Built-in hand pump

A hand pump and pump casing technology, applied to pumps, pump components, variable capacity pump components, etc., can solve the problems of easy air leakage, poor sealing, and unsatisfactory performance of the built-in manual pump, etc., and achieve a simple and ingenious structural design. The effect of improving airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

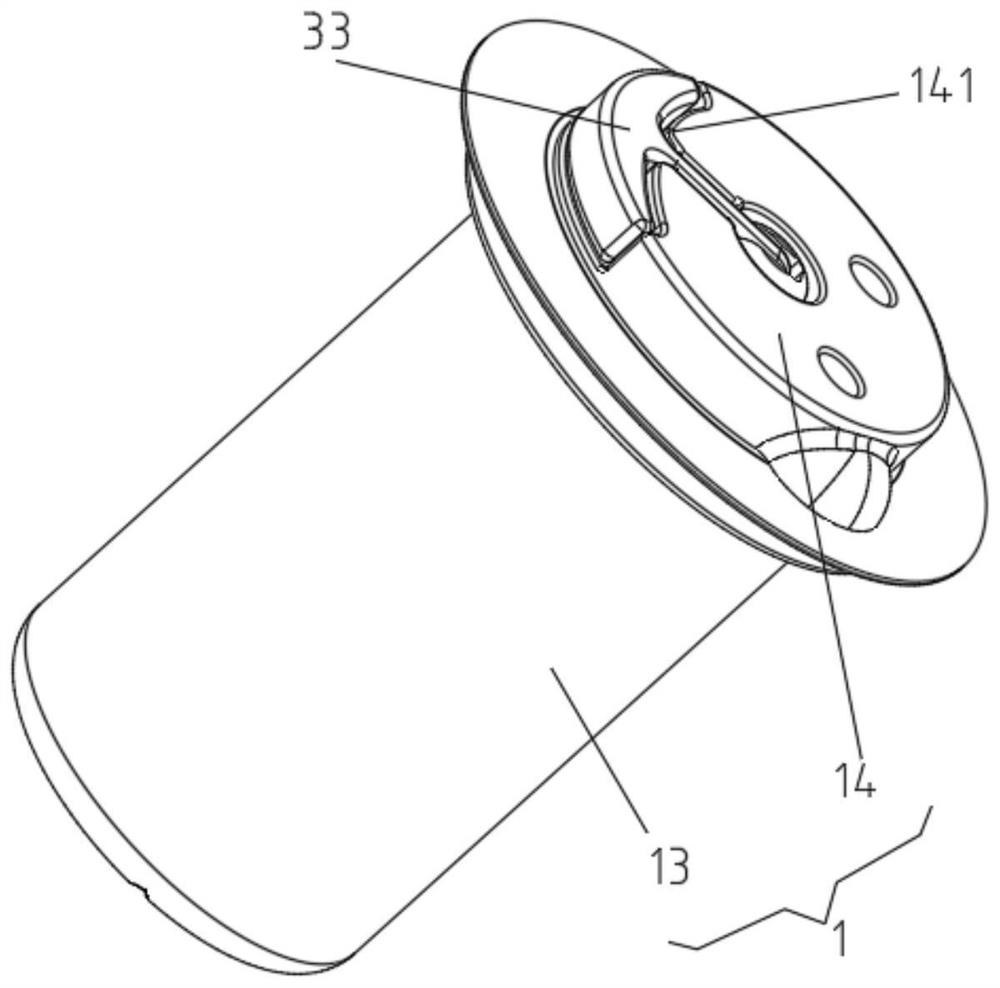

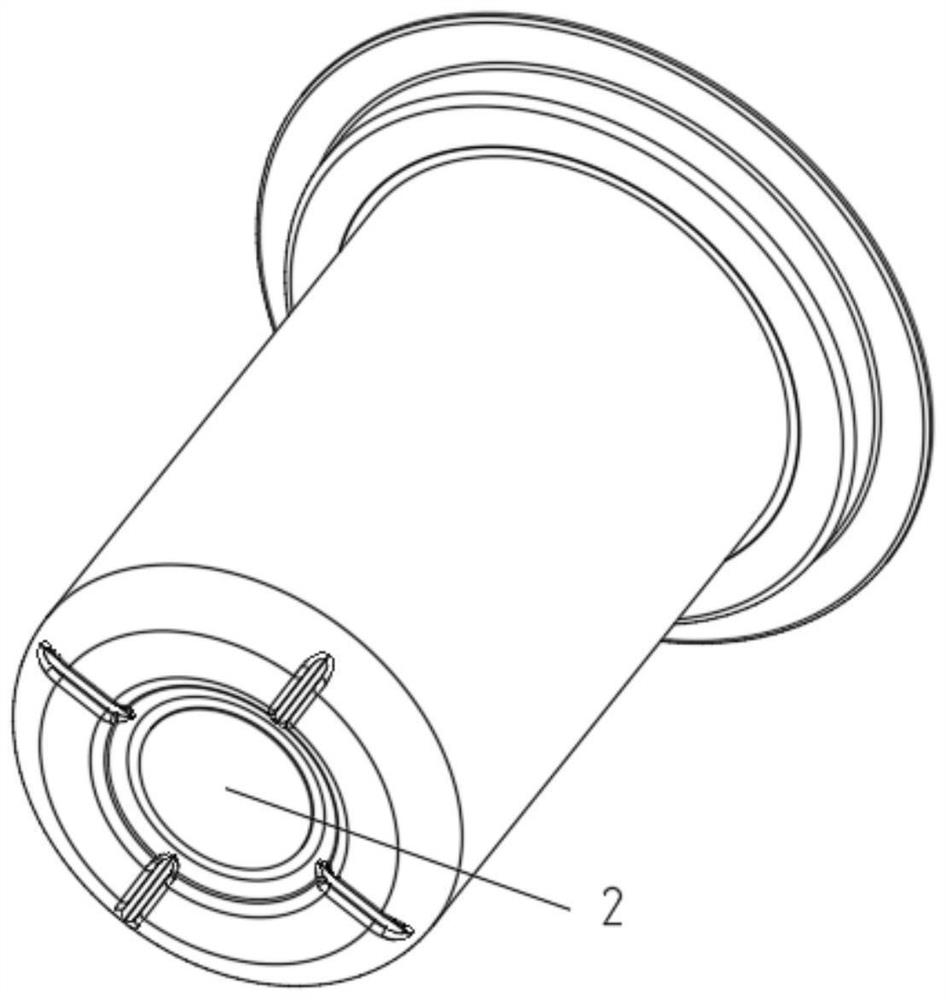

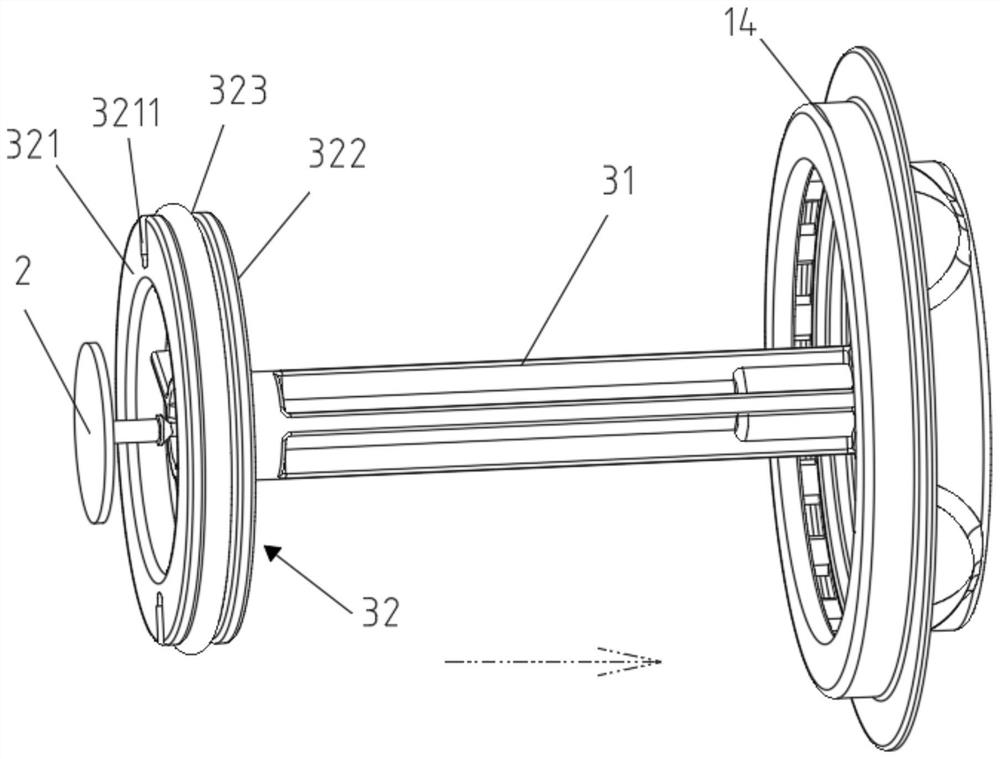

[0036] Embodiment: a kind of built-in hand pump, such as Figure 1 to Figure 8 As shown, it includes a pump casing 1 and a push-pull assembly. The bottom of the pump casing is provided with an air outlet 11, and the air outlet is equipped with a one-way valve 2. The push-pull assembly includes a push-pull rod 31 and a sealed air outlet structure 32. One end of the push-pull rod is connected to the sealed air outlet structure;

[0037] The sealed air outlet structure includes a first piston 321, a second piston 322, and a first seal 323 between the first piston and the second piston, and the outer peripheries of the first piston and the second piston There is a gap between the surface and the inner wall of the pump casing, and the first sealing member is attached to the inner wall of the pump casing to form a seal;

[0038] A first cavity 4 is defined between the first seal and the upper part of the pump casing, and a second cavity 5 is defined between the first seal and the b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap