Method for measuring saturation of crude oil in formation fluid

A technology of formation fluids and measurement methods, applied in the direction of measurement devices, instruments, scientific instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

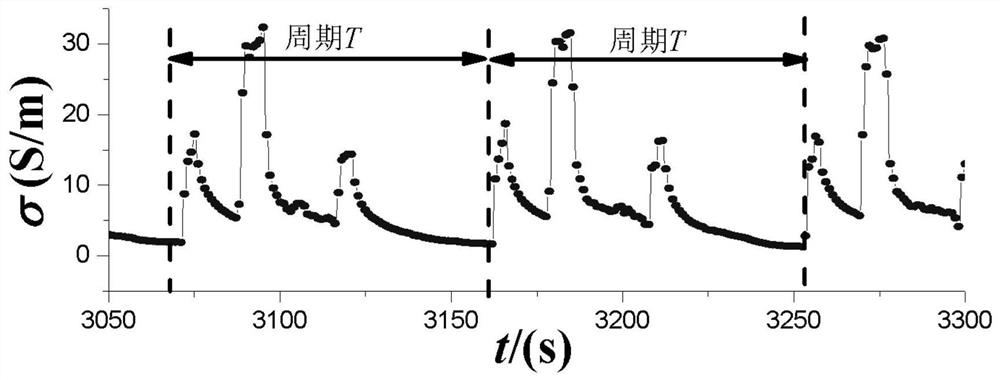

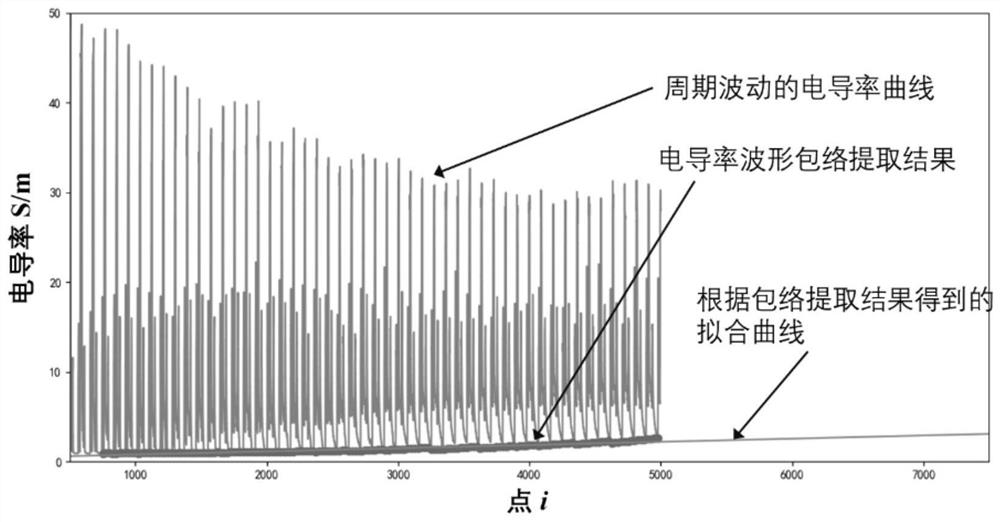

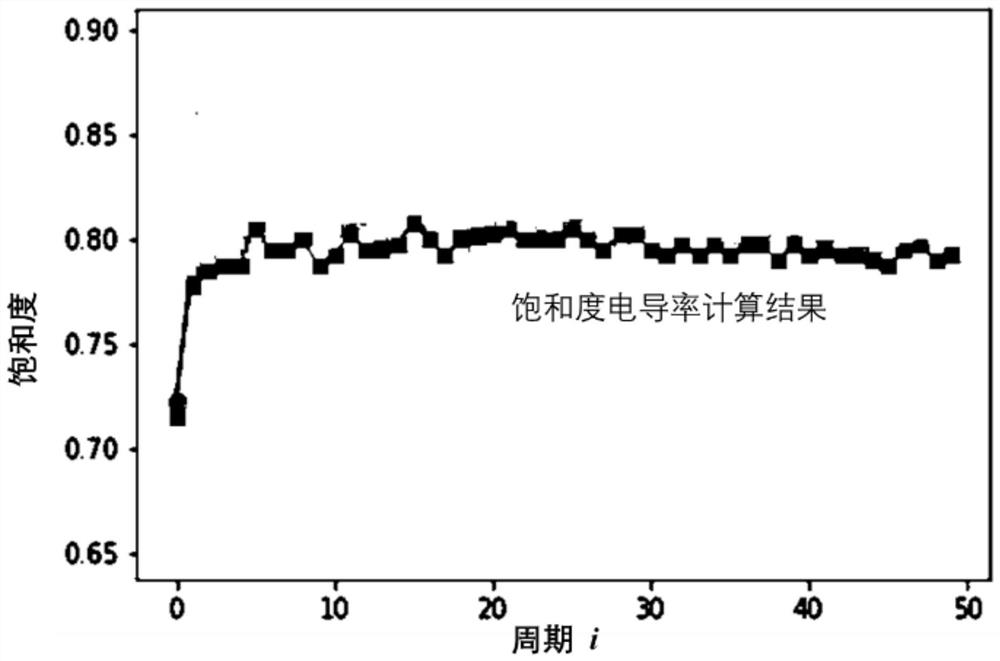

[0063] Using the calculation method for real-time monitoring of formation fluid crude oil saturation provided by this application in a well in the Bohai Sea, the conductivity difference between formation water and crude oil in this oil well is more than 10%. Embodiment 1 uses the mid-drilling oil and gas layer tester (EFDT) as the conductivity measuring device, and the device contains a piston pump, a pumping device, a suction probe and a conductivity sensor. The probe enters the conductivity measuring device, and the pumping device is used to pump the formation fluid. When pumped, only the formation fluid in the conductivity measuring device passes through the piston pump, forming a slug flow in the fluid pipeline with a constant cross-sectional area. That is, a section of crude oil and a section of formation water appear alternately in the oil-water two-phase flow. Finally, the slug flow passes through the conductivity sensor to obtain data.

[0064] figure 1 It is the cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com