Oil well pipe sleeve damage image edge detection method based on grey correlation analysis and Zernike moment

A gray correlation analysis and image edge technology, applied in the field of image processing, can solve problems such as noise interference, low edge precision, and failure to achieve better recognition results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The image processing in this example can be divided into two parts. The first part uses the gray correlation analysis algorithm to detect the pixel-level edge of the casing damage image of the oil well pipe to realize the pixel-level edge location. The second part uses the Zernike moment operator to perform secondary subpixel-level edge positioning on the image in the previous step. Take the original image of M×N pixel size as an example to illustrate the implementation steps of this example:

[0033] (1) Use the gray correlation analysis algorithm to detect the edge of the preprocessed oil well casing damage image, and complete the rough positioning of the target edge;

[0034] 1. Determine the reference sequence and comparison sequence

[0035] For the convenience of calculation, for an image of M×N size, a 3×3 template with a value of 1 is used as a reference sequence, namely: x 0 =(1,1,1,1,1,1,1,1,1), the comparison sequence is composed of each pixel in the image ...

Embodiment 2

[0076] Take the video screenshot of the underground TV software system in a certain well depth as an example to illustrate the implementation steps of this example:

[0077] (1) Use the gray correlation analysis algorithm to detect the edge of the preprocessed oil well casing damage image, and complete the rough positioning of the target edge;

[0078] 1. Determine the reference sequence and comparison sequence

[0079] For the convenience of calculation, the 3×3 template with the value of 1 is used as the reference sequence, namely: x 0 =(1,1,1,1,1,1,1,1,1), the comparison sequence is composed of each pixel in the image and the surrounding 8 neighboring pixels, that is:

[0080] x ij =(x i-1,j-1 ,x i-1,j ,x i-1,j+1 ,x i,j-1 ,x i,j ,x i,j+1 ,x i+1,j-1 ,x i+1,j ,x i+1,j+1 )

[0081] Where i=1,2,...,M; j=1,2,...,N, when i,j=1 or i=M, j=N, repeat the corresponding pixel on the adjacent row or column value as the value of the point. For convenience of description, us...

Embodiment 3

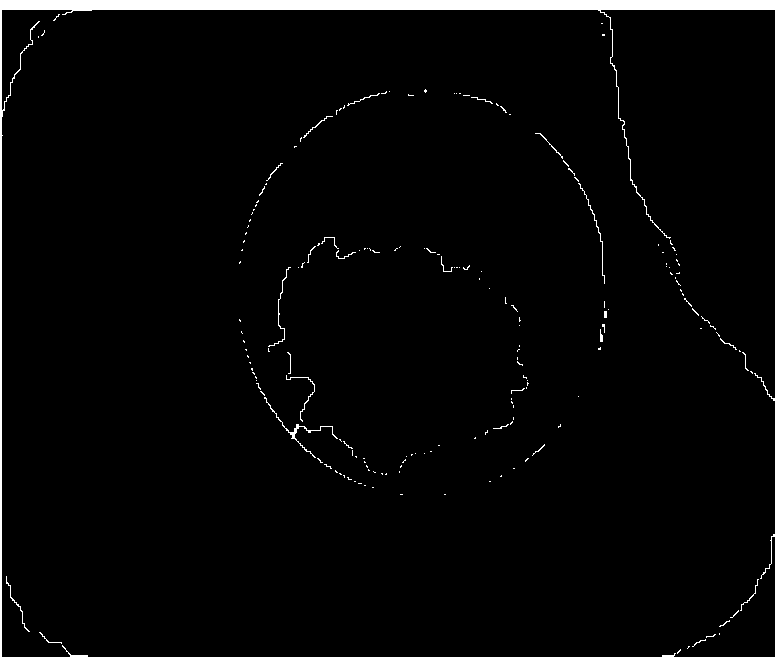

[0122] Take the video screenshot of the underground TV software system in a certain well depth as an example to illustrate the implementation steps of this example:

[0123] (1) Use the gray correlation analysis algorithm to detect the edge of the preprocessed oil well casing damage image, and complete the rough positioning of the target edge;

[0124] 1. Determine the reference sequence and comparison sequence

[0125] For the convenience of calculation, the 3×3 template with the value of 1 is used as the reference sequence, namely: x 0 =(1,1,1,1,1,1,1,1,1), the comparison sequence is composed of each pixel in the image and the surrounding 8 neighboring pixels, that is:

[0126] x ij =(x i-1,j-1 ,x i-1,j ,x i-1,j+1 ,x i,j-1 ,x i,j ,x i,j+1 ,x i+1,j-1 ,x i+1,j ,x i+1,j+1 )

[0127] Where i=1,2,...,M; j=1,2,...,N, when i,j=1 or i=M, j=N, repeat the corresponding pixel on the adjacent row or column value as the value of the point. For convenience of description, us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com