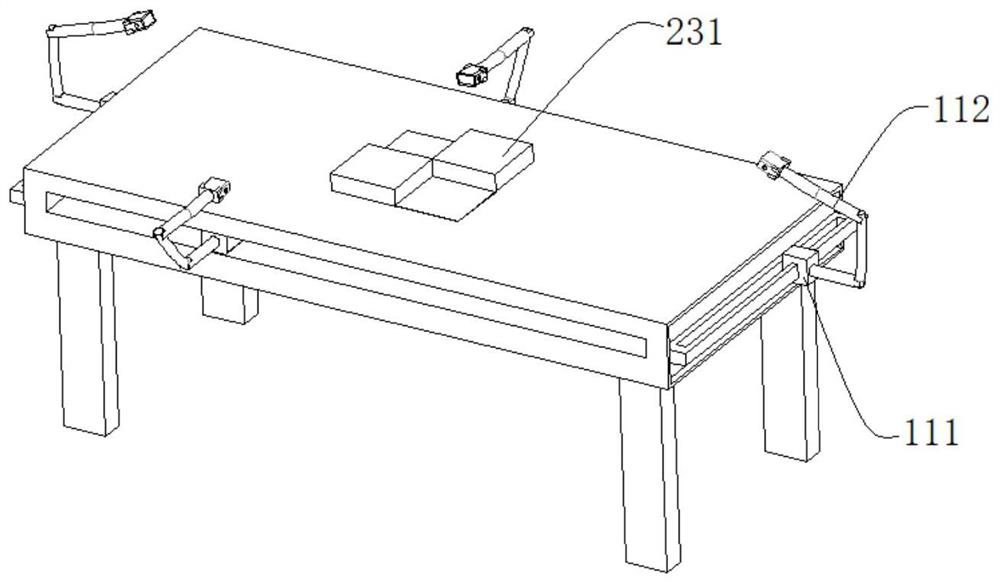

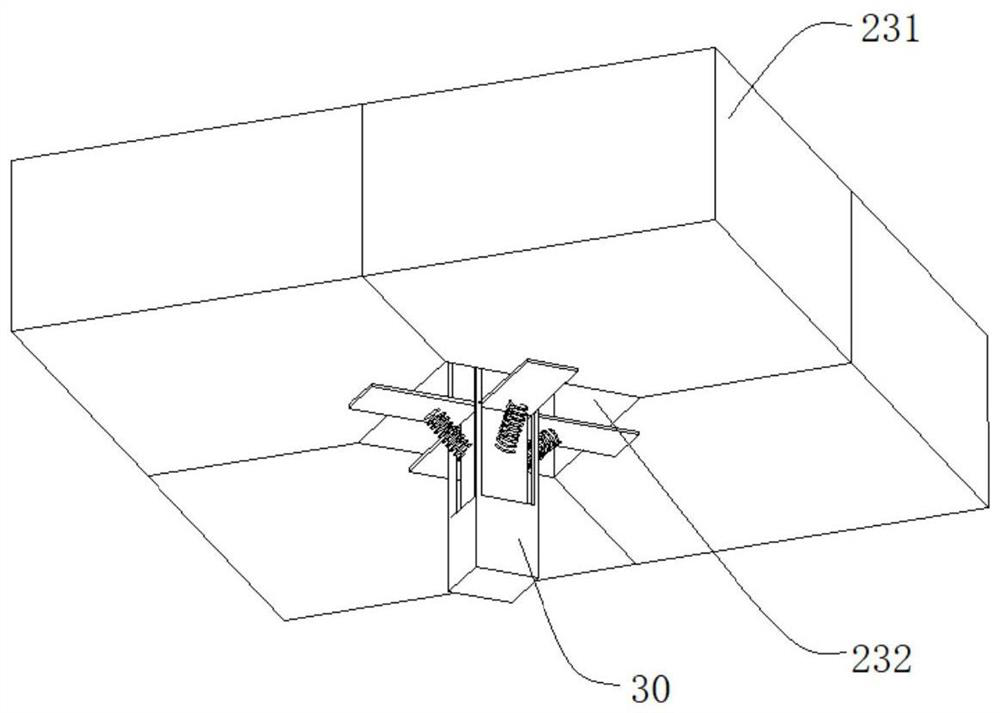

A Physical and Chemical Experiment Lesson Preparation System Applied in Network Classroom

ActiveCN112002154BEasy to understandClear and intuitive understandingTelevision system detailsColor television detailsMechanical engineeringIndustrial engineering

A physical and chemical experiment lesson preparation system applied to a network classroom of the present invention includes a lesson preparation platform and a processor, the lesson preparation platform includes a recording unit and a table body, the recording unit includes a positioning video and audio acquisition module and a dynamic audio and video acquisition module, the The audio-visual information obtained by the recording unit is sent to the processor for sorting and storage; the table top is rectangular, the short side of the table is provided with slide rails, and the long side of the table is provided with chute, two The positioning audio-visual acquisition modules are respectively arranged on the slide rails of the two short sides of the table top, and the two dynamic audio-visual acquisition modules are respectively arranged in the chute of the two long sides of the table top; the middle part of the table top is provided with a movable booth for Auxiliary experiments provide a professional lesson preparation platform for teachers to conduct experiments, and obtain all-round audio and video through the recording unit, so that students can understand the experimental process more clearly and intuitively, and help students understand the teaching content.

Owner:四川科华天府科技有限公司

Frog specimen storage device

ActiveCN109625542BClear and intuitive understandingEasy to placeRigid containersInternal fittingsTick specimenEngineering

The invention discloses a frog specimen storage device. The frog specimen storage device comprises an exhibition mechanism and a specimen storage mechanism. The exhibition mechanism comprises a base,a rotary shaft, a shaft sleeve bearing and a transparent exhibition tank. The lower end of the rotary shaft is fixedly connected with an upper board of the base. The upper end of the rotary shaft is fixedly connected with the inner ring of the shaft sleeve bearing. The outer ring of the shaft sleeve bearing is fixedly connected with a lower board at the bottom of the transparent exhibition tank. The transparent exhibition tank rotates with the rotary shaft as the axis. The specimen storage mechanism comprises a tadpole specimen storage tube, an adult frog specimen storage bottle and an adult frog skeleton specimen storage bottle. The tadpole specimen storage tube, the adult frog specimen storage bottle and the adult frog skeleton specimen storage bottle are arranged in the transparent exhibition tank. The adult frog specimen storage bottle is arranged over the adult frog skeleton specimen storage bottle. According to the frog specimen storage device, the forms of frogs in different growth stages can be compared and observed, the trouble that a frog specimen has to be taken and rotated when observed at all angles in the circumferential direction is avoided, and people can observe the forms of the frog at different growth stages conveniently.

Owner:温州普奈机械科技有限公司

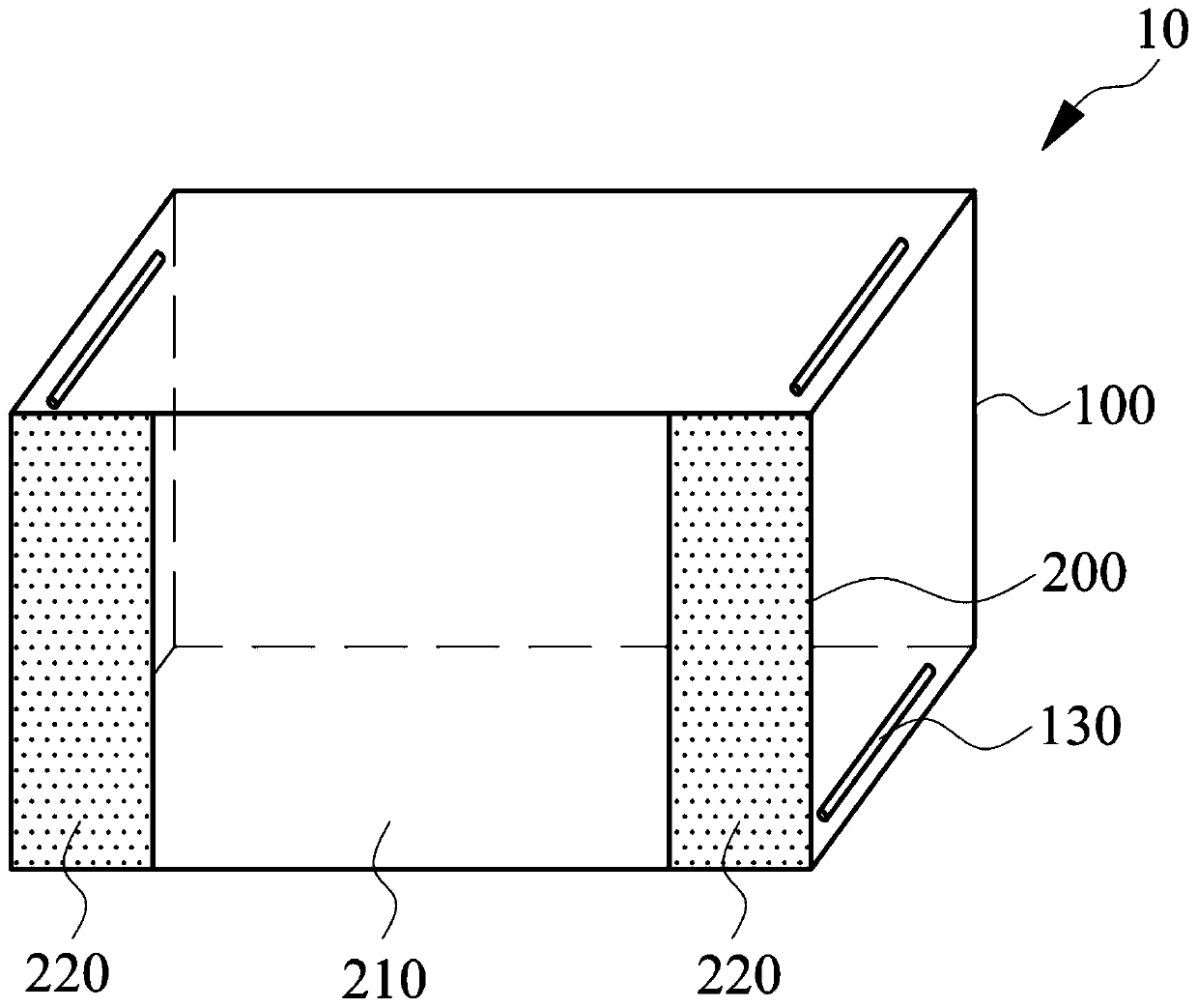

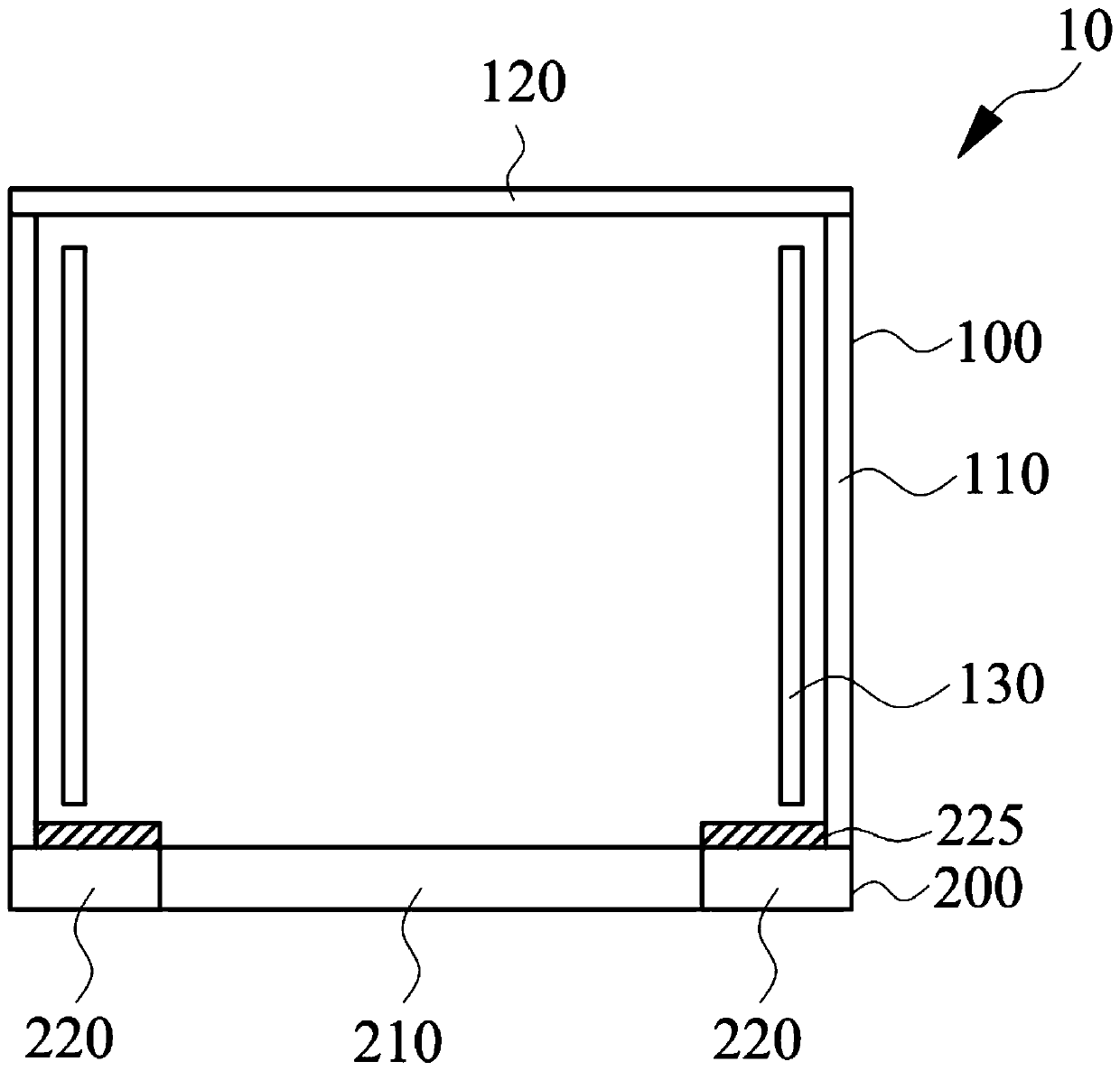

item display device

ActiveCN108968522BClear and intuitive understandingQuality improvementShow cabinetsComputer hardwareComputer graphics (images)

An embodiment of the invention discloses an object display device which comprises a shell and a display unit. The shell is provided with multiple side faces and one back, and the side faces and the back form the interior of the shell to have objects placed; the display unit is opposite to the back and is sleeved with the shell, the display unit comprises a first display area and a second display area, wherein the first display area is of a transparent display area, and the second display area is of an image display area; a backlight unit is further arranged on the second display area on the side facing back, and the backlight provides light sources to the second display area.

Owner:HUIZHOU CHINA STAR OPTOELECTRONICS TECHNOLOGY CO LTD

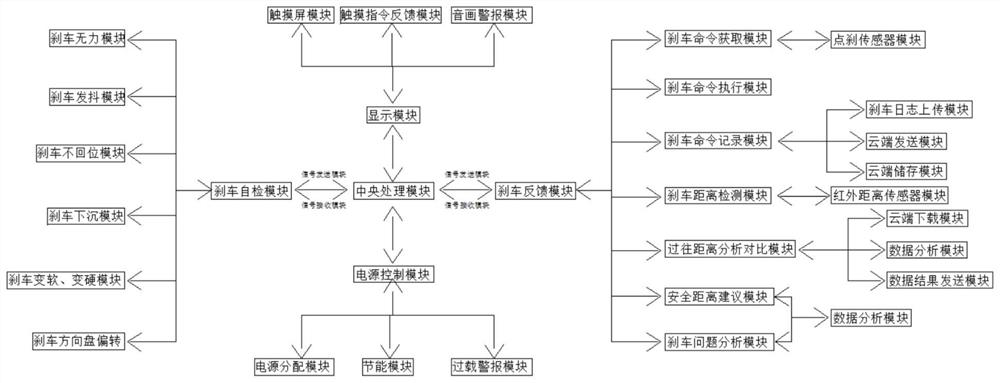

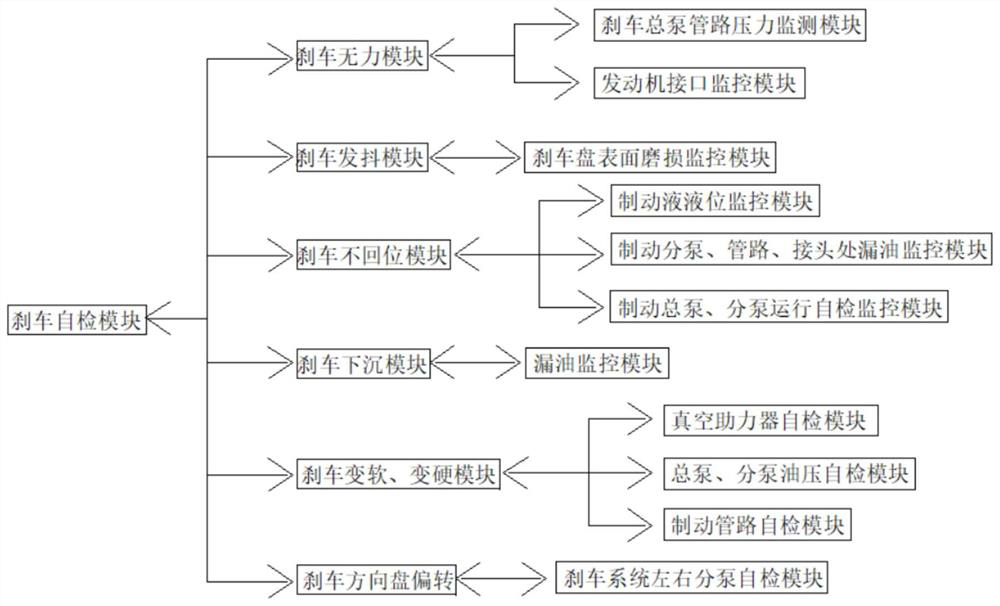

Anti-explosion brake system

PendingCN114248749AReduce damageExtended service lifeElectric/fluid circuitBrake safety systemsDriver/operatorAnalysis data

The invention discloses an anti-explosion brake system, and relates to the field of brake systems, and a central processing module is used for a central module in a vehicle brake system, summarizes a brake feedback condition, a power supply control condition and a brake self-inspection condition, analyzes and arranges the conditions, and then sends data to a display module for display. According to the system, the brake command is recorded, then the brake distance is detected and recorded, and the analysis module analyzes the recorded data, so that the brake safety degree is obtained, and the brake safety is digitally sent to the display screen to be checked by a driver; and the data analysis module can also compare and analyze the current braking condition with the previous braking condition so as to obtain whether the braking performance is reduced or not, digitalize the analysis data and send the analysis data to the display screen module, so that a driver can more intuitively know the safety degree and the loss degree of the vehicle braking.

Owner:苏州瑞来特思机械设备有限公司

Physicochemical experiment lesson preparation system applied to online classroom

ActiveCN112002154AEasy to understandClear and intuitive understandingTelevision system detailsColor television detailsComputer graphics (images)Engineering

The physical and chemical experiment lesson preparation system applied to the online class. The system comprises a lesson preparation platform and a processor, wherein the lesson preparation platformcomprises a recording unit and a table body, the recording unit comprises a positioning audio-video acquisition module and a dynamic audio-video acquisition module, the audio-video information acquired by the recording unit is transmitted to the processor to be sorted and stored, the table top of the table body is rectangular, sliding rails are arranged on the short edges of the table top, slidinggrooves are formed in the long edges of the table top, the two positioning audio and video obtaining modules are arranged on the sliding rails on the two short edges of the table top respectively, and the two dynamic audio and video obtaining modules are arranged in the sliding grooves in the two long edges of the table top respectively. The system is advantaged in that a movable exhibition standis arranged in the middle of the table top and used for assisting an experiment, a professional lesson preparation platform is provided for a teacher to do the experiment, omnibearing video and audioacquisition is conducted through the recording unit, students can know the experiment process more clearly and visually, and the students can understand teaching content easily.

Owner:四川科华天府科技有限公司

Data processing method, electronic equipment and storage medium

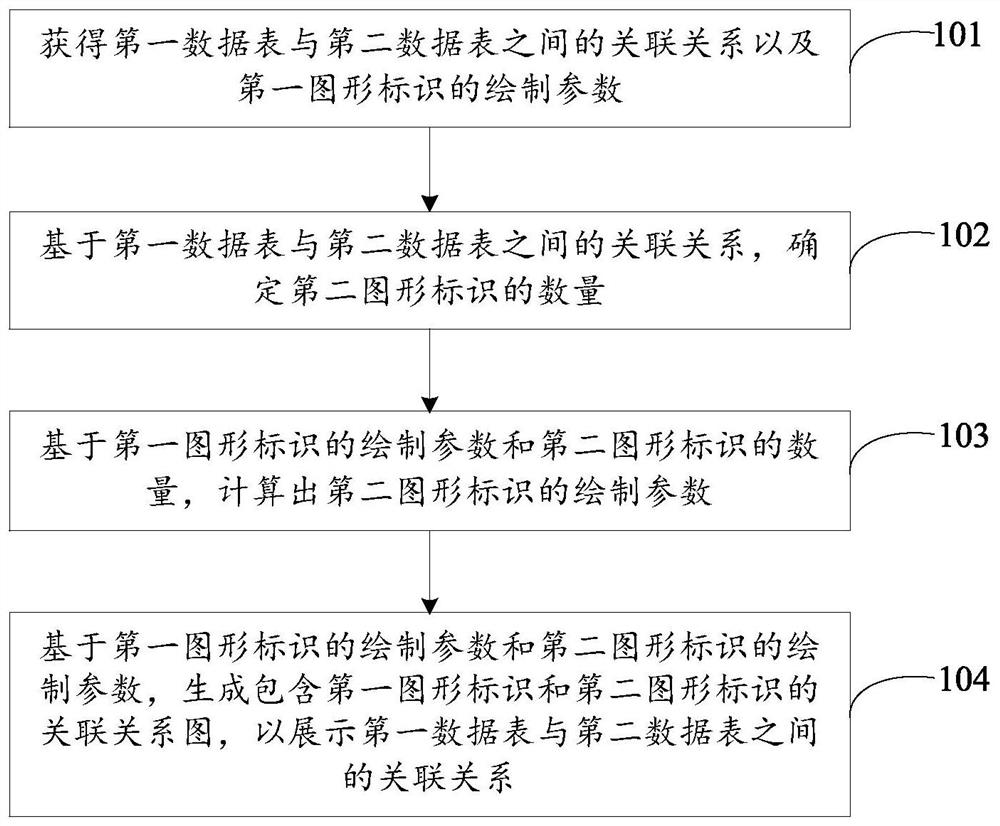

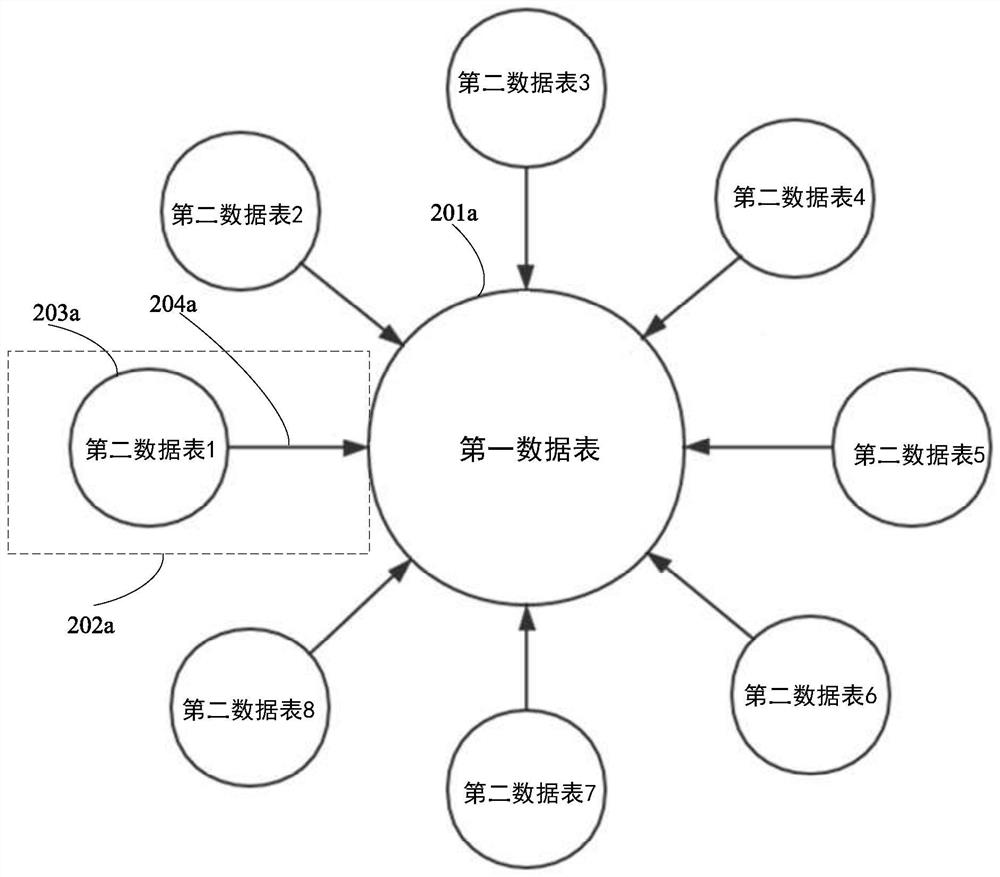

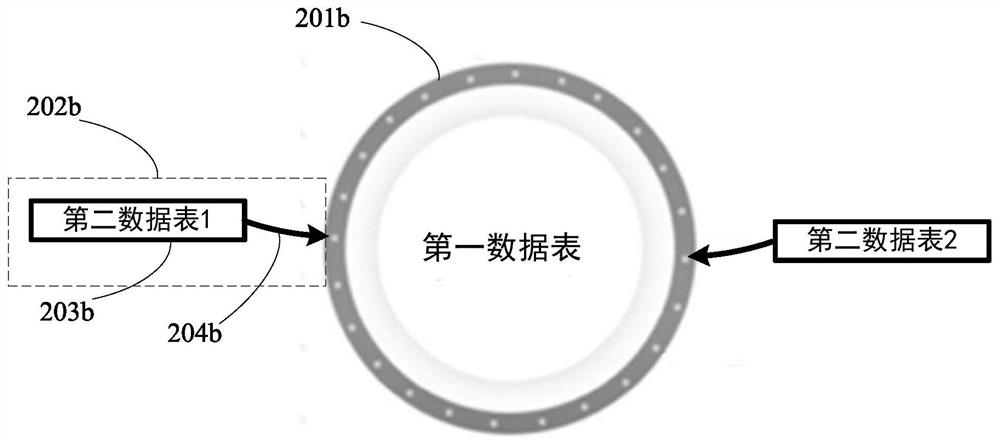

InactiveCN111708918AImprove experienceClear and intuitive understandingOther databases indexingOther databases browsing/visualisationDatasheetComputer engineering

The embodiment of the invention provides a data processing method, electronic equipment and a storage medium. The method comprises the steps: obtaining an association relation between a first data table and a second data table and a drawing parameter of a first graphic recognition, and the first graphic recognition is used for representing the first data table; the number of second graphic identifiers is determined based on the association relationship between the first data table and the second data table, and the second graphic identifiers comprise first sub-graphic identifiers used for representing the second data table and second sub-graphic identifiers used for representing association rules; calculating a drawing parameter of the second graphic identifier based on the drawing parameter of the first graphic identifier and the number of the second graphic identifiers; and based on the drawing parameters of the first graphic identifier and the drawing parameters of the second graphic identifier, generating an association relationship graph containing the first graphic identifier and the second graphic identifier so as to display an association relationship between the first datatable and the second data table. In this way, the incidence relation between the data tables can be clearly and visually displayed.

Owner:BEIJING MININGLAMP SOFTWARE SYST CO LTD

HAVP processing method and device, electronic equipment and storage medium

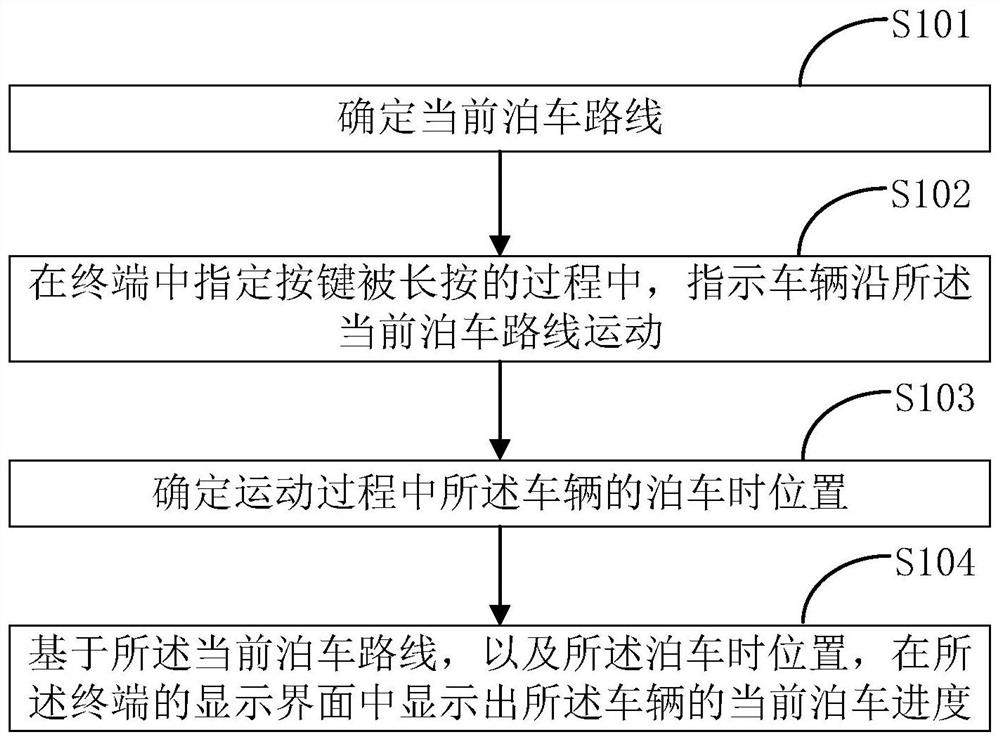

PendingCN113753031AProgress is effectively informedClear and intuitive understandingControl devicesKey pressingReal-time computing

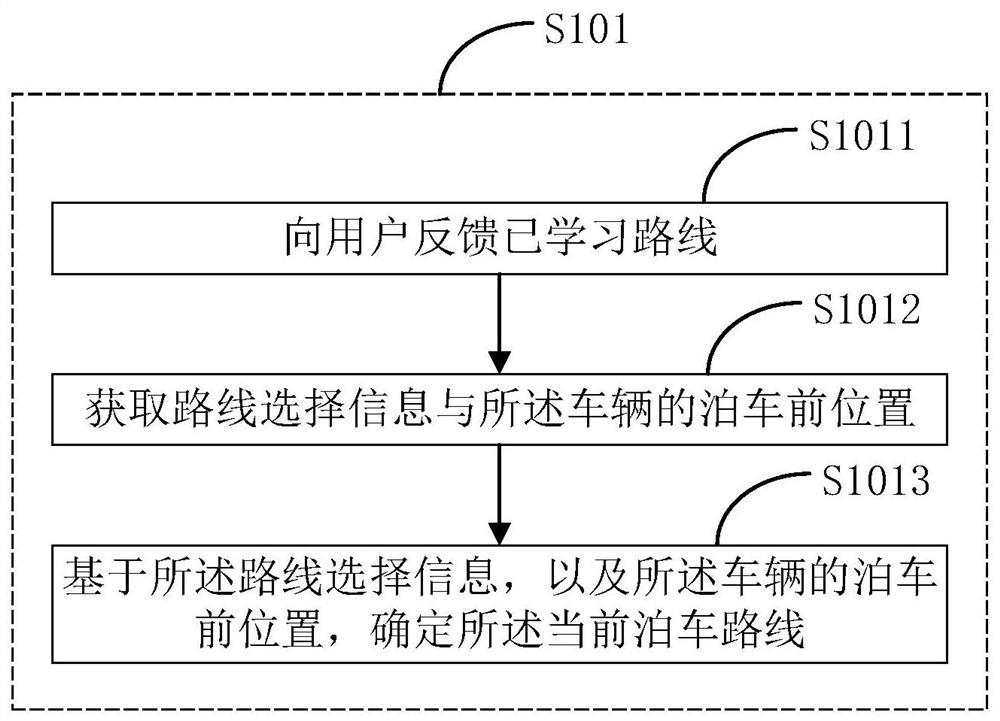

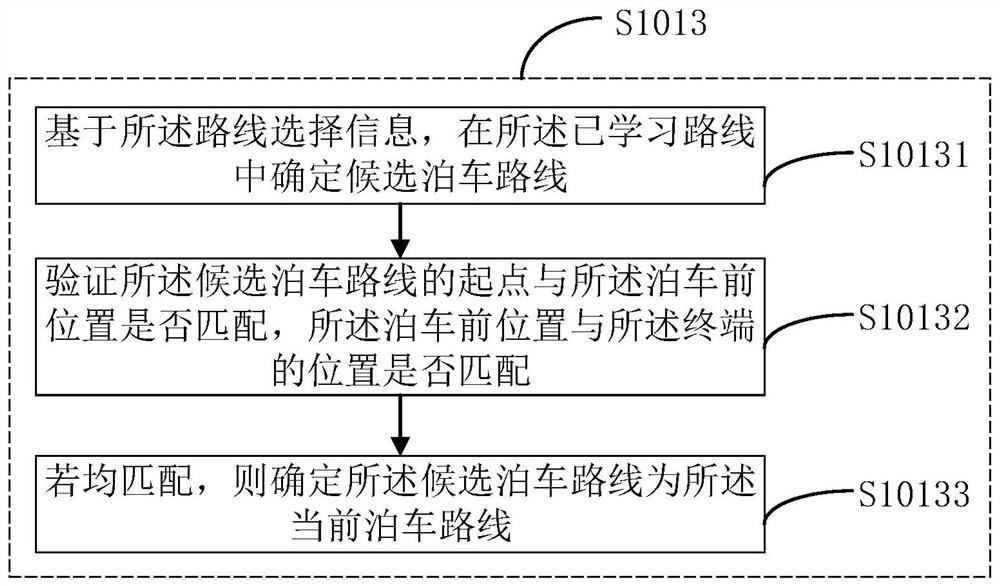

The invention provides an HAVP processing method and device, electronic equipment and a storage medium. The HAVP processing method comprises the steps: determining a current parking route, wherein the current parking route originates from a learned route; in the process that a specified key in the terminal is pressed for a long time, indicating a vehicle to move along the current parking route; determining the parking position of the vehicle in the moving process; and displaying the current parking progress of the vehicle in a display interface of the terminal based on the current parking route and the parking position.

Owner:上海仙塔智能科技有限公司

A Method for Generating the Relationship Graph of Power Grid Dispatch Operation Ticket

ActiveCN106844955BClear and intuitive understandingStrong technical supportComputer aided designSpecial data processing applicationsElectric power systemPower grid

Owner:LUDONG UNIVERSITY +2

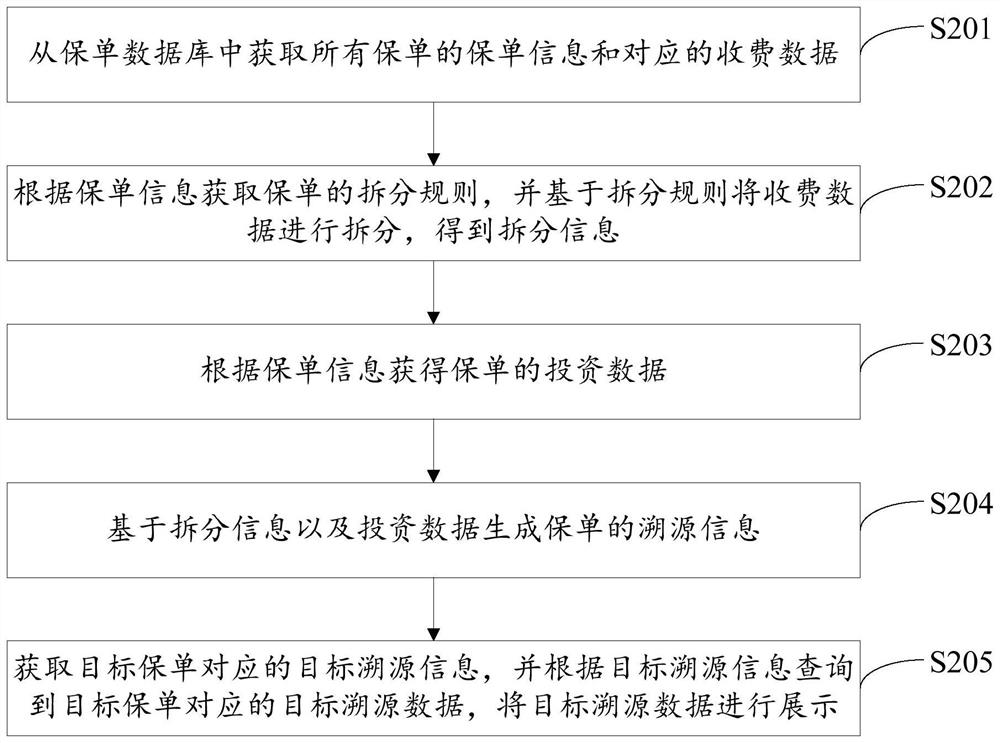

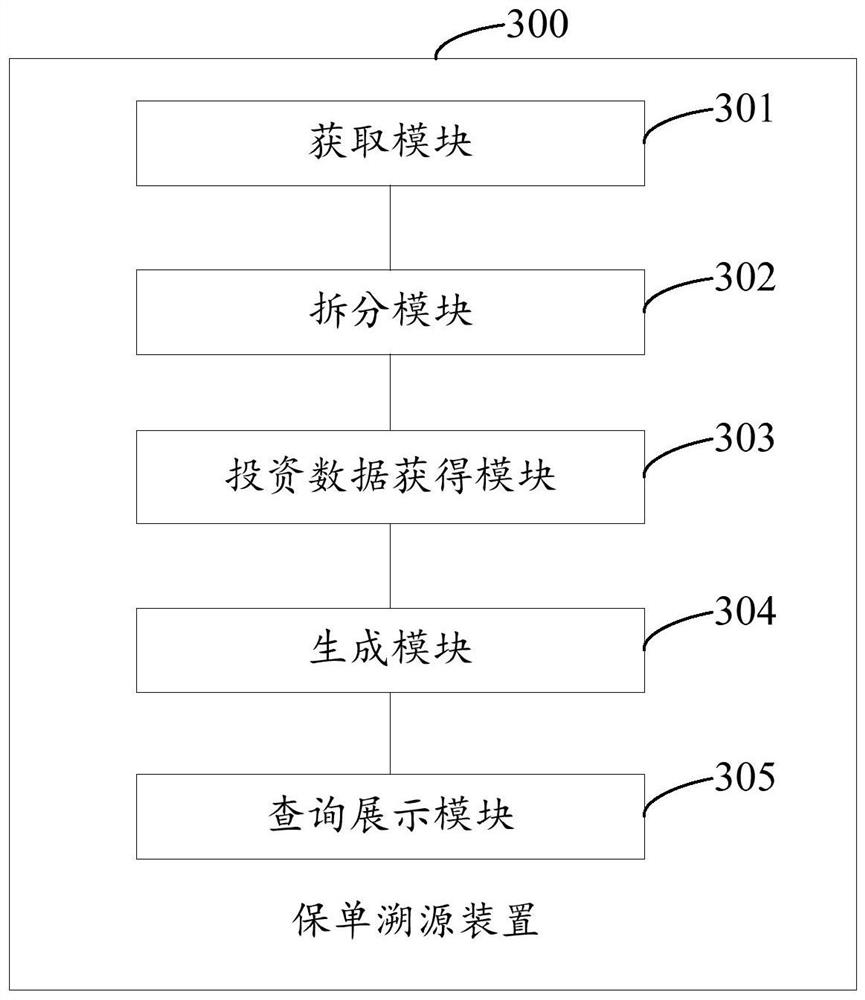

Insurance policy tracing method and device, computer equipment and storage medium

PendingCN114519648AHigh transparencyIncrease credibilityFinanceCommerceInformation acquisitionOperations research

The embodiment of the invention belongs to the technical field of data processing, and relates to an insurance policy tracing method, which comprises the following steps: acquiring insurance policy information and corresponding charging data of all insurance policies from an insurance policy database, acquiring an insurance policy splitting rule according to the insurance policy information, and splitting the charging data based on the splitting rule to obtain splitting information, and obtaining investment data of the insurance policy according to the insurance policy information, generating traceability information of the insurance policy based on the splitting information and the investment data, obtaining target traceability information corresponding to the target insurance policy, querying target traceability data corresponding to the target insurance policy according to the target traceability information, and displaying the target traceability data. The invention further provides an insurance policy traceability device, computer equipment and a storage medium. In addition, the invention also relates to a block chain technology, and the target traceability data can be stored in a block chain. According to the invention, the tracing efficiency can be improved, and the transparency and credibility of the client are improved.

Owner:CHINA PING AN LIFE INSURANCE CO LTD

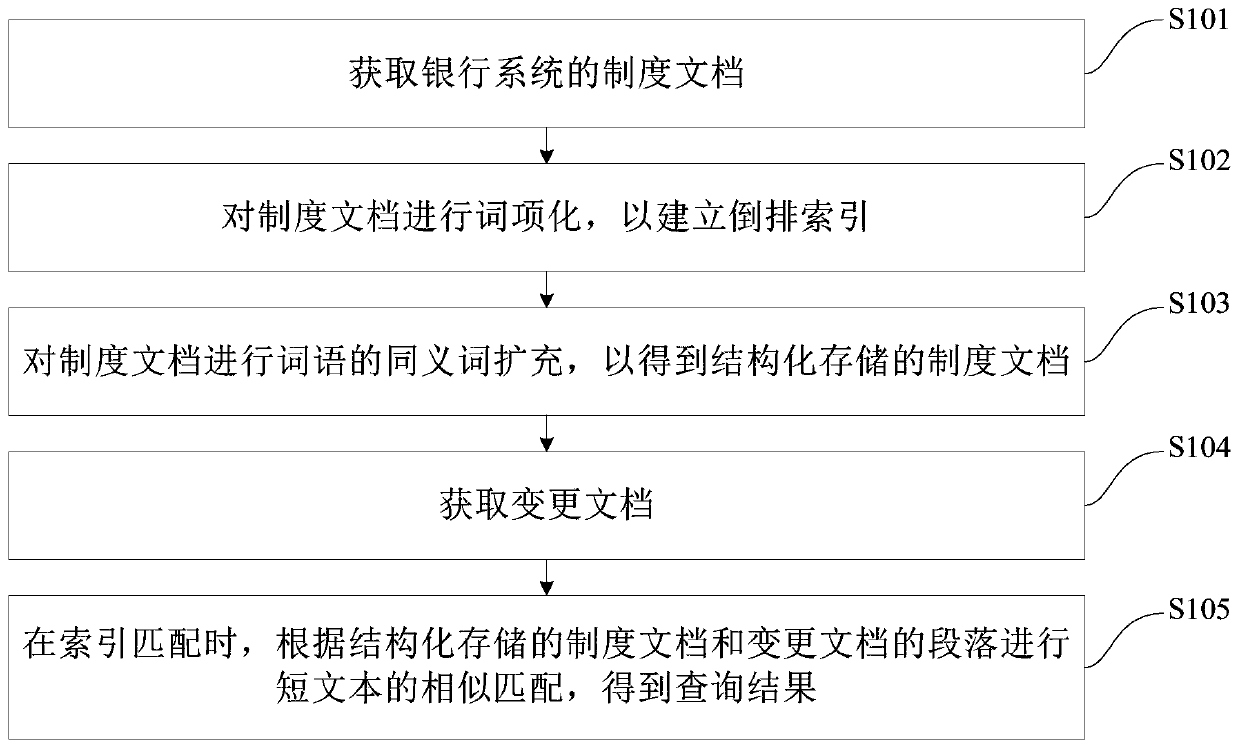

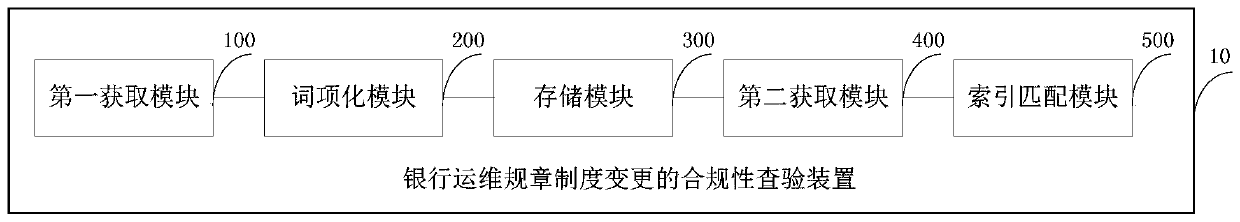

Compliance inspection method and device for changes in bank operation and maintenance rules and regulations

ActiveCN106844625BEasy to findEasy to excludeFinanceNatural language data processingLexical itemData mining

The invention discloses a method and a device for checking compliance of alteration of operation and maintenance rules and regulations of banks. The method includes acquiring regulation documents of bank systems and carrying out lexical item processing on the regulation documents so as to create inverted indexes; expanding synonyms of terms for the regulation documents so as to obtain regulation documents stored in a structured manner; acquiring alteration documents; carrying out similarity matching on short texts according to the regulation documents stored in the structured manner and paragraphs of the alteration documents during index matching so as to obtain query results. The method and the device have the advantages that the query results can be obtained according to the regulation documents stored in the structured manner and the alteration documents, accordingly, the checking accuracy and efficiency can be improved, and the method and the device are simple and are easy to implement.

Owner:TSINGHUA UNIV +1

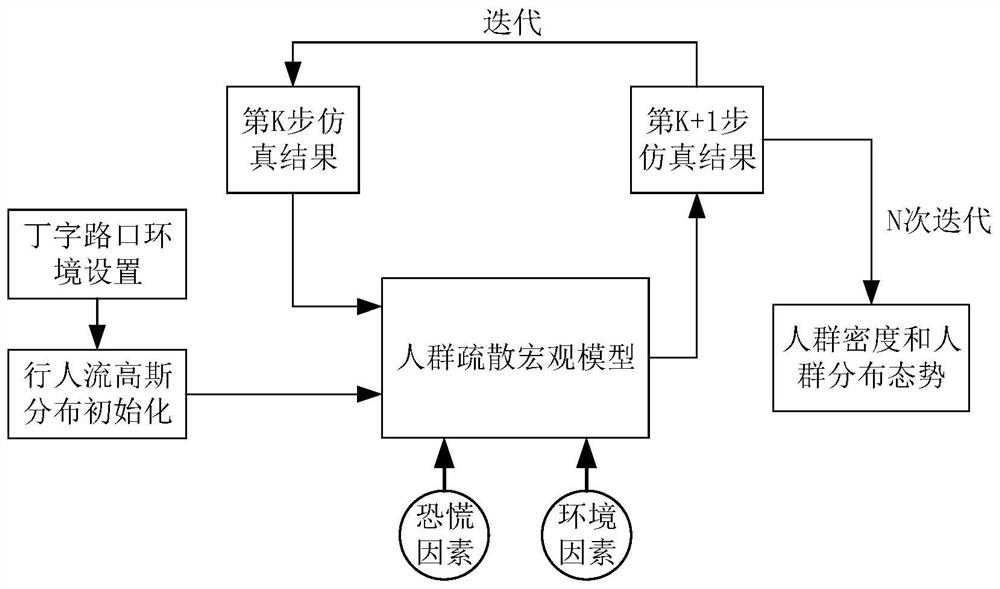

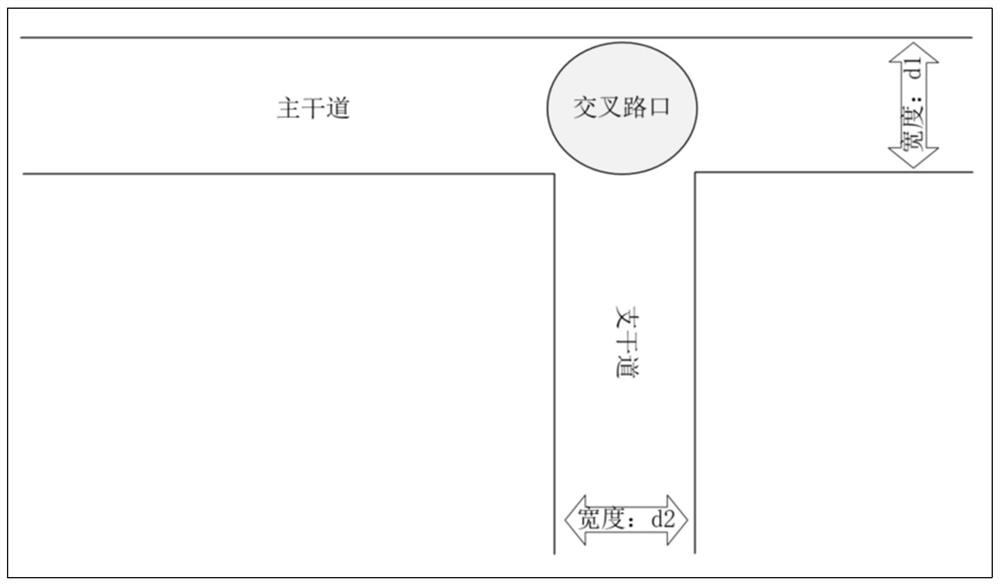

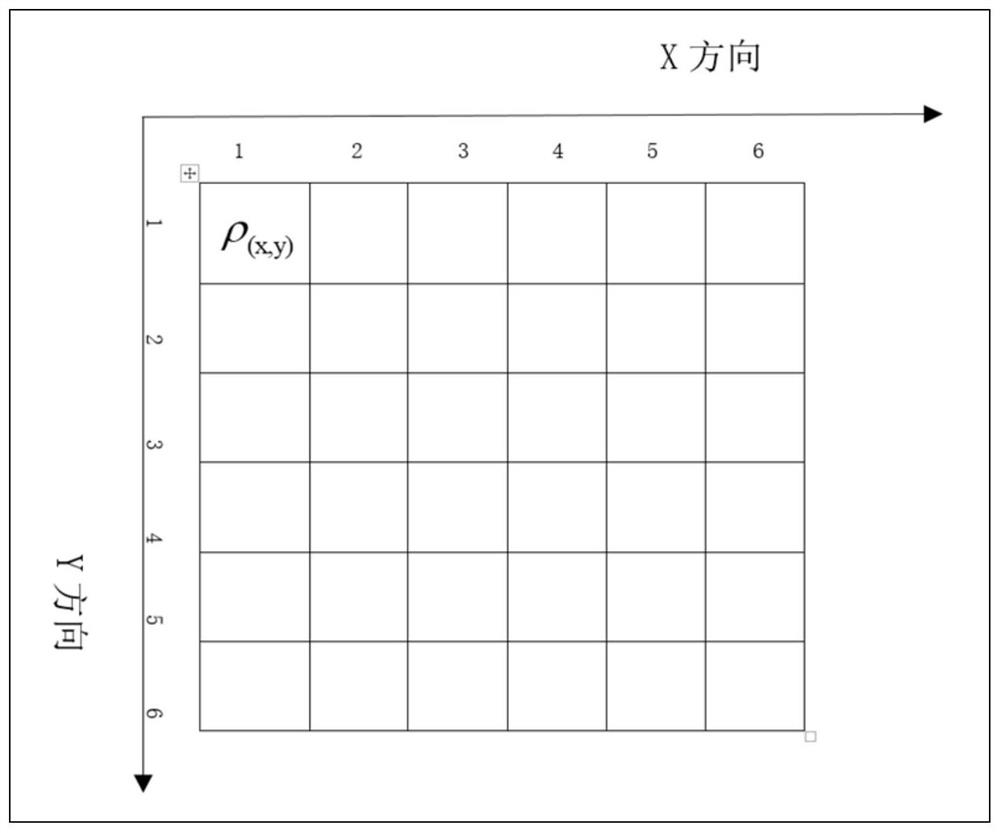

Iterative Simulation Method of Macroscopic Model of Crowd Evacuation

ActiveCN109063268BThe simulation results are close toImprove the simulation effectDesign optimisation/simulationIndividual entry/exit registersAlgorithmComputational physics

The present invention relates to a kind of iterative simulation method of crowd evacuation macro model, comprising the following steps: 1) establishing Aw-Rascle crowd dynamics macro model; 2) carrying out pedestrian Gaussian distribution initialization based on terrain environment; 3) described pedestrian flow based on initialization Gaussian distribution and Aw‑Rascle crowd dynamics macro model for iterative simulation and display of simulation results. Compared with the prior art, the present invention adopts an iterative simulation method, which can make the simulation effect closer to the real situation, and has the advantages of high precision of the simulation result.

Owner:TONGJI UNIV

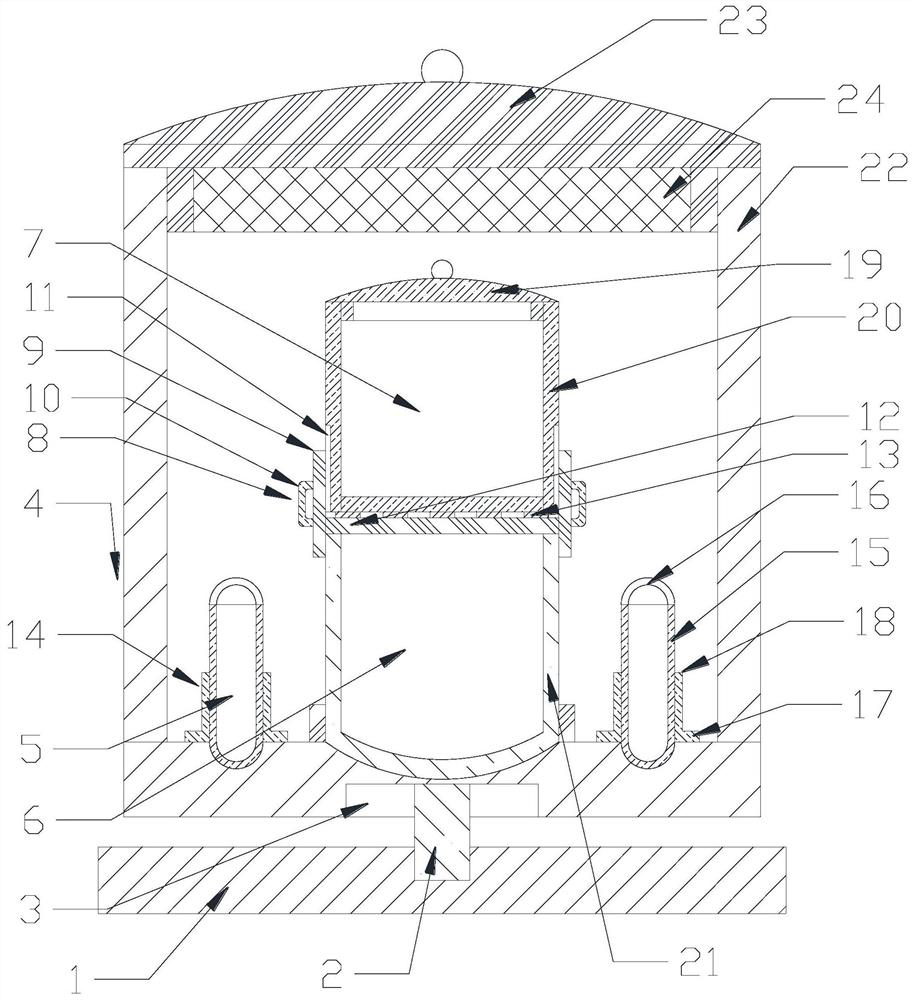

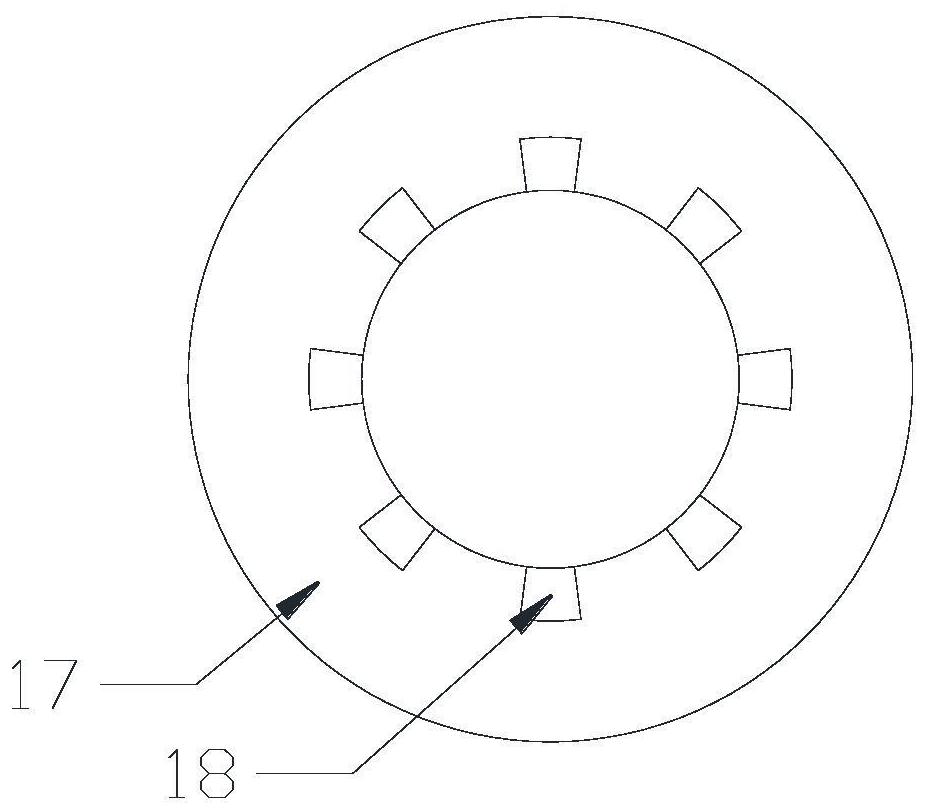

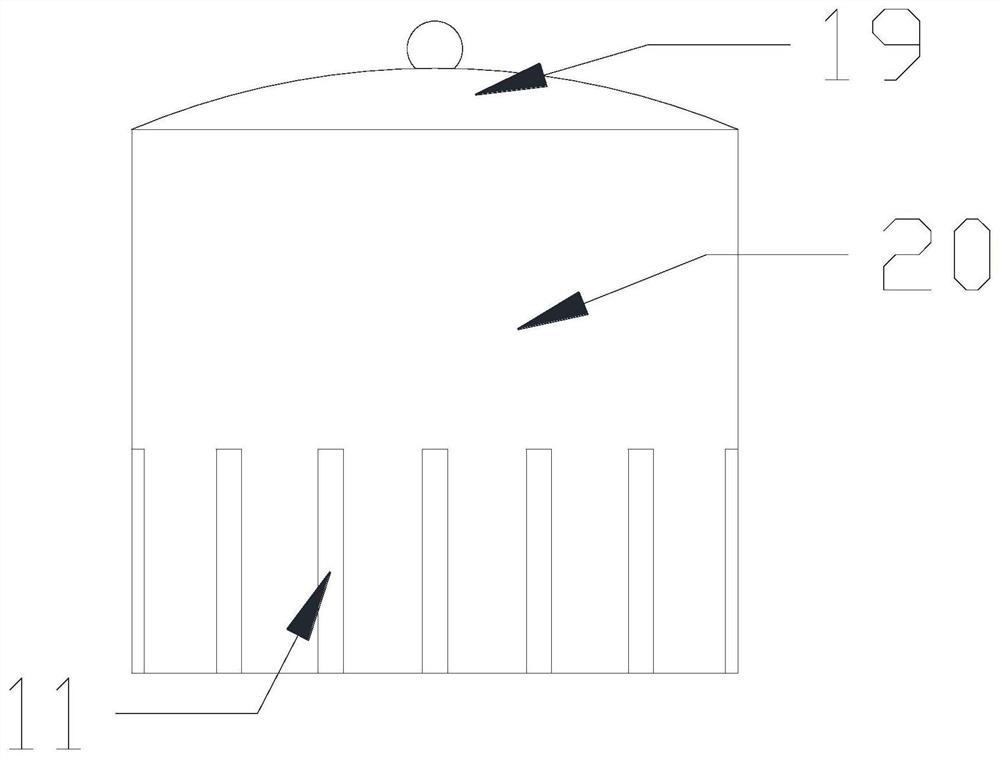

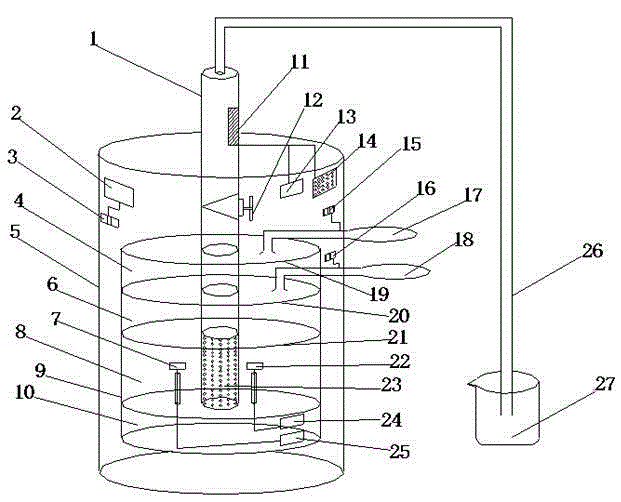

Flowing oil production demonstration model

A flowing oil production demonstration model is composed of the components of an oil well sleeve, a simulated temperature display screen, a temperature adjusting switch, an airbag 1, a control box, an airbag 2, a temperature sensor, oil sand, a glass cylinder, a rock layer, a liquid induction device, a control valve, a timing device, an LED lamp, a first air pump control switch, a second air pump control switch, an air pump 1, an air pump 2, a first sealing porous baffle plate, a second sealing porous baffle plate, a third sealing porous baffle plate, a pressure sensor, holes, a pressure display screen, an oil pipe and an oil receiving device. The flowing oil production demonstration model has advantages of simple principle, convenient operation and accurate simulated number. The flowing oil production demonstration model can clearly and visually demonstrate system structure of a flowing oil well and principle and phenomenon of flowing oil production. The flowing oil production demonstration model is particularly suitable for demonstration in teaching.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com