Novel energy-saving self-balancing vertical lifting type movable bridge

A self-balancing, straight-up technology, applied in the direction of open bridges, vertical bridges, bridges, etc., can solve problems such as high engineering costs, large amount of materials, and difficult layout of lifting towers, so as to ensure safety and economy, and reduce energy consumption. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing by specific embodiment:

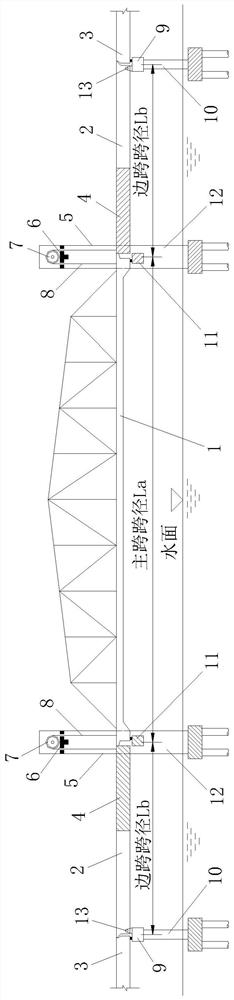

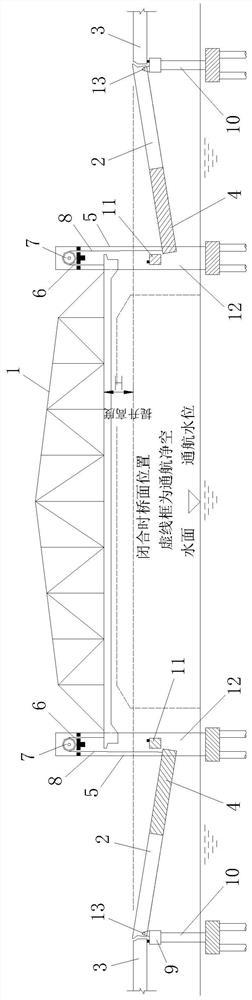

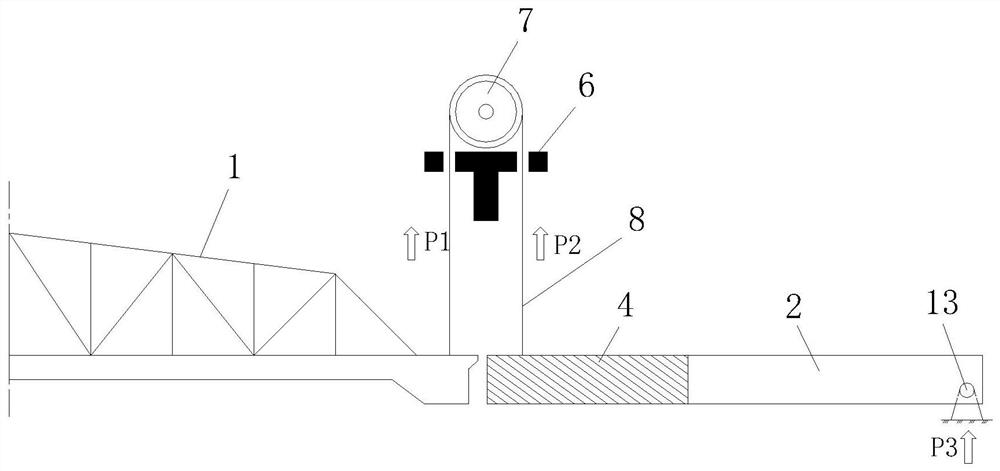

[0021] In this example, refer to Figure 1-Figure 3 , the new energy-saving self-balancing direct-lift opening bridge includes an opening span 1, a lifting tower 5, a load-bearing sling 8 and a driving drum 7, the opening span 1 is located between the lifting towers 5, and the driving drum 7 is installed on the lifting In the tower 1, the load-bearing sling 8 is wound around the driving drum 7, and the opening span 1 is connected to the load-bearing sling 8; each self-balancing side span 2 is provided on the outside of the lifting tower 5, and the load-bearing sling 8 bypasses the driving drum. The cylinder 7 is connected to the end of the self-balancing side span 2 close to the lifting tower 5, so that this end of the self-balancing side span 2 forms a vertical movable end, and the other end of the self-balancing side span 2 is hingedly connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com