Sand screening device capable of automatically adjusting vibration frequency according to sand accumulation amount

An automatic adjustment and vibration frequency technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of constant vibration frequency, affecting the quality of sieving sand, and reducing the speed of sand sieving, so as to reduce manpower consumption and reduce sieving speed. The effect of sand quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

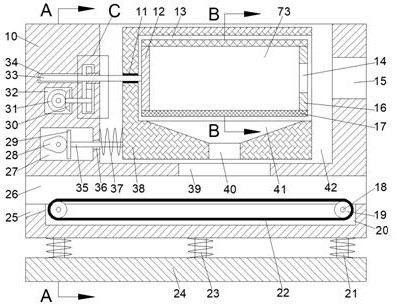

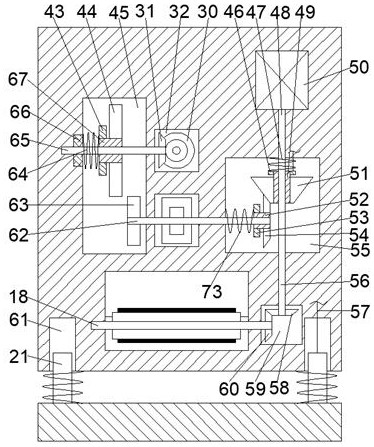

[0017] Combine below Figure 1-5 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

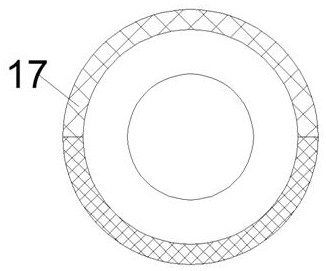

[0018] A sand screening device that can automatically adjust the vibration frequency according to the amount of sand accumulation described in conjunction with accompanying drawings 1-5 includes a main box body 10, which is provided with a vibrating block sliding chamber 42 with an upward opening. The vibrating block sliding chamber 42 is slidingly fitted with a sand screening vibrating block 38, the sand sieving vibrating block 38 is provided with a screen cavity 13 opening to the right, and the lower side of the screen cavity 13 is connected with a tapered cavity. 41, the lower side of the tapered cavity 41 is connected with a sand drop cavity 40 with an opening downward, and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com