Lubricating oil adding mechanism for numerical control machine tool

A technology of CNC machine tools and lubricating oil, applied in metal processing equipment, metal processing machinery parts, maintenance and safety accessories, etc., can solve problems such as inability to achieve uniform application, difficulty in clearing work, and accuracy errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

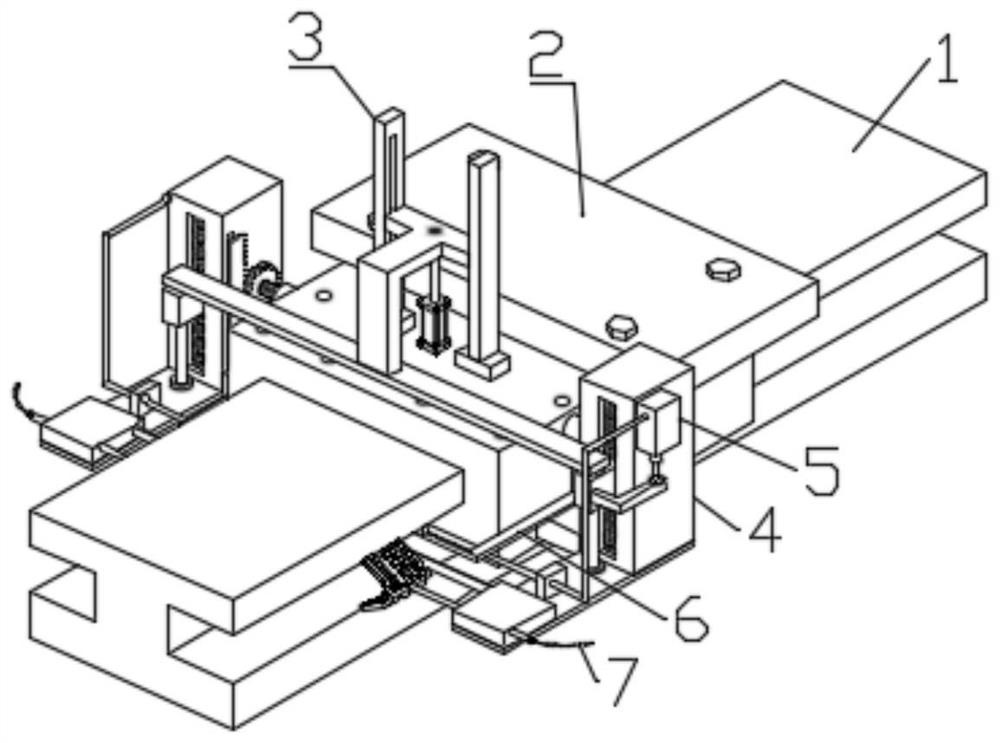

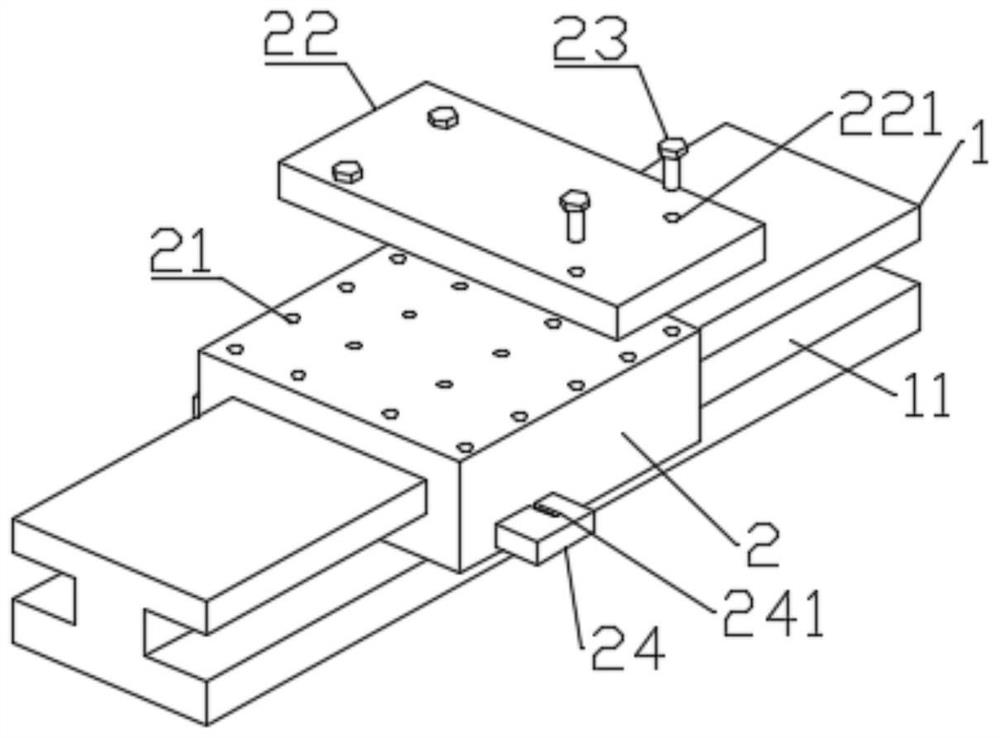

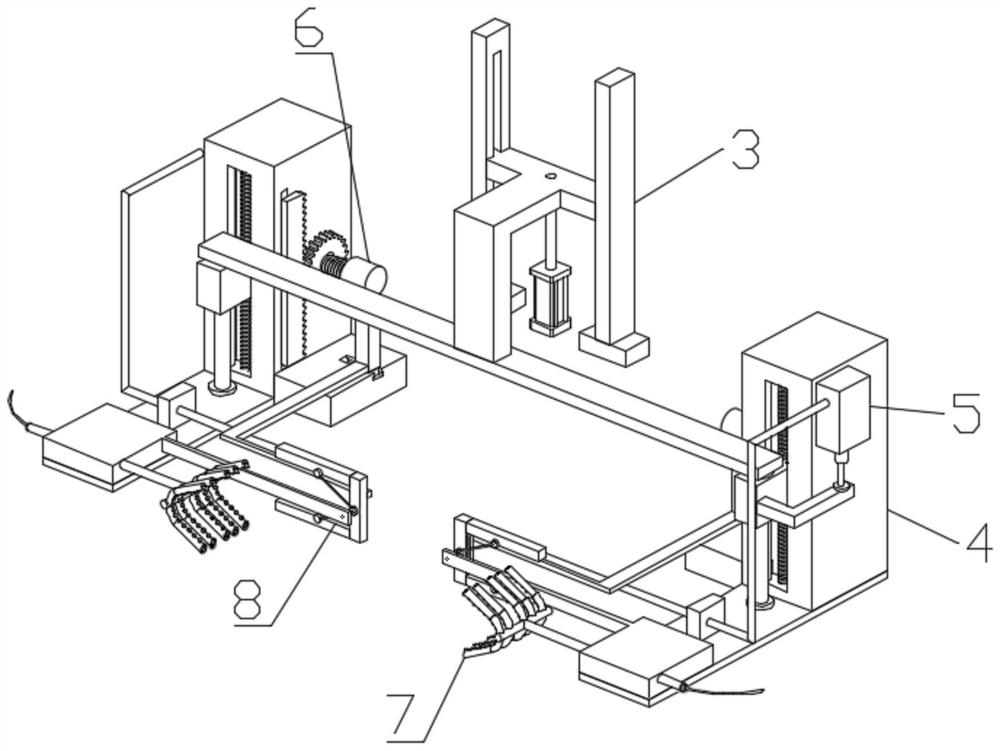

[0027] Example: such as Figure 1-8 As shown, the present invention provides a lubricating oil adding mechanism for numerically controlled machine tools, including a slide rail 1, and guide grooves 11 are provided on both sides of the slide rail 1, and a concave slider 2 is slidably engaged in the guide groove 11 , the concave slider 2 slides along the guide groove 11, the inner wall of the guide groove 11 needs to be lubricated, the upper surface of the concave slider 2 is fixedly installed with a power device 3, and the bottom end of the power device 3 is fixedly connected with Linkage device 4, said linkage device 4 is fixedly connected with the side of concave slider 2, said linkage device 4 outer surface is fixedly equipped with oil injection assembly 5, power unit 3 makes oil injection assembly 5 carry out oil injection through linkage device 4, said oil injection One end of the component 5 is set in the guide groove 11, the inner side of the linkage device 4 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com