Multifunctional sampling drum automatic gluing device

A gluing device and multi-functional technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of consuming a lot of time and energy, unable to control the gluing force, and unable to guarantee the quality of gluing, etc. Achieve the effect of reducing consumption, avoiding uneven results and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so as to better understand the purpose, features and advantages of the present invention. It should be understood that the embodiments shown in the drawings are not intended to limit the scope of the present invention, but only to illustrate the essence of the technical solutions of the present invention.

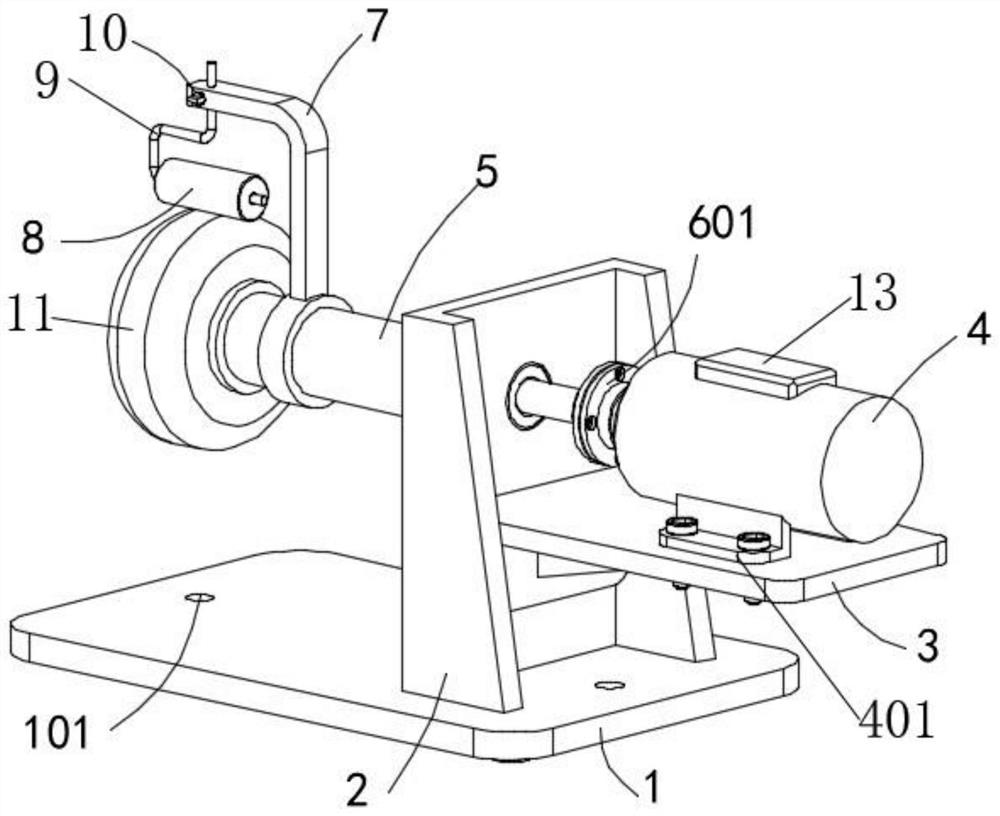

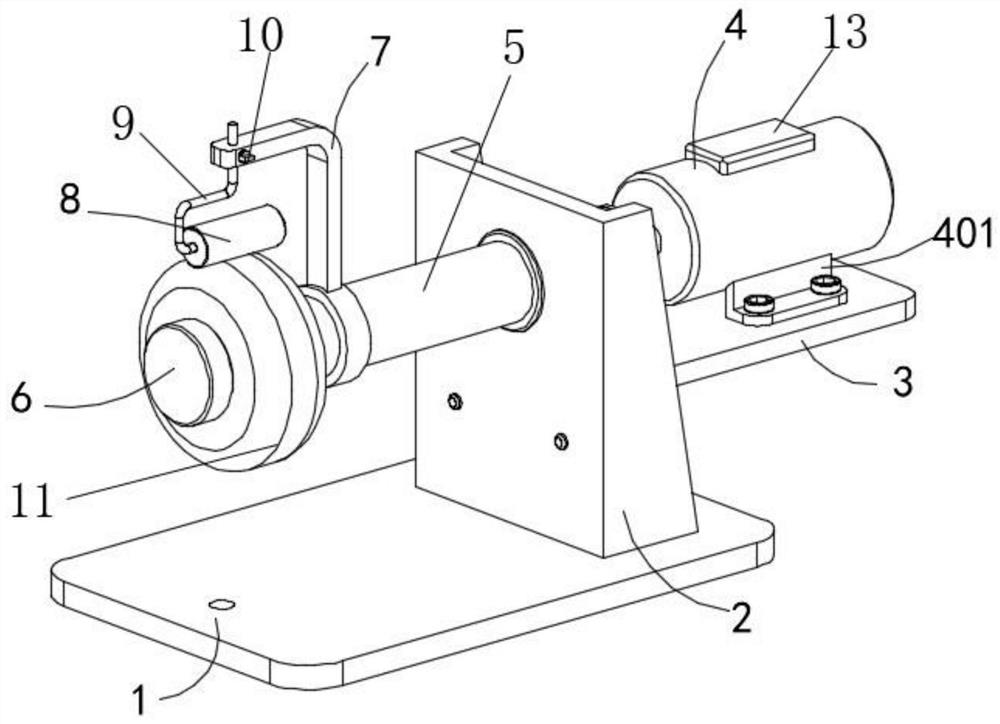

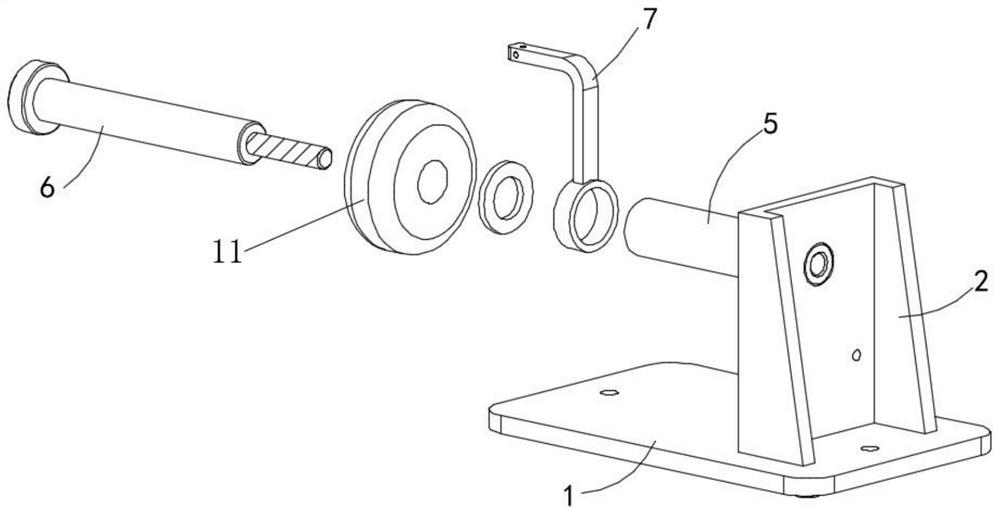

[0025] Such as Figure 1 to Figure 3 As shown, the multifunctional sampling drum automatic gluing device provided by the present invention includes: a sampling drum 11; a support 2, which is a U-shaped structure placed vertically; a sleeve 5, which is arranged on one side of the support 2, and the sleeve One end of 5 runs through the web of the support 2 and is fixedly connected with it; the support plate 3 is fixedly arranged on the support 2 on the opposite side of the casing 5 and is located below the casing 5; the stepping motor 4 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com