Beam structure of a vacuum maglev pipeline and vacuum maglev pipeline

A magnetic levitation and vacuum technology, applied in the direction of roads, tracks, tunnel systems, etc., can solve the problems of complex construction and high height, and achieve the effects of convenient construction, reduced structure height and reasonable force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

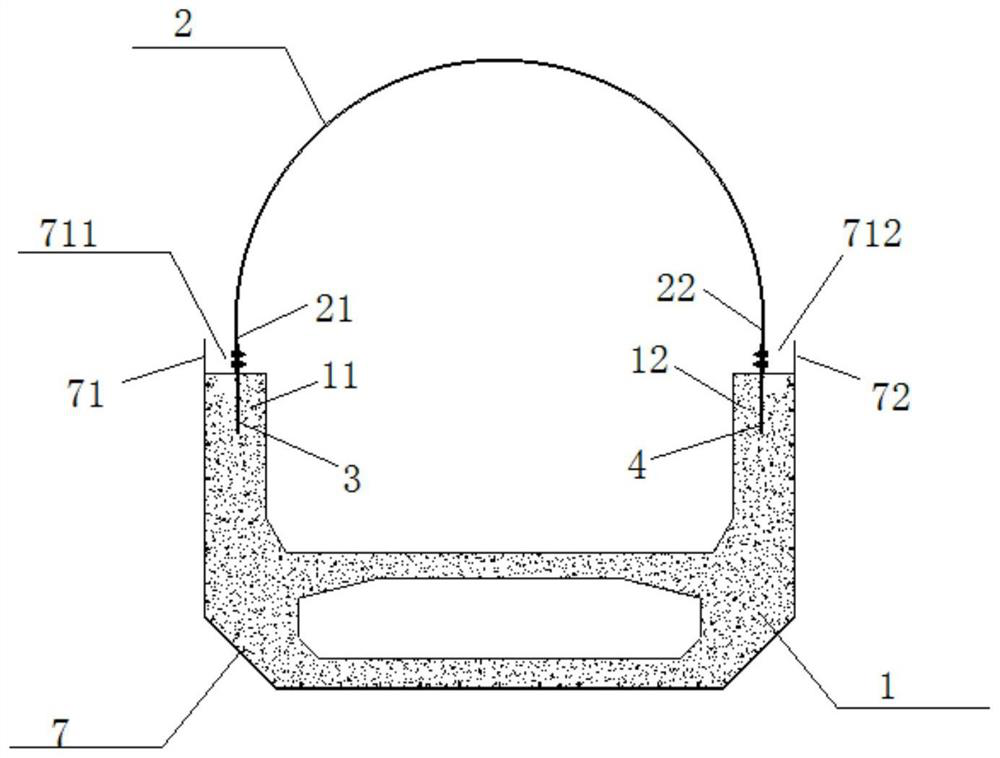

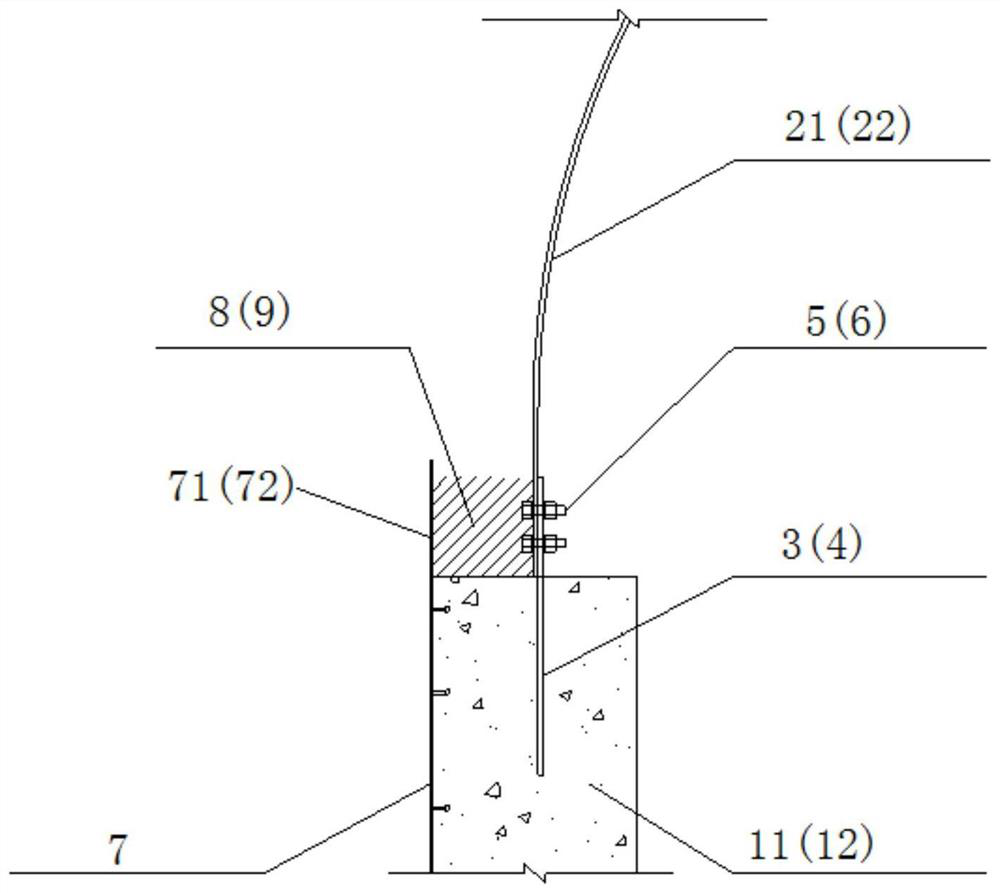

[0022] Figure 1-2The beam structure of the vacuum magnetic levitation pipe of the present invention is shown, which comprises: u-shaped bottom beam 1, which has a first beam end 11 and a second beam end 12, in the present embodiment, the U-shaped bottom beam 1 is a prestressed concrete structure in its entirety; And the first end portion 21 detachable connection, the second connection plate 4 is embedded within the second beam end 12, and the second end portion 22 detachable connection.

[0023] Specifically, the first connection plate 3 end is embedded within the first girder end 11, the other end is connected to the first end 21 by means of a first high-strength bolt 5 and the first end 21 removable; and / or, similarly, the second connection plate 4 is embedded at one end within the second beam end 12, the other end of the second end portion 22 through the second high-strength bolt 6 and the second end portion 22 detachable connection. Preferably, the first high-strength bolt ...

Embodiment 2

[0030] The present embodiment further provides a vacuum magnetic levitation pipe comprising a beam structure described in Examples I or II.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com