Circular workpiece plane coordinate high-precision positioning method based on machine vision

A technology of circular workpiece and plane coordinates, used in instruments, graphic image conversion, image data processing, etc., can solve the problem of inability to achieve micron-level precision positioning of workpieces, and achieve the effect of meeting precision requirements, high precision, and improving positioning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

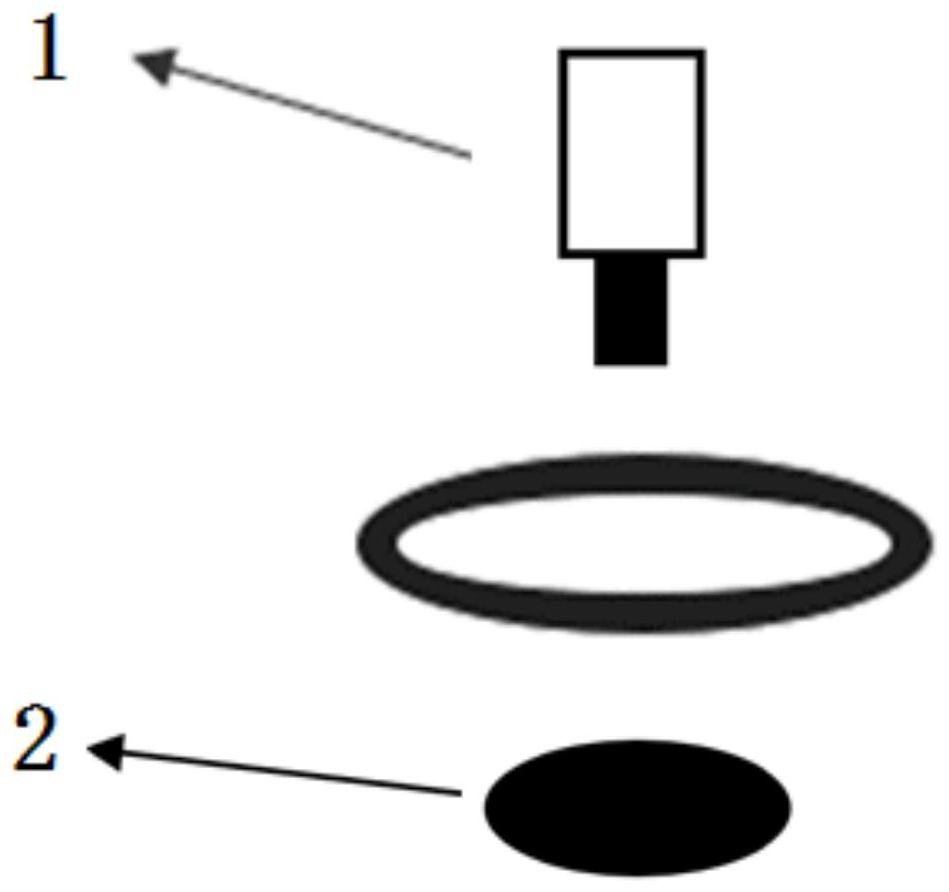

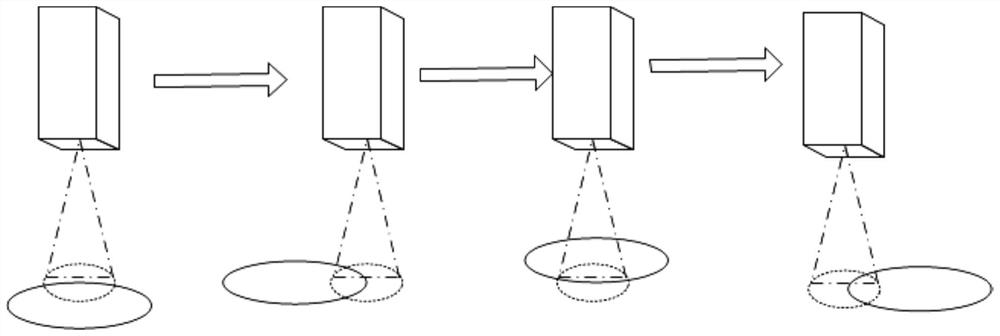

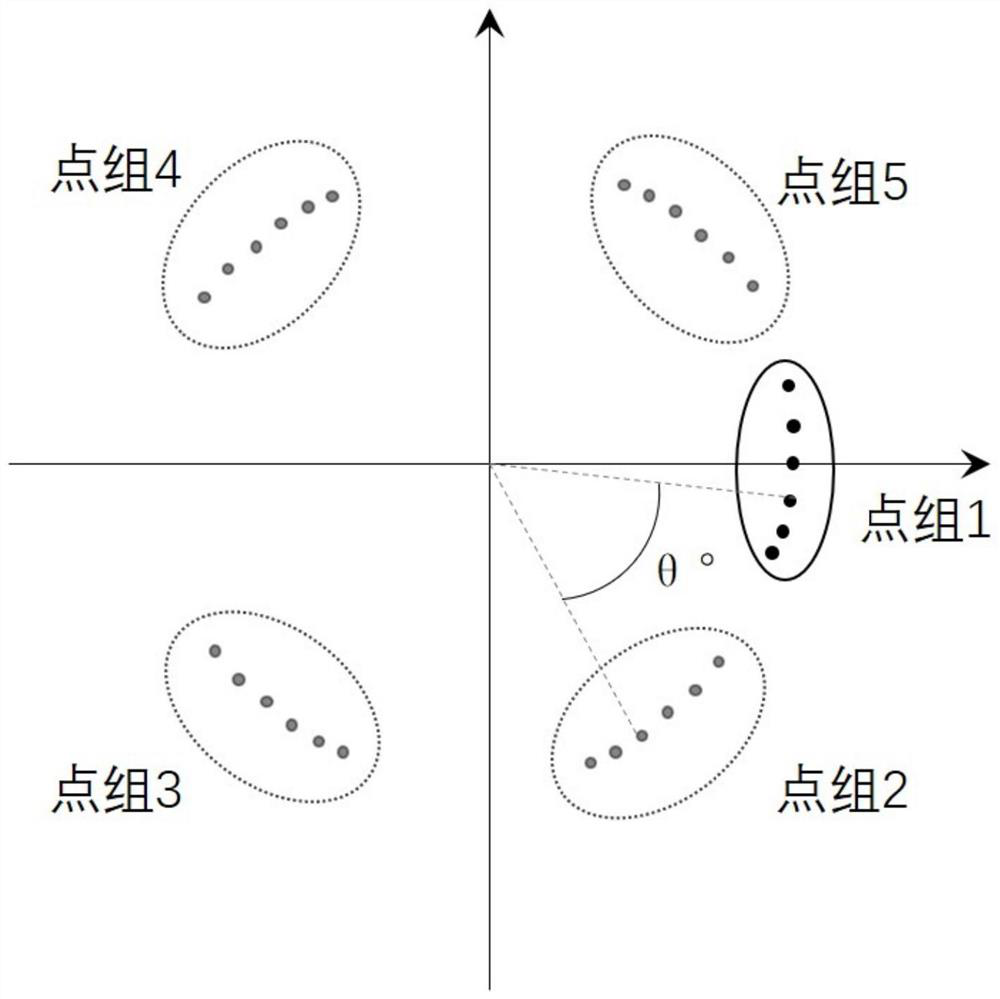

[0036] The invention provides a machine vision-based high-precision positioning method for the plane coordinates of a circular workpiece. The method mainly ensures the micron-level precision positioning of the workpiece from two aspects of hardware and algorithm. First of all, in terms of hardware, use a high-resolution camera, choose a camera with a resolution greater than 4 million, and the field of view should be less than 2mm, and 1 pixel represents 1μm, that is to say, when the light source illuminates the workpiece, the image is clear and the algorithm is accurate and there is no error Under ideal conditions, the positioning accuracy can reach up to 1 μm; in order to further ensure the accuracy and reduce the impact of imaging quality and algorithm errors, the image quali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com