Compressor shell device and compressor

A compressor shell and compressor technology, applied in the field of compressors, can solve the problems of increasing the oil discharge rate of the compressor, large vibration of the compressor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

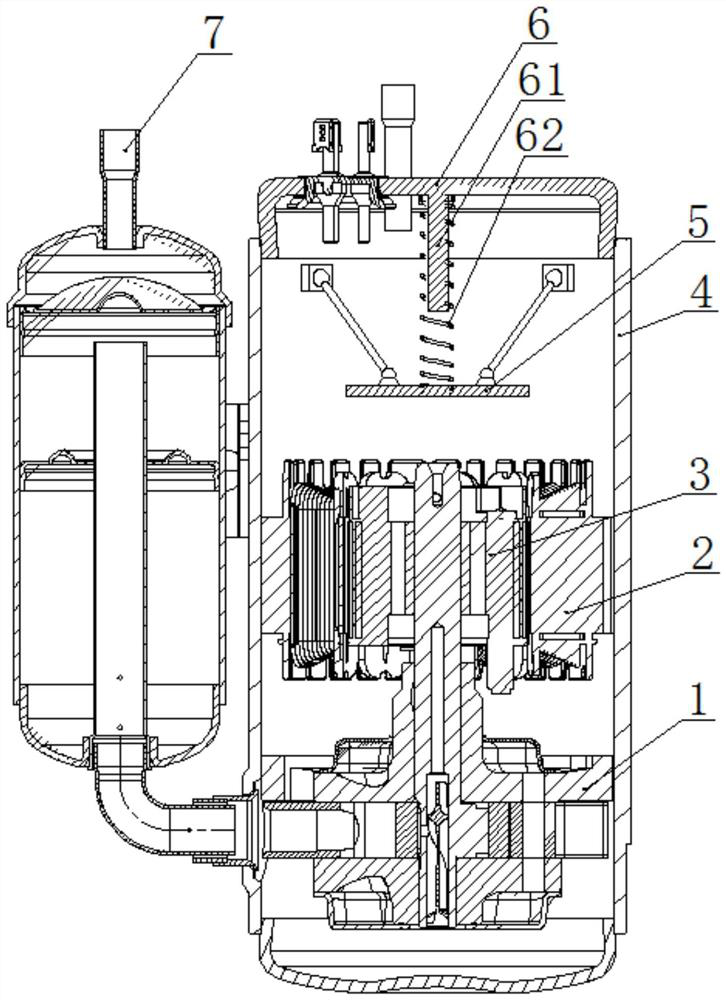

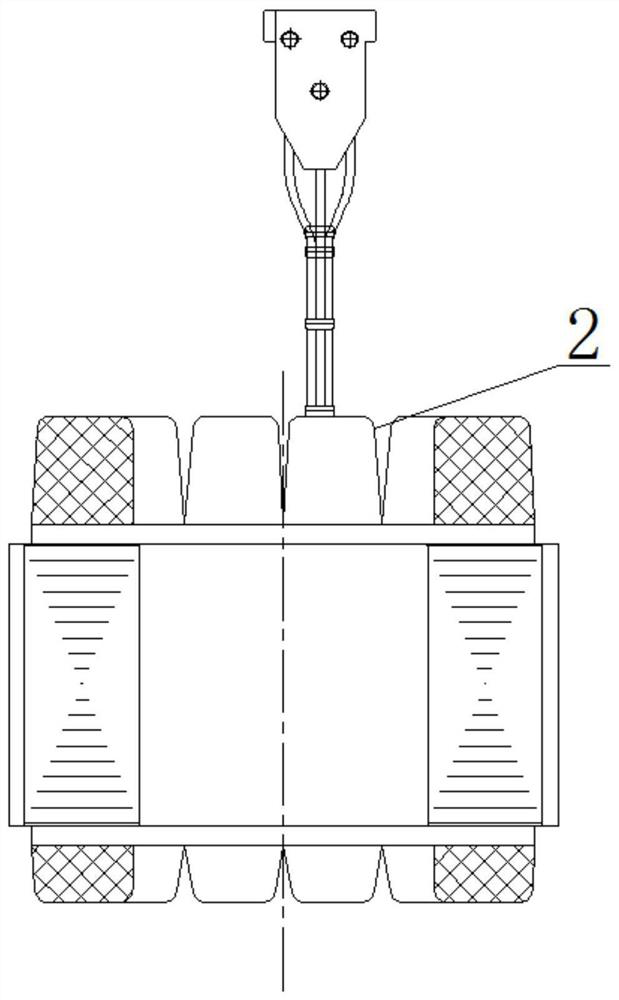

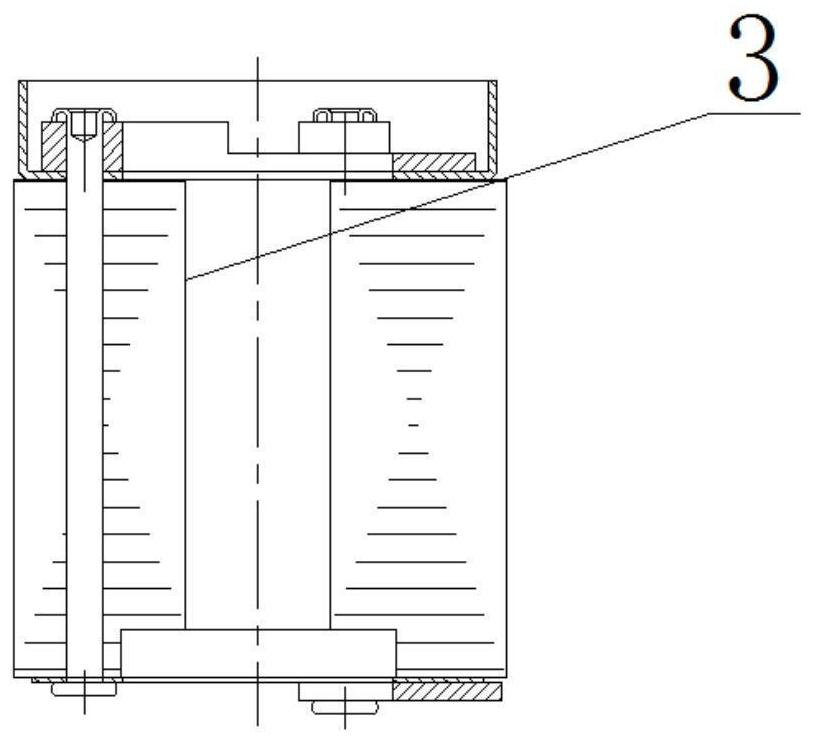

[0029] In order to better understand the purpose, structure and function of the present invention, below in conjunction with appendix Figure 1-8 , a compressor housing device and a compressor of the present invention are further described in detail.

[0030] Such as Figure 1-5 As shown, a compressor casing device is designed. This design takes the compressor as an example, and its main structure includes a casing assembly 4, a stator 2 installed in the casing assembly 4, and a rotor 3 rotatably connected to the stator 2; The housing assembly 4 is provided with a damping structure 5, which is hung on the shell wall of the housing assembly 4 in a suspended manner. When the housing assembly 4 vibrates, the damping structure 5 will move in the opposite direction of the vibration of the housing assembly 4 to offset vibrational energy. This structure is used in the compressor. When the compressor is running, the internal damping structure can be used to consume energy, reducing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com