Silt removing head steering device

A technology of steering device and silt head, which is applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc. It can solve the problems of waste of water resources, time-consuming and labor-intensive dredging methods, and low efficiency. , to achieve the effect of timely steering and simple and reliable steering method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

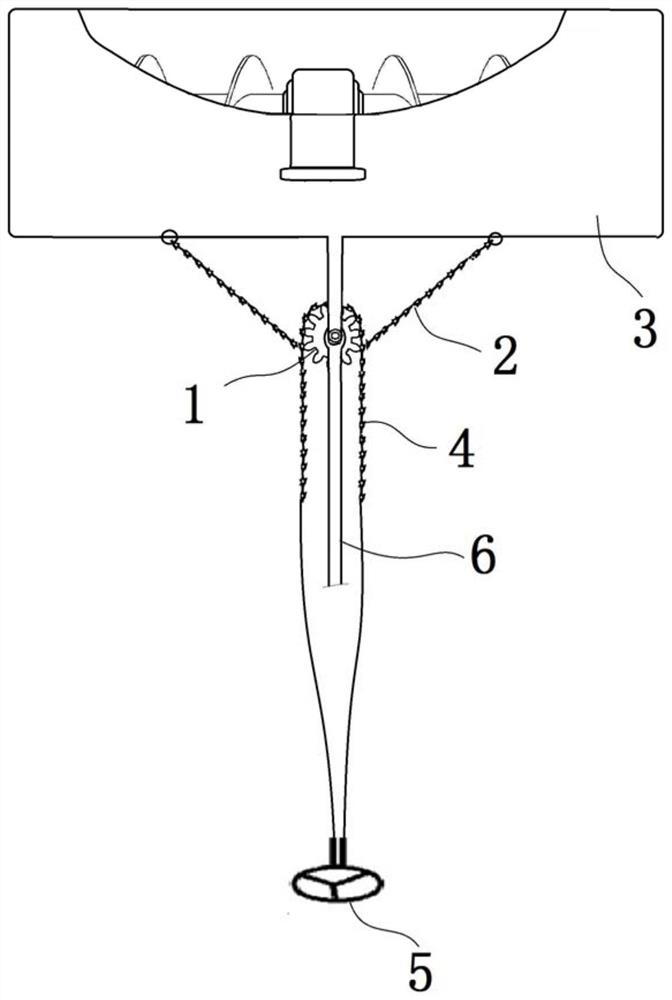

[0029] Example 1 ( figure 1 No number 7, 8 in

[0030] A dredging head steering device, such as figure 1 As shown, the steering rod 8 comprising the steering gear 1 and the steering wheel 5 installed on the floating support device is wound around the first steering chain 2 mounted on the steering gear 1, and one end of the first steering chain 2 is connected to the dredging by a rope. The left end of head 3 is connected, and the other end of this first turning chain 2 is connected with the right end of dredging head 3 by rope. In other words, the two ends of the first steering chain 2 are respectively connected with the dredging head 3 through ropes. The second steering chain 4 is also wound around the steering gear 1, and one end of the second steering chain 4 is connected with the steering rod 8 of the steering wheel 5 installed on the floating support device through a rope. The other end is connected with the steering rod 8 of the steering wheel 5 installed on the floati...

Embodiment 2

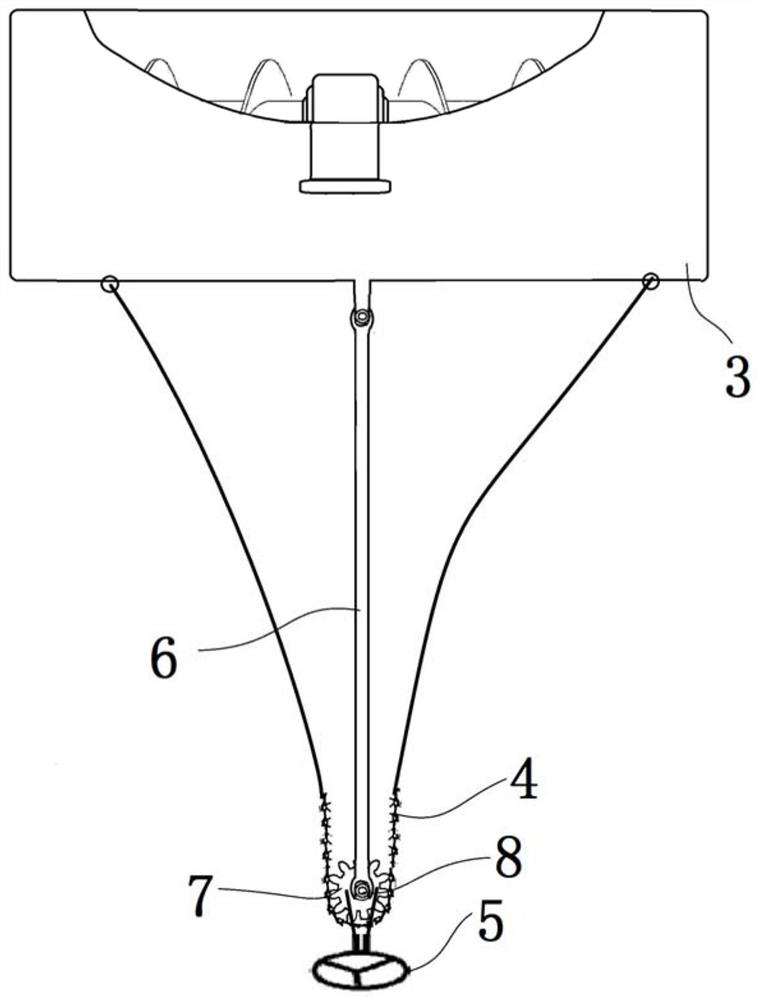

[0033] A dredging head steering device, such as figure 2 As shown, it includes a steering rod 8 mounted on a floating support device and a steering wheel 5 mounted on the top of the steering rod 8; a steering gear 7 is installed on the steering rod 8, and a steering chain is wound on the steering gear 7; One end of the chain is connected with the left end of the dredging head 3 by a rope, and the other end of the steering chain is connected with the right end of the dredging head 3 by a rope. In other words, the two ends of the steering chain are respectively connected to the dredging head 3 by ropes.

[0034] Thus, when a turn is needed, the operator drives the steering gear 7 to rotate by the steering of the steering wheel 5, and the steering gear 7 drives the steering chain to move, and the steering chain then directly drives the dredging head 3 to turn left or turn right.

[0035] Preferably, the floating support device includes at least two buoys and a support frame, an...

Embodiment 3

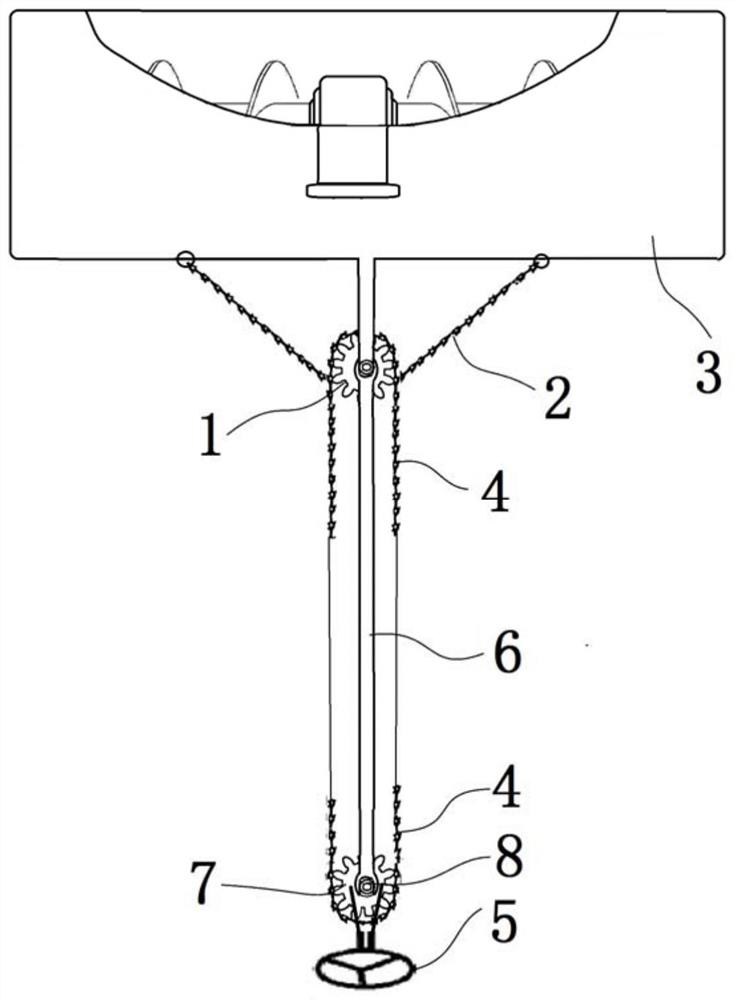

[0037] Similar to the front-end part of Embodiment 1, such as image 3 As shown, the difference is that the steering rod 8 is equipped with a steering gear 7, and the second steering chain 4 is wound around the steering gear 7 and the steering gear 1. Thus, when turning is required, the operator turns the steering wheel 5 to drive the steering gear 1 to rotate through the second steering chain 4, thereby driving the first steering chain 2 mounted on the steering gear 1 to move relative to the steering gear 1, and finally Drive the dredging head 3 to turn left or turn right.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com