A teaching model of tensile membrane structure

A technology of teaching model and tensioning membrane, applied in teaching models, educational appliances, instruments, etc., can solve the problem of not finding teaching models, and achieve the effect of facilitating teaching promotion, simple operation, and simple production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

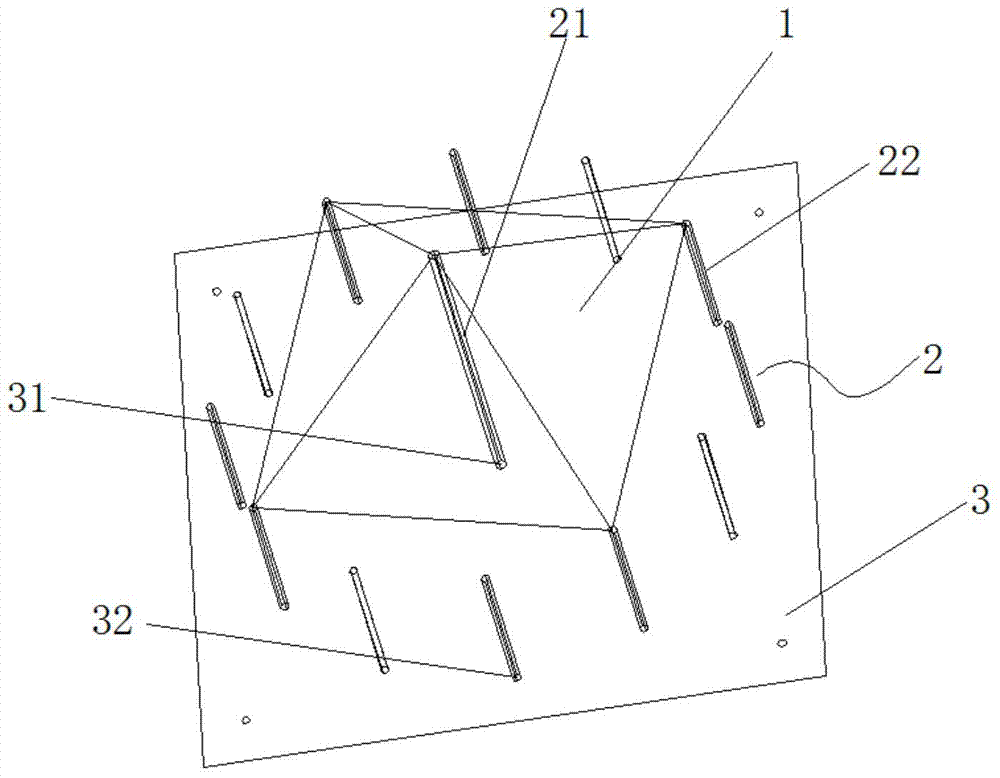

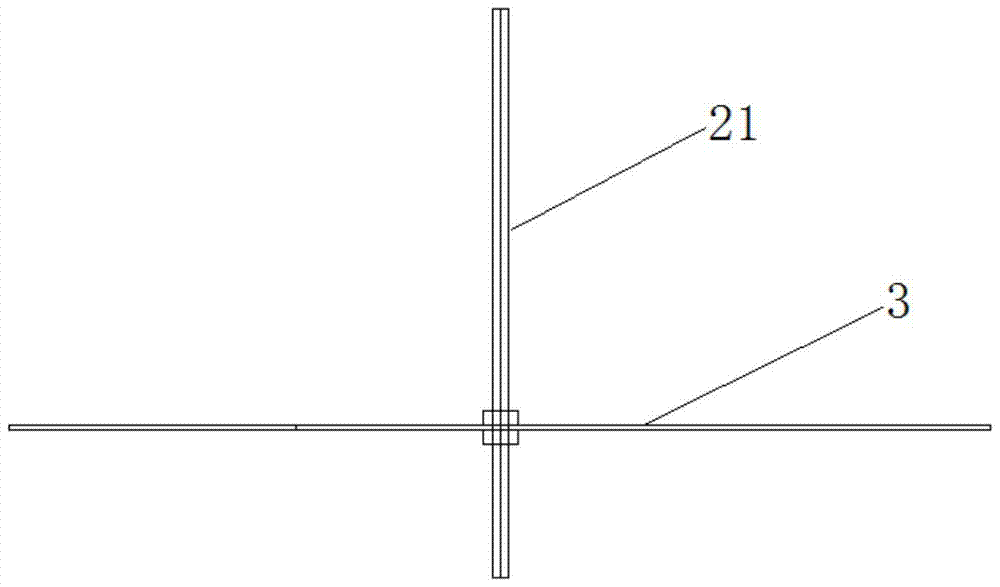

[0029] Tensile membrane structure teaching model, such as figure 1 as shown, figure 1 It is a schematic diagram of the overall structure of the tensile membrane structure teaching model of the embodiment of the present invention. It includes a working platform 3, a supporting structure 2 and at least one membrane surface 1, the supporting structure 2 is fixed on the working platform 3, and the membrane surface 1 is fixed on the supporting structure 2; Lycra cloth is used to simulate, and different shapes can be formed by stretching around. The application of tension makes the membrane structure have a certain bearing capacity. Feel free to adjust and experience the changes. The main structure is used to control the position of the tension point to control the shape of the tensioned membrane structure.

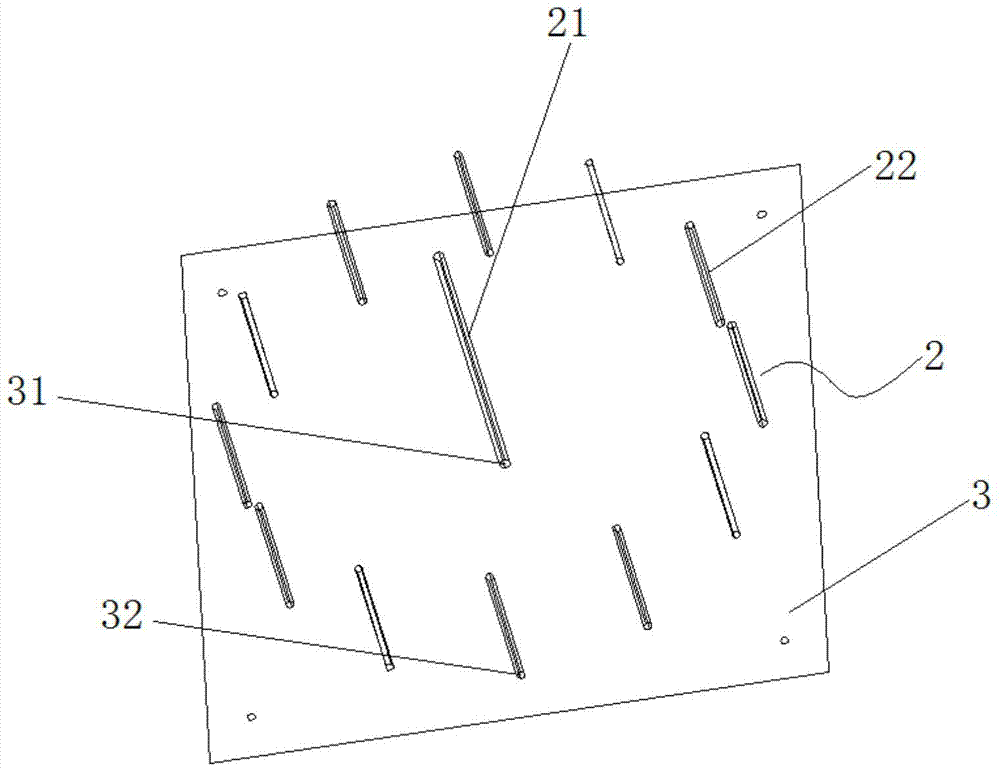

[0030] Such as figure 2 as shown, figure 2 It is a schematic diagram of a working platform and supporting structure arrangement of a tensioned membrane structure accordi...

Embodiment 2

[0036] A teaching model of tensioned membrane structure, comprising a working platform 3, a supporting structure 2 and at least one layer of membrane surface 1, the supporting structure 2 is fixed on the working platform 3, and the membrane surface 1 is fixed on the supporting structure 2; the material of the working platform 3 is selected as aluminum alloy, and its shape is circular, which is conducive to the arrangement of the struts, and the formed roof shape is more beautiful and diverse.

[0037] The center of the working platform 3 is provided with a first hole 31 that penetrates up and down; the diameter is at least 10mm, with the first hole 31 as the center and a radius of at least 15cm, there are 6 second holes 32 evenly arranged up and down on the circumference. It is also possible to evenly arrange several holes penetrating up and down in the peripheral area of the circumference where the second hole 32 is located, for installing support rods, so as to change the p...

Embodiment 3

[0040] A teaching model of tensioned membrane structure, comprising a working platform 3, a supporting structure 2 and at least one layer of membrane surface 1, the supporting structure 2 is fixed on the working platform 3, and the membrane surface 1 is fixed on the supporting structure 2. The material of the working platform 3 is selected as iron, and its shape is rectangular, which is conducive to the arrangement of the struts, and the shape of the formed roof is more beautiful and diverse.

[0041] The central position of working platform 3 is provided with the first hole 31 that runs through up and down; The diameter is at least 10mm, with the first hole 31 as the center, and the radius is that 3 second holes 32 that run up and down are evenly arranged on the circumference of 20cm (such as Figure 4 as shown, Figure 4It is a schematic diagram of another working platform and supporting structure arrangement of the tensioned membrane structure according to the embodiment of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com