Line type rock wool color steel plate manufacturing and processing system and processing technology thereof

A processing system and color steel plate technology, applied in the field of color steel plate manufacturing, can solve the problems of rock wool plate shedding, adhesive waste, wear and other problems, and achieve the effects of avoiding deformation, improving standardization, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

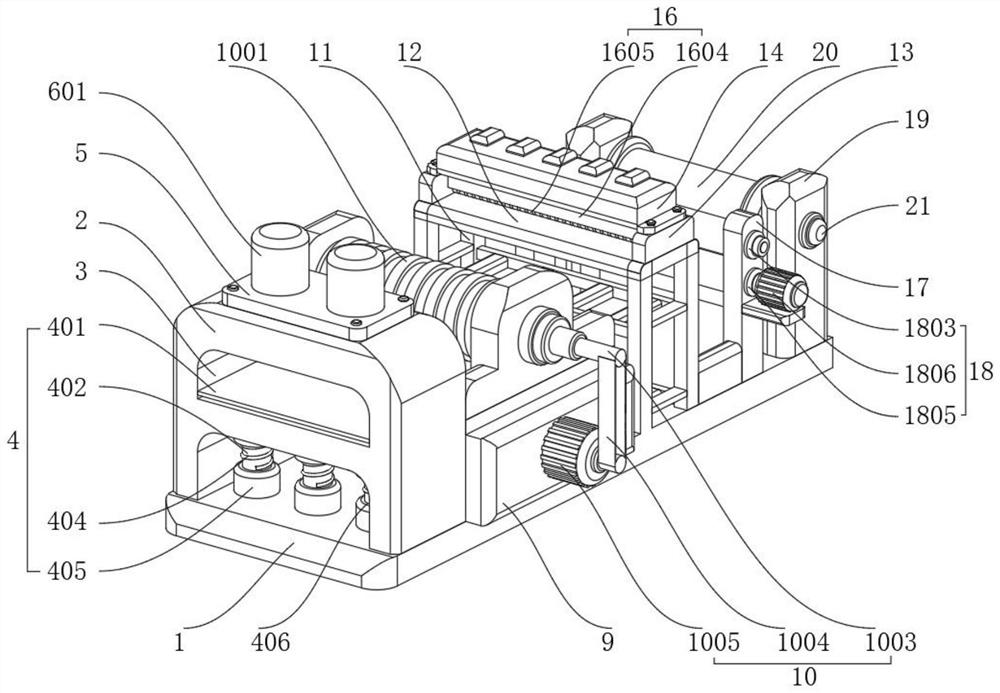

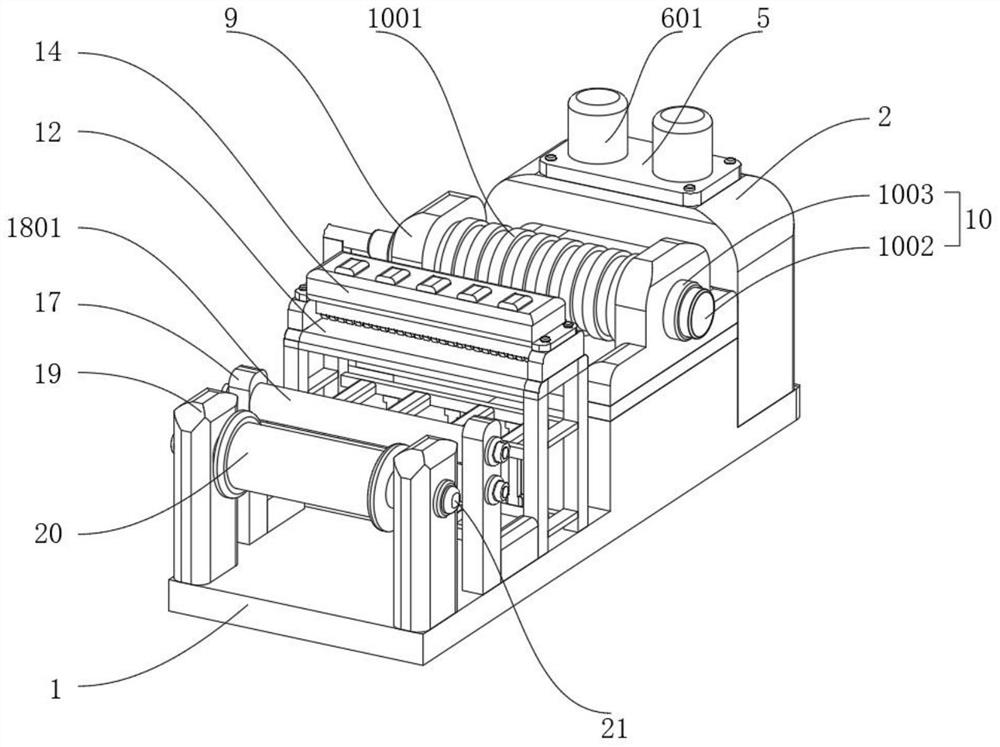

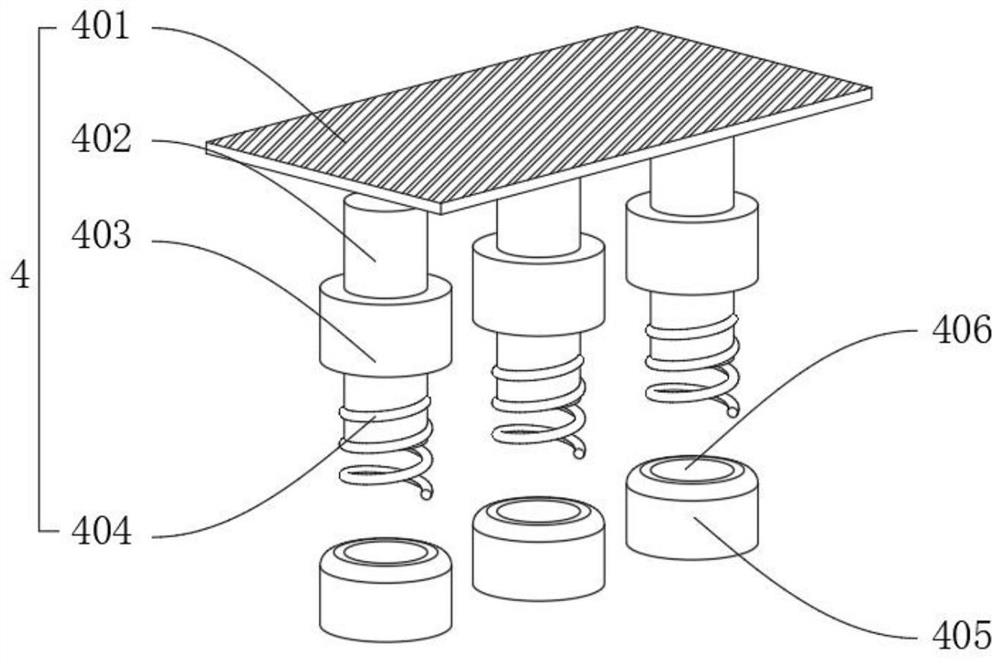

[0047] The texture type rock wool color steel plate manufacturing and processing system and its processing technology provided by this specific embodiment, such as Figure 1-8 shown, including Base 1,

[0048] On the one hand: the support arm 2 is fixed on the top of the base 1, and the inside of the support arm 2 is provided with a discharge port 3, and the inside of the discharge port 3 is slidingly connected with a cutting knife 7 in a vertical direction and is vertically connected to the color steel plate. 2 is fixedly installed with a top plate 5, the top plate 5 can work stably on the whole device, the top side of the base 1 is fixed with a base 9, the base 9 can also improve the overall stability of the device, and the top side of the base 1 is installed Support frame 11 is arranged, and the top of support frame 11 is fixed with console 12, and the top both sides of console 12 are symmetrically provided with console 12, and the tops of two groups of consoles 12 are all ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com