Air bag inflating mouthpiece device

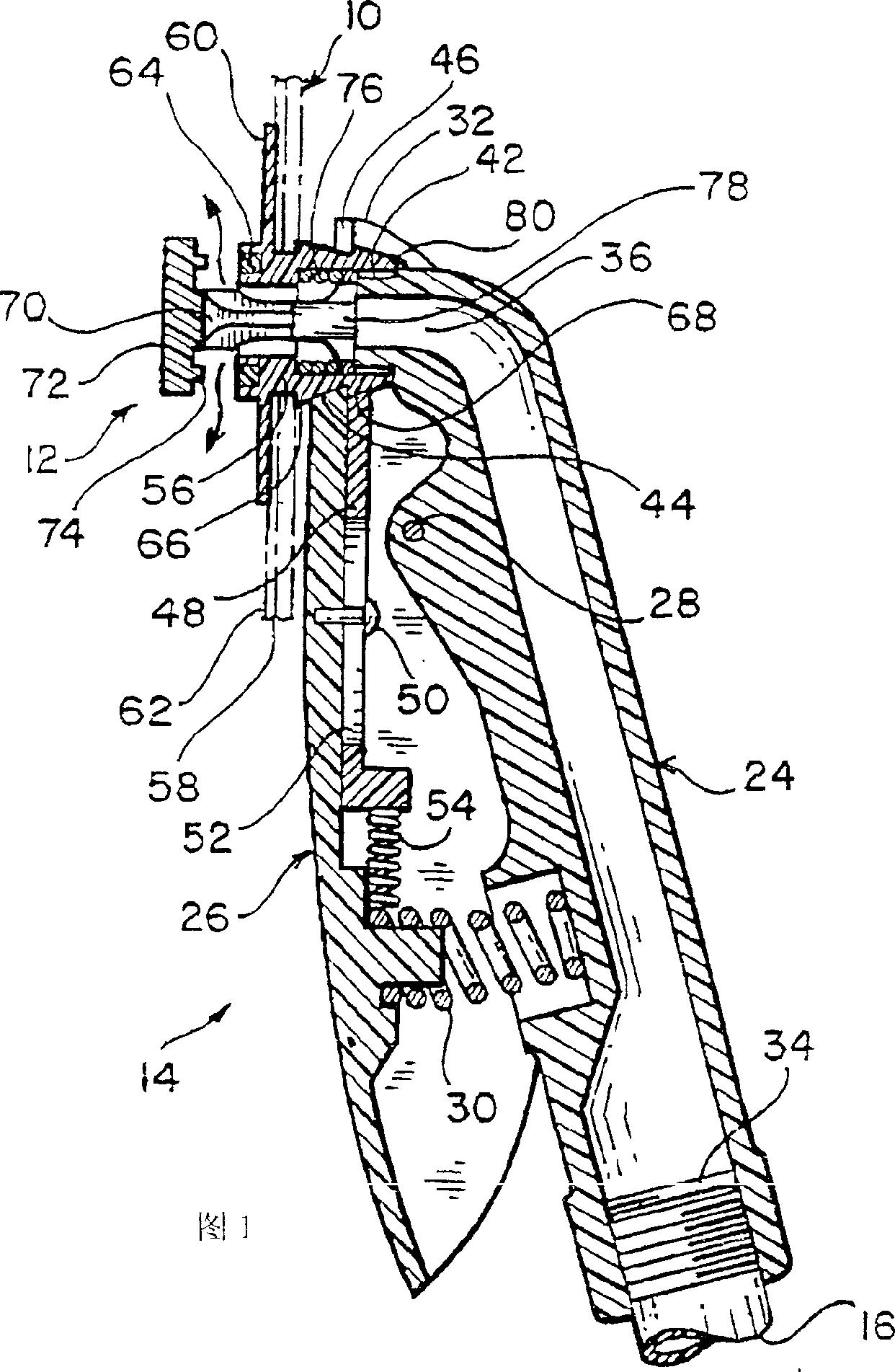

A technique of inflating tubes and nozzles, applied in the field of dunnage airbags, which can solve the problems of high manufacturing cost, large number of parts, inflatable fixtures or devices 14 that cannot be reliably seated or attached

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

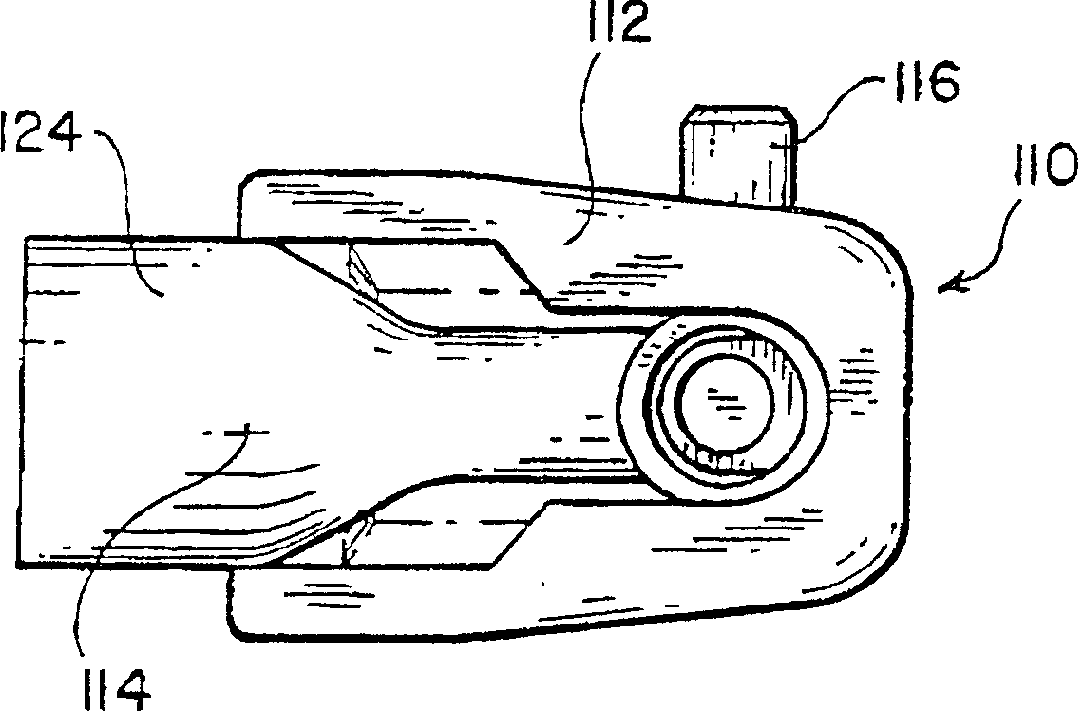

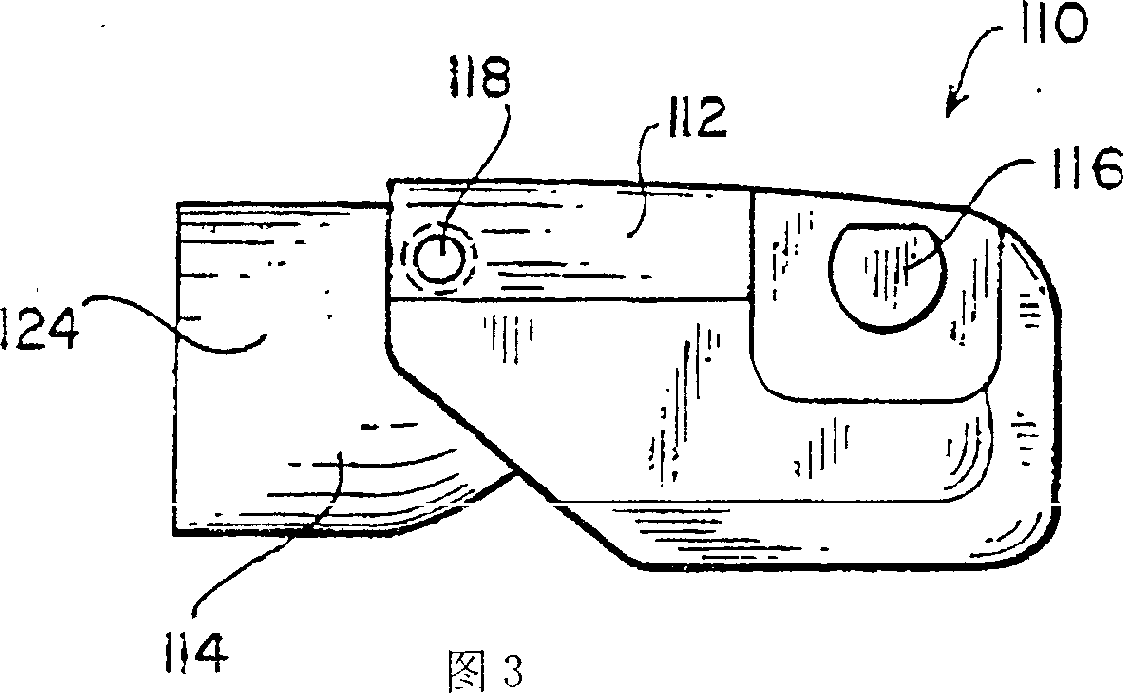

[0028] See now the attached drawings, especially the figure 2 and 3, which show a new and improved air bag inflation nozzle assembly, generally designated 110, constructed in accordance with the teachings and principles of the present invention. The structure of the airbag inflation nozzle assembly 110 is relatively simple because it basically only includes three working parts, namely an airbag inflation apparatus frame 112, an airbag inflation apparatus nozzle piece 114, and a cam lock button 116. The nozzle member 114 is mounted on the frame 112 by a pivot pin 118 so that (as will become clearer later) when the nozzle member 114 is mounted on the frame 112, the nozzle member 114 can be positioned relative to the tube of the air bag inflation valve assembly 122. A first "unengaged" and "unlatched" position (as shown in FIG. 11 ) of the tubular inflation valve body member 120 and a second "engaged" and "engaged" position of the tubular inflation valve body member 120 relative ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com