Flowing oil production demonstration model

A technology of oil sand and display screen, applied in the field of model, can solve the problem of not obvious and intuitive phenomenon, and achieve the effect of convenient operation, simple principle and accurate simulation value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

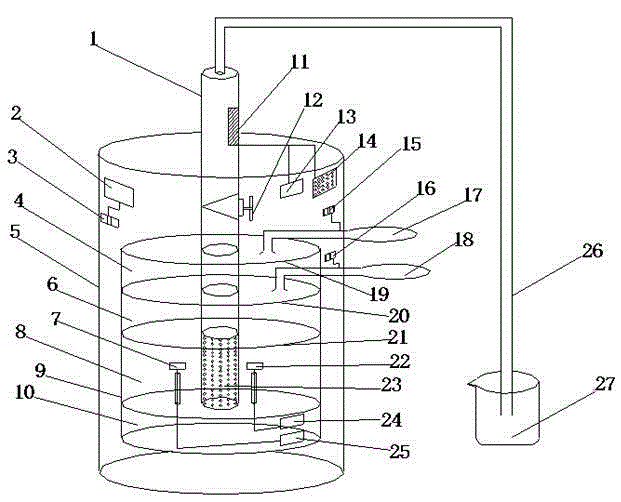

[0009] The present invention is composed of oil well casing (1), simulated temperature display screen (2), temperature adjustment switch (3), air bag 1 (4), temperature control box (5), air bag 2 (6), temperature sensor (7) , oil sand (8), glass cylinder (9), rock layer (10), liquid sensing device (11), control valve (12), timing device (13), LED light (14), air pump 1 control switch ( 15), air pump 2 control switch (16), air pump 1 (17), air pump 2 (18), sealing hole partition 1 (19), sealing hole partition 2 (20), sealing hole partition 3 ( 21), pressure sensor (22), hole (23), pressure display (24), actual temperature display (25), oil pipe (26), oil receiving device (27). During the demonstration, the start of the self-injection process is controlled by controlling the switch of the control valve (12); the oil produced by the self-injection flows into the oil receiving device (27) through the oil pipe (26); when the model passes the self-injection When the extracted oil p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com