Galvanizing lifting and pressing linkage device

A linkage mechanism and vertical pressing technology, applied in the field of automation, can solve problems such as personal casualties, loss of hot-dip galvanizing automation equipment, etc., and achieve the effect of reducing control risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below.

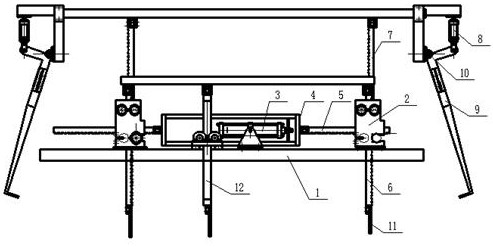

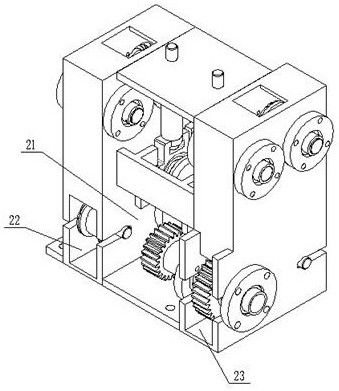

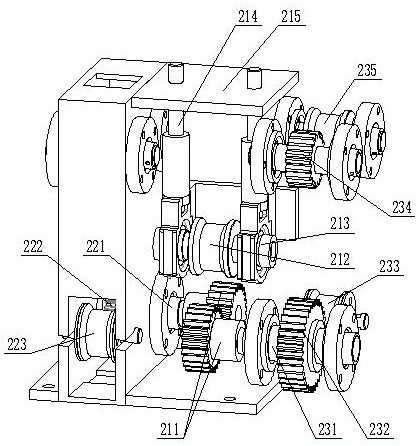

[0028] Such as Figure 1 to Figure 3 As shown, a galvanized lifting and lowering linkage device includes a main frame 1. The main frame 1 should sit on the zinc pot. The two ends of the drive cylinder 3 are respectively provided with a set of linkage mechanisms 2. The drive cylinder 3 ends of the present invention are connected with the drive frame 4, and the two ends of the drive frame 4 are respectively provided with a horizontally moving rack 5 to cooperate with the two linkage mechanisms 2. The linkage mechanism 2 is arranged on the main frame 1. Specifically, the linkage mechanism 2 includes a horizontal drive compartment 21, a vertical lifting compartment 22 is provided on the front side of the horizontal drive compartment 21, and a vertical pressing compartment 23 is provided on the rear side of the horizontal drive compartment 21;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com