Camera module and manufacturing method of circuit board in camera module

A camera module and circuit board technology, applied in the optical field, can solve the problems of different circuit board materials, temperature drift, etc., and achieve the effect of solving temperature drift, improving resolution and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

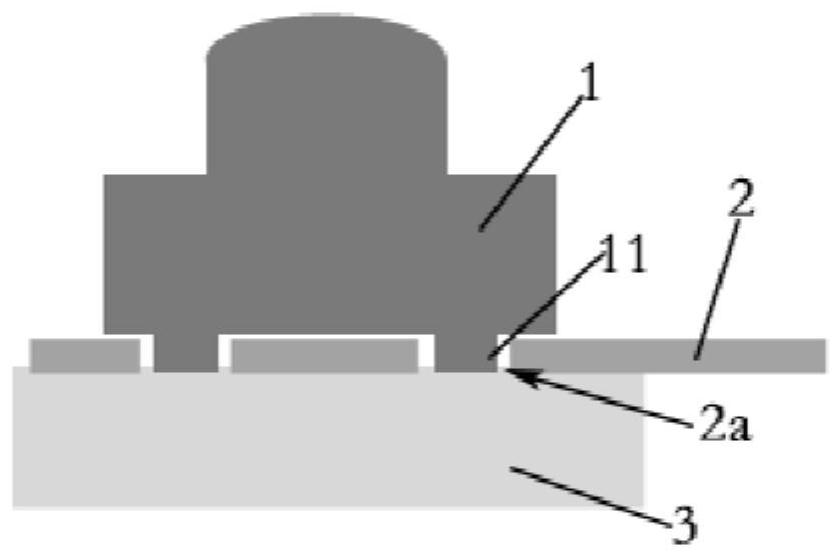

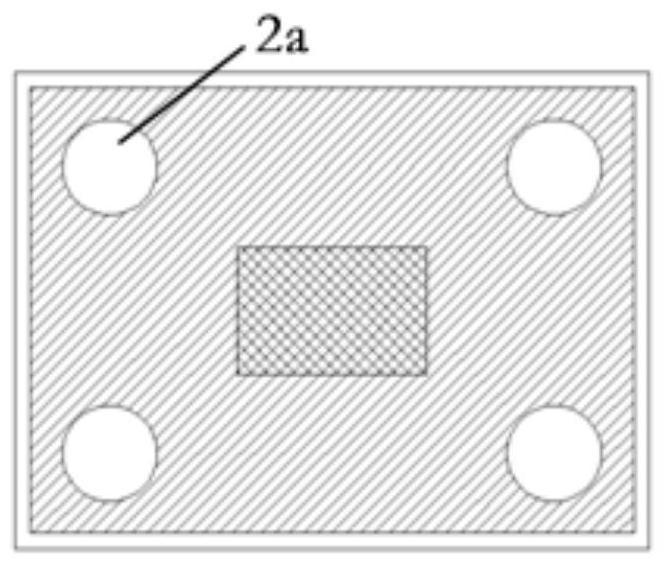

[0032]Such asFigure 4 As shown, according to a second embodiment of the present invention, the mounting boss 11 of the present invention is disposed such that the mounting through hole 2a is provided as a rectangular hole, and two mounting through holes 2a, two mounting holes 2a, two mounting The through hole 2a extends in the width direction of the wire panel 2.

[0033]Such asFigure 5 As shown, according to a third embodiment of the present invention, the mounting boss 11 of the present invention is disposed such that the mounting through hole 2a is provided as a rectangular hole, and two mounting through holes 2a are provided on the circuit board 2, two mounting The through hole 2a extends in the longitudinal direction of the wire panel 2.

[0034]Such asFigure 6 As shown, according to a fourth embodiment of the present invention, the mounting boss is disposed as an L-shaped structure, and the mounting through hole 2a is adapted to the shape of the mounting boss 11. The mounting throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com