Method for detecting burrs of circular injection molded part

A detection method and a technology of injection molded parts, which are applied in the directions of measuring devices, optical testing flaws/defects, image data processing, etc., can solve the problems of low detection rate, large labor force, high detection cost, etc., and achieve high detection efficiency, high detection accuracy, Effects that enhance image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

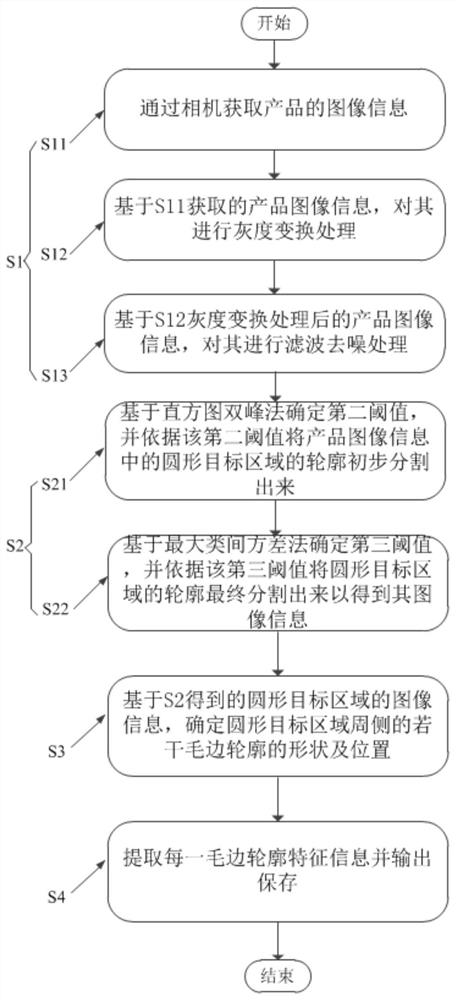

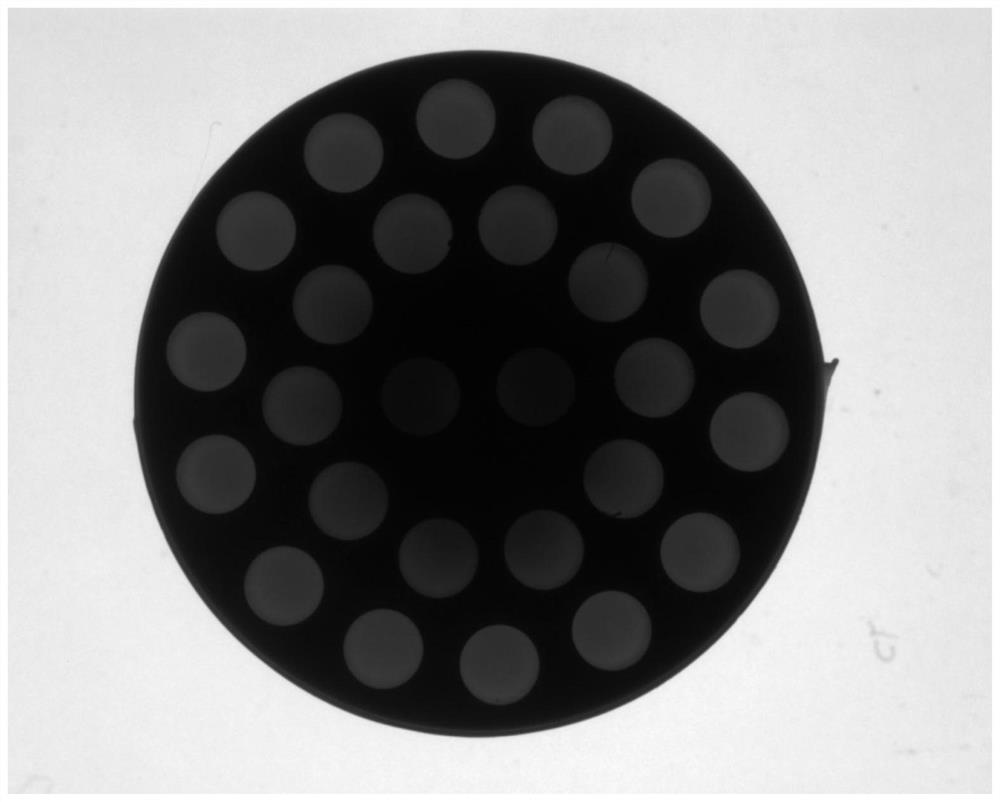

[0031] refer to Figures 1 to 3 As shown, the present invention provides a method for detecting burrs of circular injection molded parts, comprising the following steps:

[0032] S1: Collect image information of the product and preprocess it;

[0033] S2: Based on the image information preprocessed in S1, perform threshold segmentation processing on it to obtain the image information of the circular target area;

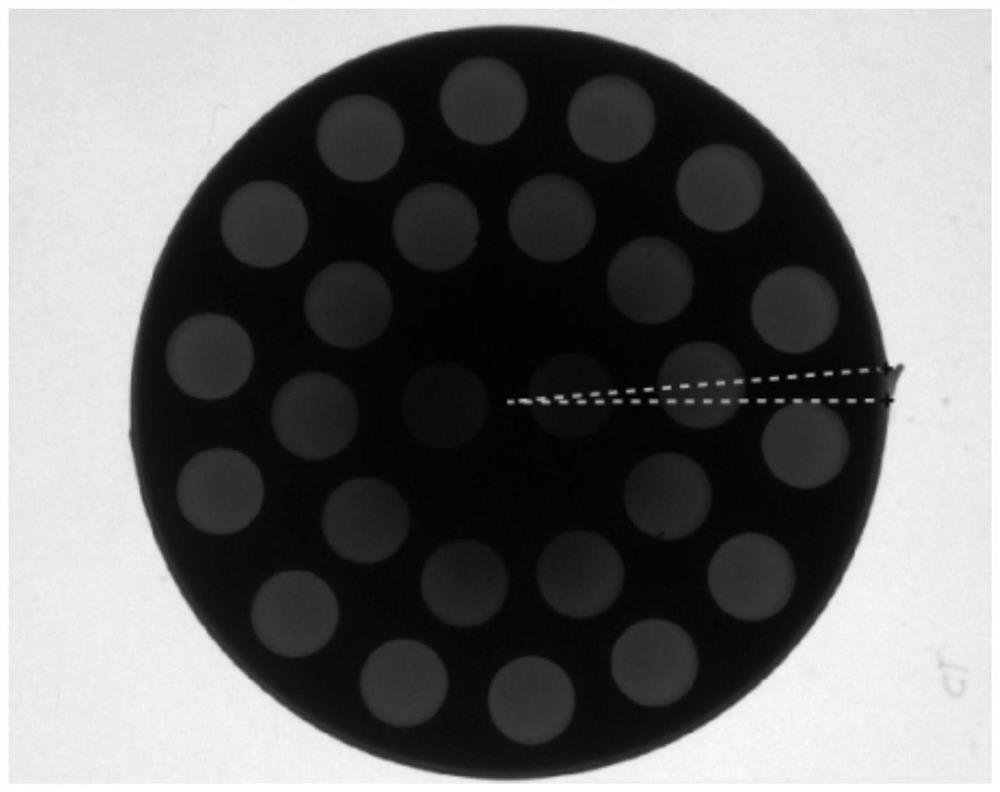

[0034] S3: Based on the image information of the circular target area obtained in S2, determine the shapes and positions of some burr contours around the circular target area;

[0035] S4: Extract the contour feature information of each burr and output and save it.

[0036] Wherein, said S1 includes the following steps:

[0037] S11: Obtain the image information of the product through the camera;

[0038] S12: Based on the prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com