A kind of rolling method after heating based on pure nickel plate

A technology of pure nickel after heating, which is applied in the direction of metal rolling, metal rolling, workpiece heating equipment, etc. Precise control and high flatness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

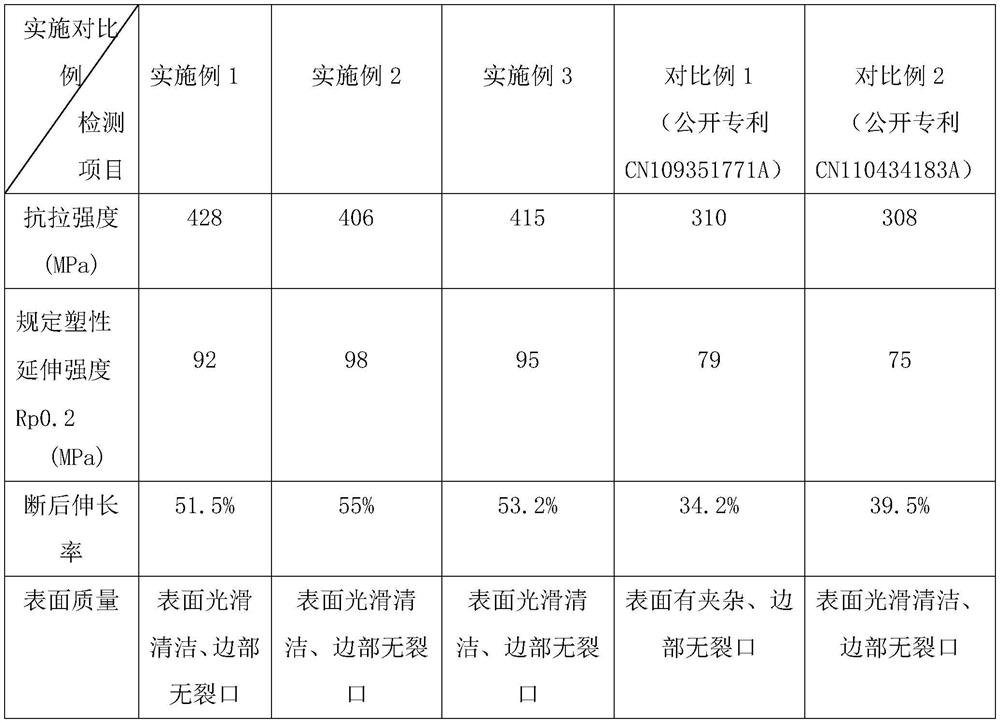

Examples

Embodiment 1

[0030] The size of the slab is 152*1388*5089mm, the grade is N5, and the target size is 3*1388mm. The heating and rolling methods are as follows:

[0031] Step 1. Preheat the slab. The heating temperature is 160°C / min to heat the slab. The preheating temperature reaches 300°C and lasts for 10 minutes. The oxygen content in the heating furnace is 9.5%;

[0032] Step 2. After the preheating is completed, the slab is heated for 35 minutes in one stage, the heating temperature is 950°C, the temperature of the upper burner in the heating furnace is 1000°C, the lower burner is 950°C, and the oxygen content in the furnace is 4.05%;

[0033] Step 3, second-stage heating of the slab: temperature 1050°C, time 45min, heating temperature of the upper burner in the heating furnace in the second-stage heating 1070°C, heating temperature of the lower burner 1050°C, oxygen content in the heating furnace 10%;

[0034] Step 4, slab soaking section: temperature 1080°C, heating time 55min, heatin...

Embodiment 2

[0042] The size of the slab is 154*1378*5080mm, the grade is N5, and the target size is 4*1388mm. The heating and rolling methods are as follows:

[0043] Step 1. Preheat the slab. The heating temperature is 200°C / min to heat the slab. The preheating temperature reaches 350°C and lasts for 12 minutes. The oxygen content in the heating furnace is 10%;

[0044] Step 2. After the preheating is completed, the slab is heated for 40 minutes in the first stage, the heating temperature is 1000 ° C, the temperature of the upper burner in the heating furnace is 1010 ° C, the lower burner is 970 ° C, and the oxygen content in the heating furnace is 4.5%.

[0045] Step 3, second-stage heating of the slab: temperature 1060°C, time 55min, heating temperature of the upper burner in the heating furnace in the second-stage heating 1070°C, heating temperature of the lower burner 1060°C, oxygen content in the heating furnace 10.89%;

[0046] Step 4, slab soaking section: temperature 1100°C, heat...

Embodiment 3

[0054] The size of the slab is 118*1388*5865mm, the grade is N5, and the target size is 5*1388mm. The heating and rolling methods are as follows:

[0055] Step 1. Preheat the slab. The heating temperature is 220°C / min to heat the slab. The preheating temperature reaches 380°C and lasts for 15 minutes. The oxygen content in the heating furnace is 11%;

[0056] Step 2. After the preheating is completed, the slab is heated in the first stage for 45 minutes. The heating temperature is 980°C. During the first stage heating, the temperature of the upper burner in the heating furnace is 1000°C, the lower burner is 980°C, and the oxygen content in the heating furnace is 4.45%.

[0057] Step 3, second-stage heating of the slab: temperature 1070°C, time 55min, heating temperature of the upper burner in the heating furnace in the second-stage heating 1072°C, heating temperature of the lower burner 1060°C, oxygen content in the heating furnace 10.58%;

[0058] Step 4, slab soaking section...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com