Grinding wheel wear detection method and system based on machine vision

A technology of machine vision and detection method, which is applied in the direction of instrumentation, image data processing, calculation, etc., can solve the problems of reducing the machining accuracy and quality of workpieces, and changing them, and achieves the effects of fast detection speed, simple detection equipment, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] The detailed content and specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

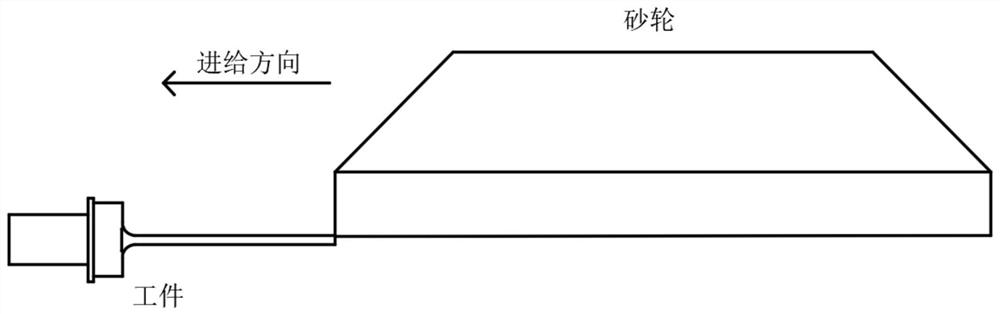

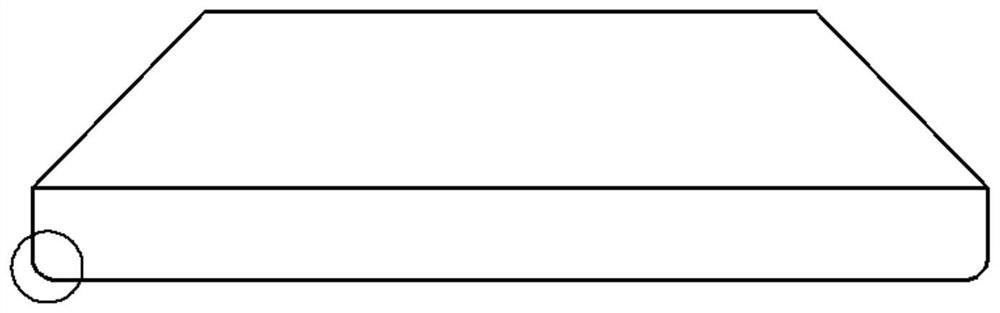

[0084] Such as figure 1 , 2 As shown, during the grinding process, the position of the workpiece is fixed, and the grinding wheel rotates at high speed to process according to the feed direction shown in the figure. As the machining progress continues to deepen, the corners of the grinding wheel will wear, so a curve will be formed at the root of the workpiece to be machined. Therefore, it is necessary to adopt a certain method to detect it accurately.

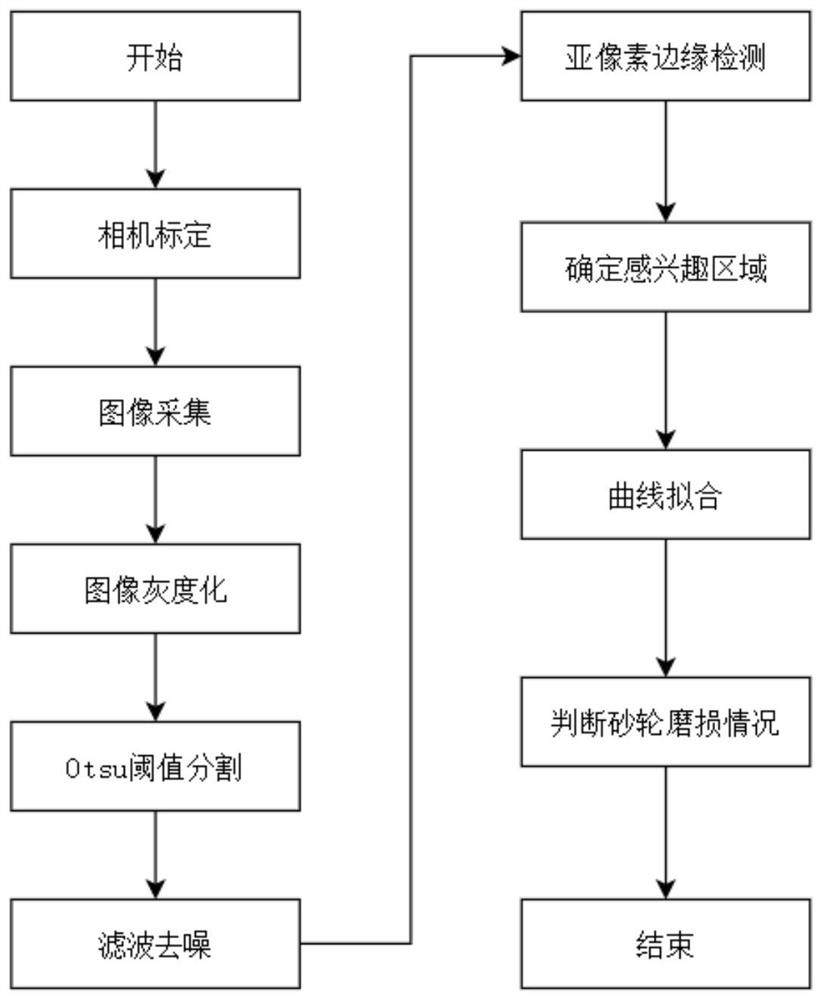

[0085] see image 3 , a method for detecting grinding wheel wear based on machine vision in this embodiment, comprising the following steps:

[0086] (1) The camera shoots 15 checkerboards in different poses, and uses MATLAB software to calibrate the internal and external parameters and distortion parameters of the camera.

[0087] (2) Place the workpiece within ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com