Barrel opening seat sealing ring mounting device

A technology for installing devices and sealing rings, which is applied in the direction of reducing greenhouse gases, climate sustainability, and manufacturing tools, etc., can solve the problems of time-consuming, labor-intensive, low-efficiency, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

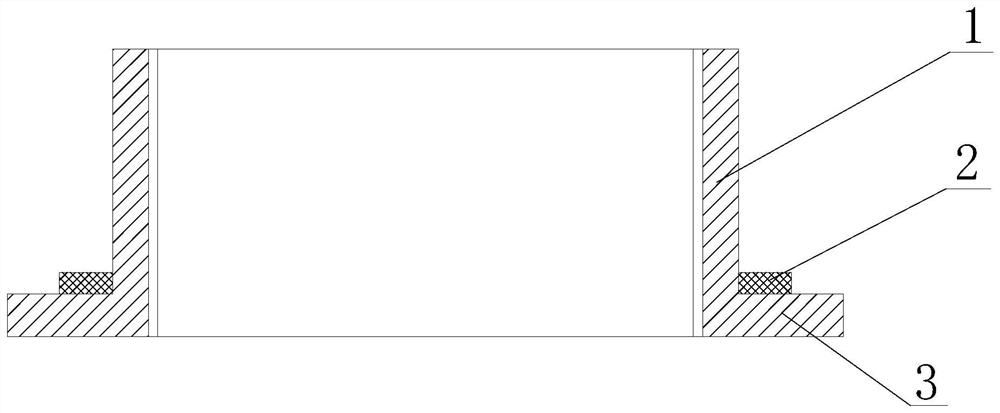

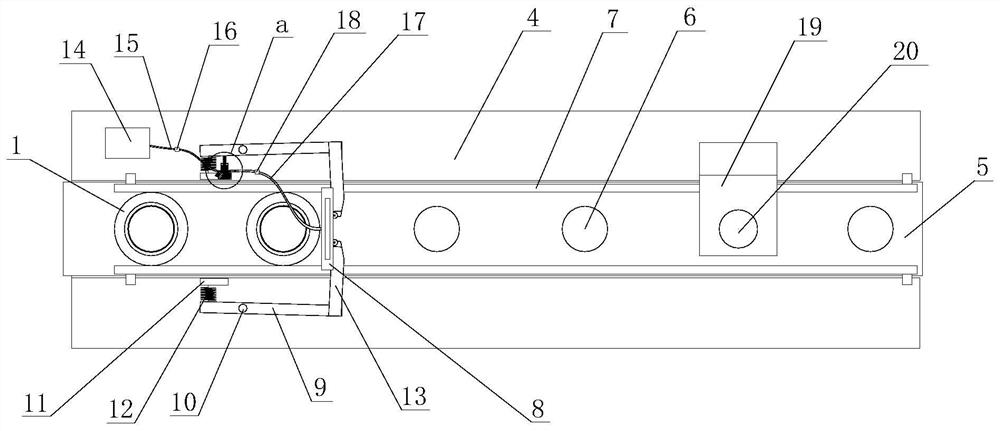

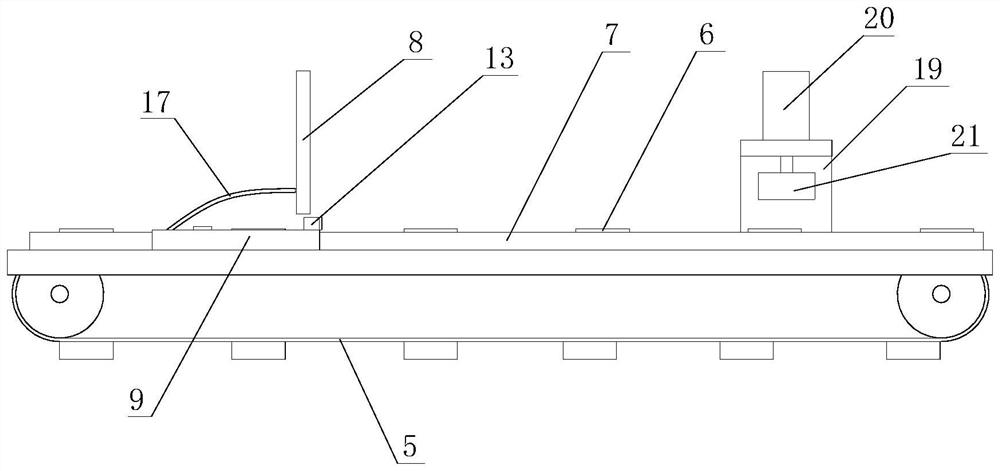

[0027] Such as Figure 1 to Figure 8 As shown, a device for installing a sealing ring of a bucket mouth seat includes a base 4 on which a conveyor belt 5 is arranged. The conveyor belt 5 is provided with several positioning bosses 6 for positioning the mouth seat. The distance between two adjacent positioning bosses is the same. The base 4 is also provided with a sealing ring set mechanism for fitting the sealing ring on the bung seat and a sealing ring pressing mechanism for pressing the sealing ring in place.

[0028]The sealing ring assembly mechanism includes a swing arm 9 and a fixed end 11 respectively arranged on two sides of the conveyor belt, and a first spring 12 is arranged between one end of the swing arm 9 and the fixed end 11 . The base 1 is provided with a fixed shaft, and the swing arm 9 is rotatably connected to the fixed shaft. The other end of the swing arm 9 is connected with a sealing ring auxiliary installation rod 13 . The front end of the sealing ri...

Embodiment 2

[0033] The difference between Embodiment 2 and Embodiment 1 is that in Embodiment 2, the lifting drive device is a hydraulic cylinder, and the rest of the structure is the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com