Sub-pixel based angular point calculation method of camera scaling board

A technology of camera calibration and calculation method, which is applied in calculation, image analysis, image data processing, etc., and can solve the problem of large measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

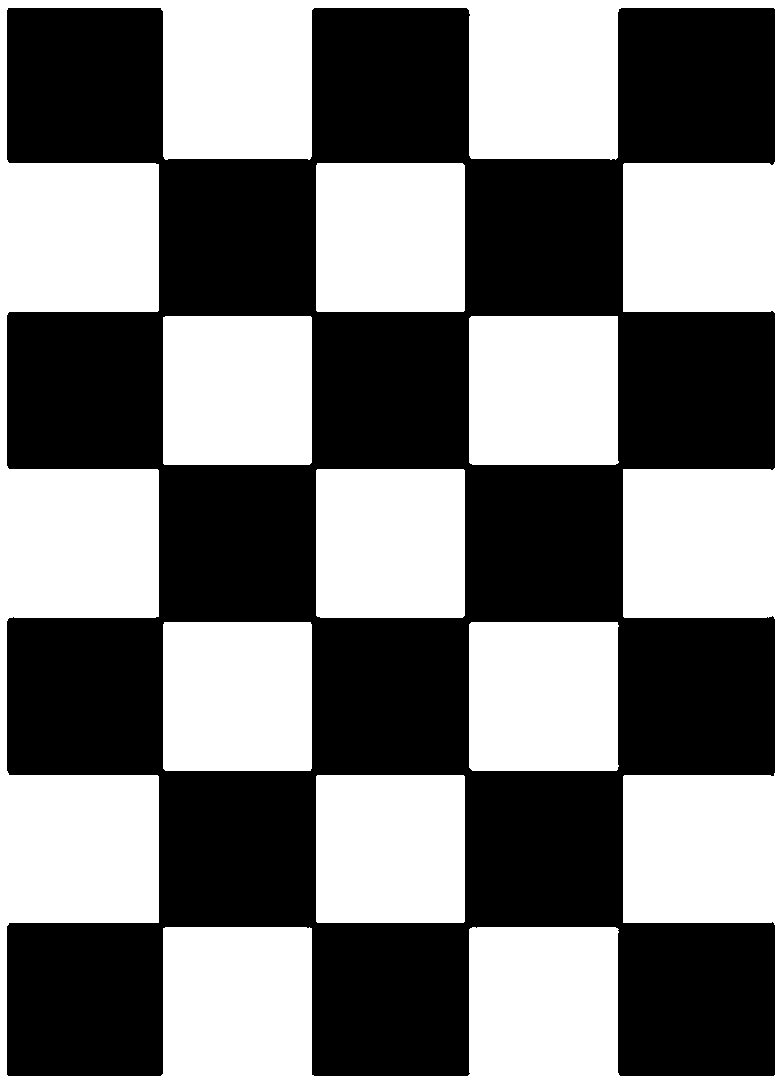

[0042] Step 1: Put the calibration plate on the stage of the one-button measuring instrument, take pictures at different positions and angles to obtain calibration pictures such as figure 1 ;

[0043] Step 2: Gaussian filtering is performed on the captured image to obtain a denoised calibration image obtained by removing noise in the image.

[0044] Step 3: Perform Harris corner detection on the filtered image to obtain pixel-level corner coordinates.

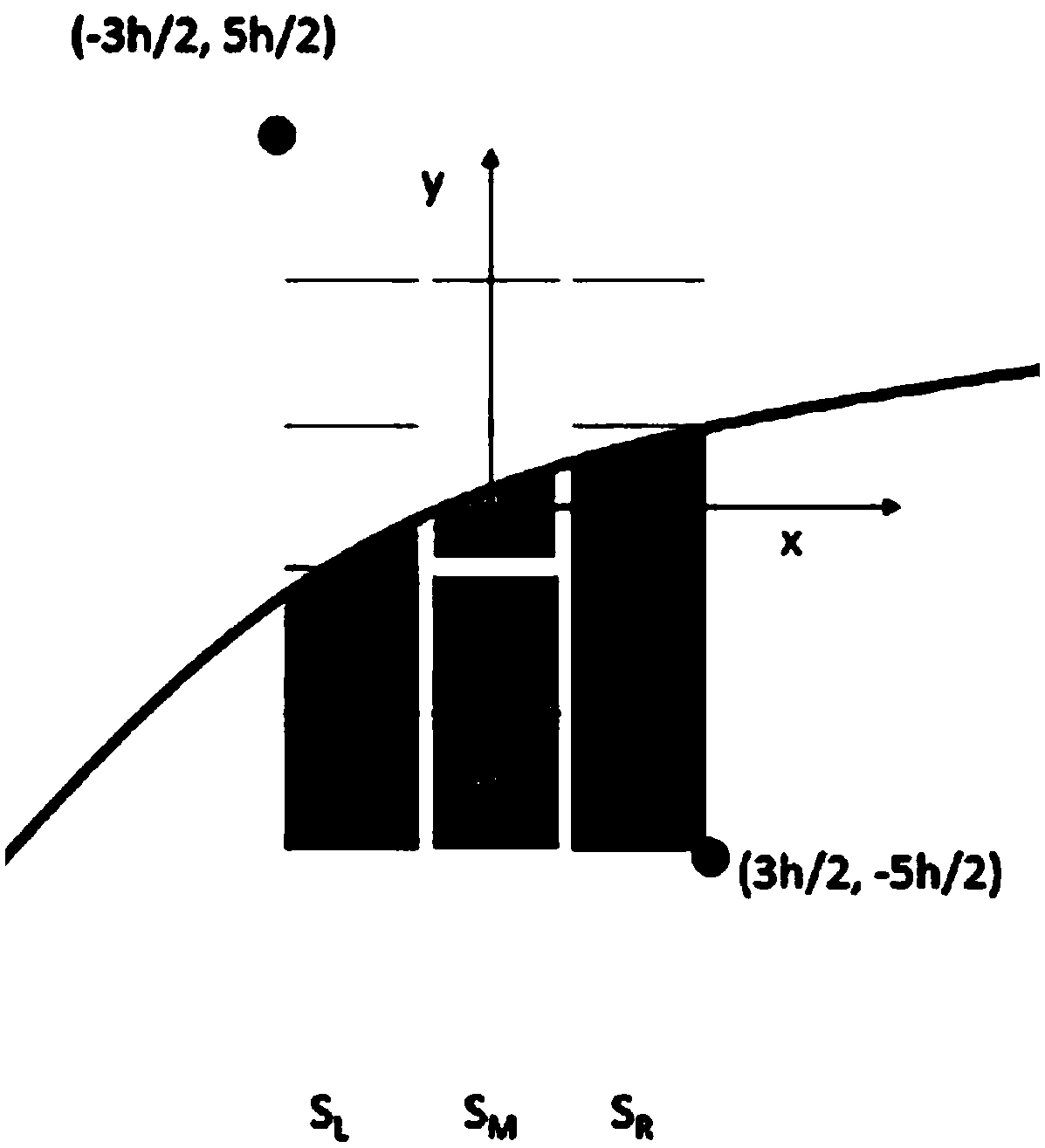

[0045] Step 4: Use the 5×3 points around the extracted pixel-level corner point coordinates as a template, and find the precise position of the sub-pixel point according to the grayscale image features.

[0046] The specific steps in Step 4 shown are:

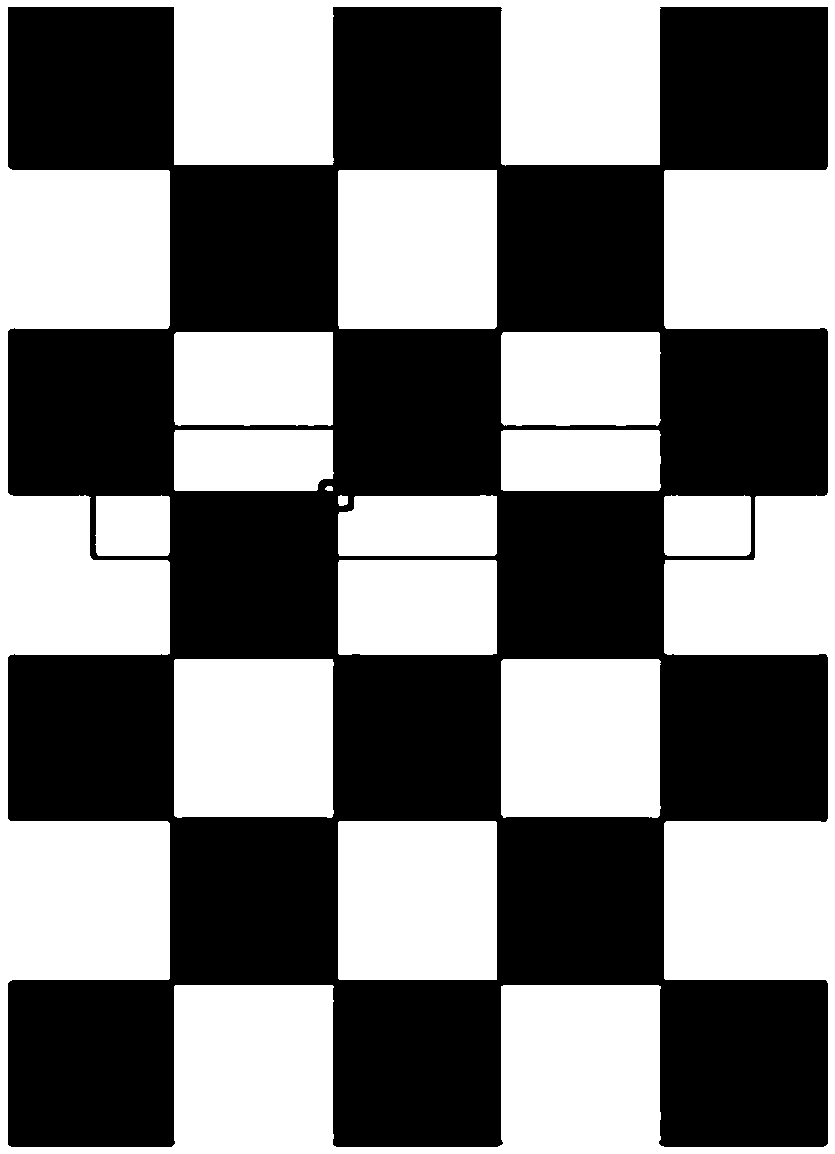

[0047] Step 4-1 Use the pixel-level corner coordinates obtained in step 3 Harris corner detection to define a rectangle in the direction parallel to the abscissa. The width of the rectangle is 30 pixels and the length is 80% of the side length of the checkerboard. Such as f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com