Non-contact measurement method of plane scratch length based on machine vision

A non-contact measurement and machine vision technology, applied in the direction of measuring devices, instruments, optical devices, etc., to achieve the effects of solving measurement errors, improving the scope of application, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

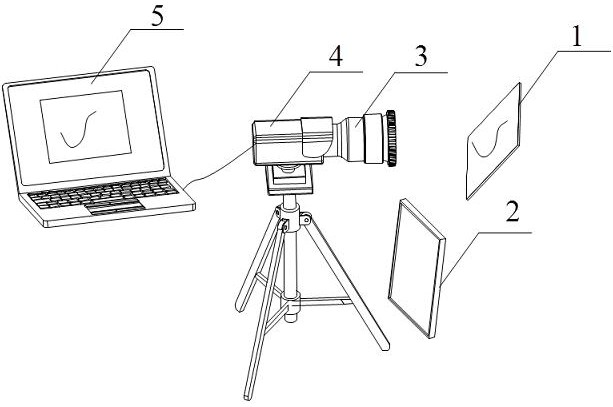

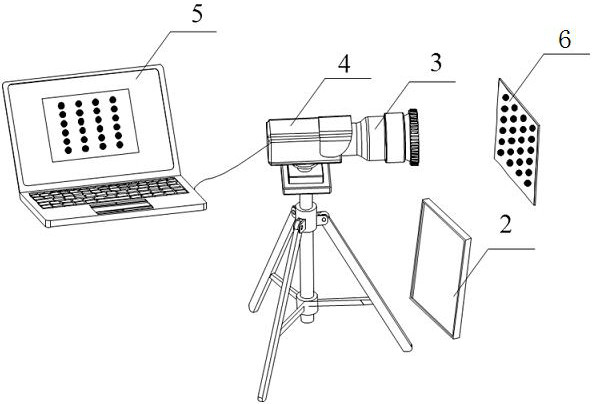

[0056] The machine vision-based non-contact measurement method of plane scratch length is to establish a rapid detection method of surface scratch length through image processing technology, and obtain surface scratches through image correction, ROI extraction, threshold segmentation and skeletonization Using the normalized ratio equivalent method to realize the measurement of the surface scratch length of the sub-pixel contour of the, it includes the following steps:

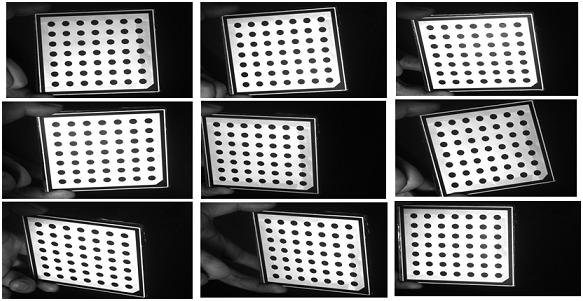

[0057] Step (1), calibrate the camera-CCD industrial camera 4 internal parameters and distortion coefficient. The images of the high-precision calibration plate 6 at different levels are collected by the camera, and the center of the solid circle on the calibration plate 6 is obtained. The camera distortion model is used to obtain the camera internal parameters and the distortion coefficient of the lens 3. The specific process includes the following steps:

[0058] (1.1) Collect 9 images of calibration plate under d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com