Hard-shell windshield wiper

A technology for wipers and hard shells, applied in the field of hard shell wipers, can solve the problems of shortening the service life of the wipers and accelerating the elastic failure of the elastic steel sheet, and achieve the effects of prolonging the service life, improving the flexibility and good anti-aging properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

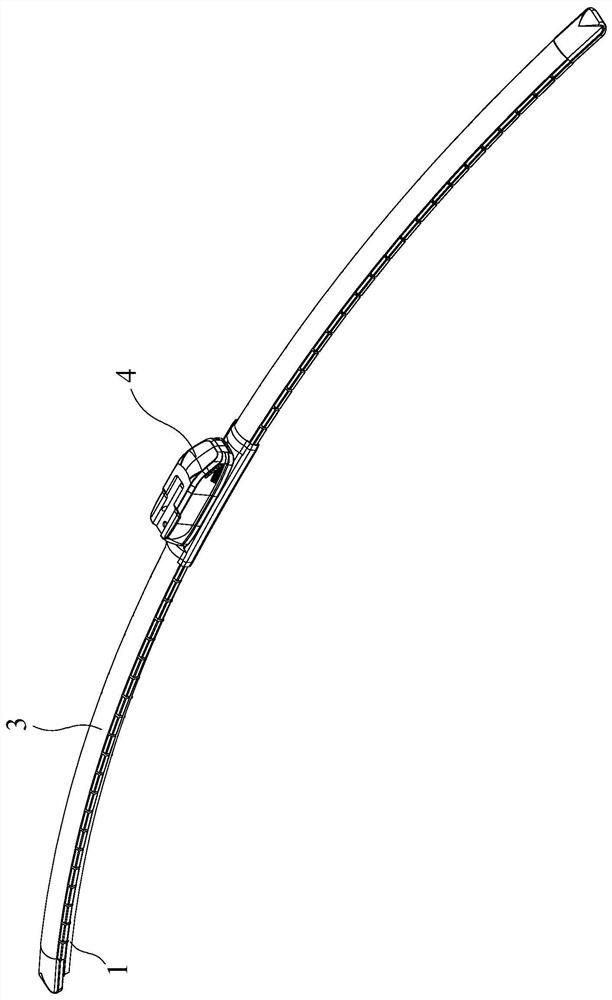

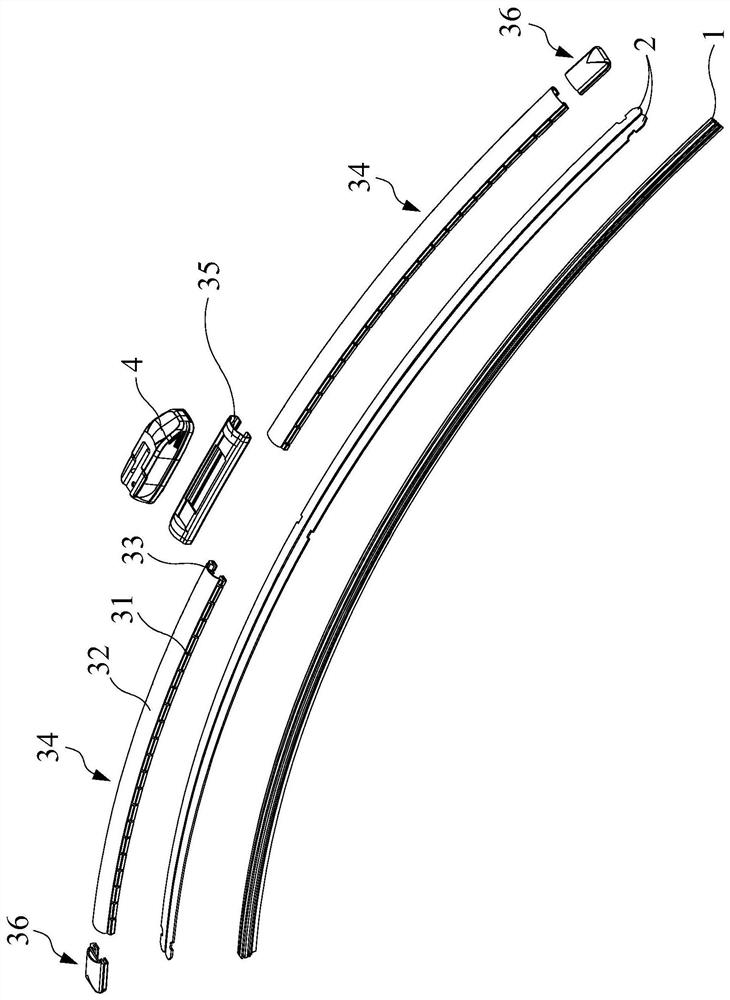

[0020] Such as Figure 1 to Figure 2 As shown, it is the first embodiment of a hard shell wiper of the present invention, the wiper includes a wiper rubber strip 1; The wiper rubber strip 1 is clamped between the two memory steel sheets 2; a deflector 3, and the two memory steel sheets 2 are inserted in the deflector 3; a wiper arm connector 4, the wiper arm connector 4 is installed on the deflector The middle part of the deflector 3 ; wherein, the upper or lower part of the deflector 3 is provided with a plurality of notch grooves 31 equidistantly along the length direction of the deflector 3 .

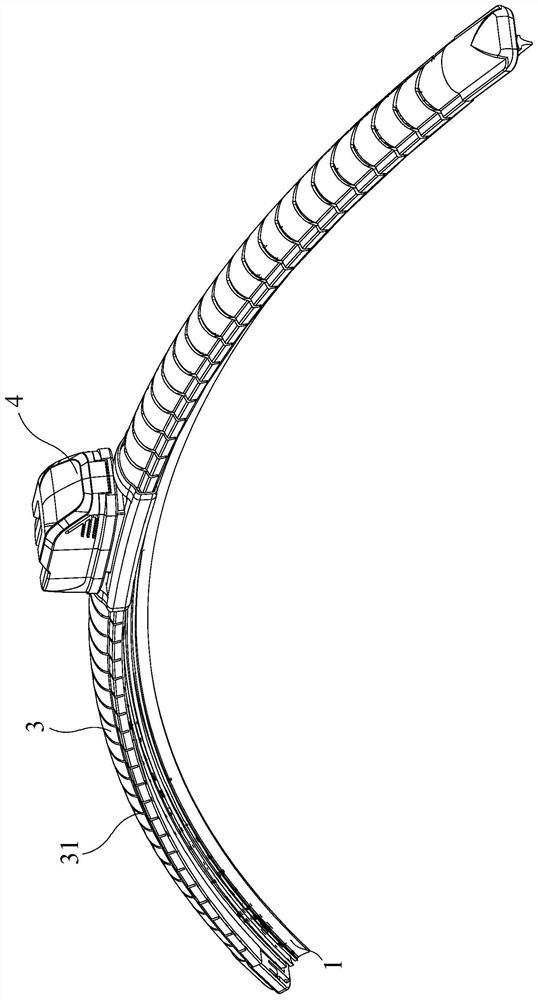

[0021] Such as image 3 As shown, it is the second embodiment of a hard-shell wiper of the present invention. The difference between the second embodiment and the first embodiment is that in this embodiment, the cutout groove 31 on the deflector 3 is arranged on the deflector. The upper part of flow plate 3.

[0022] The key point of the present invention is that the deflector 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com