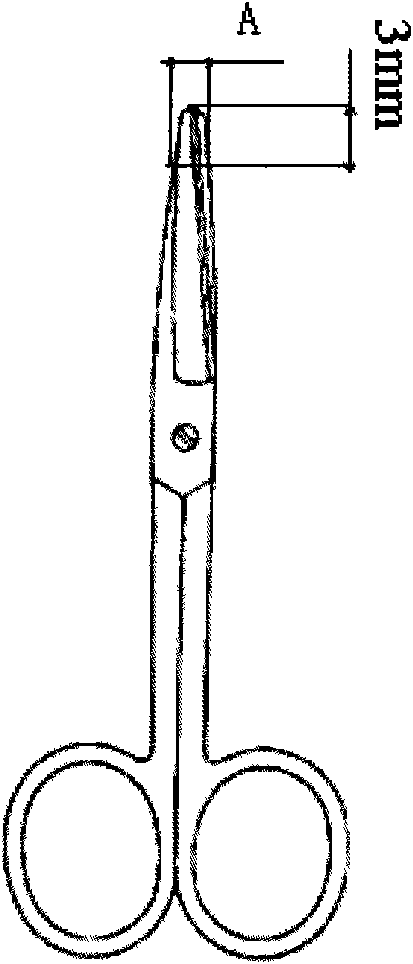

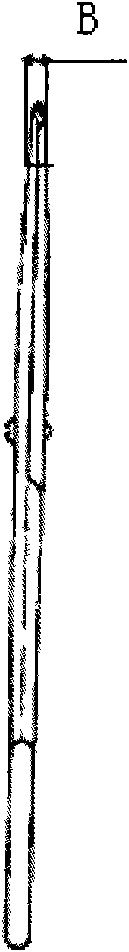

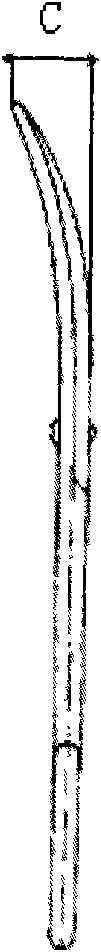

Automatic detection device for size of used position of surgical instrument and detection method thereof

An automatic detection device and surgical instrument technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of unavoidable human error, labor-intensive and low efficiency, and time-consuming manual visual inspection, so as to improve the qualified rate and Safety, high accuracy, and fast results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0039] Such as Figure 4 As shown, the automatic detection device for the size of the used part of the surgical instrument includes a computer 1, a camera 2, a light source lamp 3, a calibration gauge fixture 4, a width detection fixture 5, a height / thickness detection fixture 6, a camera fixing device 7, and a calibration gauge. Camera 2 consists of a CMOS image sensor and a CMOS camera.

[0040] Such as Figure 5 As shown, the camera fixing device 7 includes a camera frame 8, a guide rail slider 9, a guide rail 10, a guide rail base 11, and a detection platform 12. The helical tooth groove of tooth guide rail 10 connects fixed guide rail slide block 9, and guide rail slide block 9 is provided with camera frame 8, and camera frame 8 fixes camera 2, and guide rail base 11 front is provided with calibration gauge clamp 4, and platform 12 is fixed with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pixel size | aaaaa | aaaaa |

| Snr | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com