A Method of Monitoring Ground Subsidence in Mining Subsidence Area Based on 3D Laser Scanning

A three-dimensional laser, collapse area technology, applied in measurement devices, surveying and navigation, height/level measurement, etc., can solve the problems of increased transmission error, complicated operation, long time consumption, etc., and achieves increased leveling range, accuracy and High stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

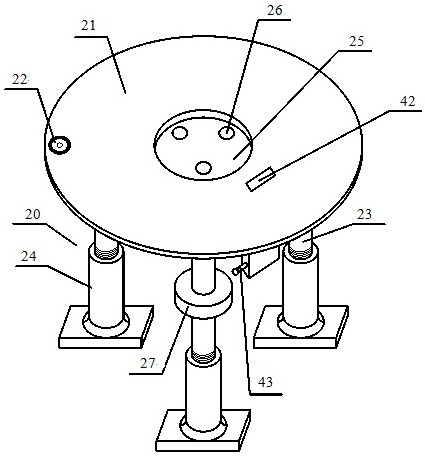

[0065] Below in conjunction with accompanying drawing, the present invention is described in further detail:

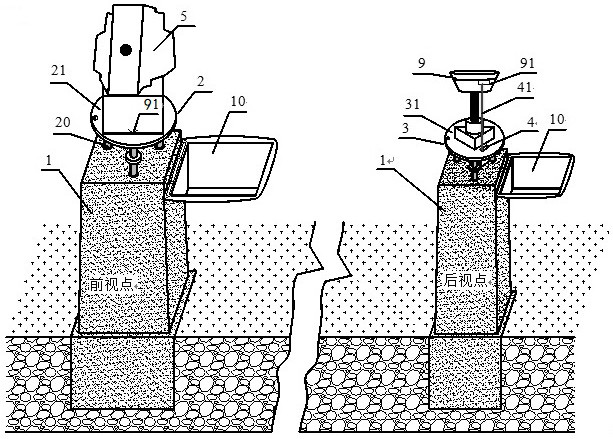

[0066] according to Figure 1~Figure 13 As shown, a method for monitoring ground subsidence in mining subsidence areas based on 3D laser scanning,

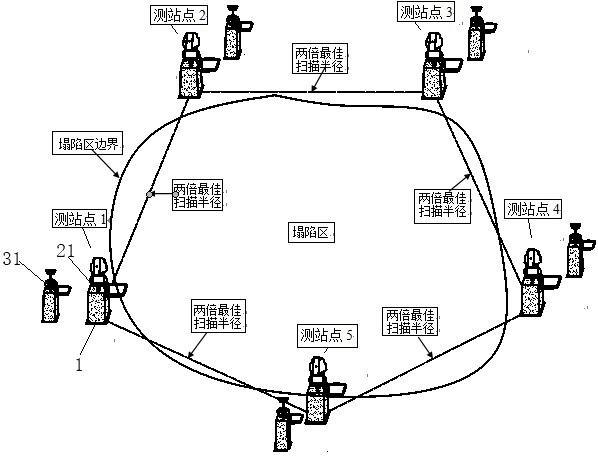

[0067] Step S01. According to the scope of the mining subsidence area and the optimal scanning radius of the three-dimensional laser scanner 5, a plurality of stations are arranged on the surface around the periphery of the mining subsidence area, such as figure 1 Shown; The distance between two adjacent stations around the mining subsidence area is twice the optimal scanning radius of the three-dimensional laser scanner 5, and the distance between the center of the mining subsidence area and each station station is no more than twice the three-dimensional laser scanning The scanning radius of instrument 5, makes the area of all circles drawn with each station point as the center position cover the mining subsidence ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com