Automatic grabbing device for axle housing waste

A technology of grabbing device and horizontal moving device, which is applied in the direction of metal processing, etc., can solve the problems of circular waste clamping, inconvenience of manual picking up waste, and inability to adapt to clamping waste equipment, so as to improve production efficiency and reduce dangerous accidents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

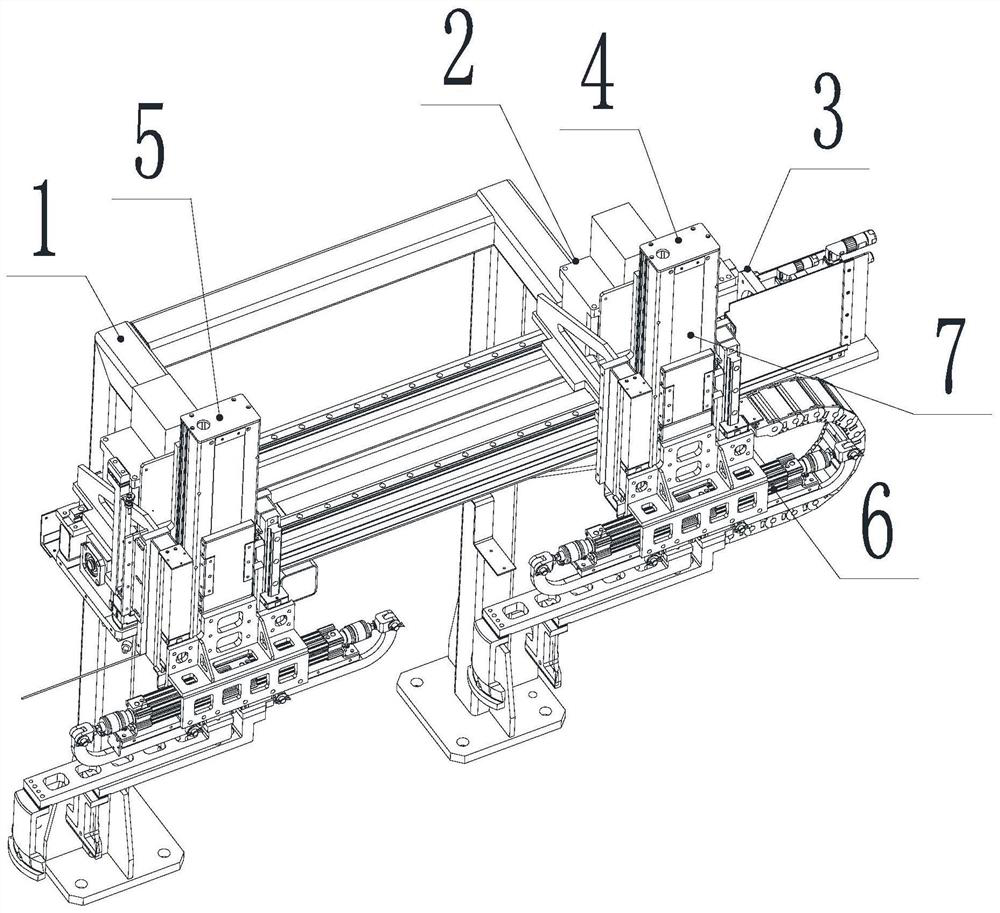

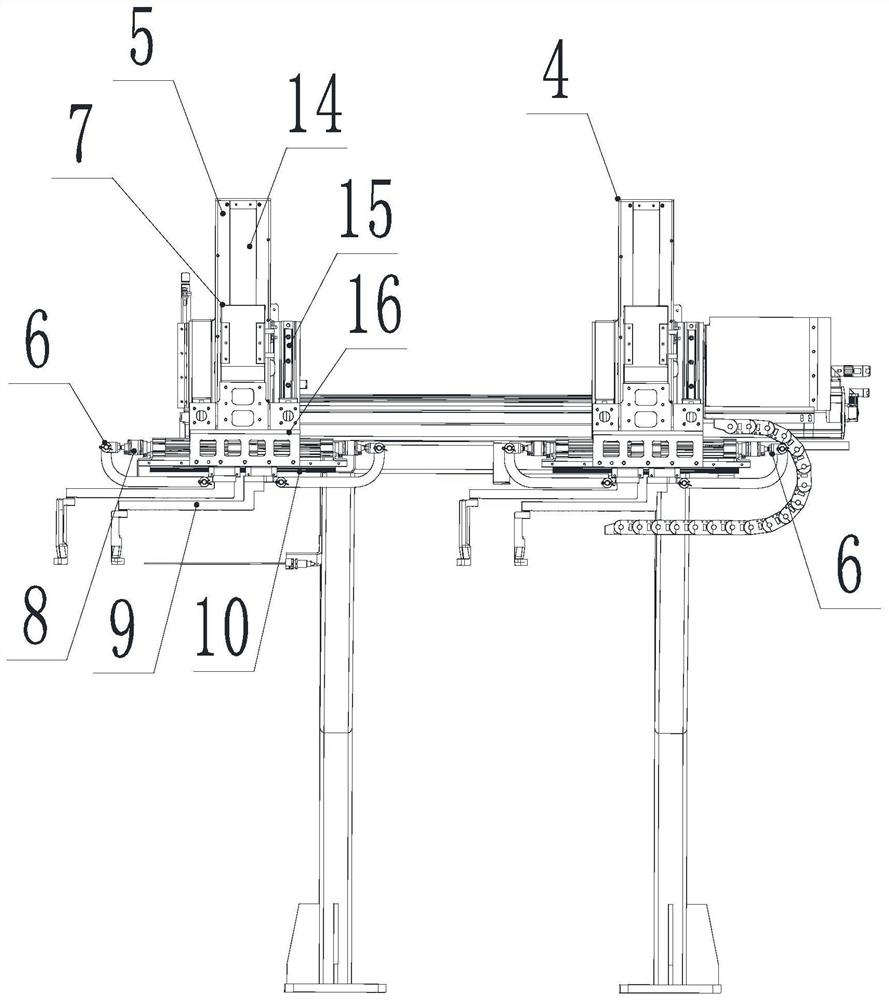

[0023] like figure 1 As shown, an automatic grabbing device for axle housing waste includes a support frame 1, and a blanking mechanism 2 is arranged on the support frame 1. The blanking mechanism 2 includes a horizontal moving device 3 connected to the supporting frame 1, and the horizontal moving device 3 is provided with a first clamping device 4 and a second clamping device 5, the first clamping device 4 and the second clamping device 5 are slidingly connected with the horizontal moving device 3, the first clamping device 4 and the second clamping device 5 Fixture device 5 all comprises pneumatic gripper 6 and lifting device 7 that lifting pneumatic gripper 6 is useful; figure 2 As shown, the pneumatic gripper 6 includes a double-rod double-acting cylinder 8, and the piston rods at both ends of the double-rod double-acting cylinder 8 are hinged with grippers 9 that cooperate with each other. 9. The first guide rail 10 for sliding, the first guide rail 10 is connected to ...

Embodiment 2

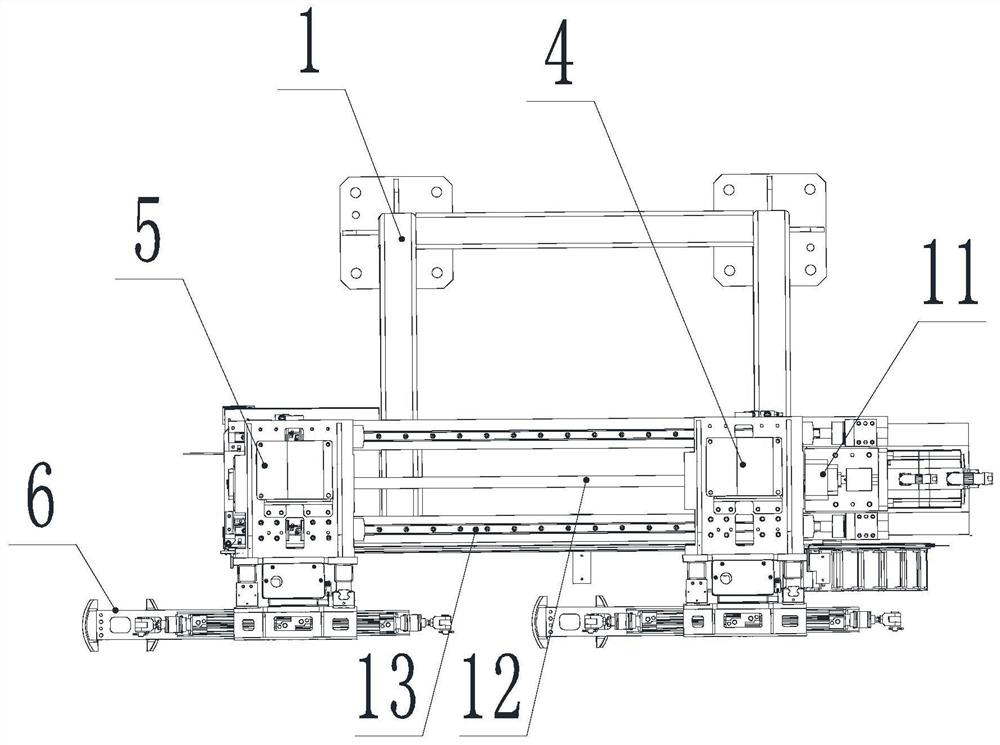

[0026] This embodiment is carried out on the basis of embodiment 1, as image 3 As shown, the horizontal moving device 3 includes a motor 11 for driving the first clamp device 4 and the second clamp device 5 to move, the motor 11 is connected to the support frame 1, and the support frame 1 is provided with a motor 11 for the first clamp device 4. With the second guide rail 13 that the second fixture device 5 slides, the second guide rail 13 is horizontally arranged on the support frame 1, and the lead screw 12 that is parallel to the second guide rail 13 is also provided on the support frame 1, and the lead screw 12 It is connected with the motor 11 through a shaft coupling, and a nut seat is connected under the first fixture device 4 and the second fixture device 5, and the two nut seats are all sleeved on the leading screw 12, and the two nut seats are both Screwed with the lead screw 12, the second guide rail 13 provided provides the motor 11 to drive the lead screw 12 to r...

Embodiment 3

[0028] This embodiment is carried out on the basis of Embodiment 1, such as Figure 5 As shown, the blanking mechanism 2 also includes an iron filing frame 17 for collecting iron filings. The iron filing frame 17 is located below the first fixture device 4, and the waste chips generated during the cutting process fall to the blanking mechanism 2. Arrive iron filings material frame 17 automatically.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com