Mobile phone glass cover plate window area defect detection method based on symmetry

A glass cover plate and defect detection technology, applied in image analysis, image enhancement, instruments, etc., can solve problems such as low efficiency, difficult recruitment, and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention is further described below in conjunction with the accompanying drawings.

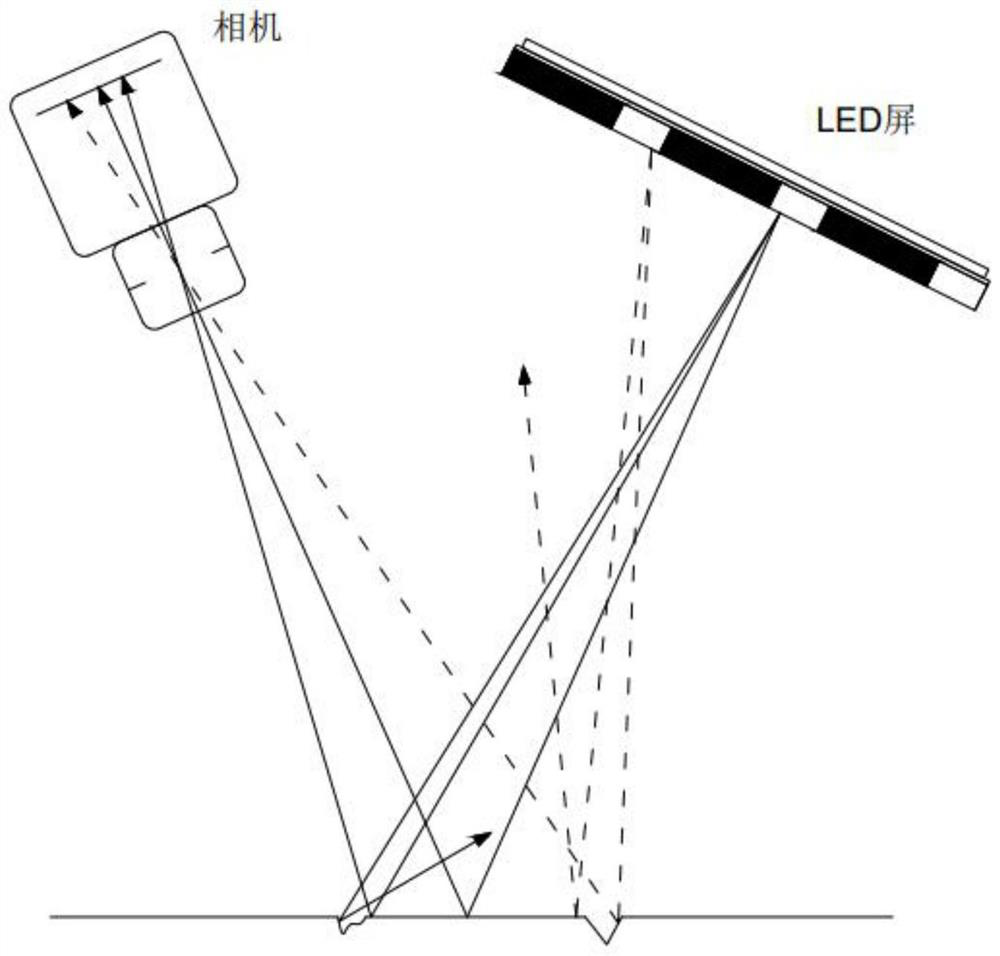

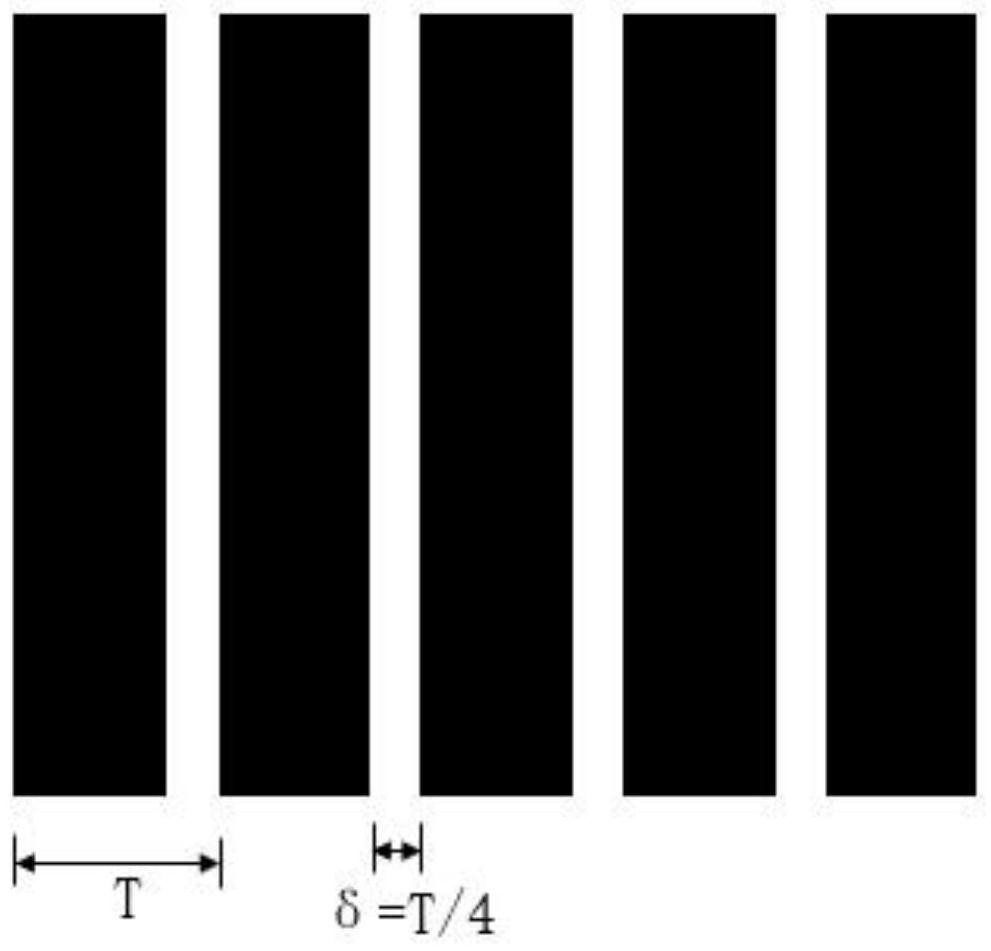

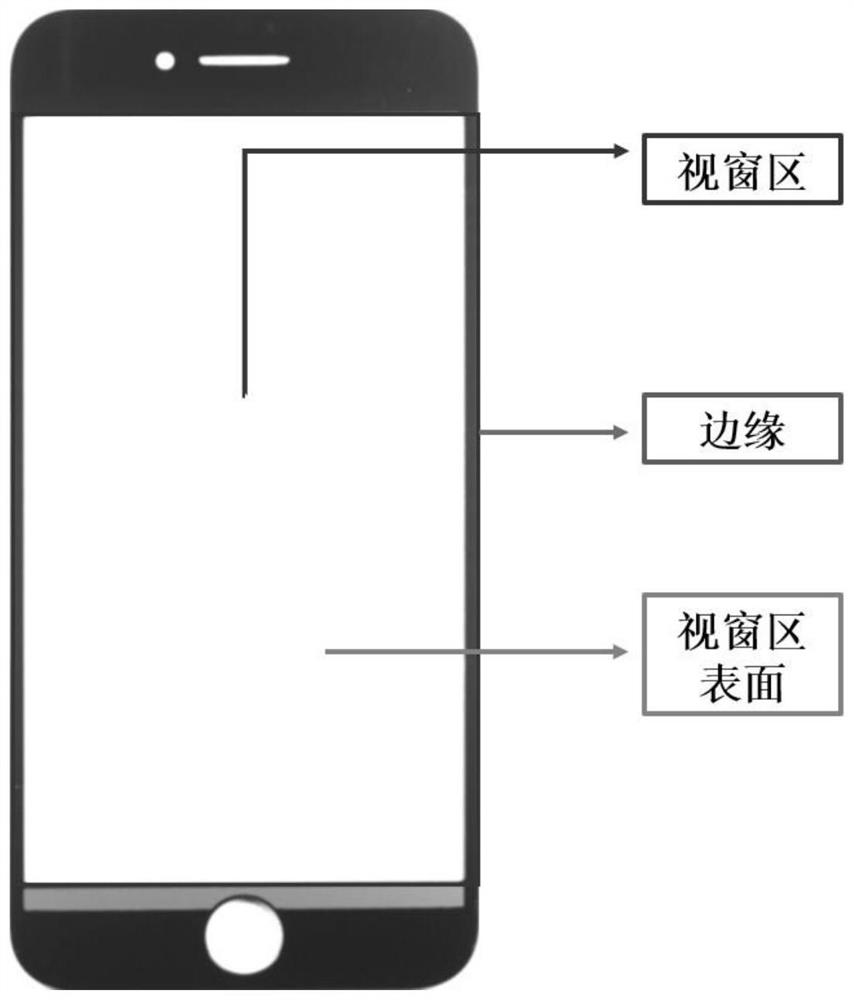

[0058] like Image 6 As shown, in the image data acquisition system, the glass cover to be tested is placed in the online detection system through the automatic transmission system of the glass cover, and the display screen of the online detection system shows as follows figure 1 The black and white periodic fringe image shown is used as the projection light source, and the controller controls the area scan camera to capture the black and white periodic fringe image reflected by the glass cover plate to be tested. The physical diagram of light scattering is shown in Fig. figure 2 Then move the black and white periodic stripes to the right on the display by a fixed step, and the area scan camera takes another image of the glass cover; repeat the above steps until the white stripes sweep through a period and every pixel on the display is Appear inside the white stripe at le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com