Patents

Literature

71 results about "Subpixel edge detection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

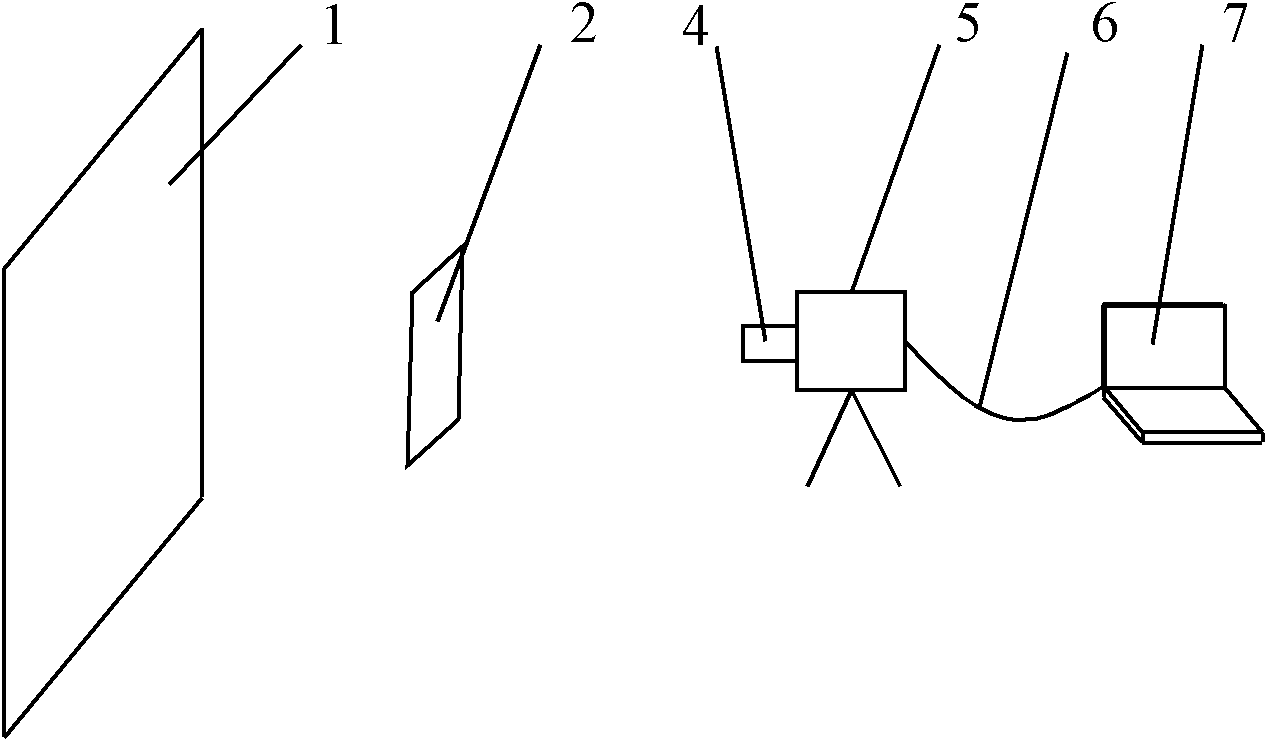

On-line detection method for diameter size of shaft disc type part

InactiveCN102107374ARelaxed placement requirementsCorrect distortionMeasurement/indication equipmentsUsing optical meansDistortionCharge couple device

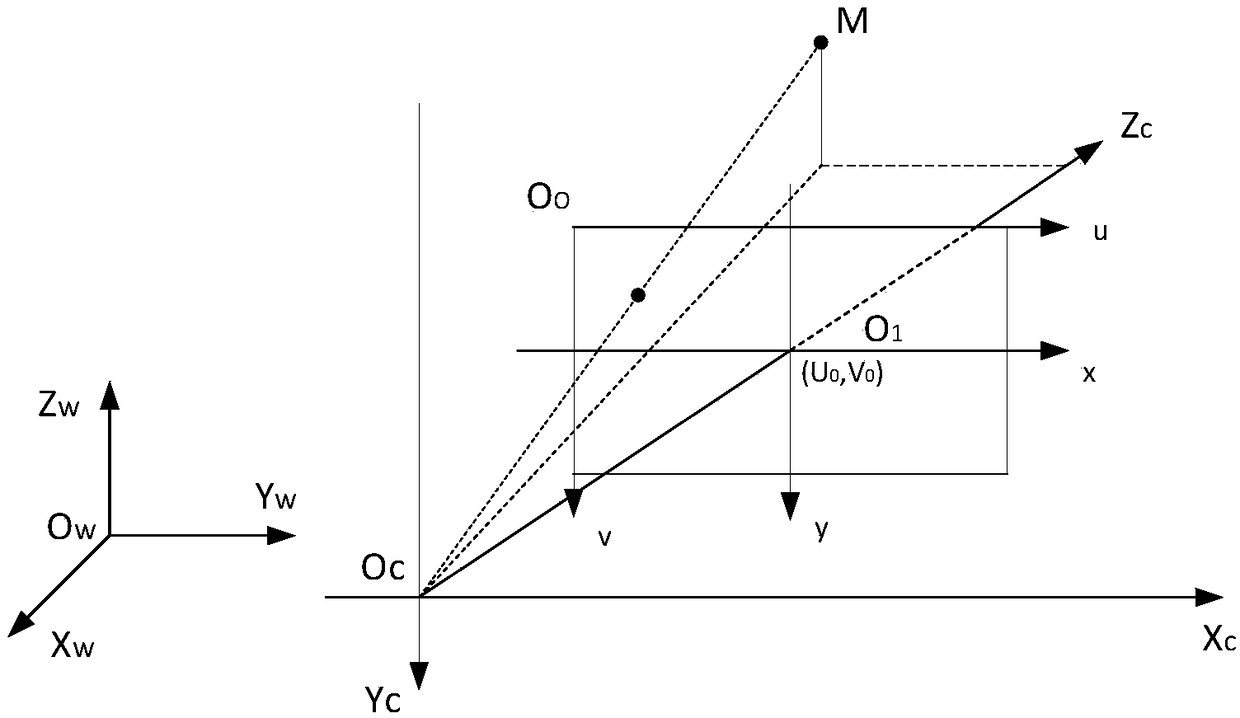

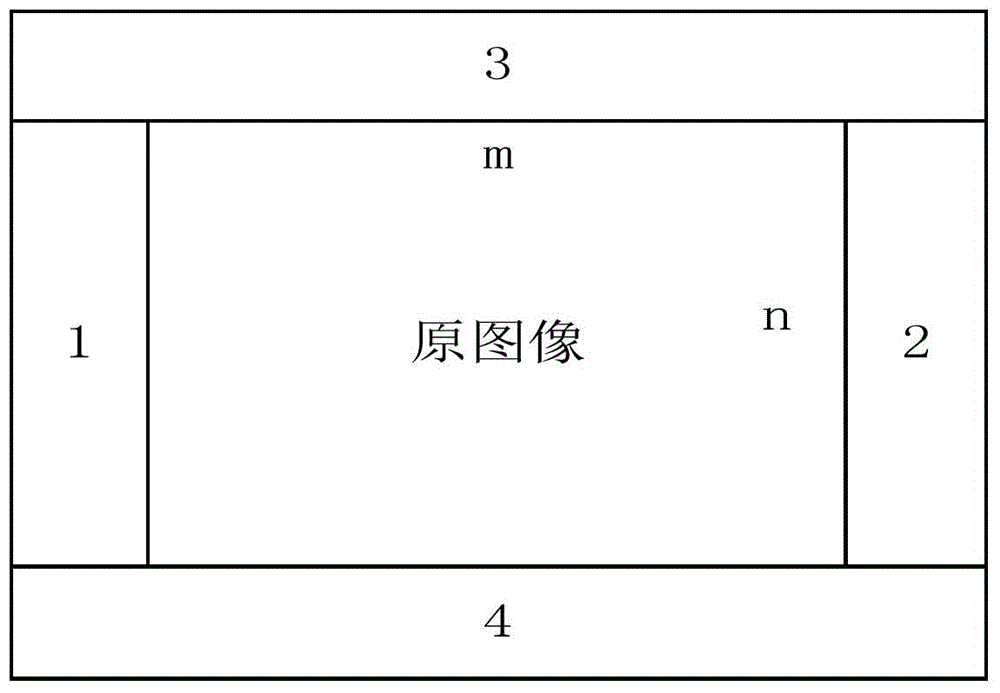

The invention relates to an on-line detection method for diameter size of a shaft disc type part, and belongs to the technical field of image measurement, which can detect variation in the diameter size during processing of the shaft disc type part in real time and guarantee higher detection efficiency and measurement accuracy. The method comprises the following steps of: calibrating internal parameters of a charge coupled device (CCD) video camera and correcting distortion of an image caused by lens distortion based on a CCD video camera plane calibration method; calibrating external parameters of the CCD video camera, acquiring the image of the shaft disc type part with a known diameter by using the CCD video camera, extracting two edges of the part from the image by a subpixel edge detection algorithm, and calibrating to acquire external parameters of the part relative to the CCD video camera by using coordinates of the subpixel edges and the acquired internal parameters of the camera video; and finally, measuring, acquiring the image of the detected shaft disc type part by using the CCD video camera, extracting the subpixel edges of the part and calibrating to acquire the internal parameters and the external parameters so as to solve the diameter size of the detected part.

Owner:JILIN UNIV

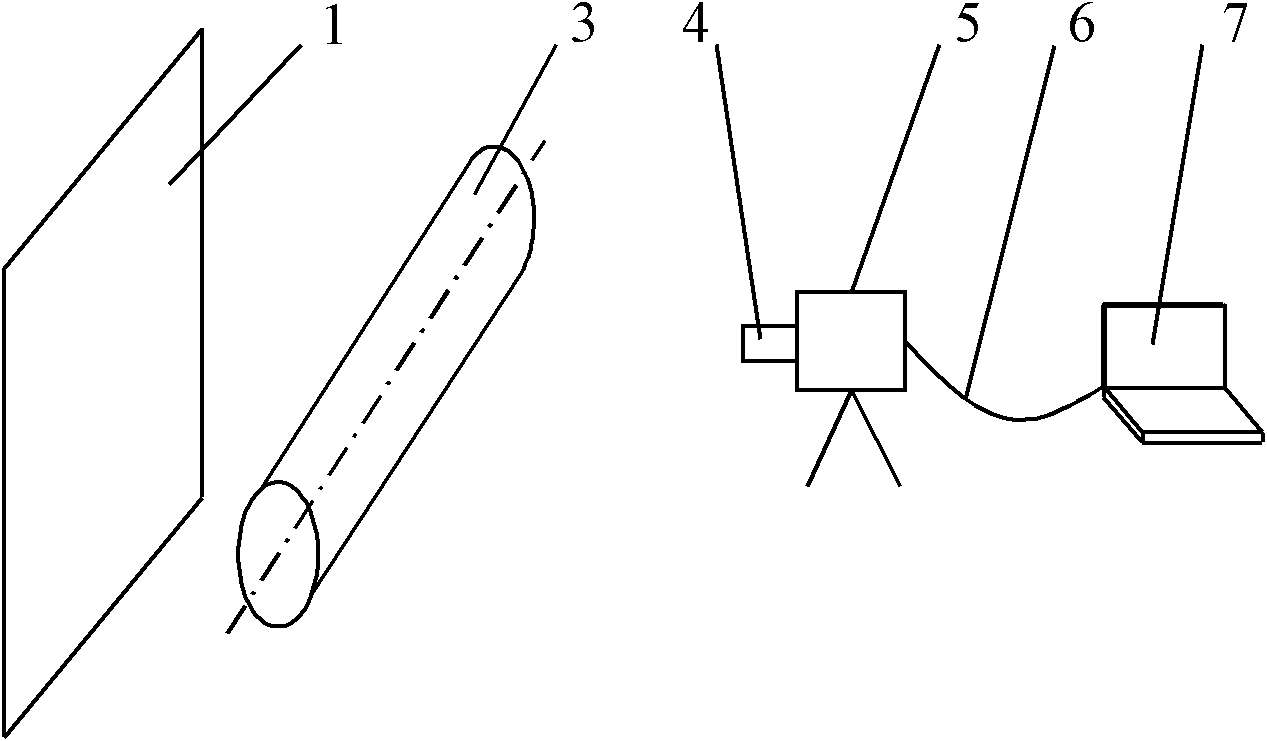

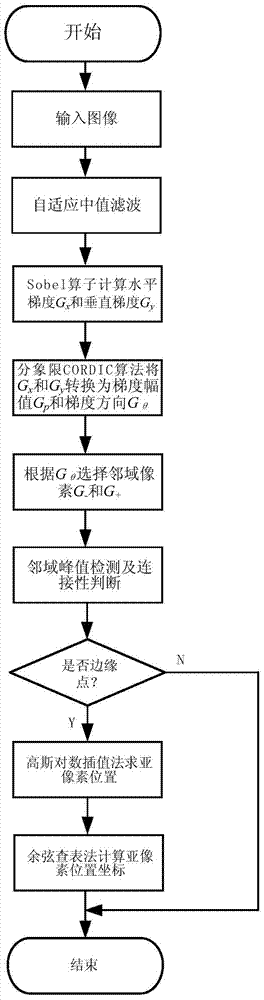

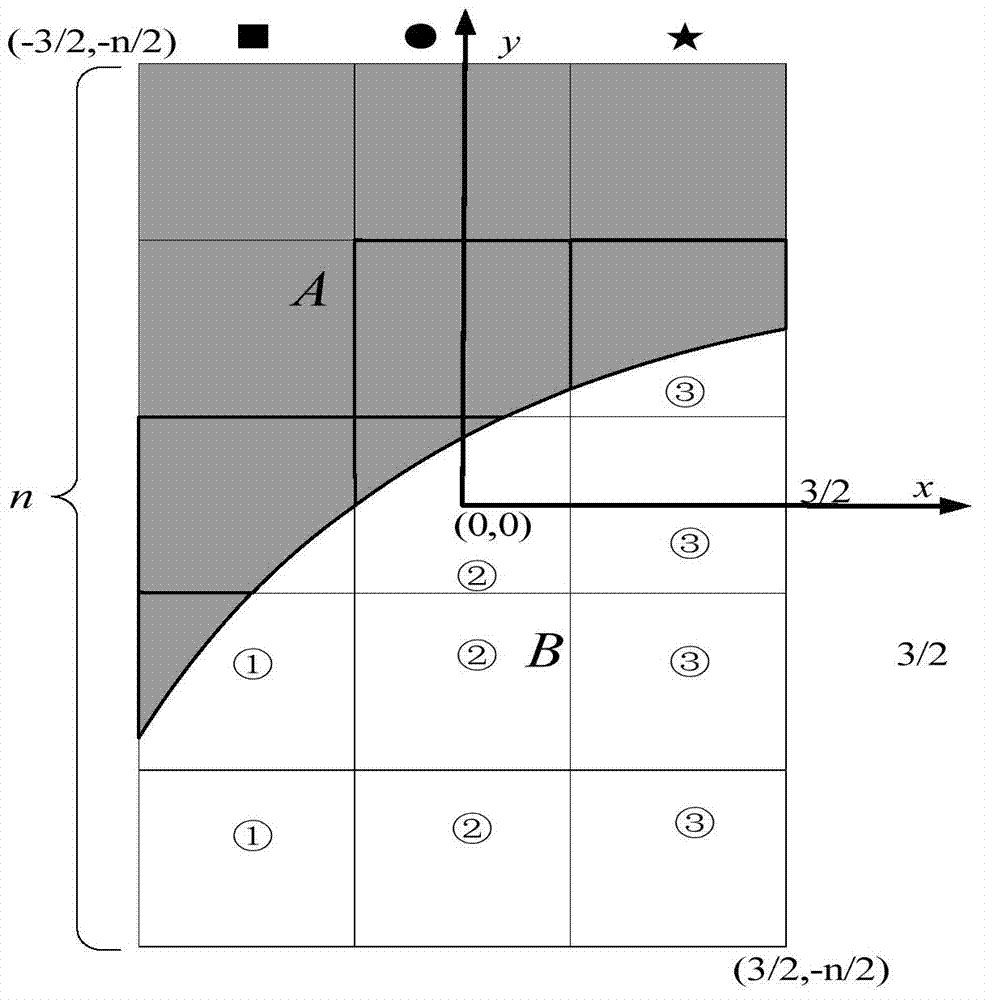

Rapid sub pixel edge detection and locating method based on machine vision

ActiveCN104268857AThe detection process is fastFast positioningImage enhancementImage analysisMachine visionRectangular coordinates

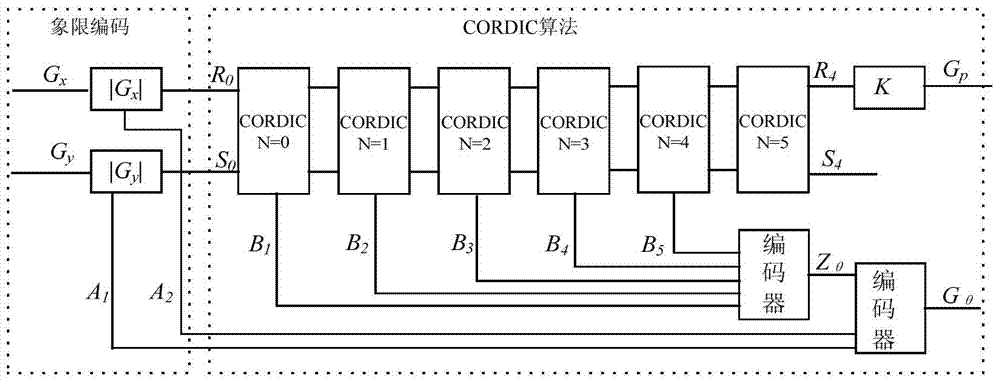

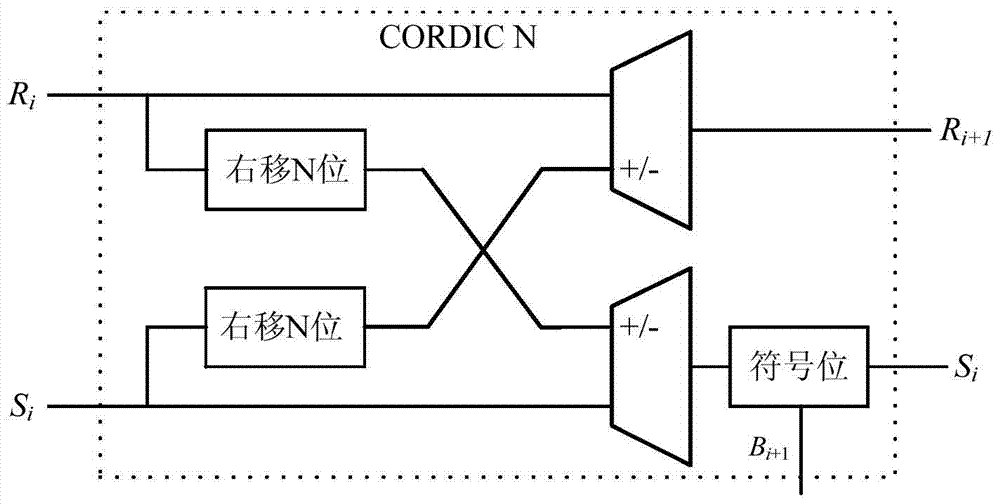

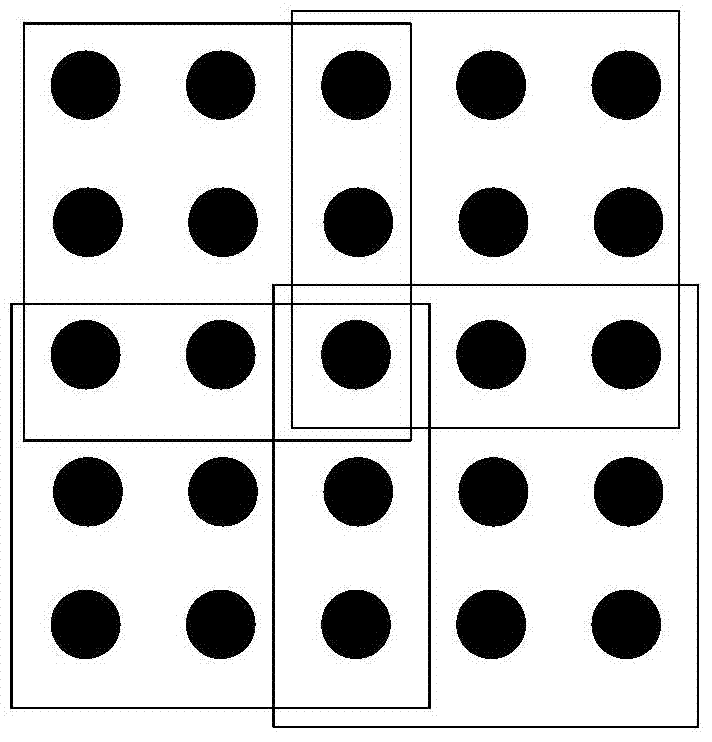

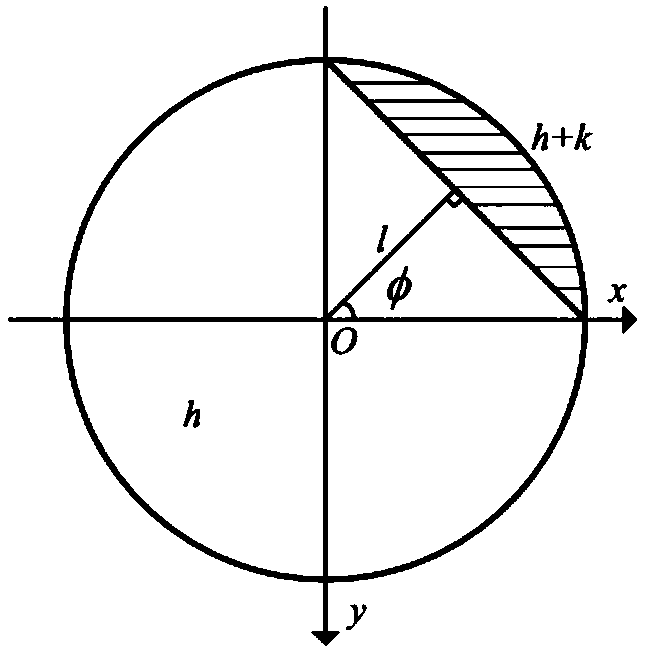

The invention discloses a rapid sub pixel edge detection and locating method based on machine vision. The method includes the following steps that firstly, a detection image is acquired; secondly, denoising pretreatment is conducted on the image; thirdly, the gradient Gx of each pixel point in the horizontal direction and the gradient Gy of each pixel point in the vertical direction are calculated; fourthly, the gradient magnitude G0 and the gradient direction Gtheta of each pixel points under polar coordinates are calculated; fifthly, neighborhood pixel points of each pixel point are determined; sixthly, pixel-level edge points are determined; seventhly, the distance between a sub pixel edge point of each pixel-level edge point in the eight-gradient direction and the pixel-level edge point is calculated; eighthly, the distance d between each sub pixel edge point in the actual gradient direction Gtheta and the corresponding pixel-level edge point is calculated; ninthly, a cosine lookup table method is adopted for calculating rectangular coordinates of each sub pixel edge point in the actual gradient direction Gtheta, so that the image edge points are detected and sub-pixel-level localization is conducted. The whole method is high in calculation accuracy and speed.

Owner:湖南湘江时代机器人研究院有限公司

A method for detecting the camber of plates based on machine vision

InactiveCN109190628ACalculate Bend CurvatureSmall amount of calculationImage analysisCharacter and pattern recognitionAutomatic controlMachine vision

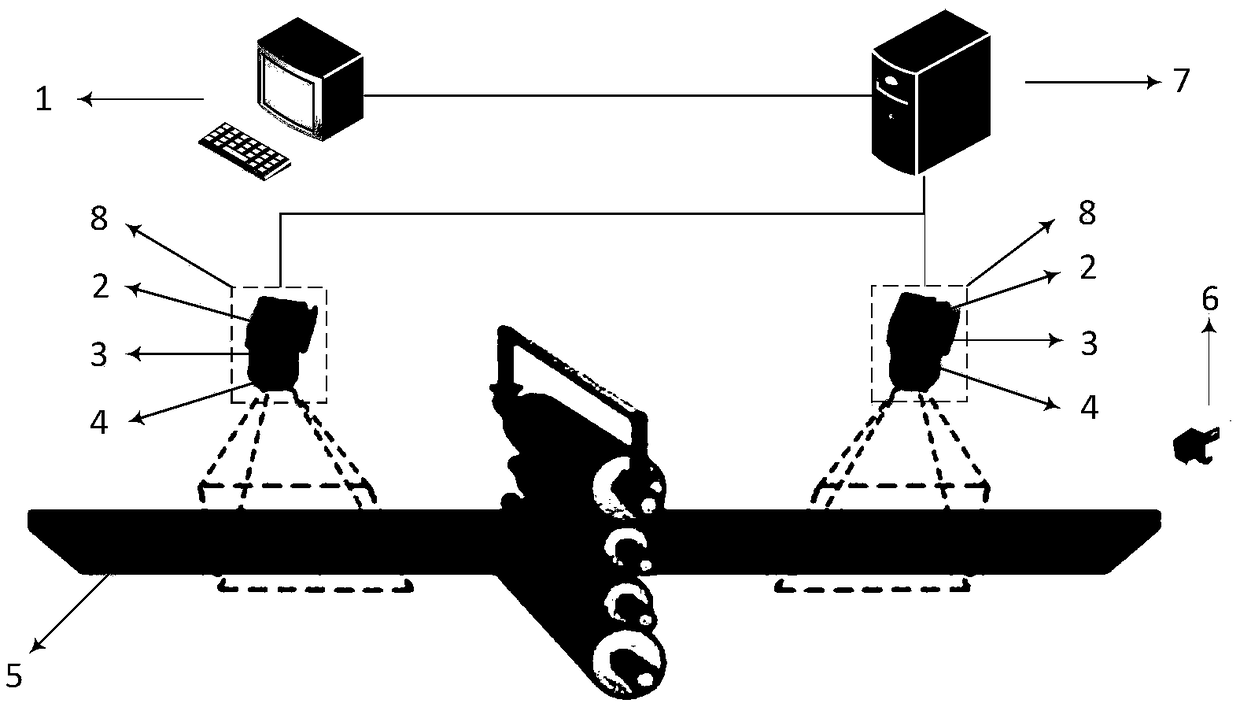

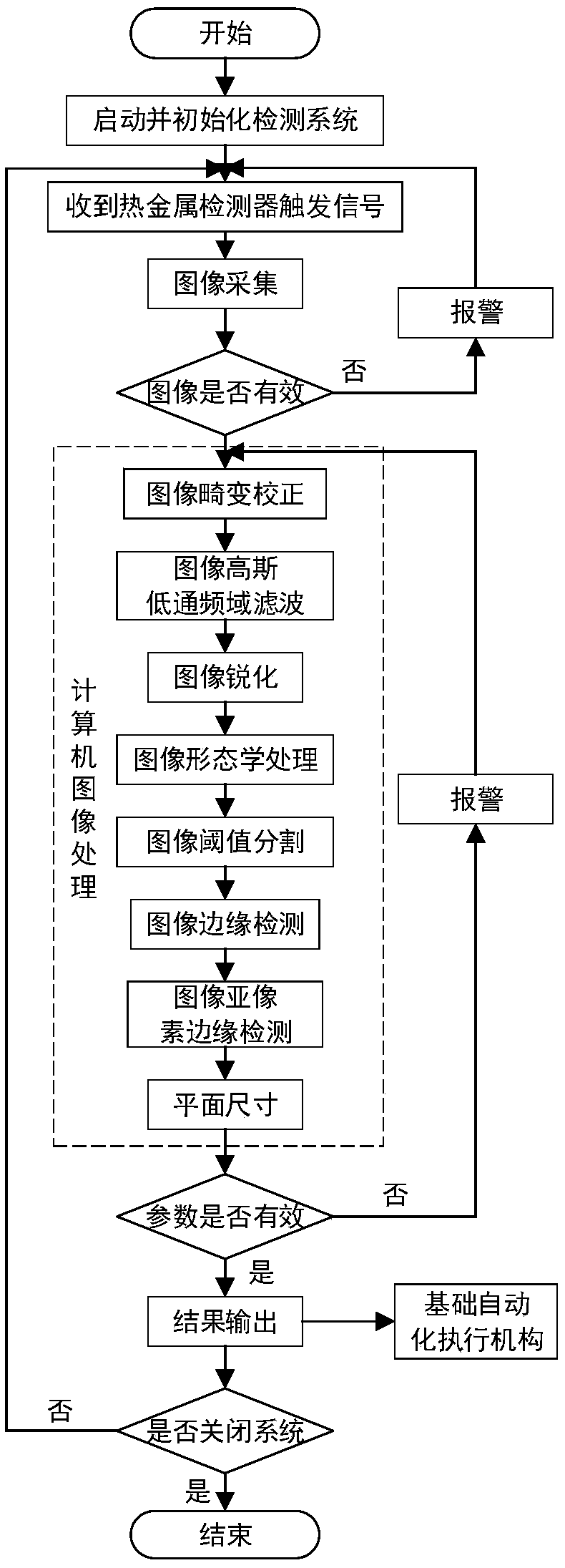

The invention particularly relates to a method for detecting the camber of plates based on machine vision, belonging to the automatic control field of steel rolling processes. The method comprises thefollowing steps: obtaining plate images through plane array CCD cameras installed right above a roller way outside of roller beds in front of and behind a rolling mill, and correcting the distortionof the images through camera calibration; performing Gaussian low-pass frequency domain filtering on the corrected images, and performing image sharpening differential operation on the filtered imagesto enhance the image boundary. Mathematical morphology transformation and threshold binarization are carried out on the images with enhanced boundaries to segment and completely extract the plate image. The pixel coordinates of the edge contour points are extracted by using the Canny edge detection operator after threshold segmentation and the sub-pixel coordinates of the plate edges are obtained by using the improved Zernike orthogonal moment sub-pixel edge detection algorithm, and the camber value is obtained by fitting.

Owner:NORTHEASTERN UNIV

Article geometrical size measuring device and method based on multi-source image fusion

InactiveCN101144703AExact edge positionHigh precisionUsing optical meansImage data processing detailsMeasurement deviceData acquisition

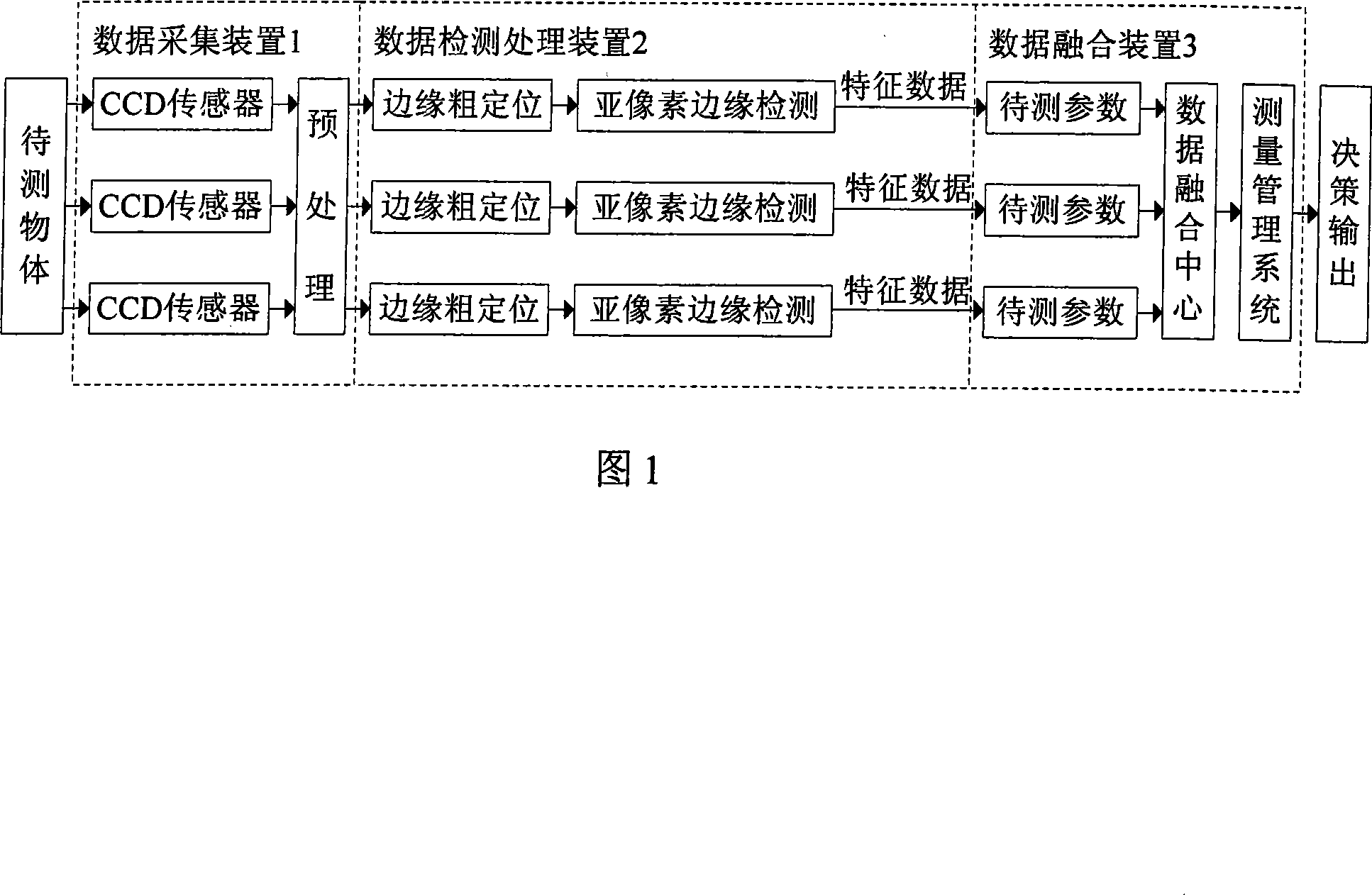

The invention relates to a measuring device and a method based on an object geometry size interfused by a multiple source image, and the measuring device comprises a data acquisition device that performs the acquisition and the attached processing to the image data of the measured object, a data detecting and processing device that performs a fringe coarse positioning and the secondary image element fringe to the image data and adopts a data fitting method to perform a fitting to the secondary image element fringe, to obtain a fringe interval; a data fusion device that performs the interfusion to the measuring object data withdrawal by the data detecting and processing device. The invention expands a single CCD sensor measurement to a multiple CCD sensor measurement, the multiple sensor redundant information is fully utilized and the weighting fusion treatment is performed to the multiple sensor redundant information, thereby obtaining the estimation result of the multiple sensor fusion; and the precision of the measuring result is improved.

Owner:SHAANXI UNIV OF SCI & TECH

Vision-based high-precision rotation angle measurement method

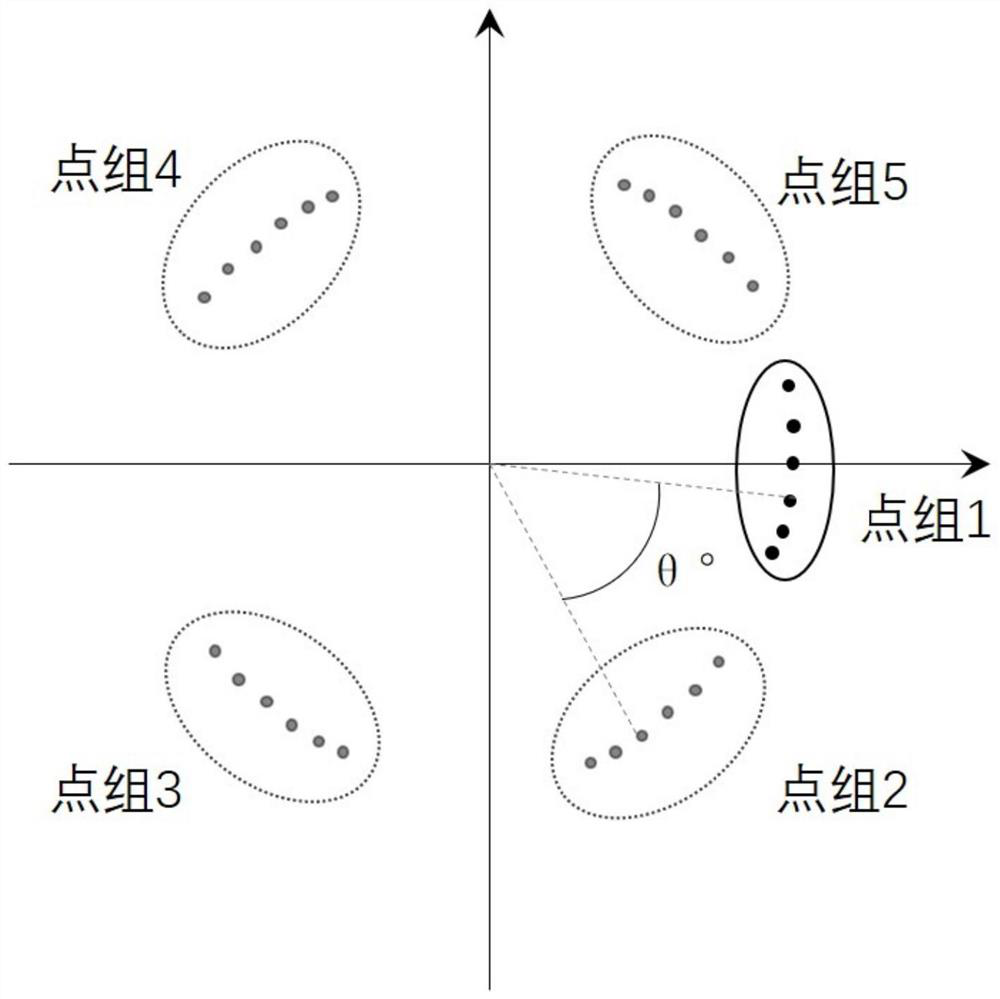

ActiveCN110672040AHigh precisionLow costImage analysisCharacter and pattern recognitionTemplate matchingEngineering

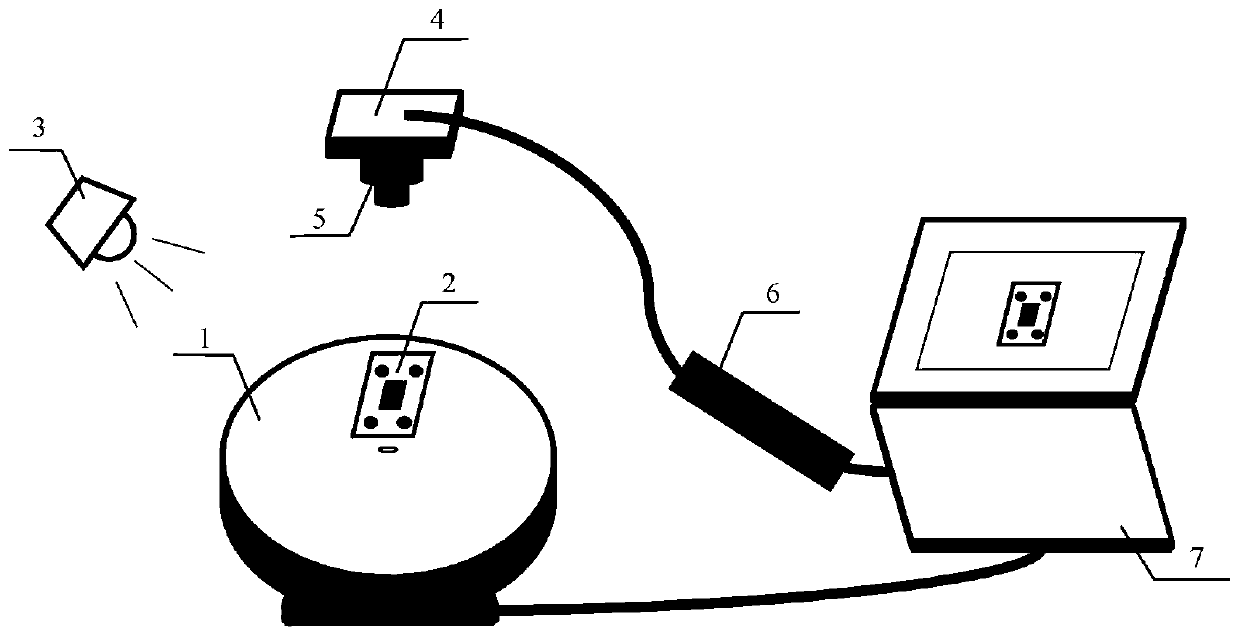

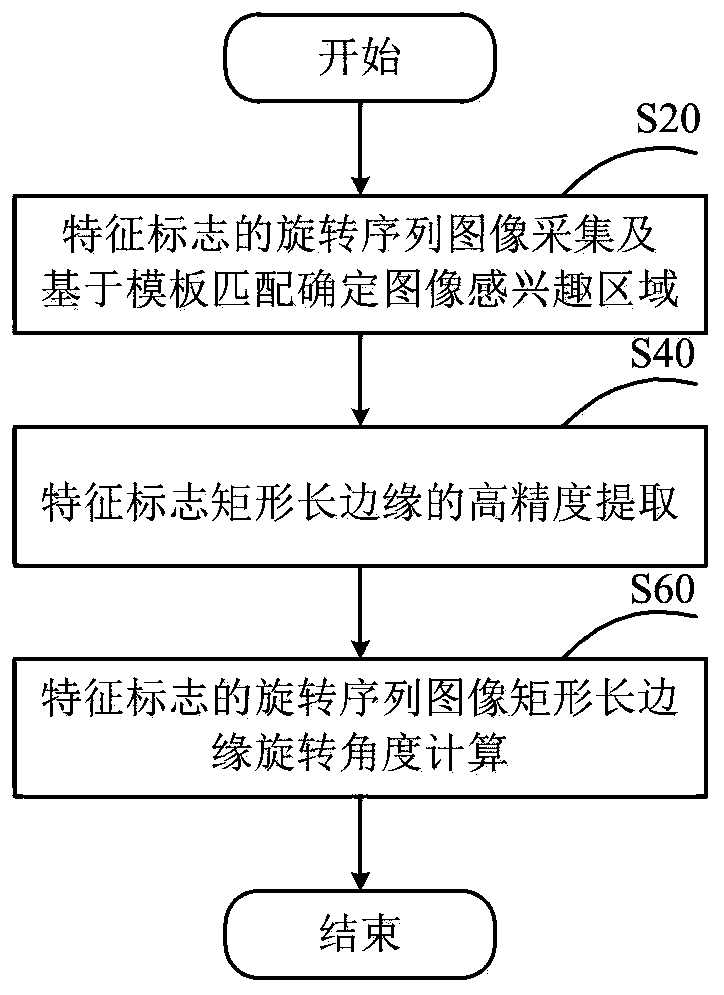

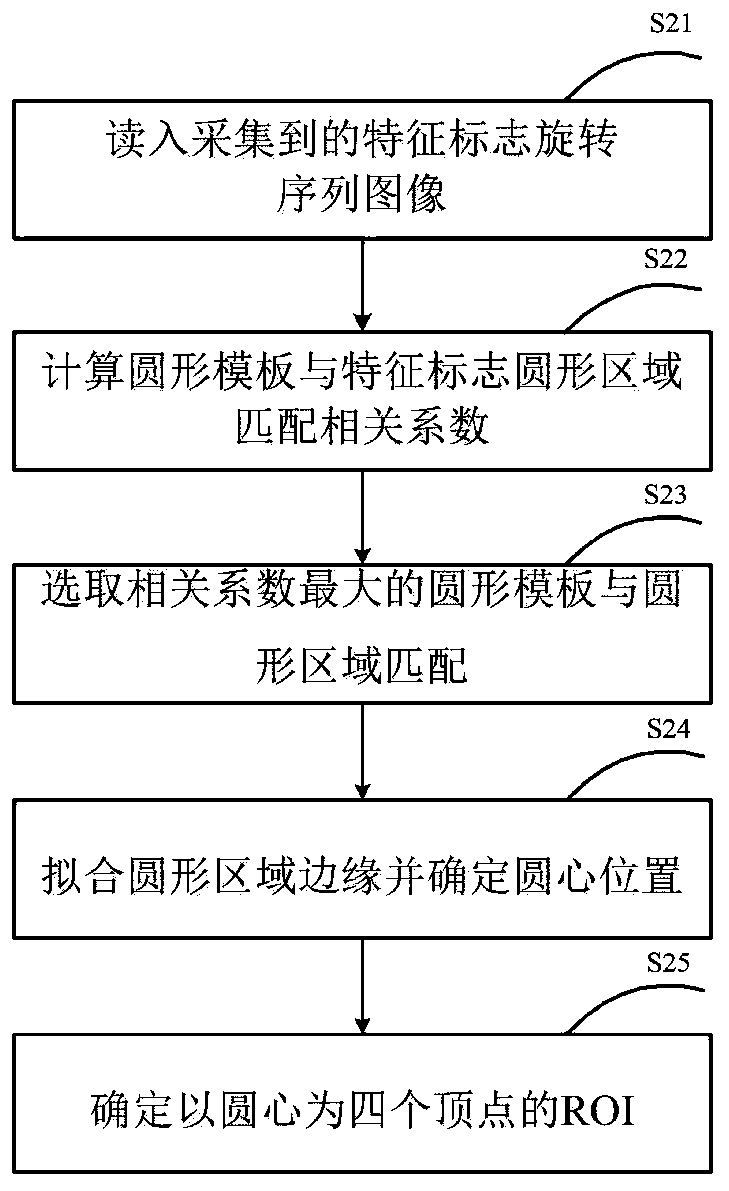

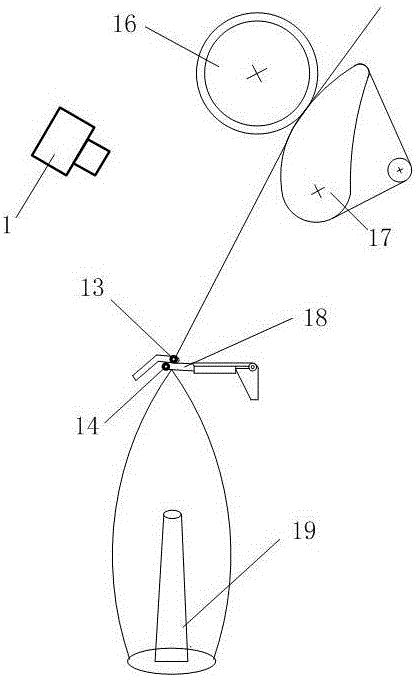

The invention discloses a vision-based high-precision rotation angle measurement method. The measurement method comprises the following steps that a characteristic mark with four circular envelope rectangles is adopted, wherein the characteristic mark is fastened to the rotating surface of a rotary table, and has the same rotation angle as the rotation surface; a region of interest ROI of the image is determined based on template matching, and the influence of the similar edge of the image background on the detection of the rectangular edge in the characteristic mark is eliminated; then high-precision extraction of the rectangular long edge is realized based on the sub-pixel edge detection method of Zernike moment to obtain sub-pixel coordinates of two long edges of the rectangles; fittingof the sub-pixel coordinates of the two long edges is carried out based on a least square fitting method to obtain corresponding fitted edge straight lines and the mean value of the slopes of the twostraight line is calculated; and the rotation angle of the rotation position relative to the reference position is calculated by using an arctangent trigonometric function of the mean value of the two slopes. The method solves the problems that the existing rotation angle measurement method is limited in measurement precision, tedious in process, complex in system and the like.

Owner:NAT INST OF METROLOGY CHINA +1

Device and method for dynamically detecting multiple targets of yarns of spinning machines

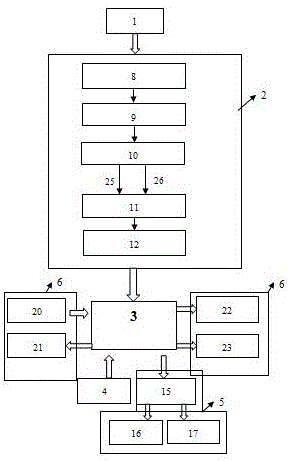

The invention relates to the field of technologies for detecting yarns, in particular to a device and a method for dynamically detecting multiple targets of yarns of spinning machines. The device comprises a CCD (charge coupled device) camera, an image processing module, a master control system, a sensing assembly, a compact spinning device and auxiliary devices. The CCD camera is provided with an illuminating system, can acquire images of the yarns and can transmit the acquired images to the image processing module, the image processing module comprises an image gray-scale transformation unit, an image filter unit, an image binarization processing unit, a sub-pixel edge detection unit and a size calibration unit, and measured yarn information is transmitted to the master control system by the image processing module and is analyzed and judged by the master control system, so that the quality of the yarns can be detected. The device and the method for dynamically detecting the multiple targets of the yarns of the spinning machines have the advantages that the quality of the yarns of the spinning machines can be automatically detected by the aid of the device and the method, and the accuracy of detection results can be improved.

Owner:JIANGSU UNIV OF TECH

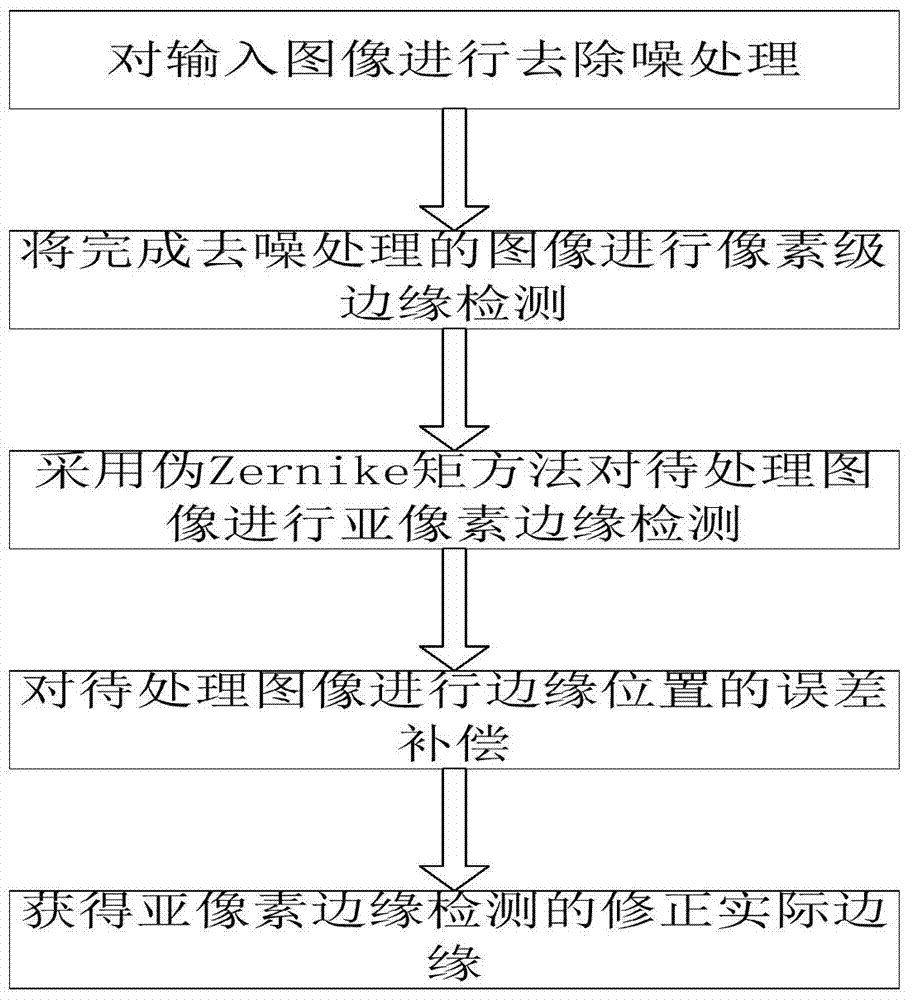

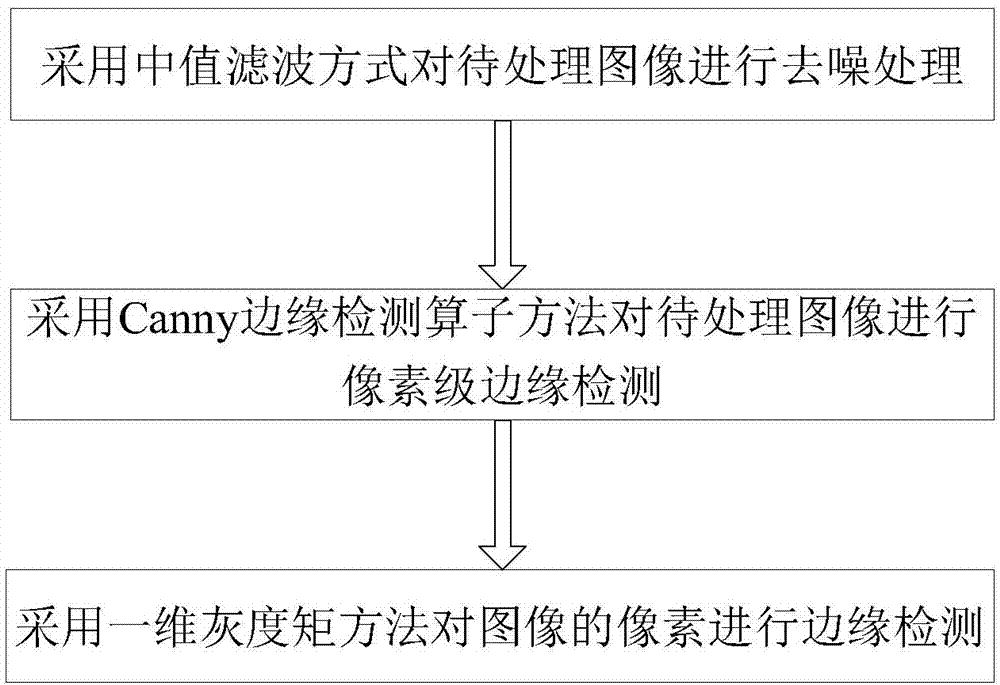

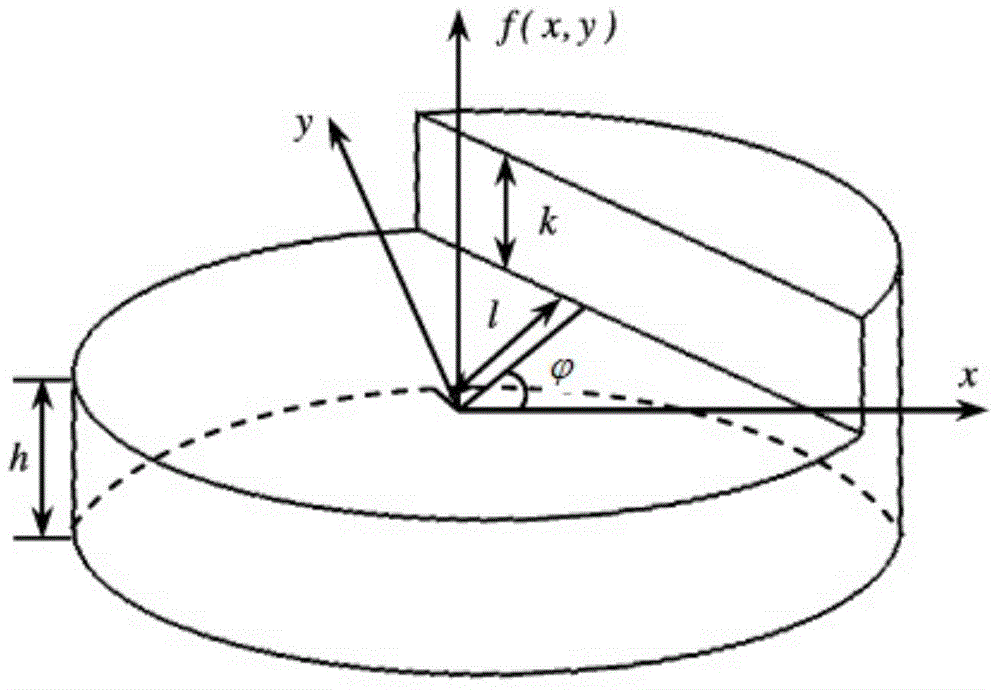

Method for sub-pixel edge detection based on pseudo Zernike moments

ActiveCN104715487AHigh precisionReduce computational complexityImage analysisComputation complexityNoise removal

The invention discloses a method for sub-pixel edge detection based on pseudo Zernike moments. The method is characterized by comprising the following steps: 1, performing noise removal on an input image; 2, performing pixel-level edge detection on the image after noise removal; 3, performing sub-pixel edge detection on a to-be-processed image by adopting a pseudo Zernike moment method; 4, performing error compensation of edge positions on the to-be-processed image; and 5, obtaining a corrected actual edge after the sub-pixel edge detection, and processing all pixels of the to-be-processed image according to the manner of the step 4 to finish the sub-pixel edge detection of the image. The method provided by the invention is insensitive to noise, so that the accuracy of a sub-pixel edge is improved, and the computational complexity required by edge detection is reduced.

Owner:DALIAN UNIV OF TECH

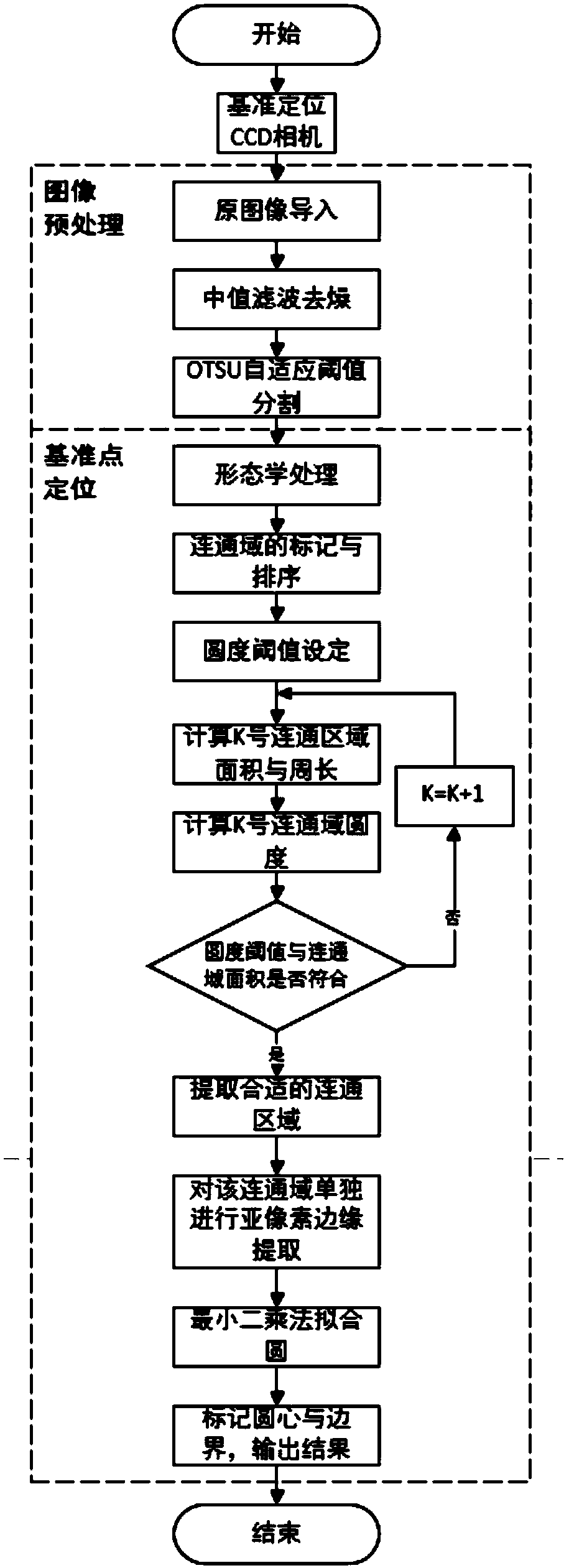

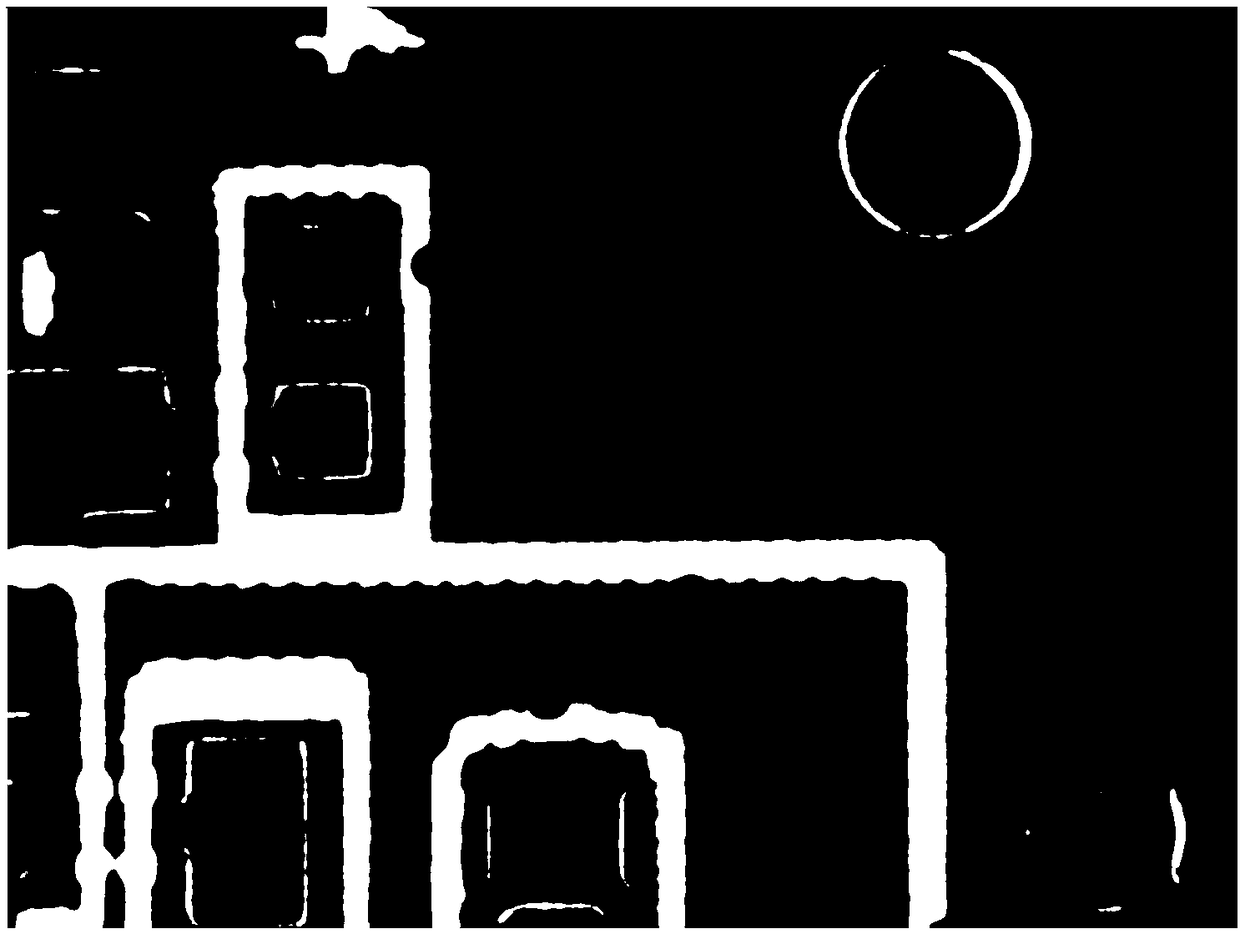

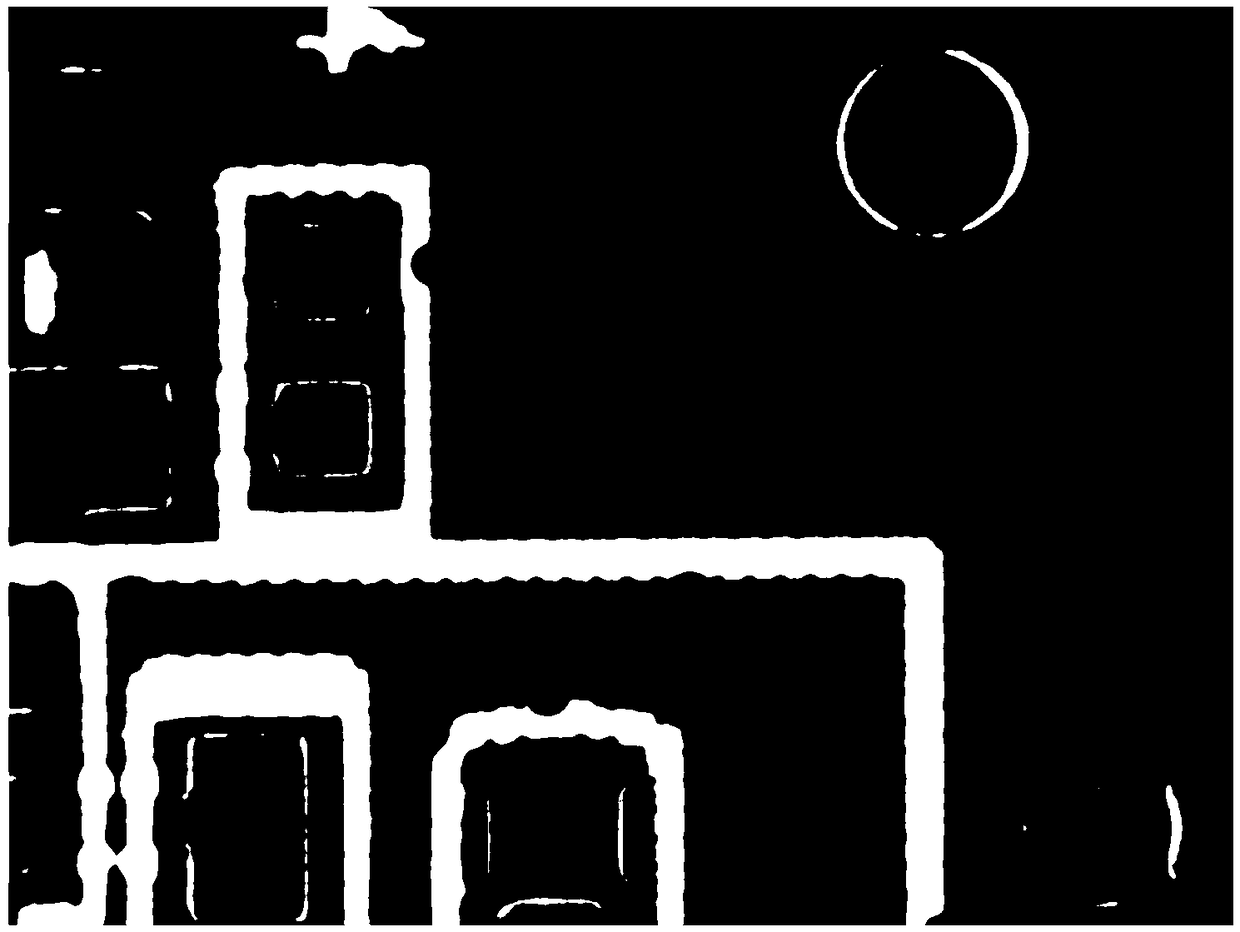

Sub-pixel-level PCB board defect reference point detection method

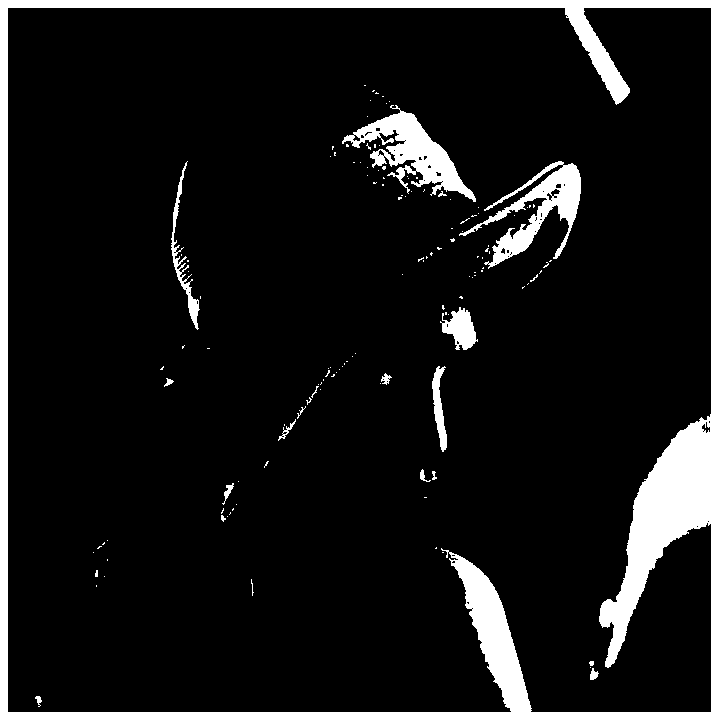

InactiveCN108830838AAvoid interferencePrecise positioningImage enhancementImage analysisLow speedImaging Feature

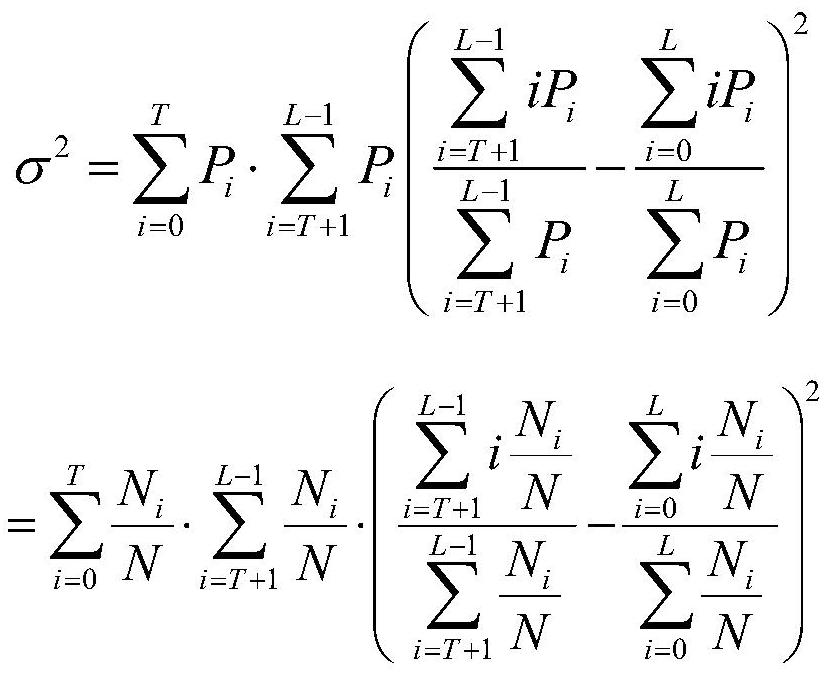

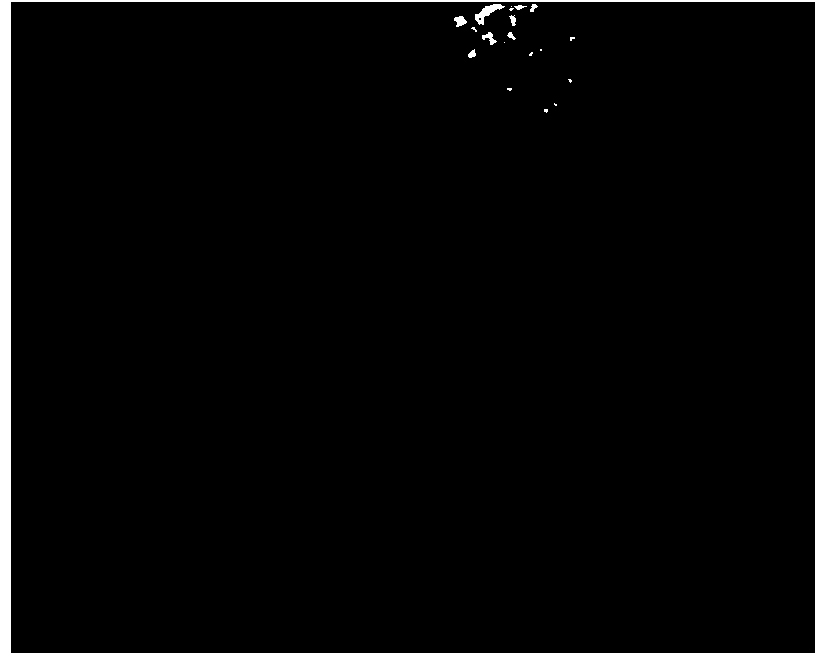

The invention provides a sub-pixel-level PCB board defect reference point detection method. The method comprises the following steps: reading in a PCB grayscale image 1; preprocessing the PCB image, wherein self-adaptive median filtering denoising is used to remove pepper-and-salt-type noises to obtain a denoised image 2, a method of maximum inter-class variance is used to carry out binary segmentation of the image to obtain a binarized image 3, and a mathematical morphology method is used to process the image to further remove small interference points and holes to obtain an image 4; using acommunicate-domain algorithm to obtain a position and a scale of a preprocessed image feature region; and then enabling reference circle extraction and positioning efficiency and precision to be improved through a sub-pixel edge detection algorithm and fitting of a least square method. Requirements of high-precision reference point extraction and positioning are effectively satisfied, defects of low precision and low speed of previous reference point positioning are overcome, and the method has the characteristics of high applicability and high accuracy.

Owner:JIANGSU UNIV

Sub-pixel edge detection method based on improved morphology

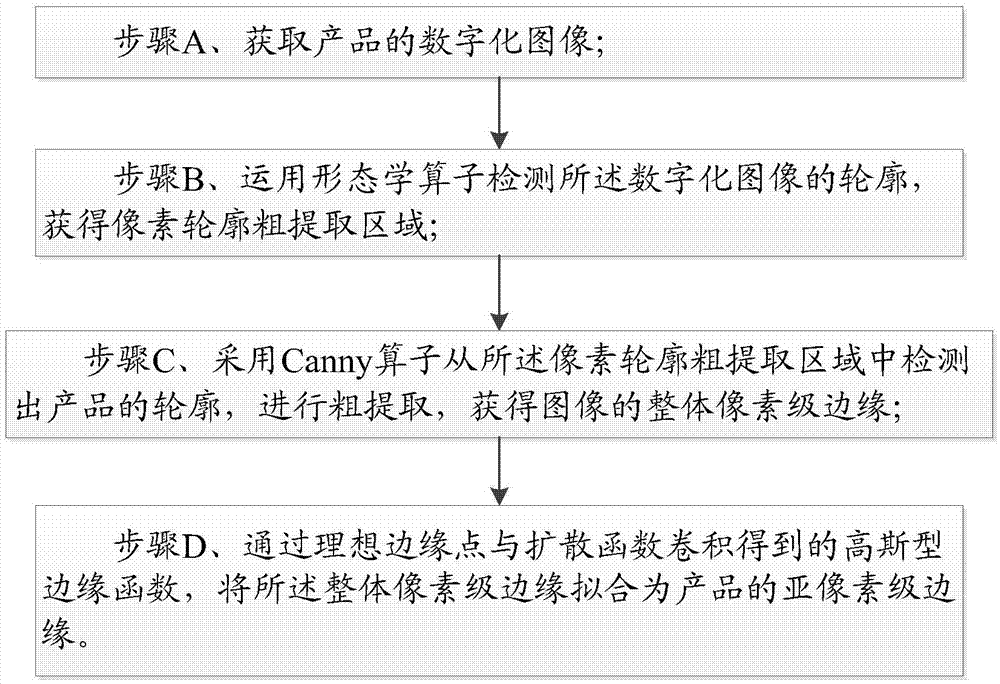

InactiveCN104732536ASmooth Outline EdgesAccurate detectionImage analysisDiffusion functionImage edge

The invention provides a sub-pixel edge detection method based on improved morphology. The method comprises the steps that a digitized image of a product is obtained; morphology operators are applied for detecting the outline of the digitized image to obtain a pixel outline rough extraction region; Canny operators are adopted for detecting the whole pixel-level edge of the product from the pixel outline rough extraction region; by means of Gaussian edge functions obtained through ideal edge points and diffusion function convolution, the whole pixel-level edge is fitted into a sub-pixel-level edge of the product. According to the method, the edge detection operators of the morphology are improved, the edge of the image outline can be smoothed, edge details are kept better, anti-noise performance is improved, image edge information is kept, the smoothness and the continuity of the edge are kept, the image edge can be detected accurately, the connectivity of an original image is ensured, an image edge extraction region is reduced, and the processing speed is increased.

Owner:GUANGDONG XIAN JIAOTONG UNIV ACADEMY +1

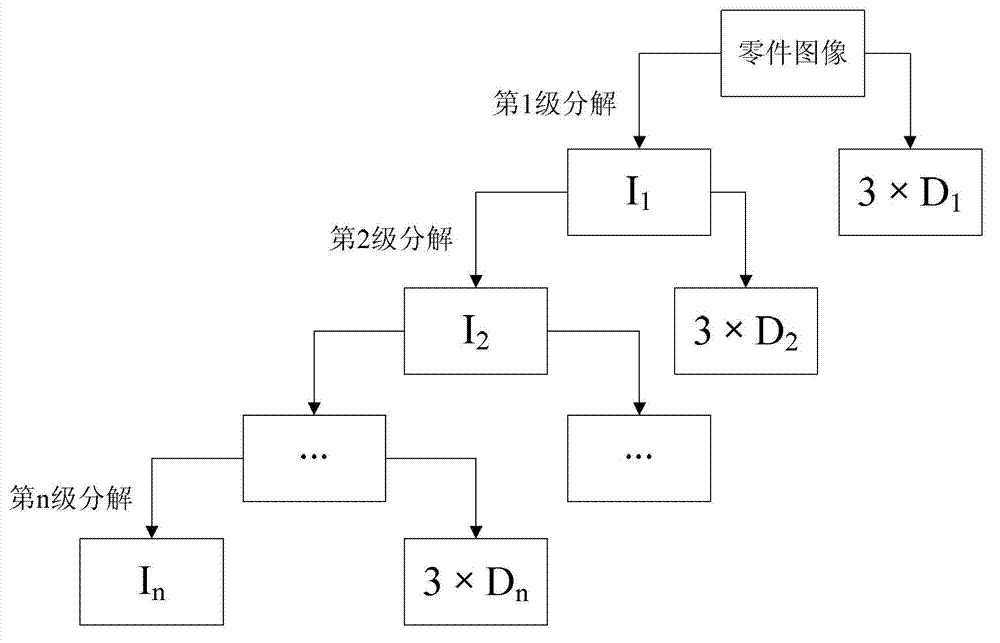

Method for detecting component size based on matching pursuit (MP) wavelet filtering and detecting system thereof

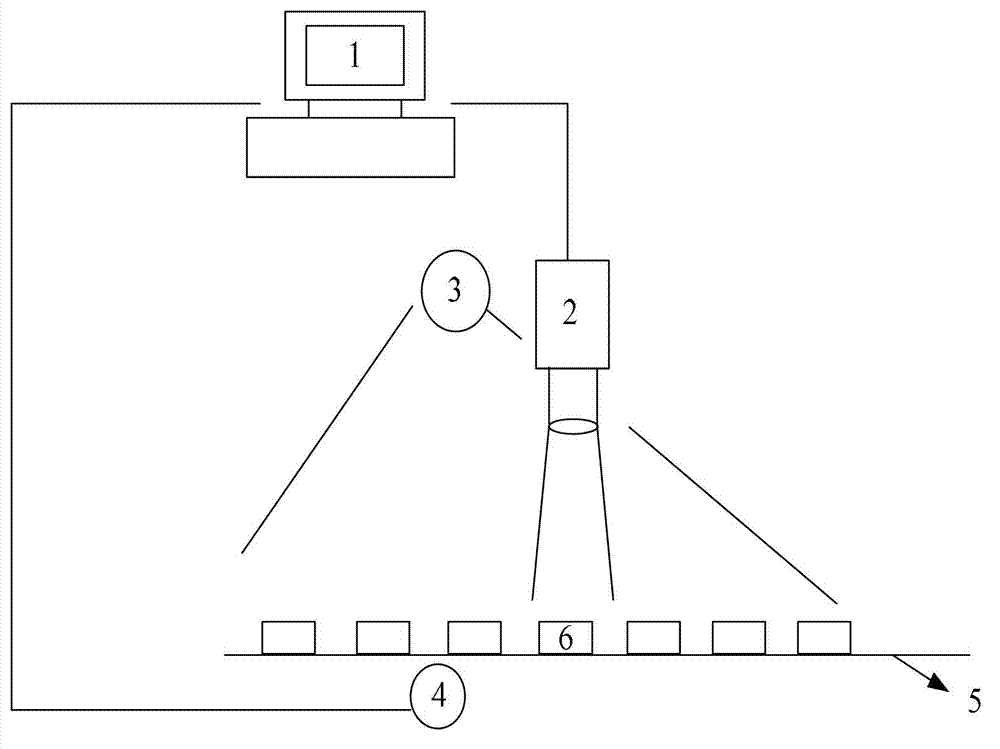

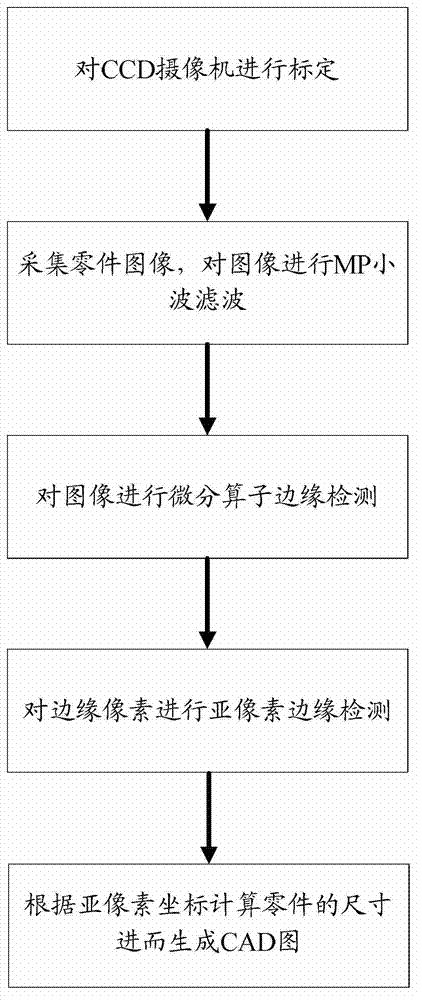

InactiveCN102901444AGuaranteed real-timeGuaranteed fully automaticUsing optical meansSpecial data processing applicationsMatching pursuitCharge couple device

The invention discloses a method for detecting component size based on matching pursuit (MP) wavelet filtering. The method comprises the steps of (1), calibrating a charge coupled device (CCD) camera; (2), acquiring a component image and performing MP wavelet filtering on an image; (3), performing differential operator edge detection on the image; (4) performing sub-pixel edge detection on an edge pixel; and (5) calculating the size of the component according to a sub-pixel coordinate to generate computer-aided design (CAD) graph. According to the method, the image of the component is subjected to the MP wavelet filtering, the filtered image is subjected to the sub-pixel edge detection, and the size of the component is calculated and extracted according to the sub-pixel coordinate, so that the detection accuracy can be correspondingly improved, and the detection speed is quickened. The invention discloses a detecting system based on the detecting method. The system comprises an image acquisition unit, an image processing unit and an image generating unit. Because the camera is combined with a personal computer (PC), image acquisition and image processing on components on the production line can be realized, so that the timeliness for detecting the components is guaranteed.

Owner:ZHEJIANG UNIV

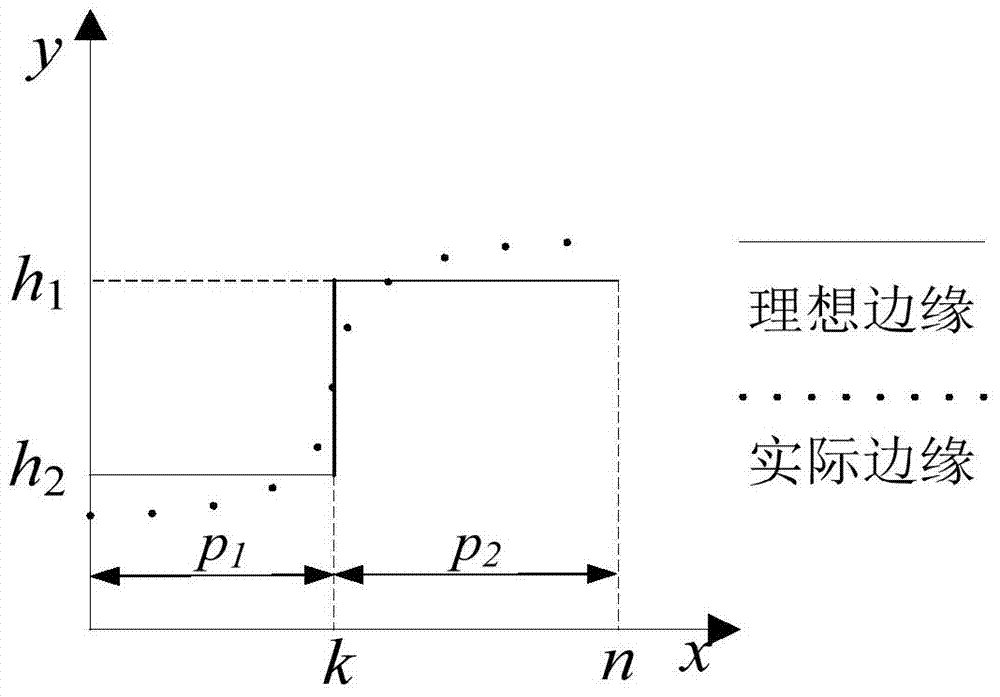

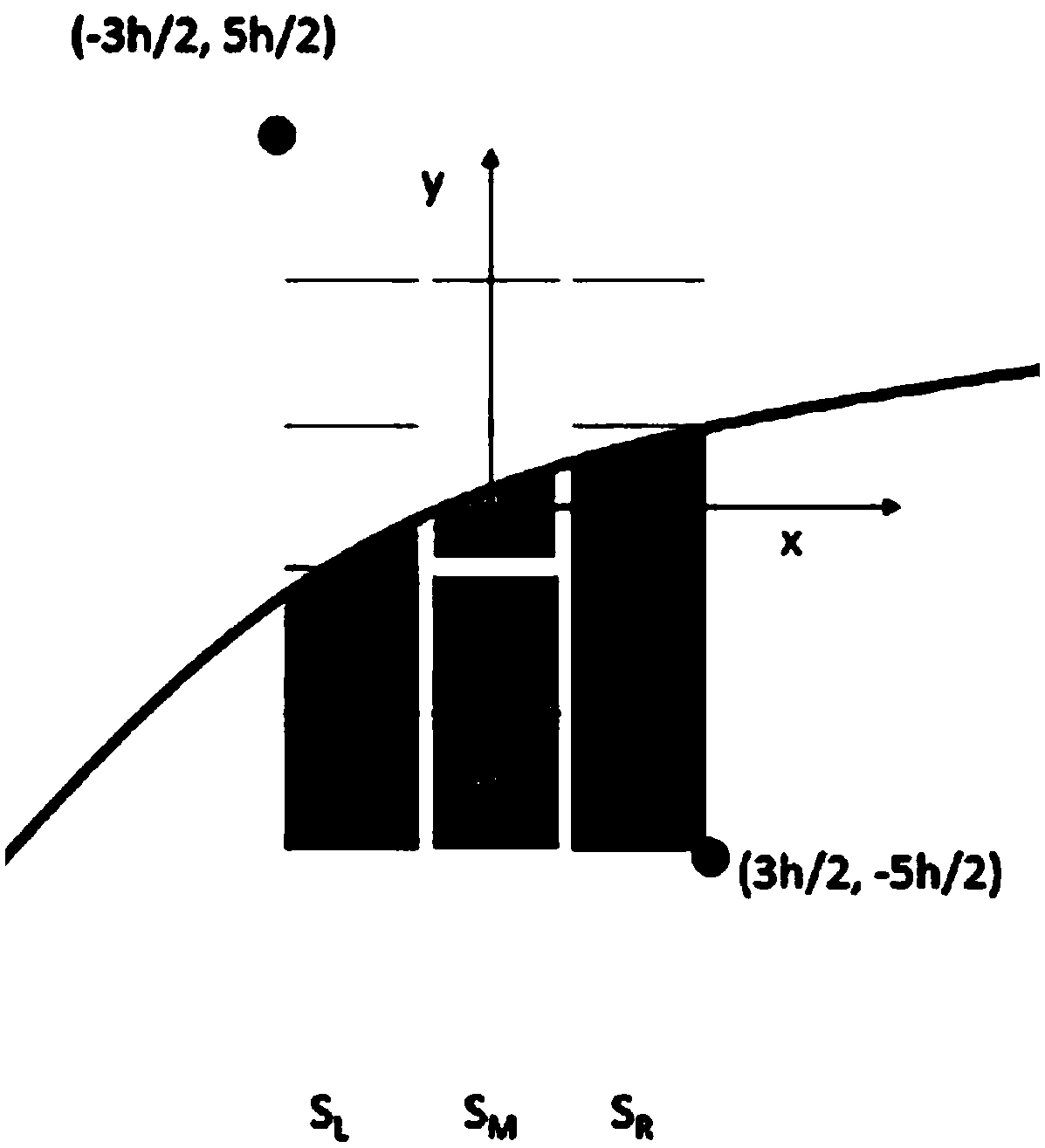

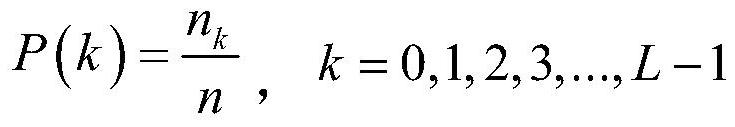

Subpixel edge detection method based on one-dimensional gray moment

The invention discloses a subpixel edge detection method based on one-dimensional gray moment, which comprises the following steps: S1, carrying out denoising on a to-be-processed image in a median filtering mode; S2, carrying out pixel-level edge detection on the to-be-processed image by using a Canny edge detection operator method; and S3, carrying out edge detection on the pixel of the image by using a one-dimensional gray moment method so as to complete the subpixel edge detection of the image. The method disclosed by the invention is implemented by carrying out One-dimensional gray moment by using a median filter firstly, then carrying out pixel-level edge detection by using a Canny operator, and then carrying out pixel edge detection by using a one-dimensional gray moment in the Cartesian coordinates of a spatial domain.

Owner:DALIAN UNIV OF TECH

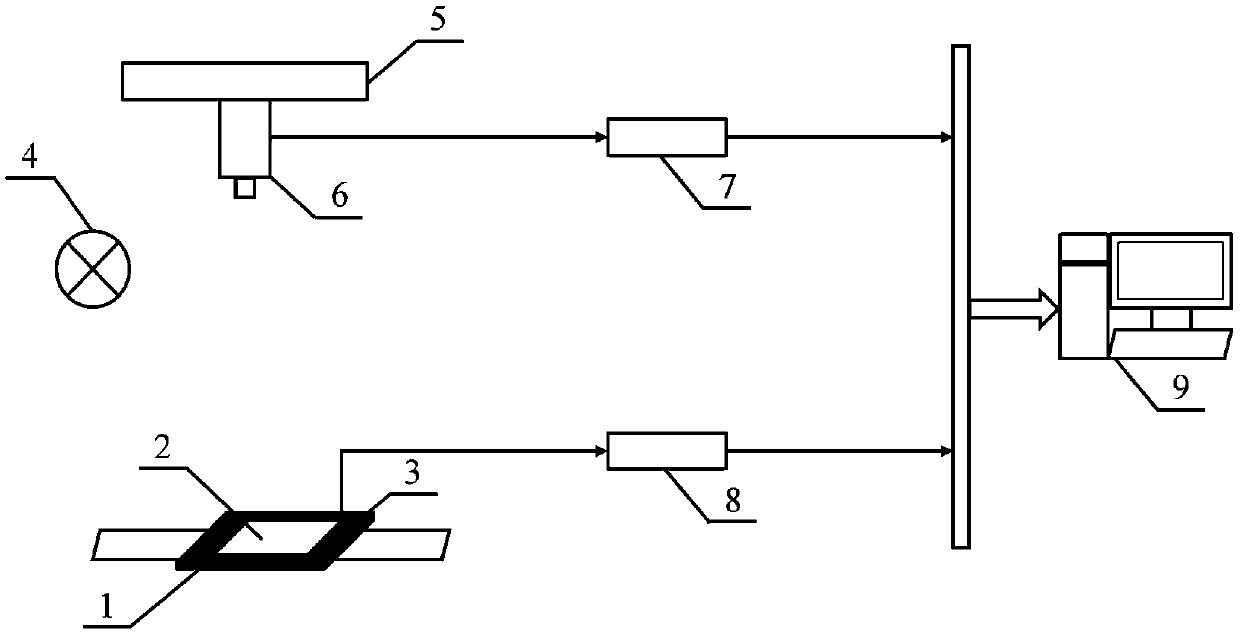

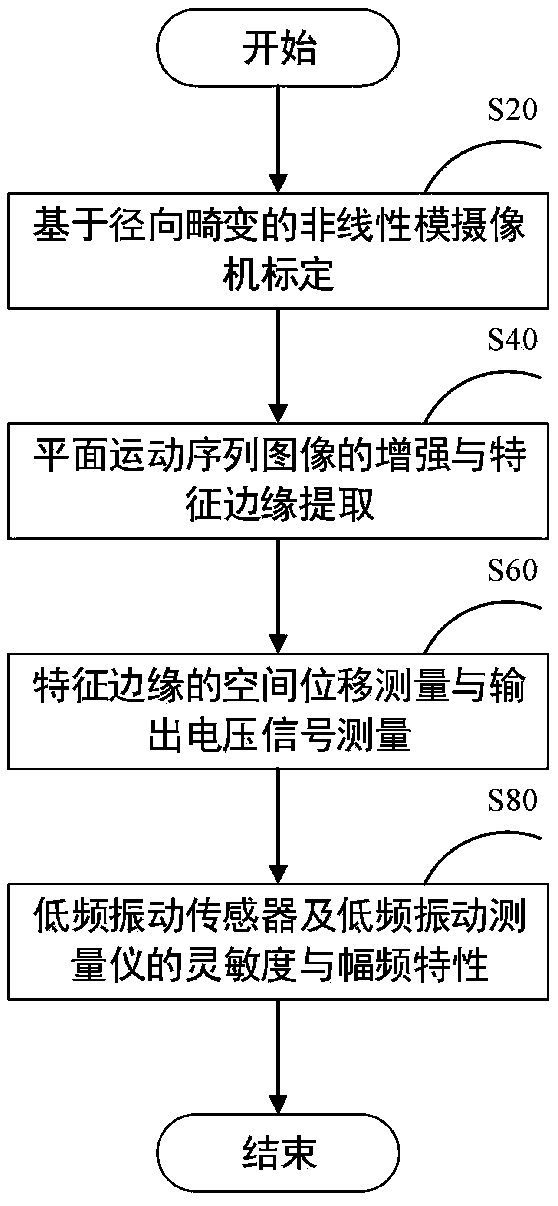

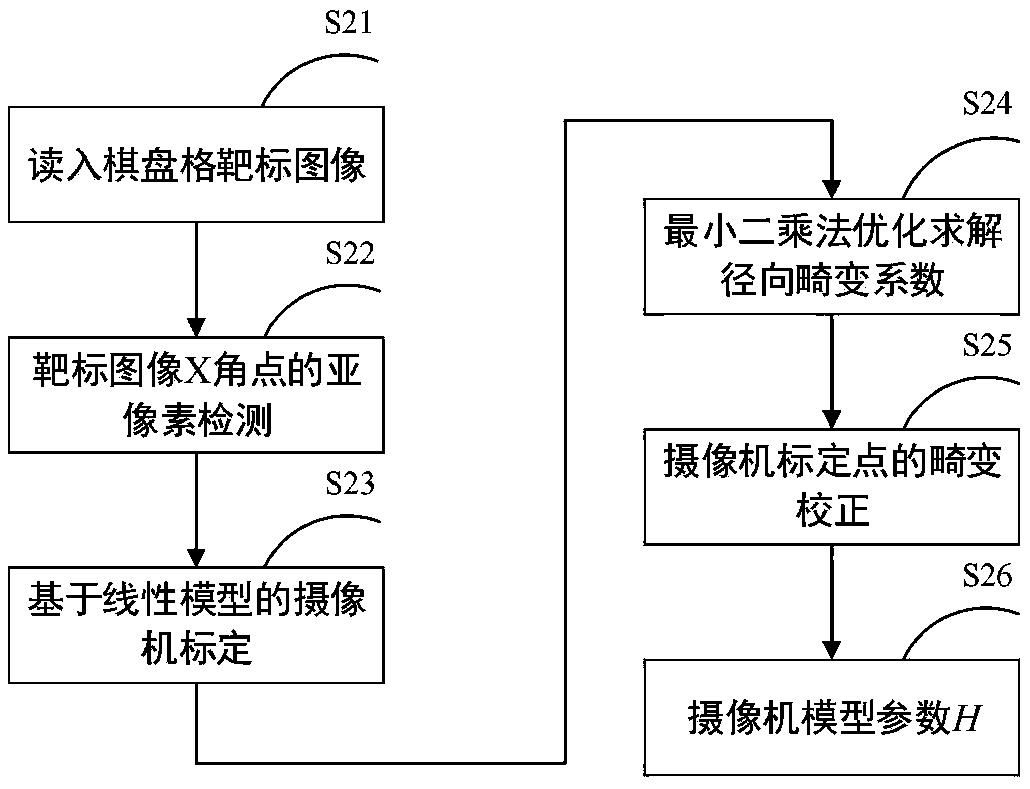

Low-frequency vibration calibration method based on monocular vision

ActiveCN109632085AMethod stableReliable methodSubsonic/sonic/ultrasonic wave measurementGeological measurementsMeasuring instrumentEdge extraction

The invention discloses a low-frequency vibration calibration method based on monocular vision. The method comprises the following steps that: utilizing a nonlinear camera model with radial distortionto realize high-accuracy camera calibration; putting forward an effective image enhancement method to realize the enhancement of blurred images of different motion directions to guarantee the position accuracy of an enhanced edge; then, on the basis of a sub pixel edge detection method of a Zernike moment, realizing the high-accuracy characteristic edge extraction of an enhanced sequence image; on the basis of a vision measurement model, measuring the spatial motion displacement of the characteristic edge; and utilizing the output voltage signals, which are synchronously collected, of a low-frequency vibration sensor and a low-frequency vibration measuring instrument to realize low-frequency vibration calibration. By use of the method, on a premise that calibration accuracy is effectivelyguaranteed, low-frequency vibration calibration can be stably, reliably and quickly realized. By use of the method, the deficiencies that an existing low-frequency vibration calibration method is limited in calibration accuracy, complex in process and complex in system for the low-frequency vibration sensor and the measuring instrument and is not suitable for wide-frequency range calibration areeliminated.

Owner:NAT INST OF METROLOGY CHINA +1

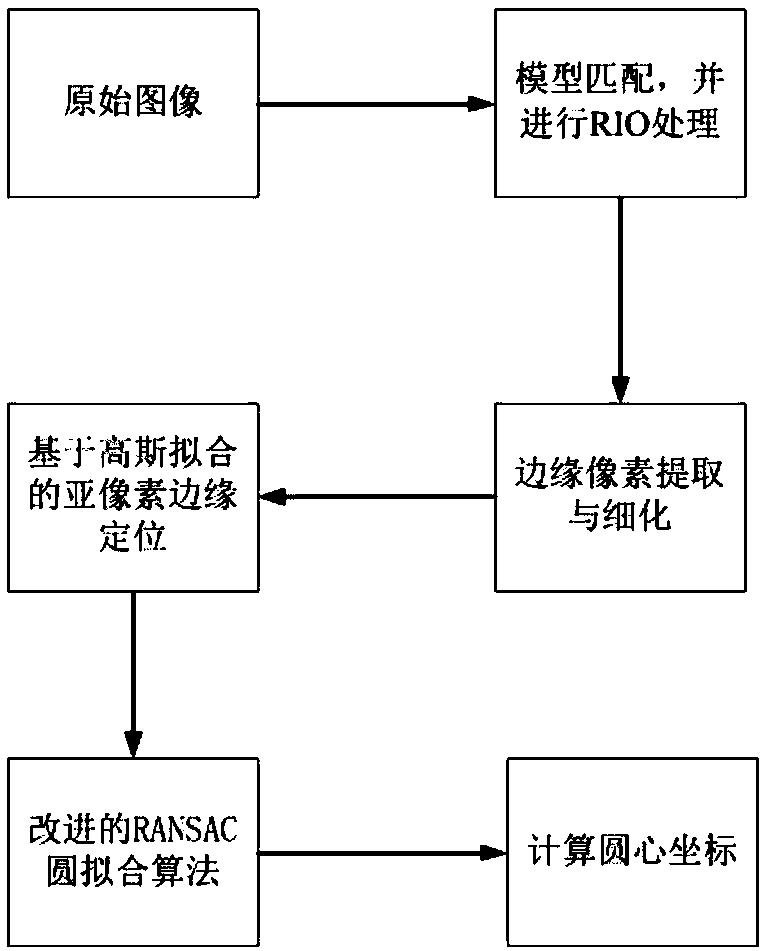

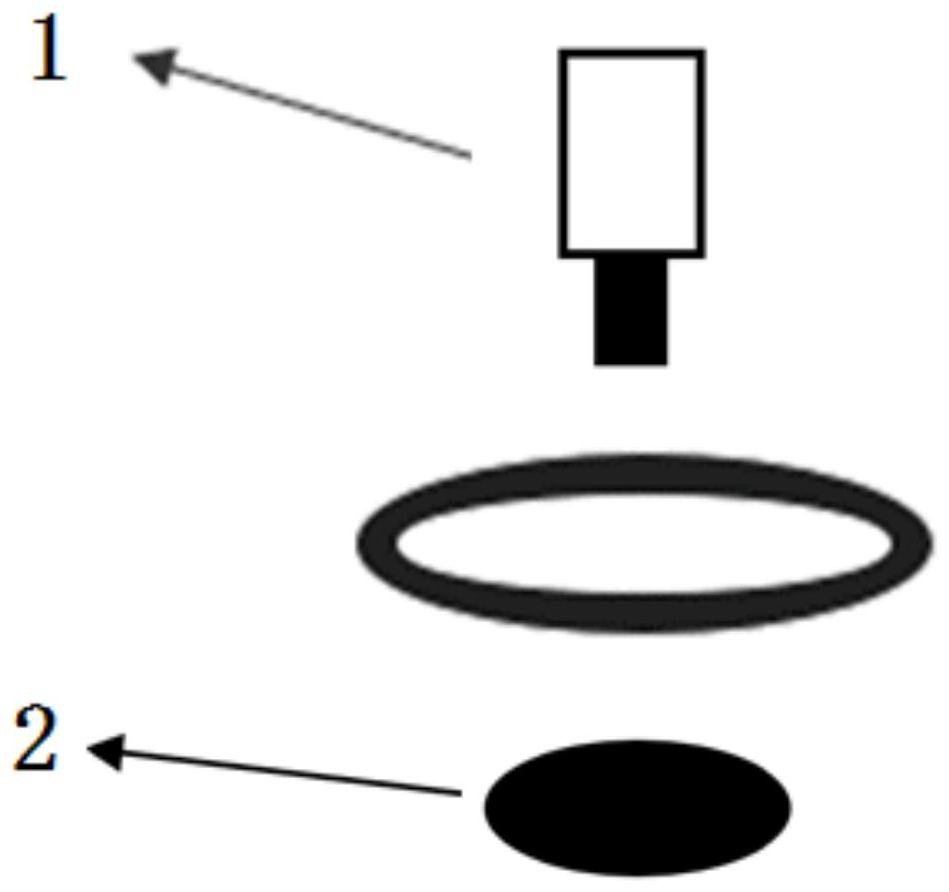

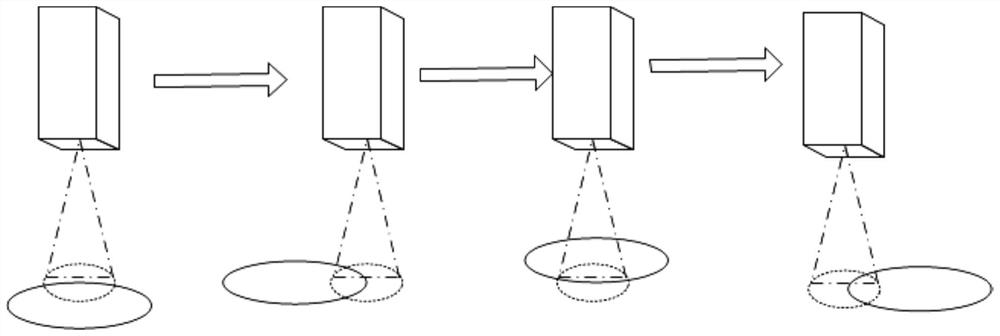

Circular center detection method based on Gaussian fitting sub-pixel edge detection and improved RANSAC algorithm

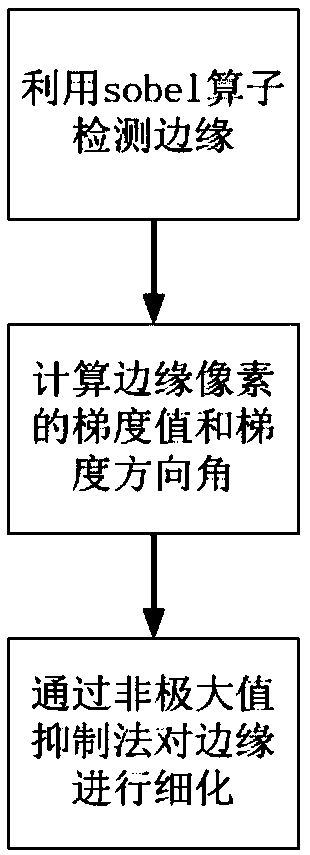

InactiveCN108986126AImprove accuracyImprove stabilityImage enhancementImage analysisImaging processingThinning

The invention provides a circular center detection method based on Gaussian fitting sub-pixel edge detection and an improved RANSAC algorithm, belonging to the field of aircraft ground simulation. Themethod comprises the follow concrete steps: an original image is matched by a model and RIO processing is conducted on the image; edge pixel extraction and thinning is carried out; sub-pixel edge location based on Gaussian fitting is carried out; an improved RANSAC circle fitting algorithm is provided; the coordinates of the center of a circle are calculated. The invention roughly locates the position of the circular marker through a model matching mode, and performs RIO processing to reduce the size of image processing. Gaussian fitting improves the accuracy and stability of the algorithm. The improved RACNAC algorithm reduces the sampling times, optimizes and screens the candidate circles, reduces the running time and improves the accuracy and stability.

Owner:HARBIN INST OF TECH

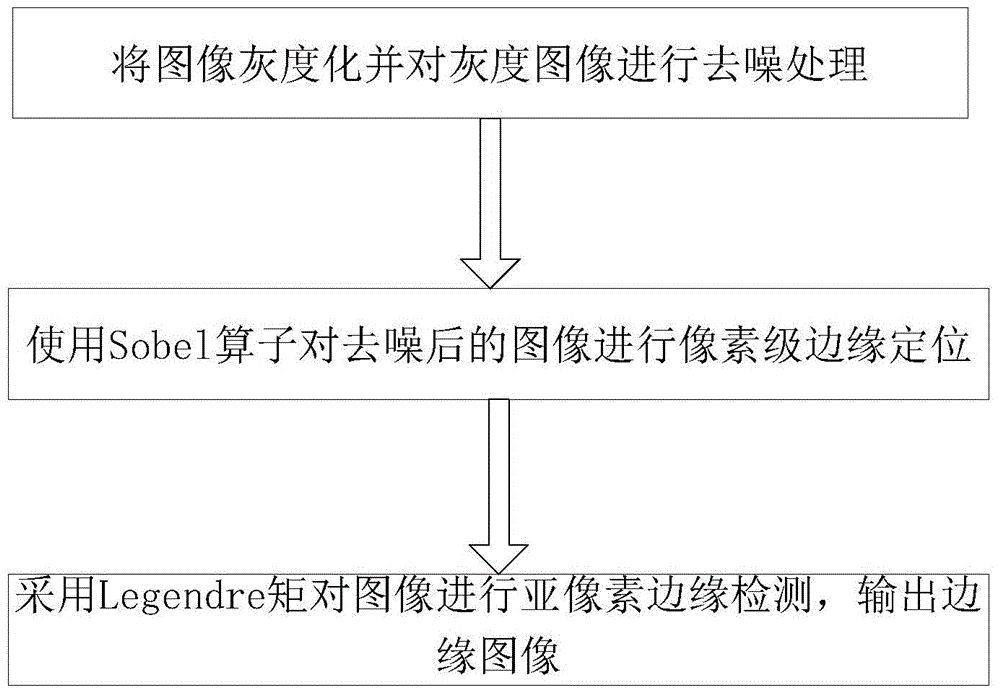

Legemdre moment-based image subpixel edge detection method

ActiveCN104899888AReduce in quantityAccurate Edge Orientation InformationImage analysisDirection informationGrayscale

The invention discloses a Legendre moment-based image subpixel edge detection method. The method includes the steps of: S1. reading image information, graying an image and performing de-noising processing on the grayscale image; S2. adopting a Sobel operator to perform pixel-level edge positioning on the de-noised image: using a phenomenon that a weighted value of an adjacent point of a pixel points reaches a maximum value at an edge point to perform edge detection; and S3. adopting Legendre moment to perform subpixel edge detection on the image, and outputting an edge image. The Sobel operator has a smoothing effect on noise, thereby providing relatively accurate edge direction information, the Legendre moment is used to perform subpixel edge detection, the number of templates required by operations is reduced, the complexity of calculation is lowered, and better robustness is achieved in noise-proof performance at the same time.

Owner:DALIAN UNIV OF TECH

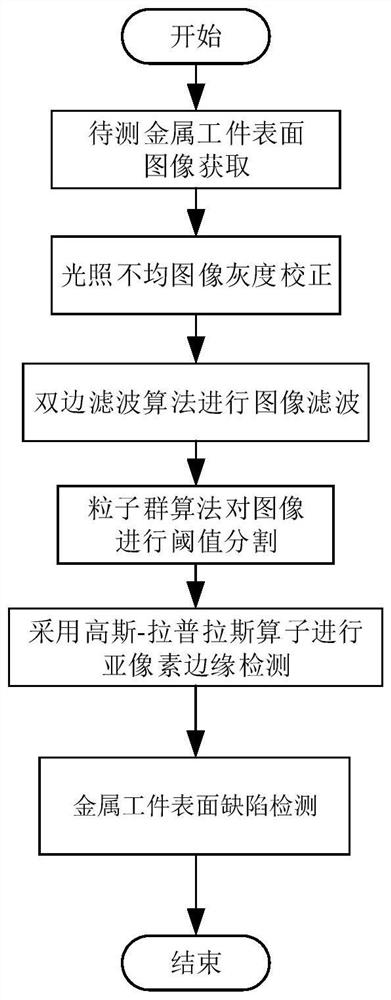

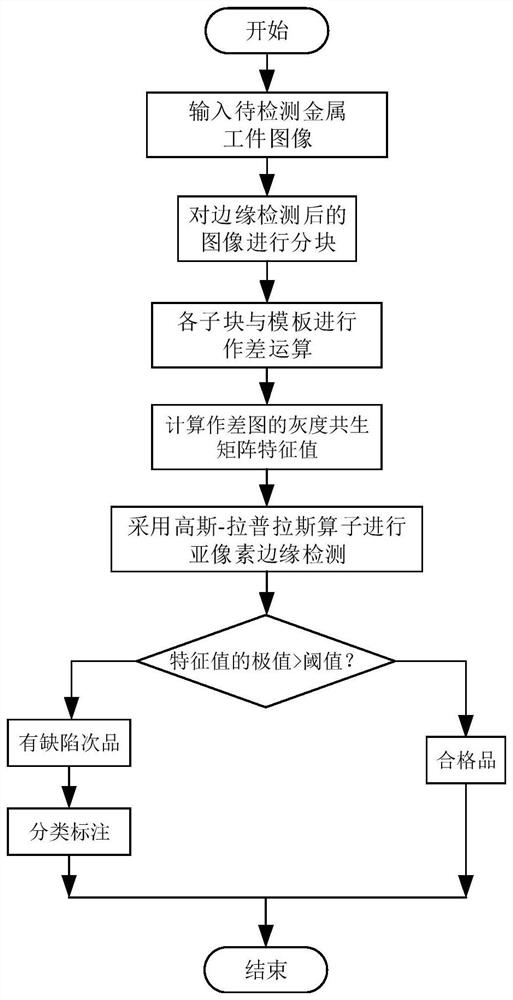

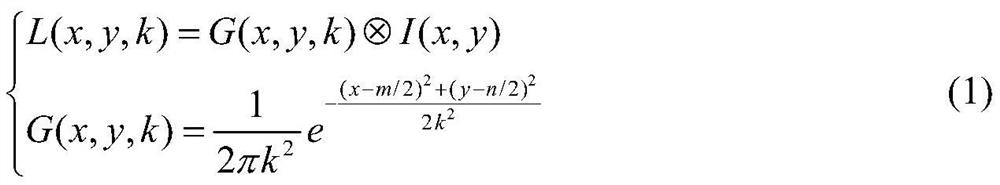

Metal workpiece surface defect image detection method

InactiveCN112330628AImprove defect detection accuracyPromote the development of visual automatic inspection technologyImage enhancementImage analysisFeature extractionMachine vision

The invention discloses a metal workpiece surface defect image detection method. The method comprises the steps of: firstly, collecting a surface image of a metal workpiece through professional imaging equipment, and then enabling the collected image to be subjected to image early-stage preprocessing including the steps of uneven illumination image gray scale correction, image filtering, image threshold segmentation and the like; further performing feature extraction and analysis on the preprocessed image, and introducing a sub-pixel edge detection algorithm to perform edge detection on the metal workpiece; and finally, carrying out template matching on the template image and the measurement image by adopting a gray-level co-occurrence matrix algorithm so as to carry out defect detection on the surface of the metal workpiece. According to the metal workpiece surface defect image detection method provided by the invention, the traditional manual visual inspection is replaced by an automatic detection technology based on machine vision, the production efficiency is improved, the labor cost is reduced, the metal workpiece defect detection precision is improved by adopting a sub-pixeledge detection algorithm, and the production quality is optimized.

Owner:NANTONG SAMER PRECISION EQUIP CO LTD

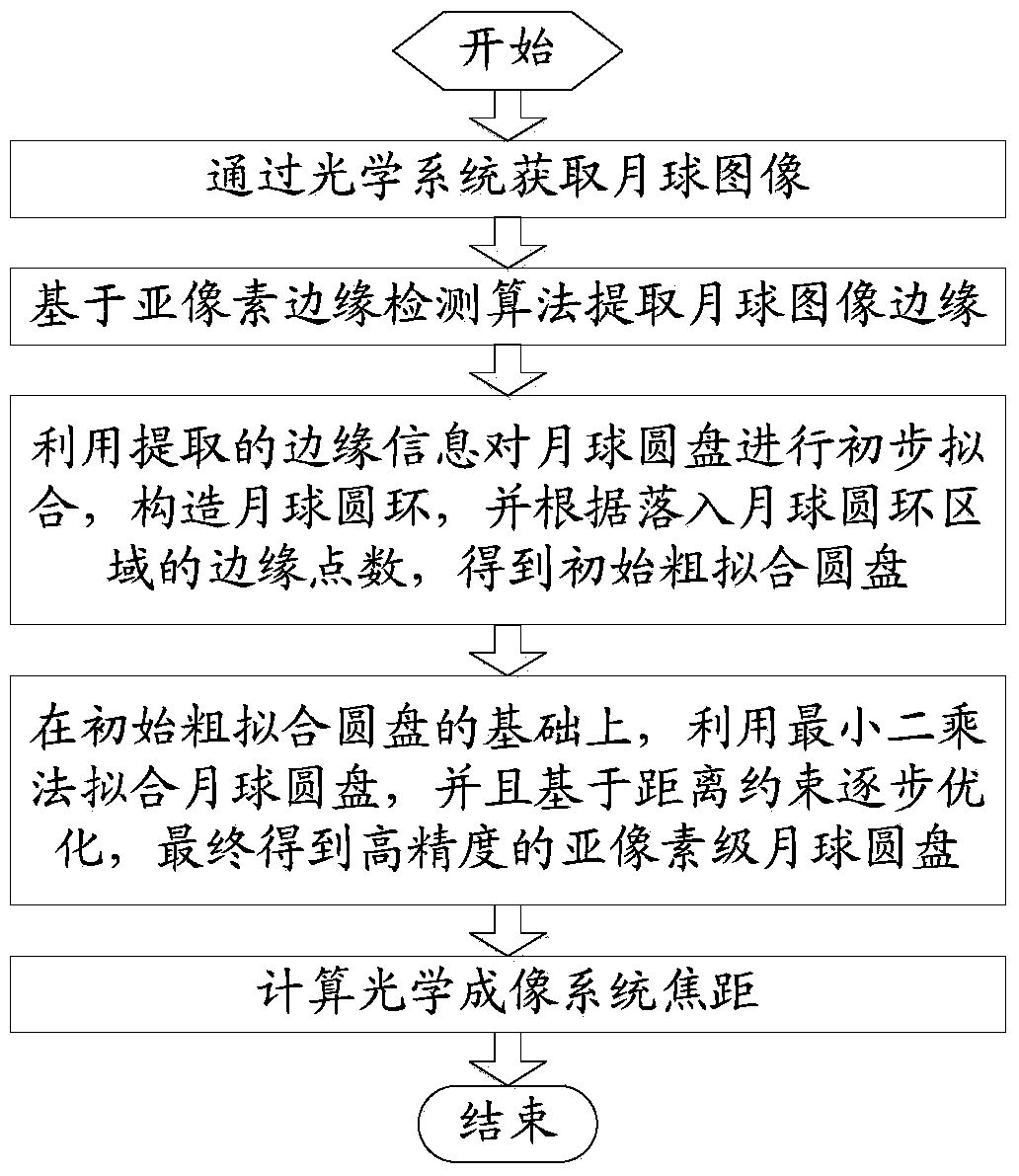

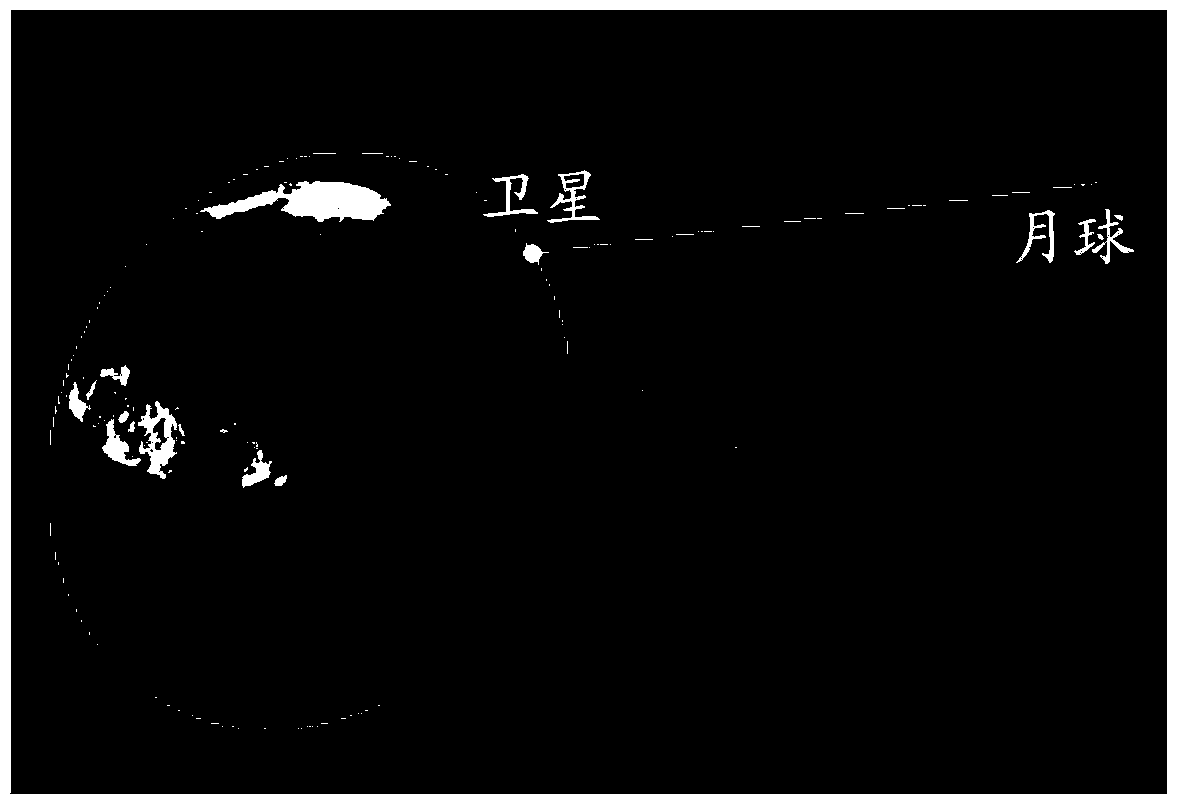

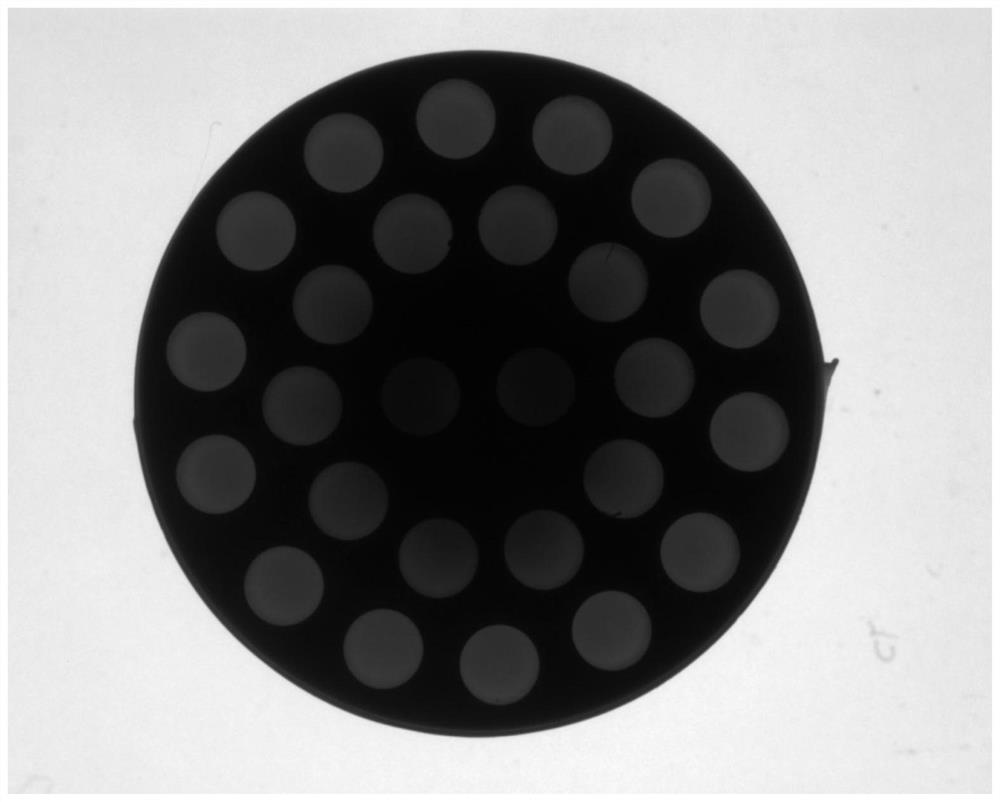

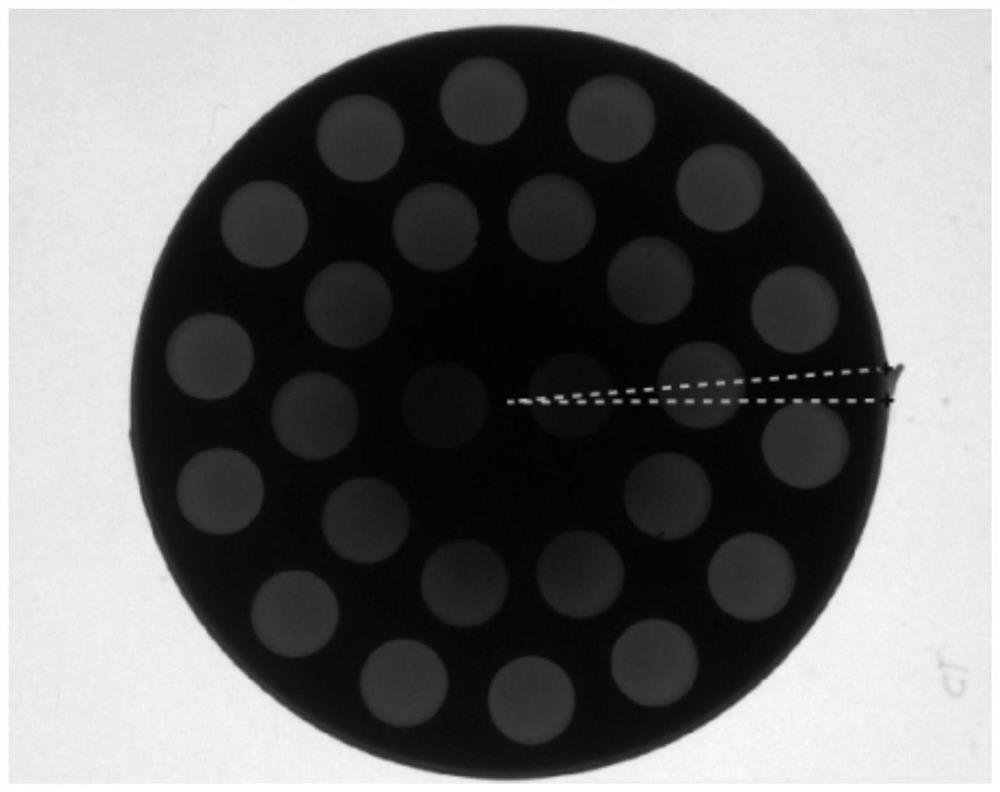

Method for accurate focal length measurement of optical imaging system based on moon imaging

InactiveCN103792069AAchieve high-precision focal length measurementAvoid difficultyTesting optical propertiesMeasurement costMeasurement device

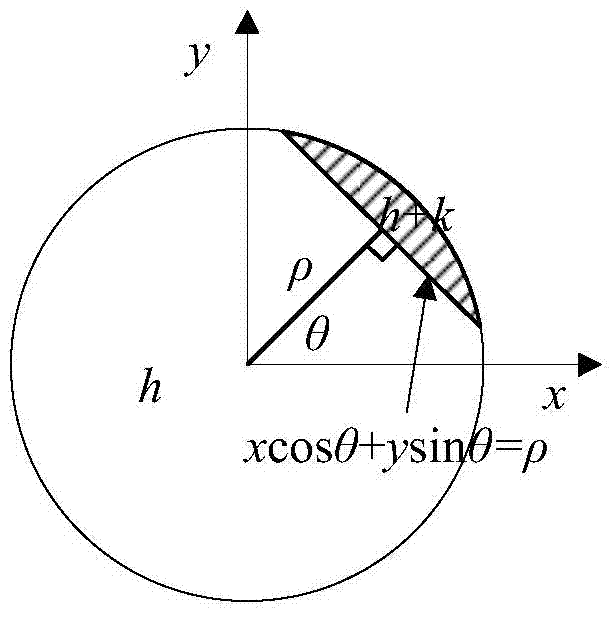

The invention discloses a method for accurate focal length measurement of an optical imaging system based on moon imaging. The method for accurate focal length measurement of the optical imaging system based on moon imaging comprises the steps that a moon image is obtained through the optical imaging system, the edge of the moon image is extracted based on the sub pixel edge detection algorithm, primary fitting is conducted by means of extracted edge information to enable a primary rough fitting disc to be obtained, fitting is conducted on the moon disc with the least square method and progressive optimization is conducted based on distance constraint to enable a high-precision sub-pixel-level moon disc to be obtained, and the focal length of the optical imaging system is calculated by means of the relative position geometrical relationship. Compared with the prior art, the method for accurate focal length measurement of the optical imaging system based on moon imaging has the advantages that the problems that during ground development, the measurement cost of a large-focal-length optical imaging system is high, a measurement device is complicated, the difficulty of focal length measurement of the optical imaging system is high during in-orbit operation, and the precision is limited are solved, the moon is fully used for imaging, the diameter of the moon disc is obtained through sub pixel extraction with the least square method, both a 'full moon' and a 'waning moon' can be used for focal length measurement, and the method is an economical and reliable focal length measurement method for large-focal-length optical imaging systems.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

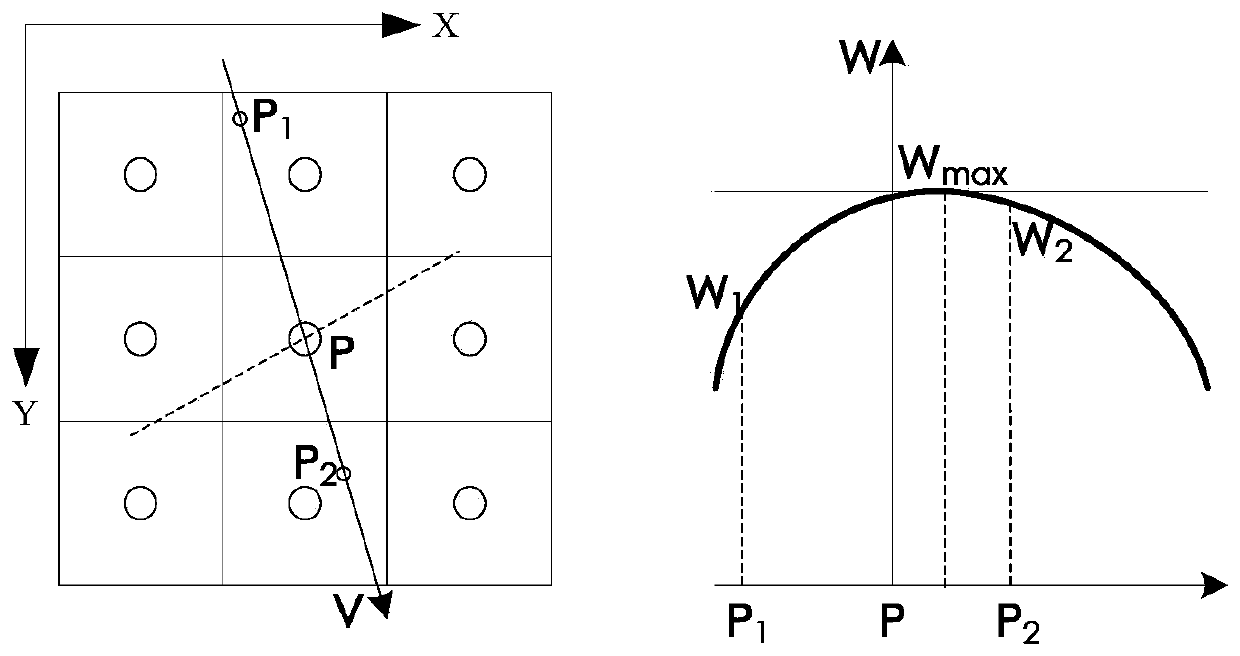

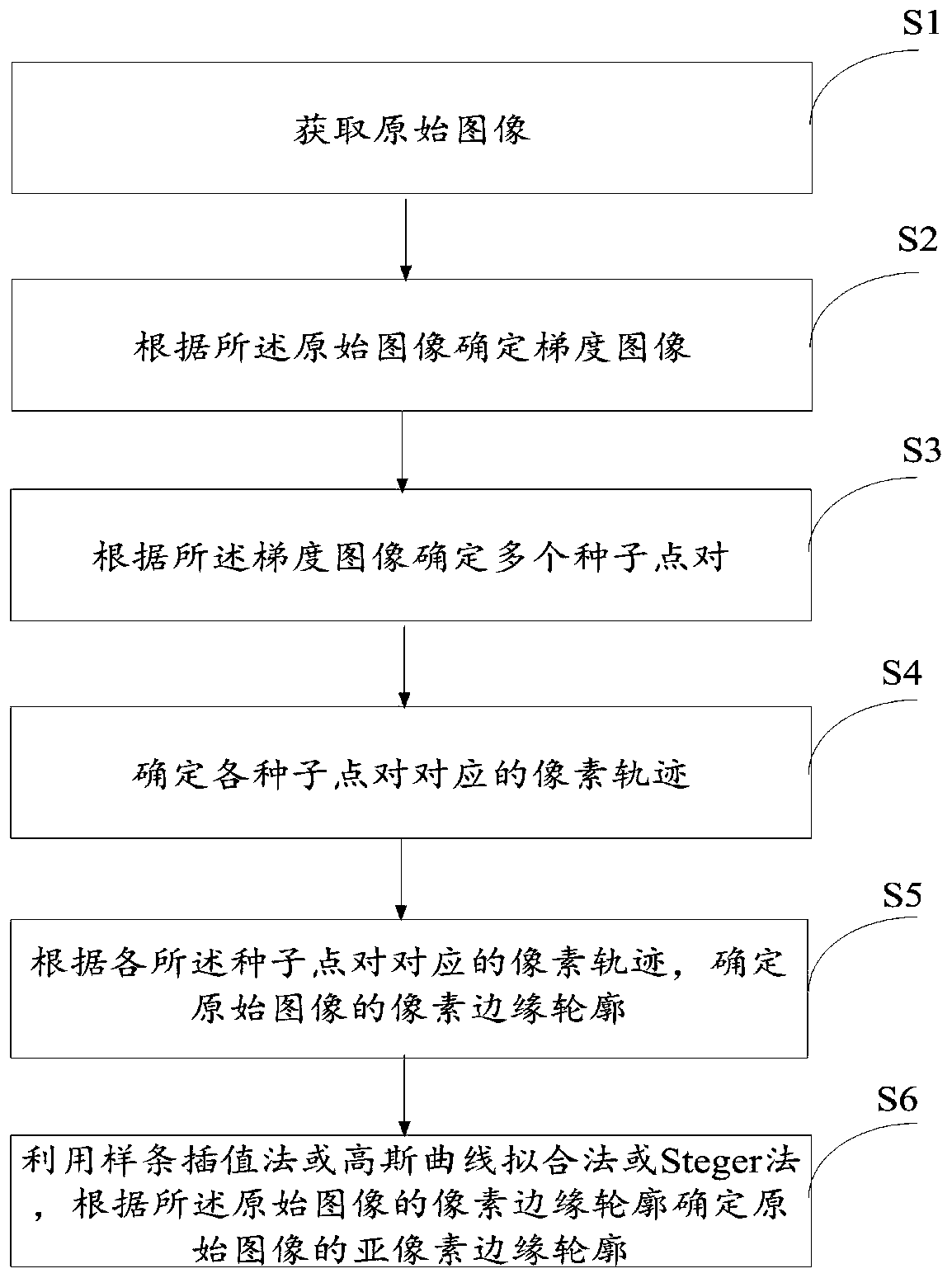

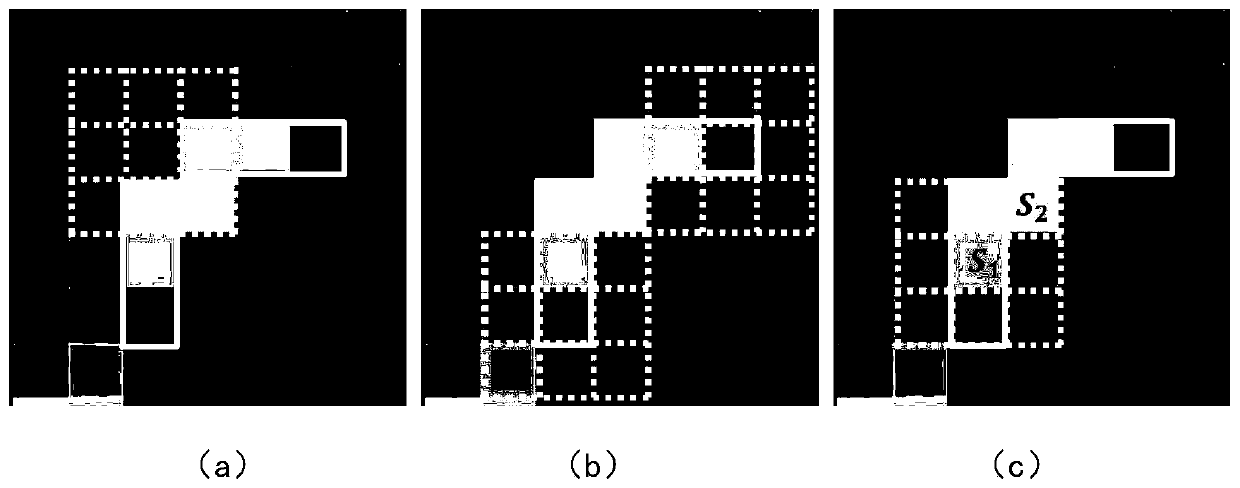

A sub-pixel edge detection method and system

The invention discloses a sub-pixel edge detection method and system. The method comprises the following steps: firstly, determining a gradient image according to an original image, determining a plurality of seed point pairs according to the gradient image, secondly, extracting edges by taking a pixel track corresponding to each seed point pair as a unit, and then determining a pixel edge contourof the original image according to the pixel track corresponding to each seed point pair; and finally, determining the sub-pixel edge contour of the original image according to the pixel edge contourof the original image by utilizing a spline interpolation method or a Gaussian curve fitting method or a Steger method. The contour tracking is realized by adopting a tracking idea, and compared withthe traditional pixel-by-pixel edge contour detection in a sliding window manner, the integrity of the contour is better kept.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

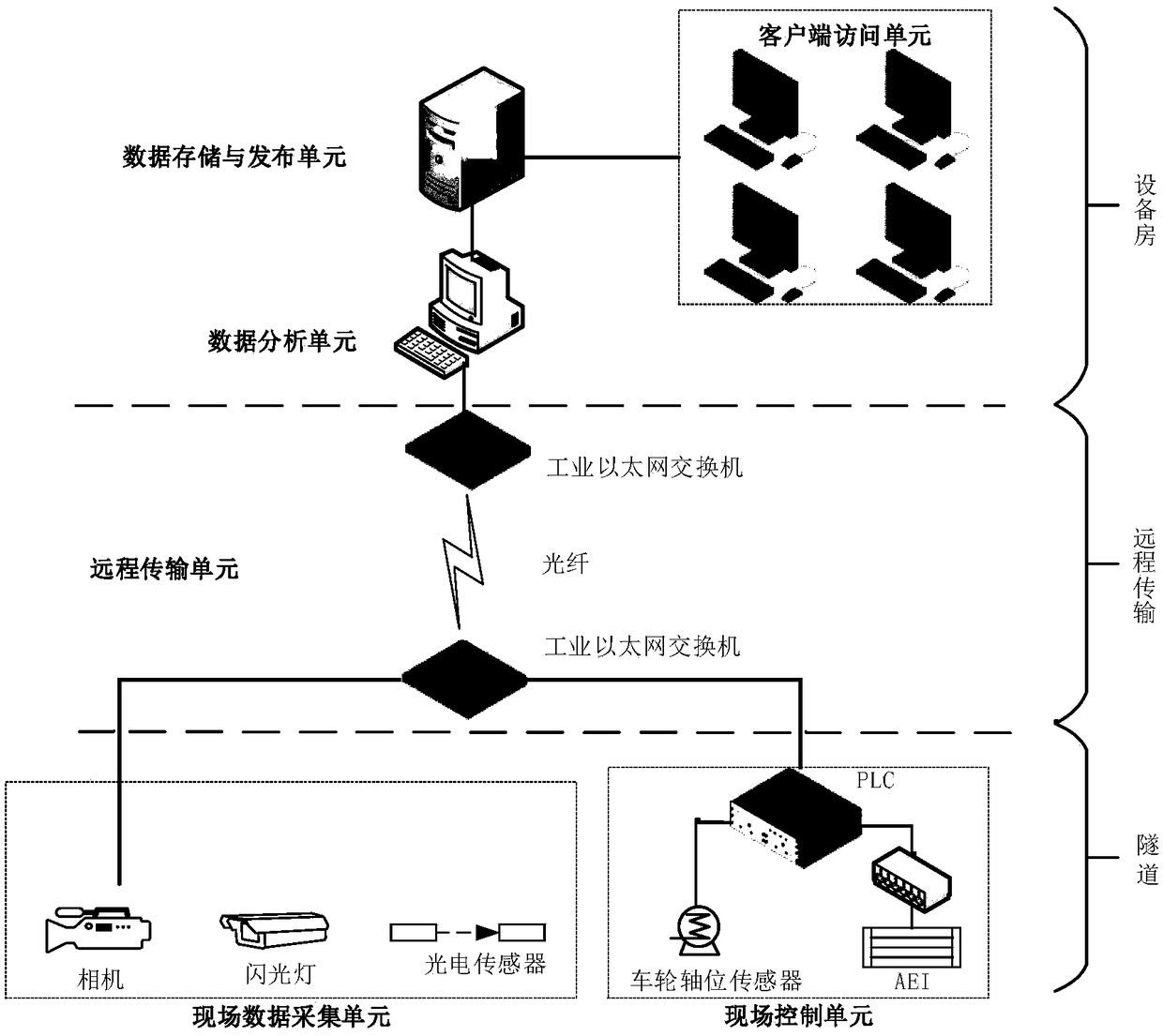

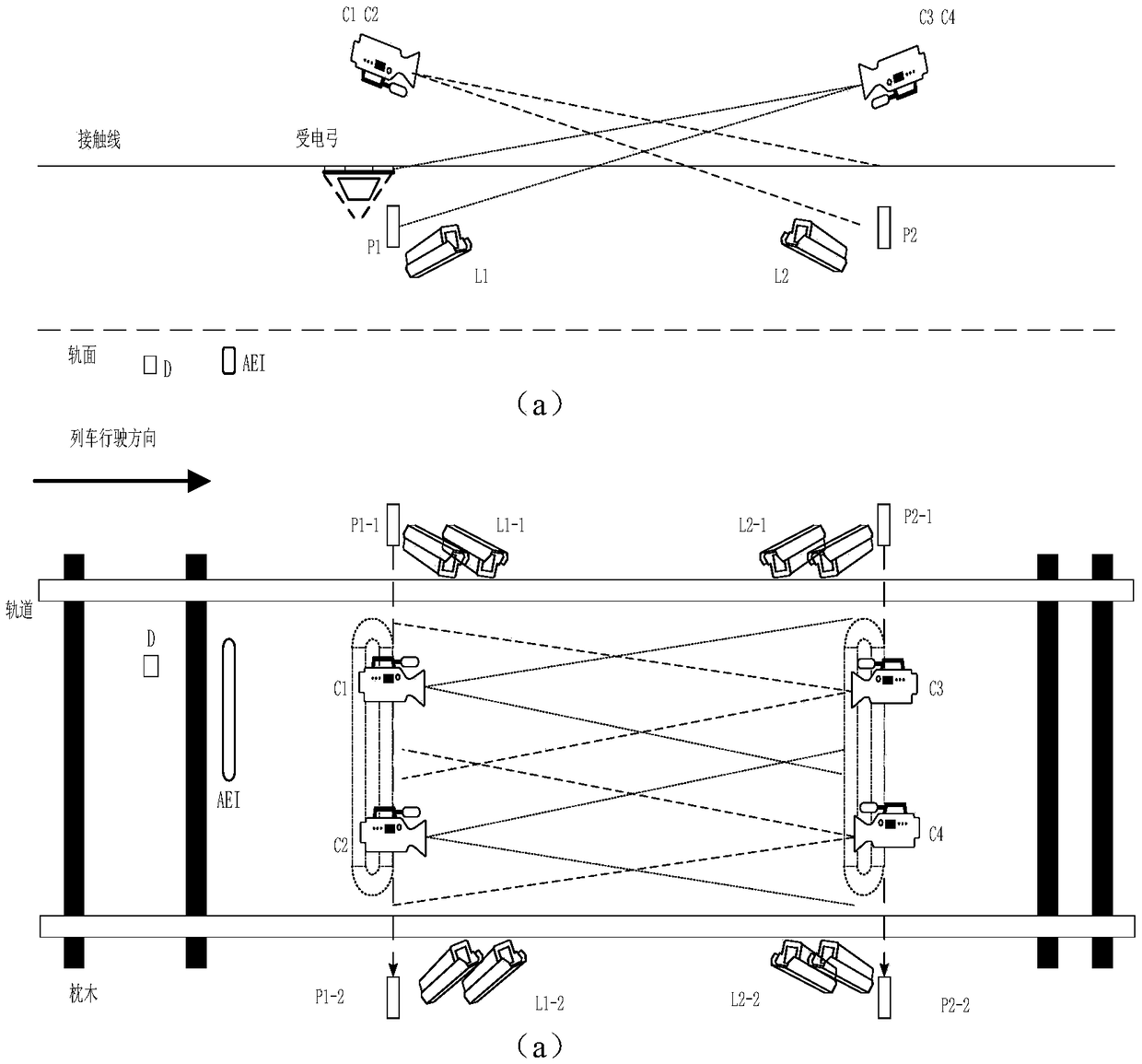

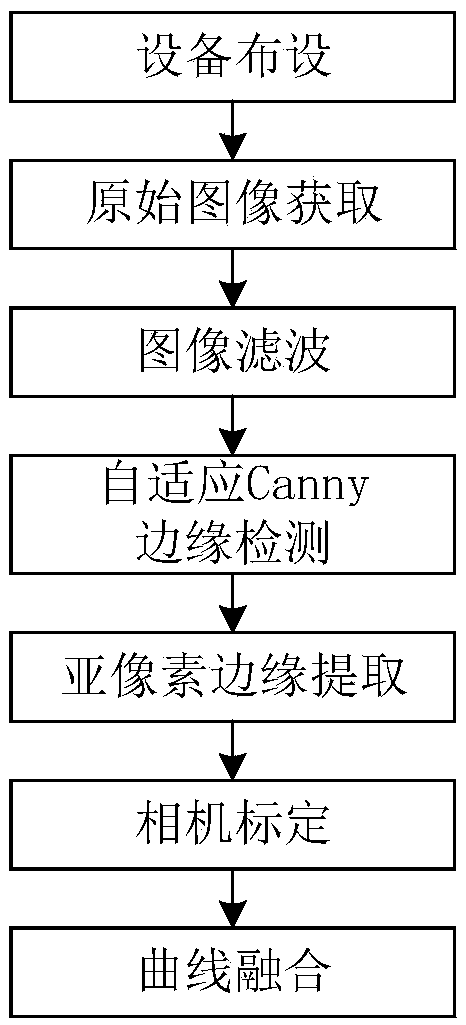

Device and method for monitoring abrasion of pantograph slide plate based on sub-pixel edge detection

InactiveCN108801134AHigh precisionThe detection structure is accurateImage analysisUsing optical meansEdge extractionSlide plate

The invention discloses a device and method for monitoring the abrasion of a pantograph slide plate based on sub-pixel edge detection. The device comprises a field control and data acquisition unit, aremote transmission unit, a data analysis unit, a data storage and release unit and a client access unit. The method comprises the steps that firstly an industrial camera collects a half-pantograph image of the pantograph slide plate; secondly, filtering processing is performed on the image; then the processed image is processed by adopting an adaptive Canny edge detection algorithm to obtain upper and lower edges of the pantograph slide plate with whole pixels, and sub-pixel edge extraction is performed on the upper and lower edges; coordinates of a sub-pixel slide plate edge image are transformed into world coordinates through camera calibration, and a residual abrasion curve of the half-pantograph slide plate is obtained; and finally, a complete residual abrasion curve of the slide plate is obtained through curve integration, the minimum residual thickness of the abrasion region is obtained so as to judge whether it is necessary to replace the slide plate or not. The device adoptsa non-contact online measurement method, and has the advantages of good stability and high detection accuracy.

Owner:NANJING UNIV OF SCI & TECH

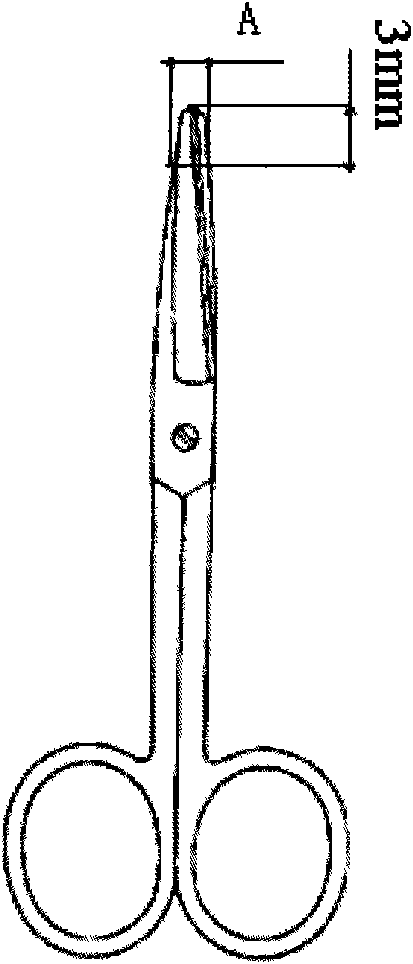

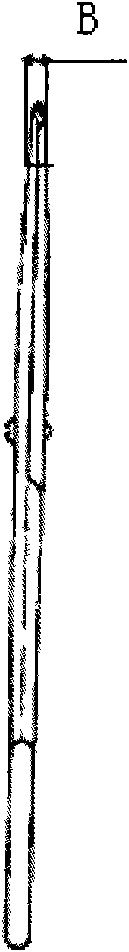

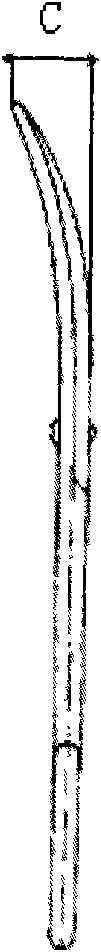

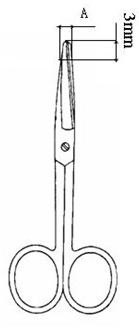

Automatic detection device for size of used position of surgical instrument and detection method thereof

InactiveCN101576372AVisual display of test resultsSolve the use part detection problemUsing optical meansCamera lensEngineering

The invention relates to an automatic detection device for size of a used position of a surgical instrument and a detection method thereof. A video camera consists of a CMOS image sensor and a CMOS camera; the above of a detecting platform is fixedly connected with a helical-toothed upright post guide rail through a guide rail pedestal; a helical-toothed groove of the upright post guide rail is connected and fixed with a guide rail sliding block; the front of the guide rail sliding block is fixedly connected with a camera frame; the above of the camera frame is fixed with the video camera; the below of the video camera is fixed with a calibration gauge block fixture, the front of the calibration gauge block fixture is provided with a width detecting fixture, and the left side of the calibration gauge block fixture is provided with a height / thickness detecting fixture; an illuminator is placed on a platform under the video camera, and the center of a camera lens, the center of the calibration gauge block fixture, and the centers of the calibration gauge block and a detection position are in the same perpendicular line; and the video camera is connected with a computer through a USB 2.0 universal serial bus interface. The detection method comprises the following steps: 1, image acquisition; 2, system calibration; and 3, image processing, namely automatic positioning of the used position and edge detection of sub-pixel.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

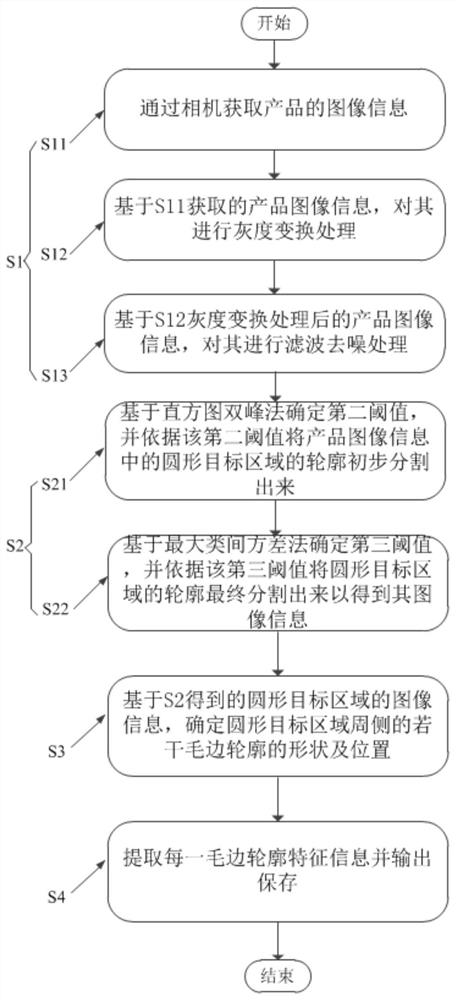

Method for detecting burrs of circular injection molded part

PendingCN112884708AAutomatic quick identificationAutomatic quick extractionImage enhancementImage analysisImaging qualityEngineering

The invention discloses a method for detecting burrs of a circular injection molded part. The method comprises the following steps: S1, collecting image information of a product and preprocessing the image information; S2, based on the image information preprocessed in the S1, performing threshold segmentation processing on the image information to obtain image information of a circular target area; S3, on the basis of the image information of the circular target area obtained in the S2, determining the shapes and positions of a plurality of rough edge contours on the peripheral side of the circular target area; and S4, extracting contour feature information of each burr, and outputting and storing the contour feature information. Firstly, collected product image information is preprocessed to enhance image quality, then, threshold segmentation is performed on a target feature region of the product image information, then, the shape and the position of a burr are determined through a region morphology detection method and a sub-pixel edge detection method, and finally, the burr is extracted, output and stored. The invention can quickly extra blurr. Therefore, a large amount of human resources can be saved, the detection efficiency is high, and the detection precision is high.

Owner:深圳市悦创进科技有限公司

Circular workpiece plane coordinate high-precision positioning method based on machine vision

PendingCN113592955AHigh precisionHigh degree of automationImage enhancementImage analysisPattern recognitionMachine vision

The invention provides a circular workpiece plane coordinate high-precision positioning method based on machine vision. The problem that workpiece micron-order precision positioning cannot be achieved through existing laser machining is solved. The method comprises the following steps: 1) determining parameters of a camera; 2) acquiring images of edges of different parts of the processed workpiece; 3) acquiring a high-resolution image; 4) eliminating holes in the workpiece area in the image; 5) by adopting a sub-pixel edge detection algorithm based on a Zernike moment, extracting contour coordinate points of the processed workpiece in each image, then converting pixel coordinates into machine tool coordinate system coordinates, and compensating the contour coordinate points of each part to obtain machine tool coordinate system absolute coordinates corresponding to the coordinates of the contour pixel points of each part; and 6, fitting the absolute coordinates obtained in the step 5 by adopting a random sampling consistency algorithm, and finally obtaining the coordinates of the circle center. The method is based on a machine vision algorithm, and is high in precision, automation degree and efficiency.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

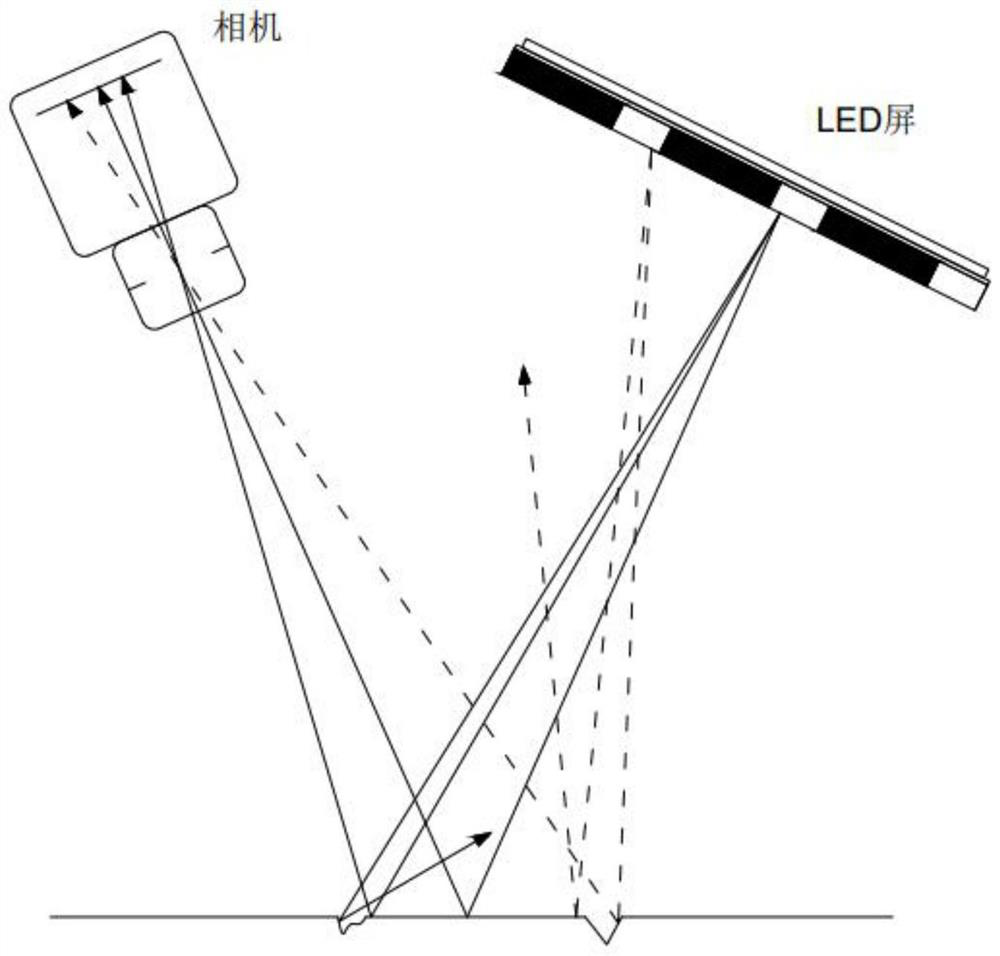

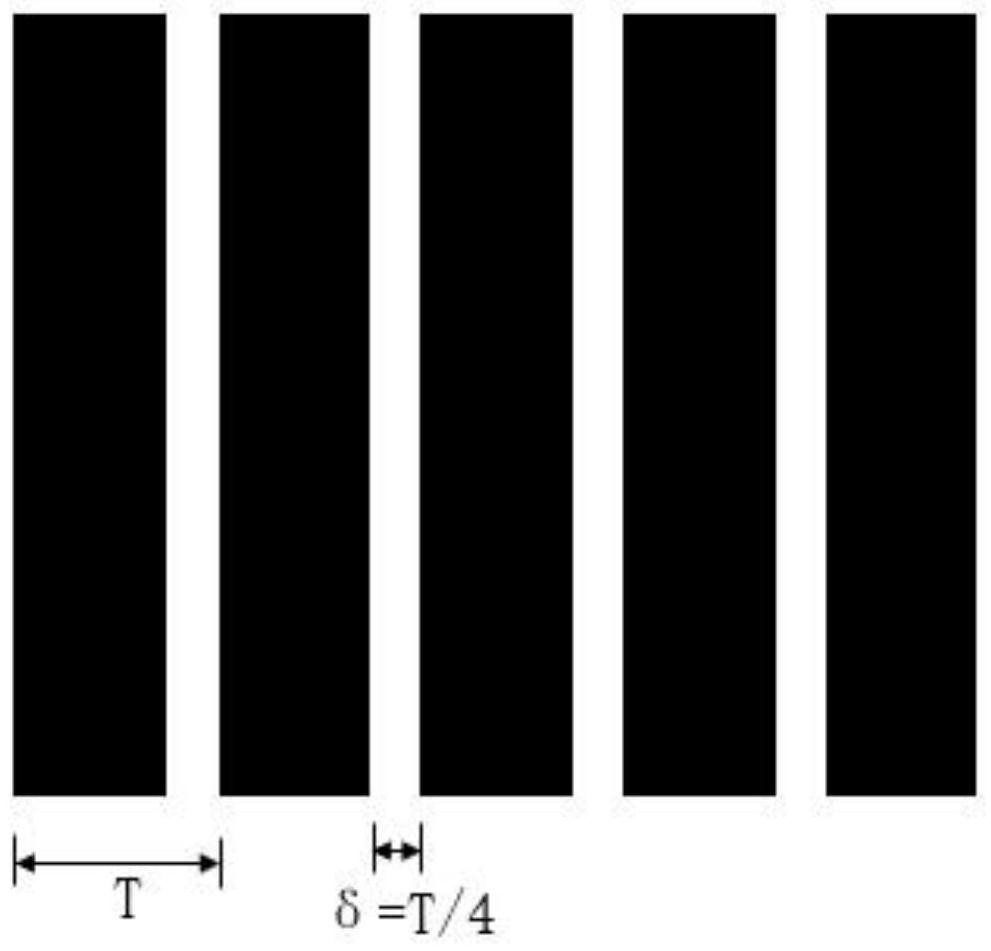

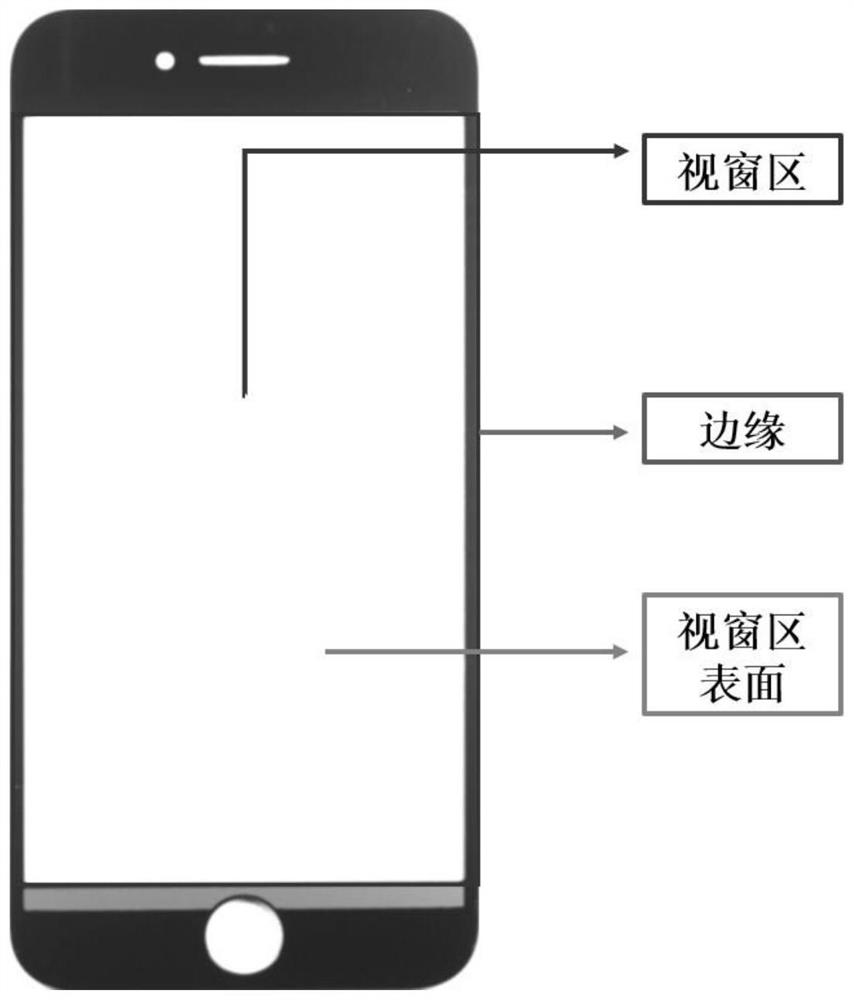

Mobile phone glass cover plate window area defect detection method based on symmetry

PendingCN114881915AMeet real-time requirementsImage enhancementImage analysisTemplate matchingGlass cover

The invention discloses a symmetry-based mobile phone glass cover plate window area defect detection method, and relates to mobile phone glass cover plate defect detection, which comprises the following steps of: calculating a defect enhanced image by using an image sequence shot by black and white periodic structured light, and then preprocessing and denoising. The ROI is extracted, contour extraction is carried out on the window area twice through a sub-pixel edge detection method, the contour extraction is a real contour edge and a standard contour edge for straight line fitting, and the symmetry axis is calculated. And detecting edge breakage and burrs according to the difference between the two contours. And performing subtraction operation on pixel points at corresponding positions on two sides of the symmetry axis in a spatial domain, and extracting a binary image only having a defect area by using difference information so as to detect defects on the surface of the window area. The detection method provided by the invention overcomes the problems that traditional template matching needs a standard template and cannot adapt to detection of various models, and can realize rapid and high-recognition-rate automatic detection of the defects of the window area of the mobile phone glass cover plate.

Owner:XIDIAN UNIV

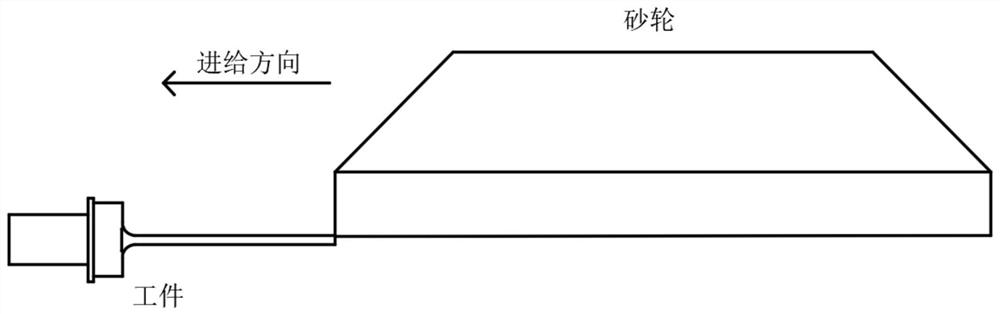

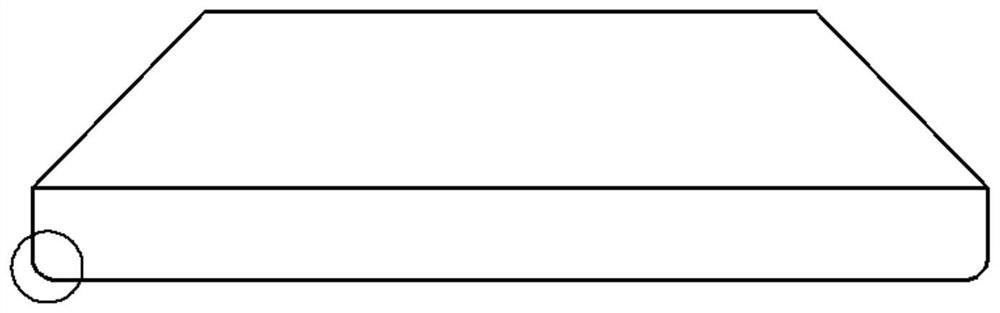

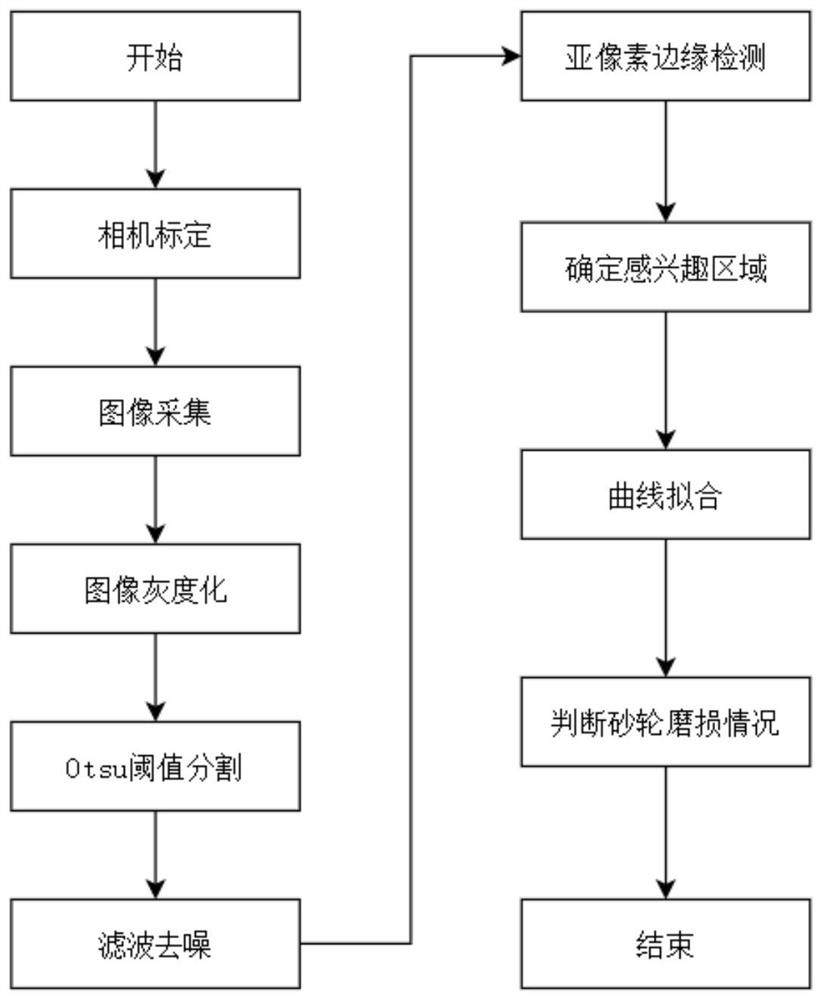

Grinding wheel wear detection method and system based on machine vision

PendingCN114092403AEasy to detectReminder to trim in timeImage enhancementImage analysisEngineeringGrinding wheel

The invention relates to a grinding wheel abrasion detection method and system based on machine vision. The method comprises the following steps of: calibrating the internal and external parameters of a camera; placing a workpiece in a view range of a camera, and shooting a workpiece image; converting the acquired image into a grayscale image; converting the image into a binary image by using an Otsu threshold segmentation method; removing noise in the image by using median filtering; carrying out sub-pixel edge detection by using a zernike moment; determining a region of interest; performing curve fitting on the detected edge; and determining the abrasion condition of the grinding wheel. According to the invention, the method can quickly and efficiently detect the abrasion condition of the grinding wheel, judges whether the grinding wheel needs to be trimmed or not, and improves the grinding machining quality.

Owner:HANGZHOU DIANZI UNIV

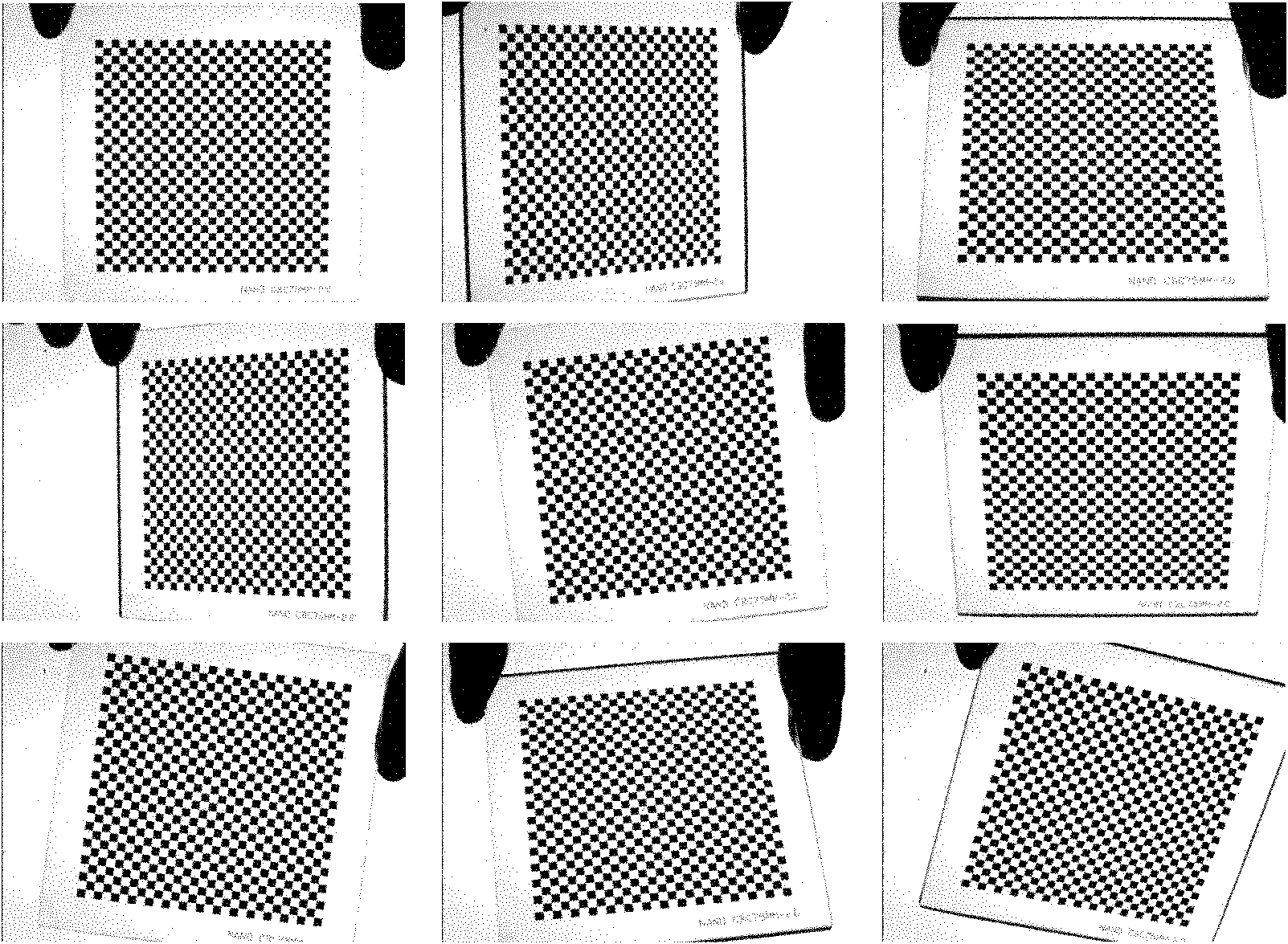

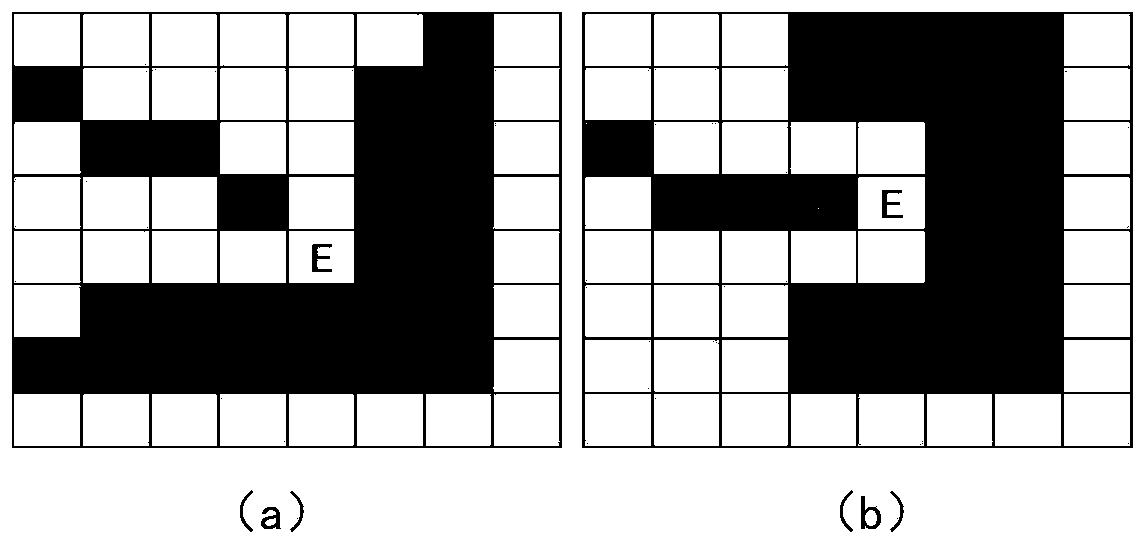

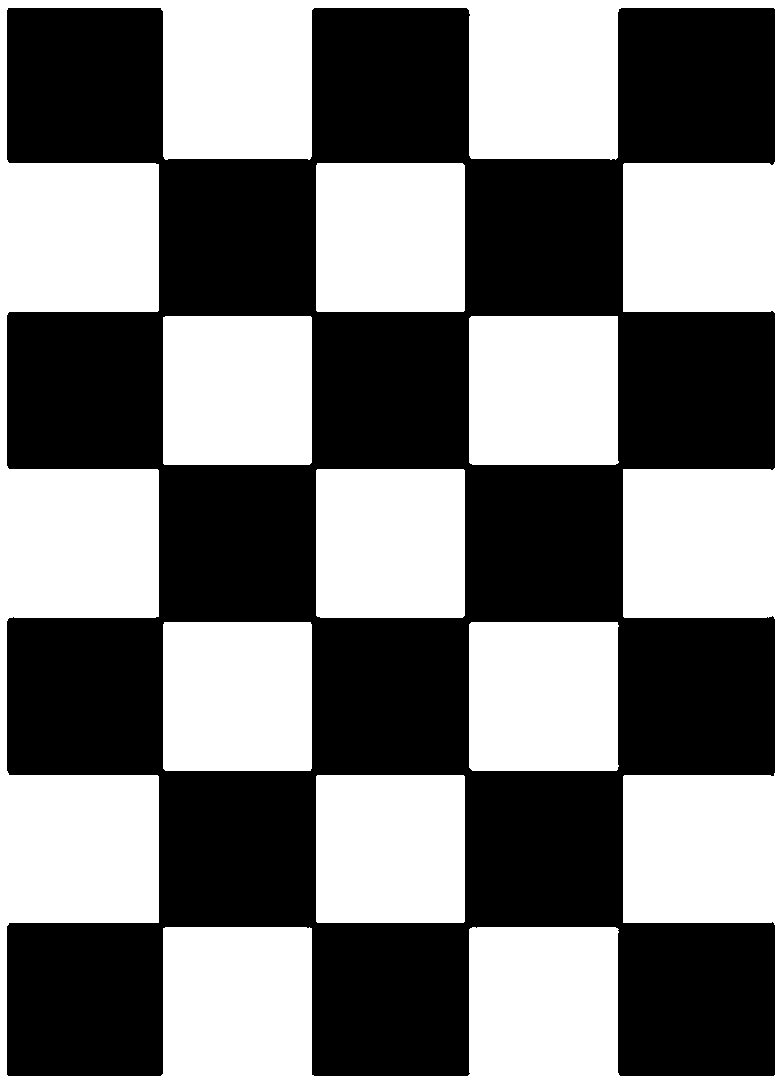

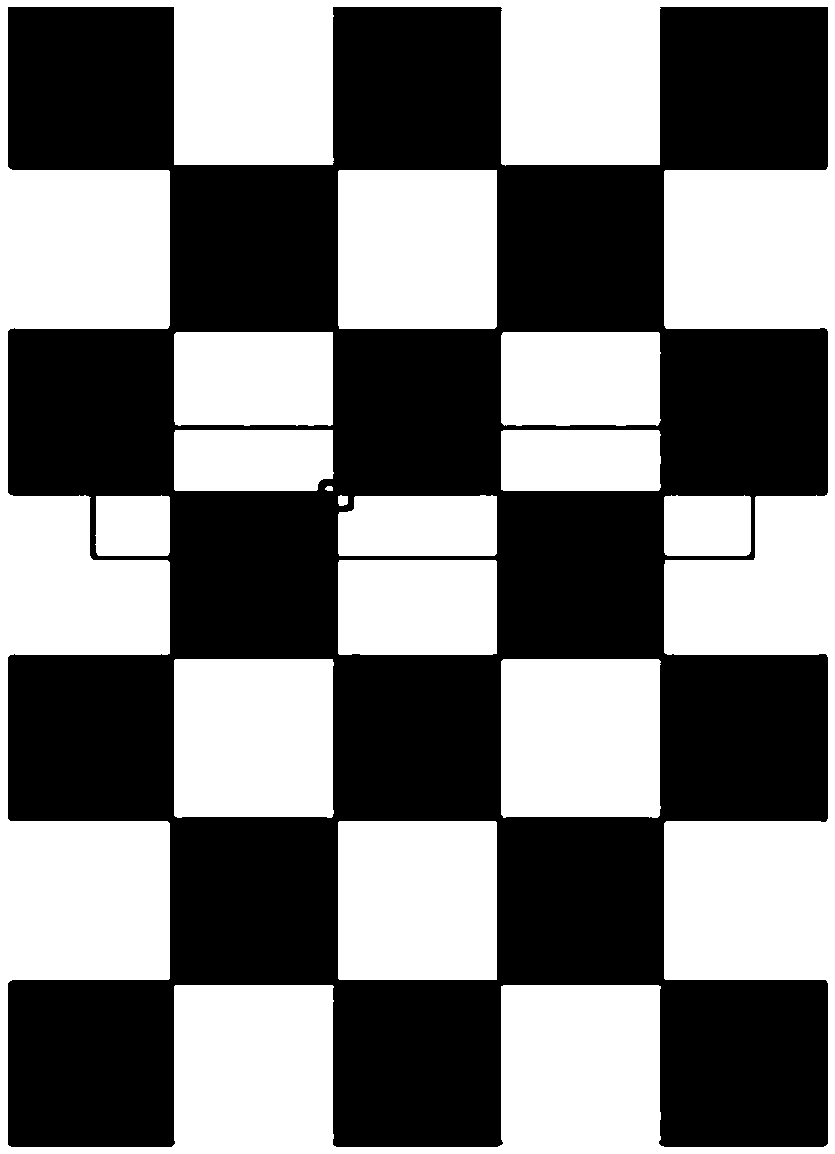

Sub-pixel based angular point calculation method of camera scaling board

The invention discloses a sub-pixel based angular point calculation method of a camera scaling board, belongs to the field of digital image processing, relates to an angular point detection method inone-click measuring instrument calibration, and aims at overcoming the disadvantage that a practical object size measuring error is large due to inaccurate positioning of the angular point in a planebased template scaling method. Sub-pixel angular point detection based on a grayscale value module replaces a traditional sub pixel method, the angle point position is more accurate, the object detection precision is improved, and it is proved that a sub pixel edge detection algorithm based on the grayscale value module can control the precision of the angular point within 0.1 pixel which doublesthat of other sub pixel angular point detection methods (the angular point precision of other methods is about 0.2 pixel).

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

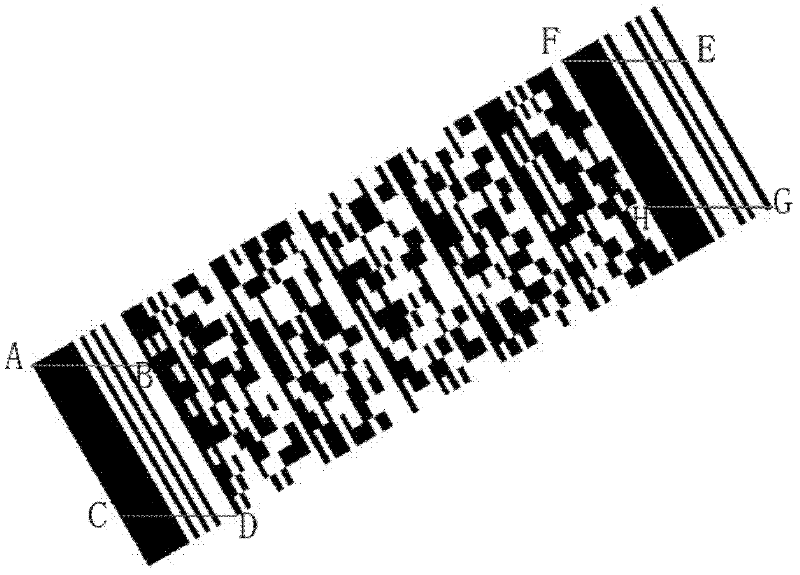

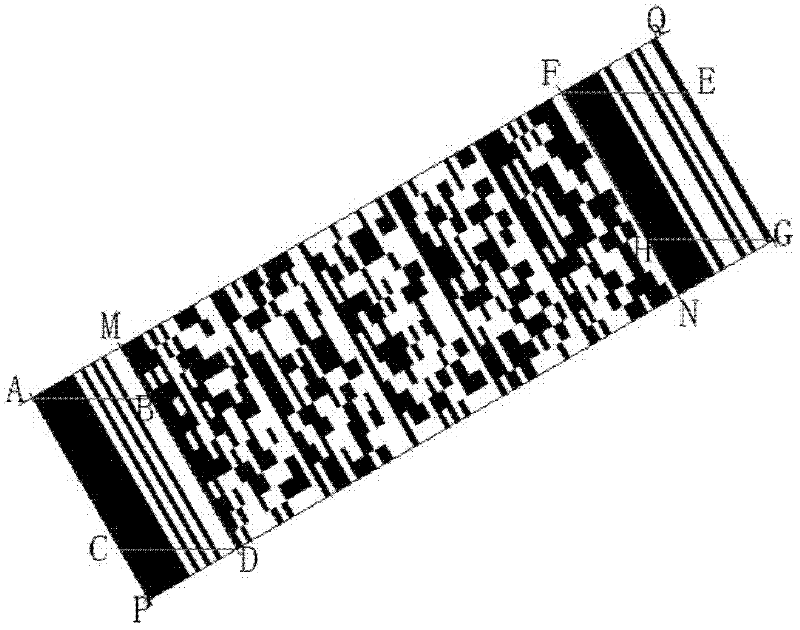

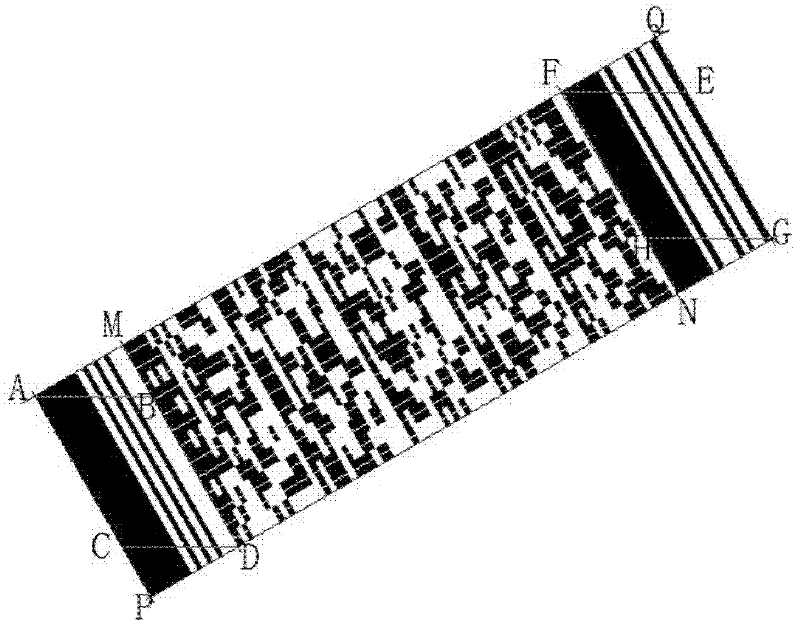

417 bar code identification method based on sub-pixel edge detection

ActiveCN102521559AProcessing speedRapid positioningSensing by electromagnetic radiationImage resolutionComputer engineering

The invention discloses a 417 bar code identification method based on sub-pixel edge detection, which aims at defects of the traditional 417 bar code identification method such as slow processing, poor anti-interference performance, large error an the like. The 417 bar code identification method based on sub-pixel edge detection can identify 417 bar codes fast, accurately and efficiently, and is very remarkable in identification effect especially when image resolution ratio of the 417 bar codes is low. When the 417 bar codes are blurring in images or poor in printed quality, the 417 bar code identification method also has a certain effect on improvement of 417 bar code recognition rate. The 417 bar code identification method is further suitable for conditions of intercepted 417 bar codes. The 417 bar code identification method based on sub-pixel edge detection has good instantaneity, strong fouling resistance and high identification efficiency, and can be widely applied to smart phones and other terminal embedded devices.

Owner:SICHUAN UNIV

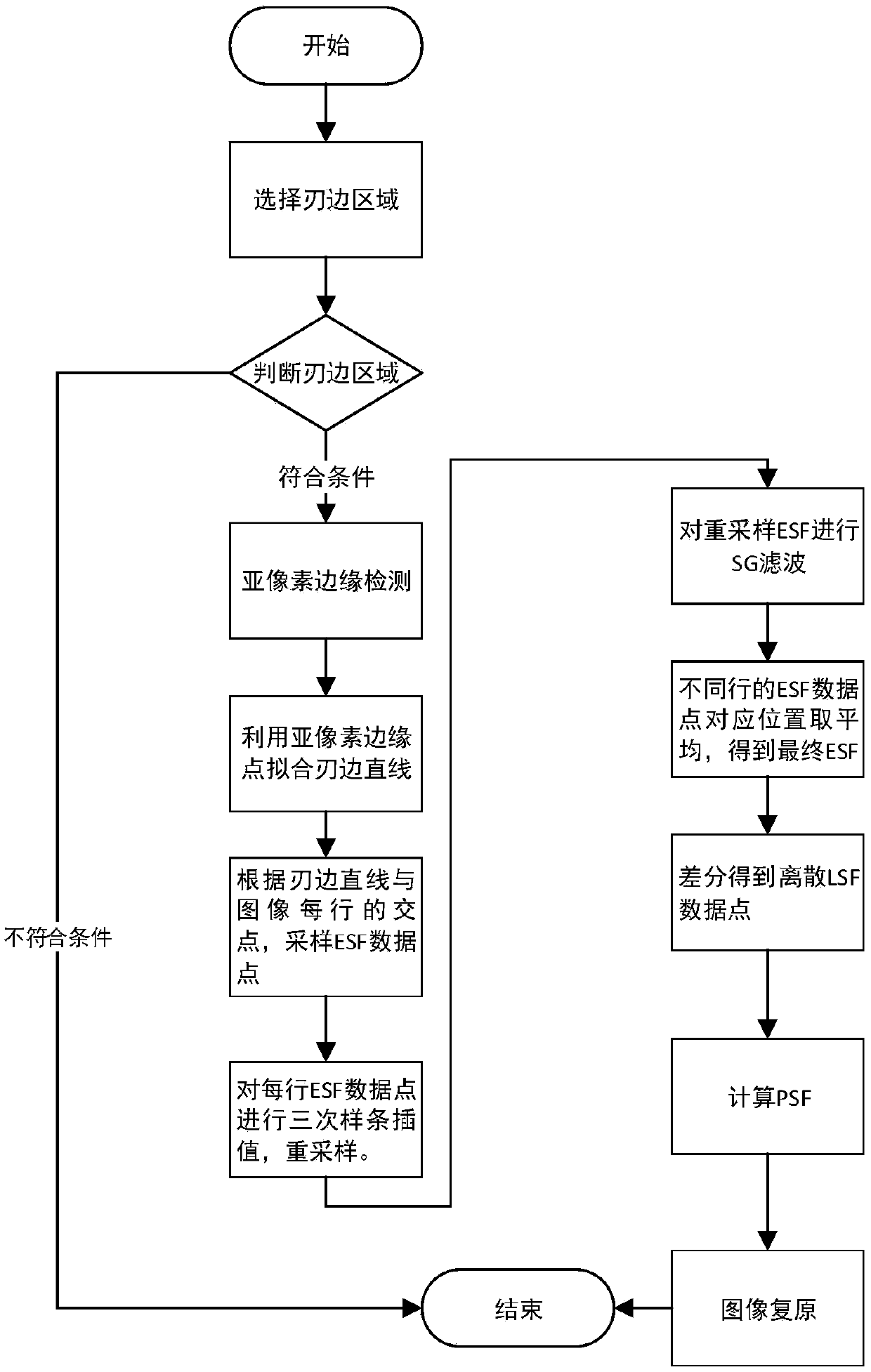

A method for compensating for modulation transfer function of high-resolution satellite images

ActiveCN109035139AGuaranteed accuracyEfficient removalImage enhancementImage analysisComputation complexityDiffusion function

A method for compensating for modulation transfer function of high-resolution satellite images is provided, which relates to the design of MTFC (Modulation Transfer Function Compensation) processing method for domestic high resolution satellite images. The invention solves the problems that the prior image compensation method leads to the degradation of the image signal-to-noise ratio, the noise amplification, the low quality of the restored image, and the high computational complexity in the restoration process. The invention improves from two stages of the point spread function calculation and the image deconvolution restoration. Compared with the traditional pixel-level edge detection method, the precision of sub-pixel edge detection is higher. The high precision can ensure the accuracyof the subsequent edge spread function, line spread function and even the final point spread function. In the process of image deconvolution restoration, for the GPU and multithreaded optimization ofthe maximum likelihood iterative deconvolution algorithm, the windowing radius is calculated according to the point spread function radius, and the ultra-high resolution remote sensing image is windowed and divided into blocks, which effectively removes the influence of boundary ringing and further improves the computational efficiency.

Owner:CHANGGUANG SATELLITE TECH CO LTD

Automatic method for detecting dimension of use part of surgical instrument

InactiveCN102052896AVisual display of test resultsSolve the use part detection problemUsing optical meansImaging processingComputer science

The invention relates to an automatic method for detecting the dimension of the use part of a surgical instrument. The detection method provided by the invention comprises the following steps: image acquisition, system calibration and image processing, wherein the image processing includes automatic use part positioning and sub-pixel edge detection.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

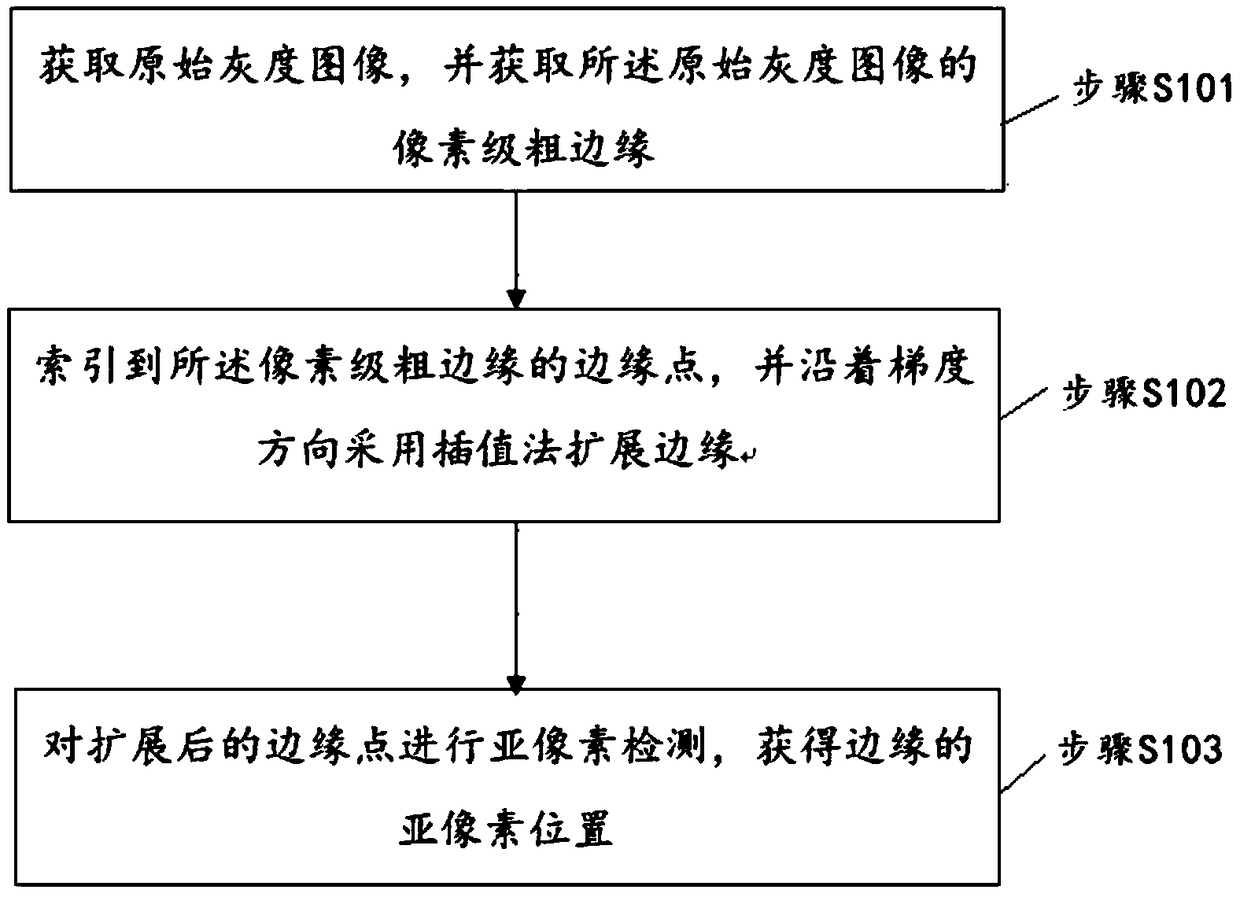

Sub-pixel edge detection method

InactiveCN108648205AIncrease intervalHigh precisionImage enhancementImage analysisGrayscaleSubpixel edge detection

The invention provides a sub-pixel edge detection method, comprising the steps of: acquiring an original gray image, and acquiring a pixel-level thick edge of the original gray image; indexing edge points of the pixel-level thick edge, and extending the edge by interpolation along a gradient direction; and performing sub-pixel detection on the extended edge points to obtain sub-pixel positions ofthe edge. The interval between edges in complex edges is extended by interpolating edge point neighborhoods based on the gradient direction, so that the precision of sub-pixel edge detection is greatly improved, and the sub-pixel level positioning capability on the complex edges is also significantly enhanced.

Owner:GUANGZHOU UNIVERSITY

Sub-pixel shaft part size measurement method based on adaptive threshold

ActiveCN113112496AAdaptableImprove efficiencyImage enhancementImage analysisCorrection algorithmStructure analysis

The invention discloses a sub-pixel shaft part size measurement method based on a self-adaptive threshold value, and relates to a size measurement method. Calibrating a visual system to obtain internal and external parameters and a mutual position relation; preprocessing the collected image, and improving a gamma correction algorithm by combining a gray histogram to realize automatic selection of a gamma value; completing edge detection, and recording a pixel-level edge position by adopting a Canny operator edge detection method; based on neighborhood edge connection, checking all edge pixel points of the image to complete edge connection; carrying out region extraction based on contour tracking, and converting the binary image into contour description by adopting a contour tracking algorithm with topological structure analysis capability; performing sub-pixel edge detection based on an adaptive threshold, dividing an image region for edge detection, and adaptively selecting a threshold of sub-pixel edge detection; and size calculation: solving the size of the straight line included angle. The precision and the efficiency are higher, the manpower is saved, and the adaptability to the measurement environment is strong.

Owner:HARBIN INST OF TECH

Oil well pipe sleeve damage image edge detection method based on grey correlation analysis and Zernike moment

InactiveCN104050671AReduce orderPrecise positioningImage analysisGrey correlation analysisComputer vision

The invention provides an oil well pipe sleeve damage image edge detection method based on grey correlation analysis and Zernike moment. For an intercepted oil well pipe sleeve damage image, at first, a grey correlation analysis algorithm is adopted for locating image edges coarsely, and then a Zernike moment operator is utilized for achieving sub-pixel level location of the image edges. By means of a fast edge detecting method combining the grey correlation analysis with the Zernike moment, the continuous effective image edges can be detected through the grey correlation analysis, a large number of image details can be retained by adjusting a threshold value, and the applicability range is wide. Due to Zernike, in the sub-pixel edge detecting process, the number of templates needed by sub-pixel edge detecting can be effectively reduced, orders of a function are reduced, the capacity of resisting disturbance is improved, and the edge locating precision is improved. According to the method, at first, coarse locating is carried out for sleeve damage image edge detection through the grey correlation analysis, then the Zernike moment operator is utilized, and therefore the method has the advantages of being high in locating precision and good in noise immunity, and the sleeve damage image edges can be located accurately to the sub-pixel level.

Owner:XI'AN PETROLEUM UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com