Device and method for monitoring abrasion of pantograph slide plate based on sub-pixel edge detection

A pantograph slide and sub-pixel edge technology, applied in the field of traffic safety engineering, can solve problems such as low reliability, incomplete detection of pantograph status, and complex detection structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

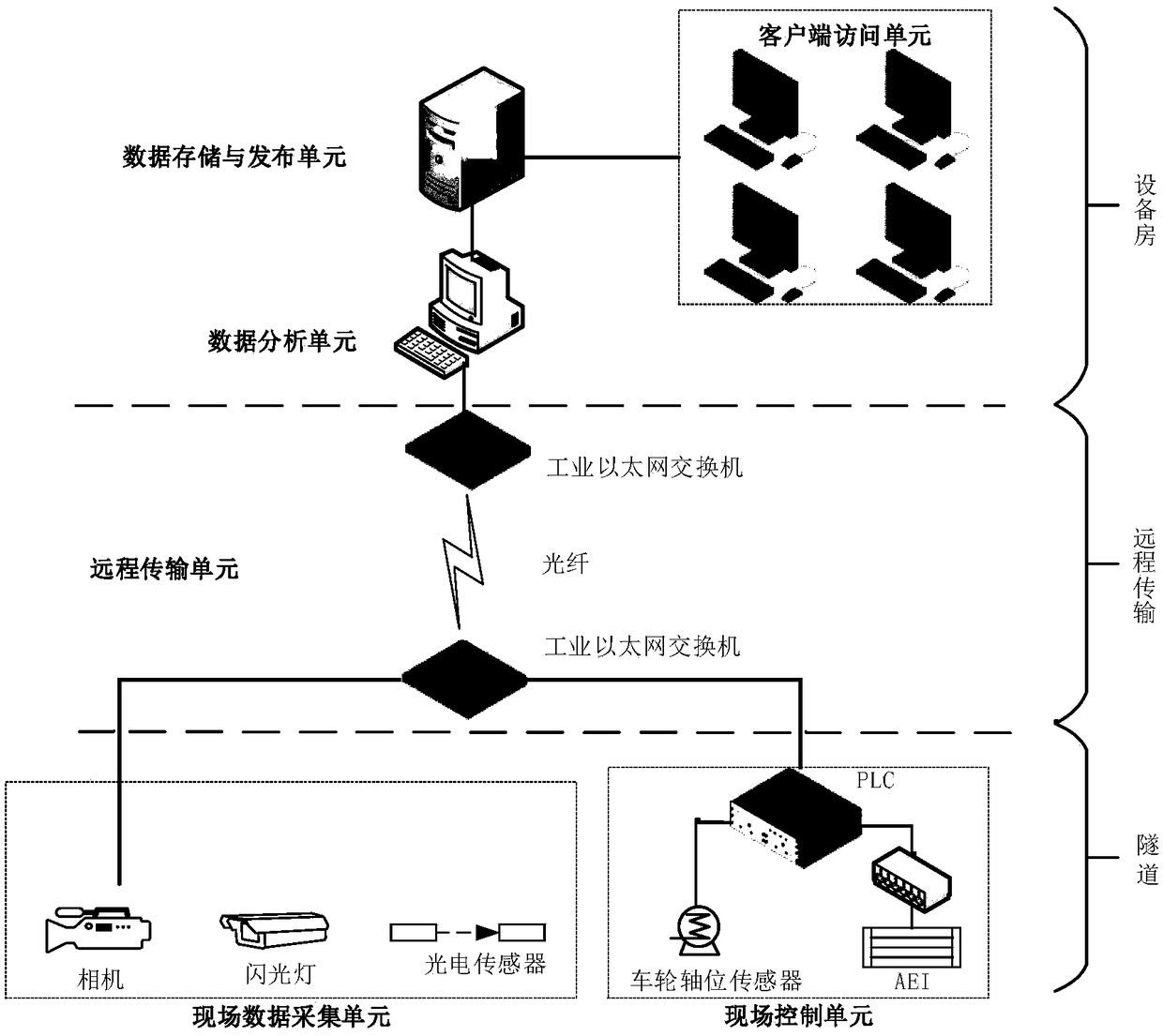

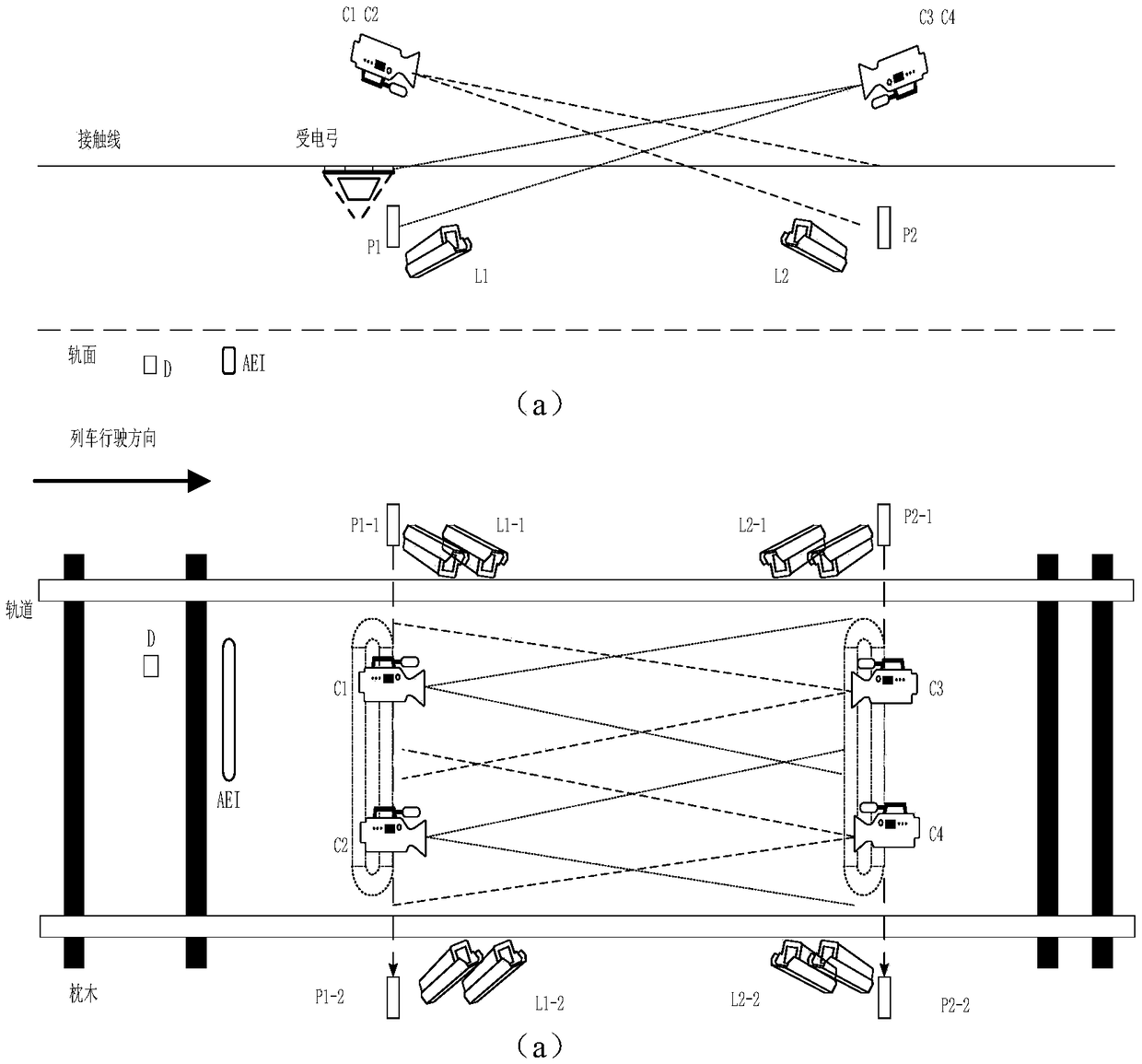

[0130] combine figure 1 , figure 2 , the present invention is a pantograph sliding plate wear monitoring device based on sub-pixel edge detection, the device includes a field control and data acquisition unit, a remote transmission unit, a data analysis unit, a data storage and release unit and a client access unit. The on-site control and data collection unit detects the arrival of the train and obtains the train number information, and collects the original image of the pantograph slide; the remote transmission unit is used for the transmission between the scene and the equipment room; processing; the data storage and publishing unit is used for data storage and publishing; the client access unit is used for remote access.

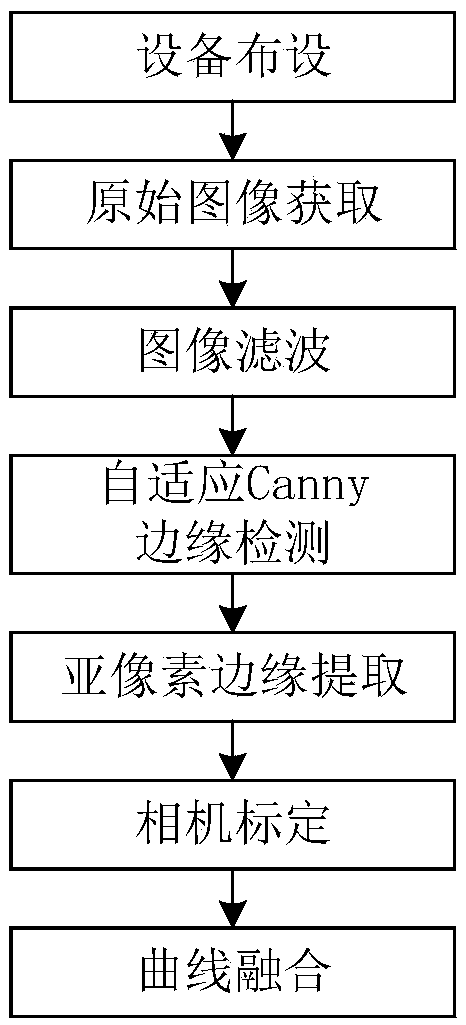

[0131] The pantograph slide wear monitoring based on sub-pixel edge detection

[0132] The on-site control and data acquisition unit includes PLC, wheel axle position sensor D, vehicle number identification device AEI, reverse industrial flashlight gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com