Gearbox gear shifting gas cylinder control system and using method

A technology of shifting cylinders and control systems, applied in transmission control, fluid pressure actuation devices, elements with teeth, etc., can solve problems such as piston dwelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

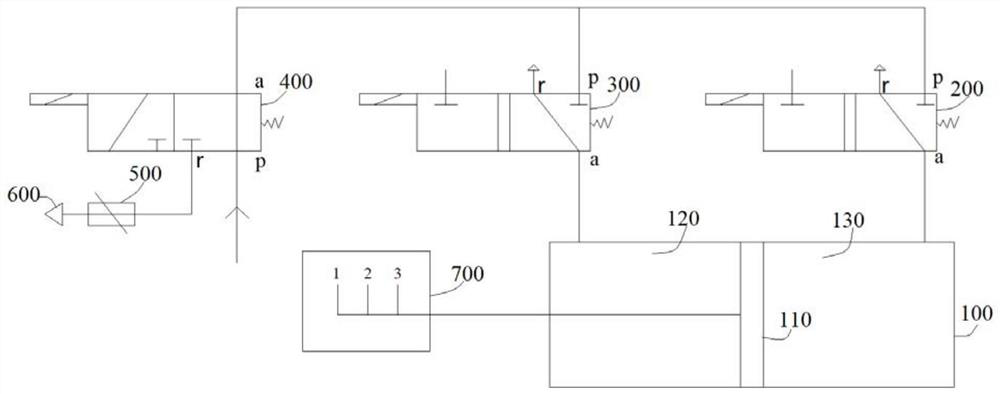

[0028] Refer to attached figure 1 , a gearbox shift cylinder control system of the present embodiment, comprising a cylinder 100, a solenoid valve 1 200 and a solenoid valve 2 300 communicating with the two cavities of the cylinder 100 respectively, the solenoid valve 1 200 and solenoid valve 2 300 The air intake hole of the valve is connected in parallel with the working port of the electromagnetic valve three 400. The cylinder 100 includes a left cavity 120 and a right cavity 130 , and the working ports of the first solenoid valve 200 and the second solenoid valve 300 communicate with the left cavity 120 and the right cavity 130 respectively. The piston 110 of the cylinder 100 in this embodiment is a combined piston. When it is necessary to control position 1 of the cylinder, the control solenoid valve 1200 is turned on, the other solenoid valves are powered off, the cylinder is fed in, the combined piston 110 moves to the left, and after position 1 is generated, the contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com