Water flow sensor and water heater

A technology of water flow sensor and water flow channel, which is applied in the direction of fluid heater, lighting and heating equipment, lifting valve, etc., and can solve the problems of complex connection structure and large space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

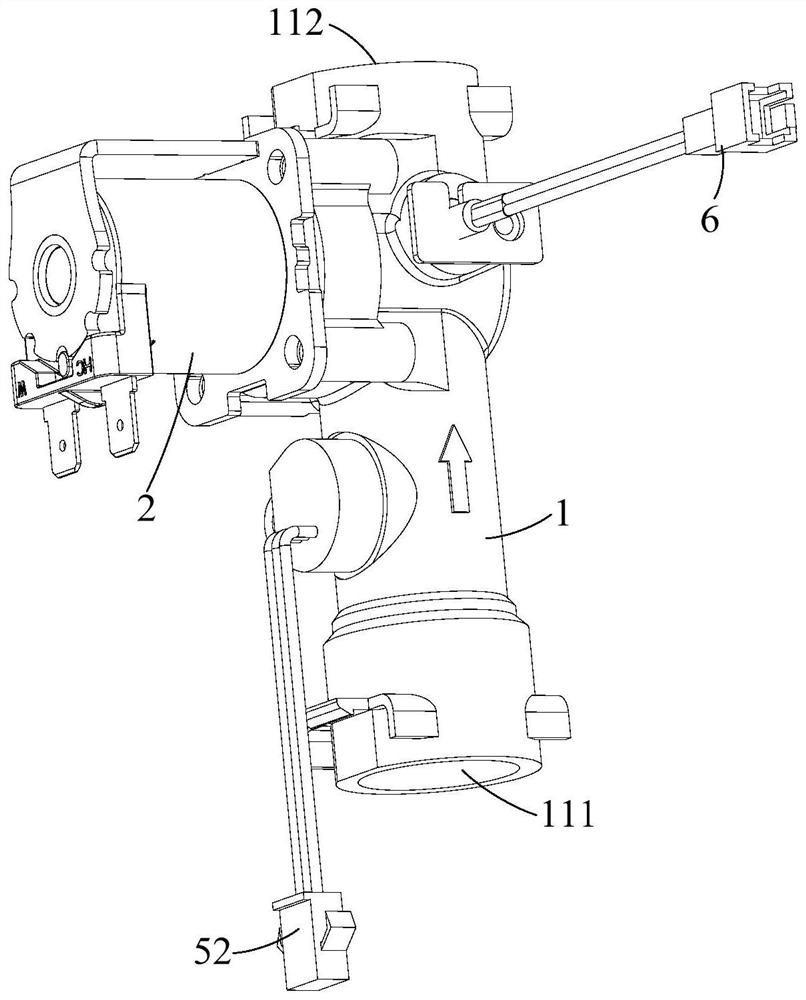

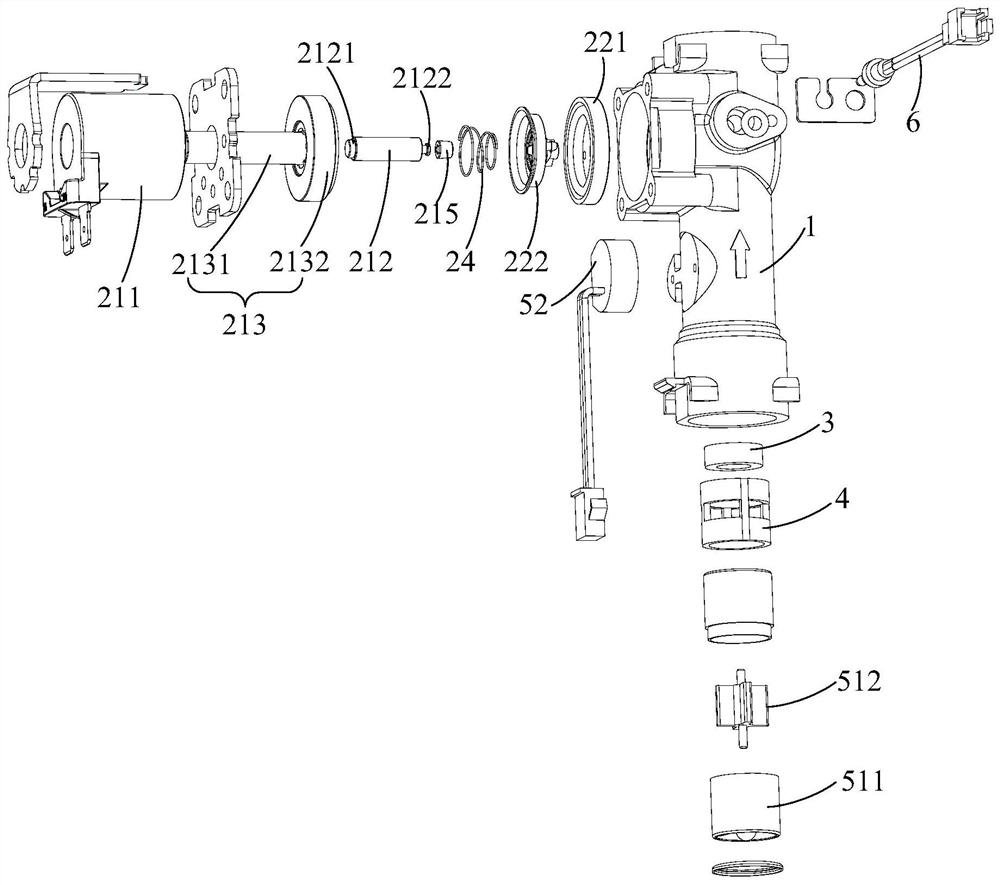

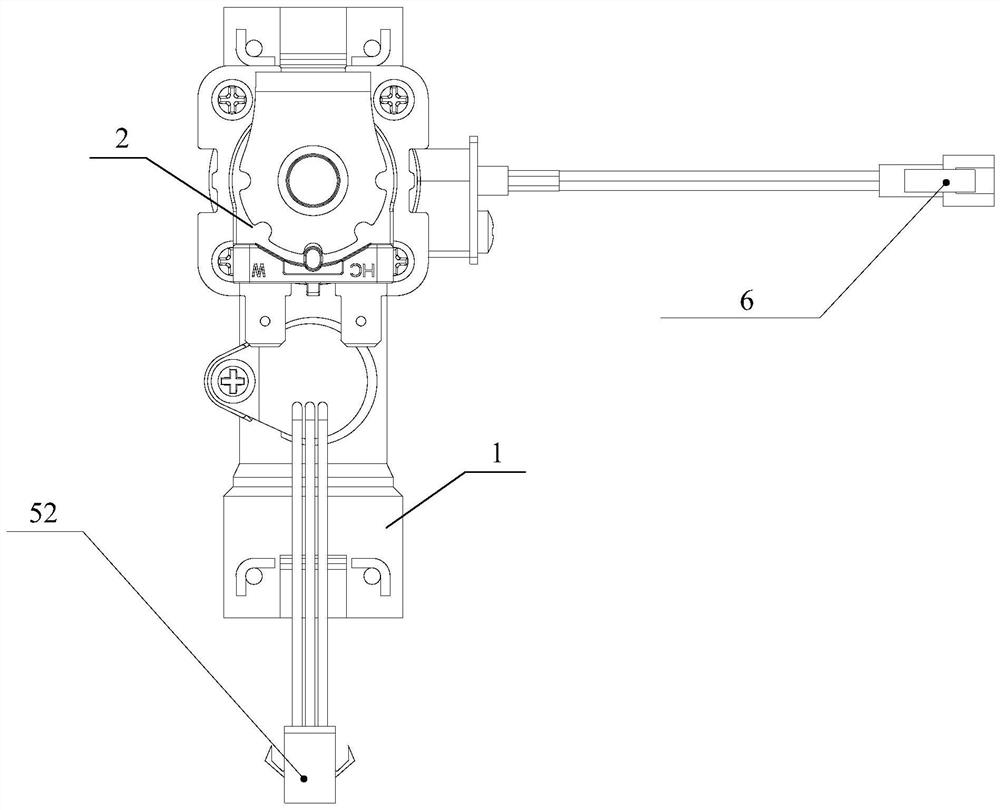

[0081] A water flow sensor, comprising: a water valve body 1 and a valve assembly, such as figure 1 and image 3 shown.

[0082] Specifically, the water valve body 1 is provided with a water flow channel 11, such as Figure 4 and Figure 6 shown. The water flow channel 11 has a water inlet 111 and a water outlet 112, such as figure 1 , Figure 4 and Figure 6 shown. The water valve body 1 is also provided with a valve port 113 communicated with the water flow passage 11, such as Figure 6 As shown, the valve port 113 is located between the water inlet 111 and the water outlet 112 .

[0083] The valve assembly is located at the valve port 113 and is connected to the water valve body 1 for opening or closing the valve port 113, such as Figure 4 and Figure 6 As shown, and in the case of opening the valve port 113, the water passage 12 is defined between the water valve body 1, as Figure 6 As shown, and the two ends of the water passage 12 communicate with the water ...

Embodiment 2

[0094] On the basis of Embodiment 1, further, a water chamber 23 is formed between the valve 21 and the sealing member 22, such as Figure 5 shown. Water valve body 1 is provided with water port 114, and water port 114 is positioned at the upstream side of valve port 113, as Figure 5 shown. The sealing member 22 is provided with a water hole 224 corresponding to the water port 114, such as Figure 5 As shown, to communicate with the water chamber 23 and the water inlet 111.

[0095] A water chamber 23 is formed between the valve 21 and the sealing member 22, and the water chamber 23 is connected to the water inlet 111 of the water valve body 1 through the water hole 224 on the sealing member 22 and the water outlet 114 on the water valve body 1 and the valve port 113 is located on the downstream side of the water port 114 and thus communicates with the water outlet 112, then when the valve assembly closes the valve port 113, the side of the sealing member 22 away from the ...

Embodiment 3

[0106] On the basis of the second embodiment, further, the sealing member 22 includes: a sealing gasket 221 and a supporting member 222 .

[0107] Specifically, the sealing gasket 221 is in contact with the valve port 113, and is suitable for defining the water passage 12 with the water valve body 1, such as Figure 6 shown. The support member 222 is connected with the gasket 221 and is located between the valve 21 and the gasket 221, such as figure 2 and Figure 5 As shown, it is used to support the gasket 221 and cooperate with the valve 21.

[0108] The sealing member 22 includes a sealing gasket 221 and a support member 222, the sealing gasket 221 can be closely attached to the water valve body 1 to play a sealing role; the supporting member 222 is connected to the sealing gasket 221 and is located between the valve 21 and the sealing member 22, When subjected to the force of the valve 21 , it can strongly support the sealing gasket 221 to prevent the sealing gasket 221 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com