On-line detection method for diameter size of shaft disc type part

A detection method and a technology of parts, which are applied in the direction of metal processing machinery parts, measuring devices, measuring/indicating equipment, etc., can solve the problems of increasing the difficulty of measurement work, high cost, and the impact of measurement results, and achieve the elimination of perspective deformation and high detection efficiency , the effect of relaxing the placement requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

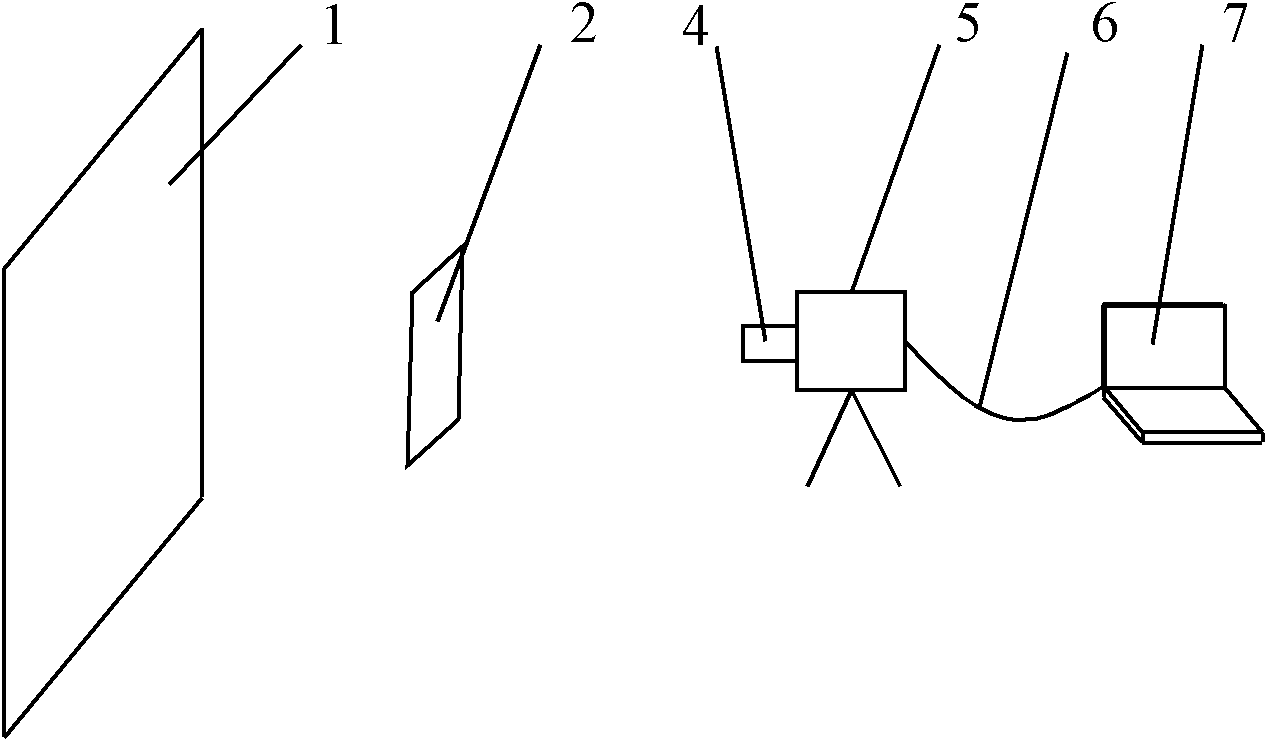

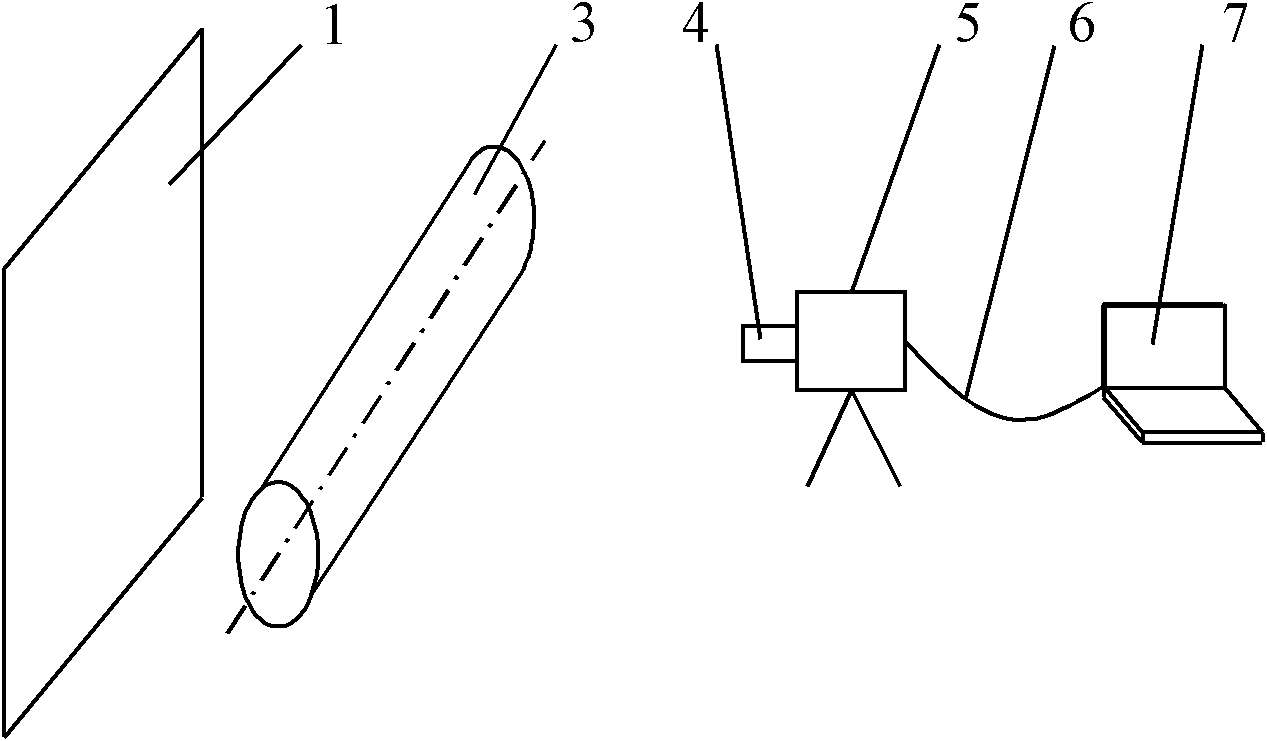

[0038] The present invention realizes the on-line measurement of the diameter of the measured part by establishing the spatial geometric relationship between the diameter of the part and the imaging plane of the CCD camera, in combination with camera calibration technology, sub-pixel edge detection technology, etc., which includes the following steps:

[0039] 1. Calibrate the internal parameters of the CCD camera. Based on the camera plane calibration algorithm proposed by Zhang Zhengyou, the internal parameters of the camera are calibrated by using the images of different postures of the high-precision calibration board to correct the distortion and deformation of the image caused by lens distortion and improve the measurement accuracy. The specific process includes the following steps:

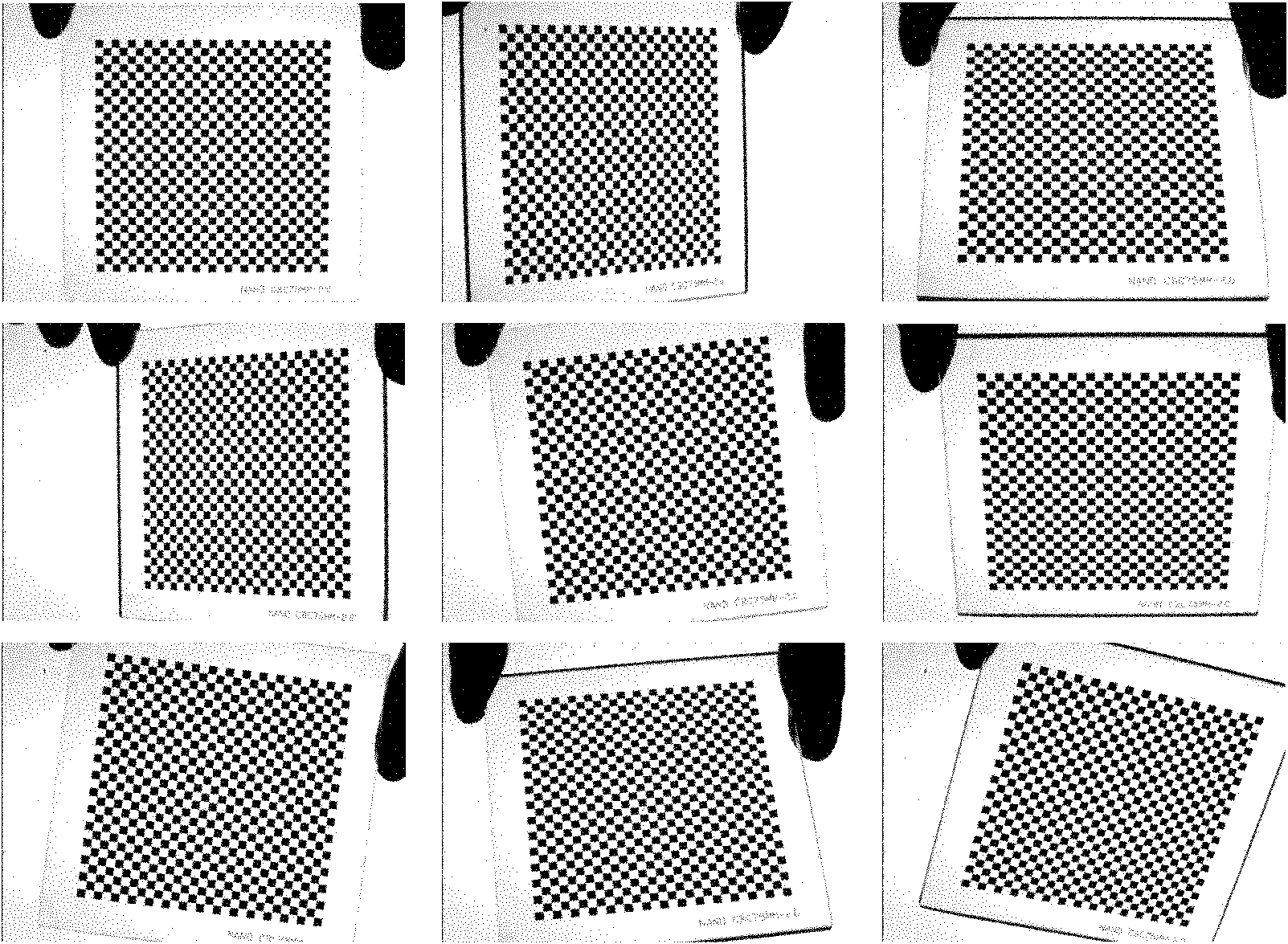

[0040] 1) Use a CCD camera to collect 9 images of different attitudes of the calibration board. Such as figure 1 As shown, the calibration board is placed between the background light sour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com