Low-frequency vibration calibration method based on monocular vision

A low-frequency vibration and calibration method technology, which is applied to instruments, measuring devices, and measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problems that the low-frequency vibration calibration method cannot be applied to a wide frequency range, the process is complicated, and the accuracy is limited, and the method is stable. The calibration process is simple and the effect of accurate extraction is guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

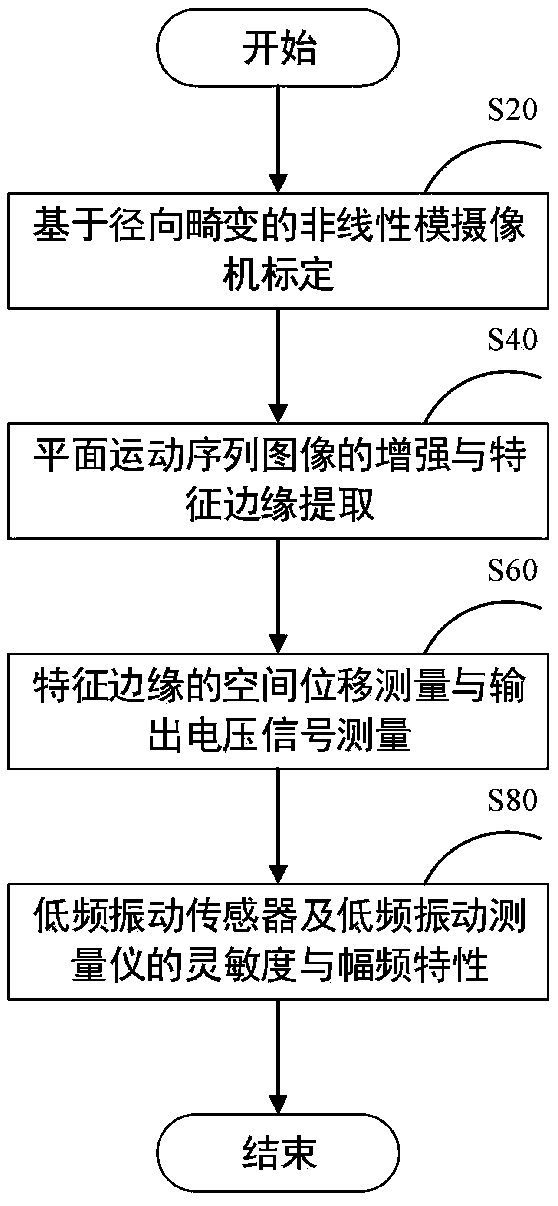

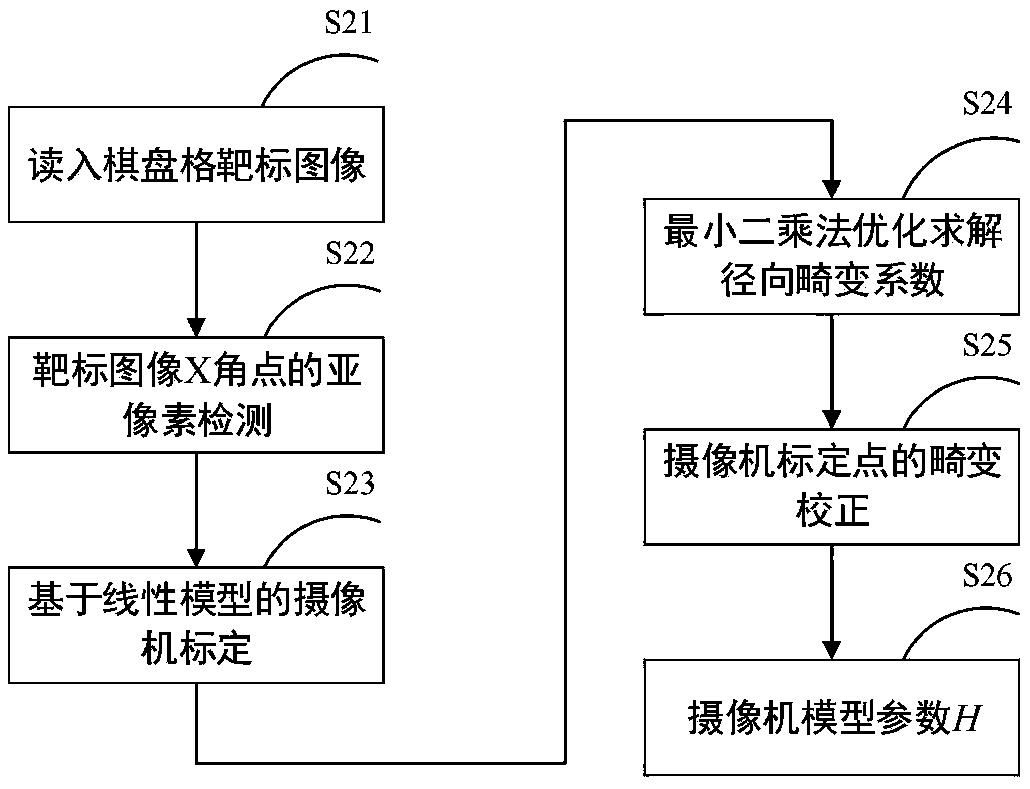

[0050] In order to solve the problems that the existing low-frequency vibration calibration method has limited calibration accuracy, complex system and high cost, and is not suitable for high-precision calibration in a wide frequency range, the present invention provides a low-frequency vibration calibration method based on monocular vision. High precision can be obtained for low-frequency vibration calibration in a wide frequency range, and the present invention will be described in detail below with reference to the accompanying drawings and specific implementation examples.

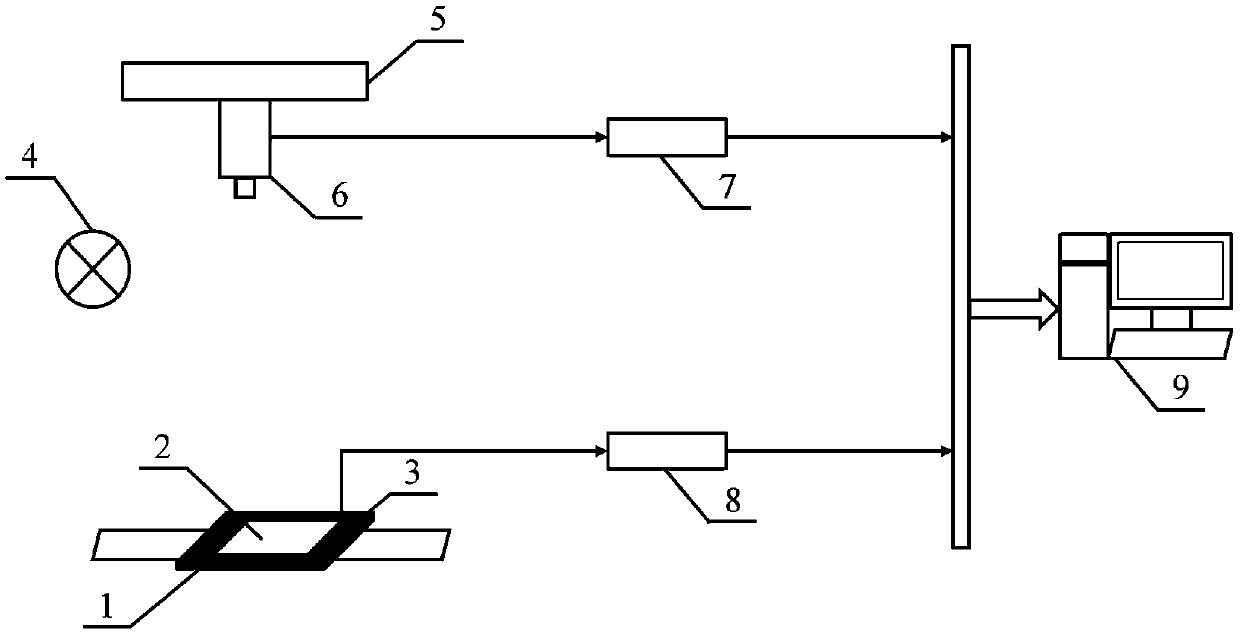

[0051] refer to figure 1 It is a schematic diagram of an implementation example device of the method of the present invention. The device mainly includes: a horizontal long-stroke vibration table (1), a feature mark (2), a low-frequency vibration sensor and a low-frequency vibration measuring instrument (3), a light source (4), and a camera fixing device (5), a camera (6), an image transmission device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com