Sub-pixel edge detection method based on improved morphology

A sub-pixel edge and detection method technology, applied in image analysis, image data processing, instruments, etc., can solve problems such as slow speed, low precision, noise interference, etc., to improve processing speed, ensure connectivity, and improve anti-noise performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

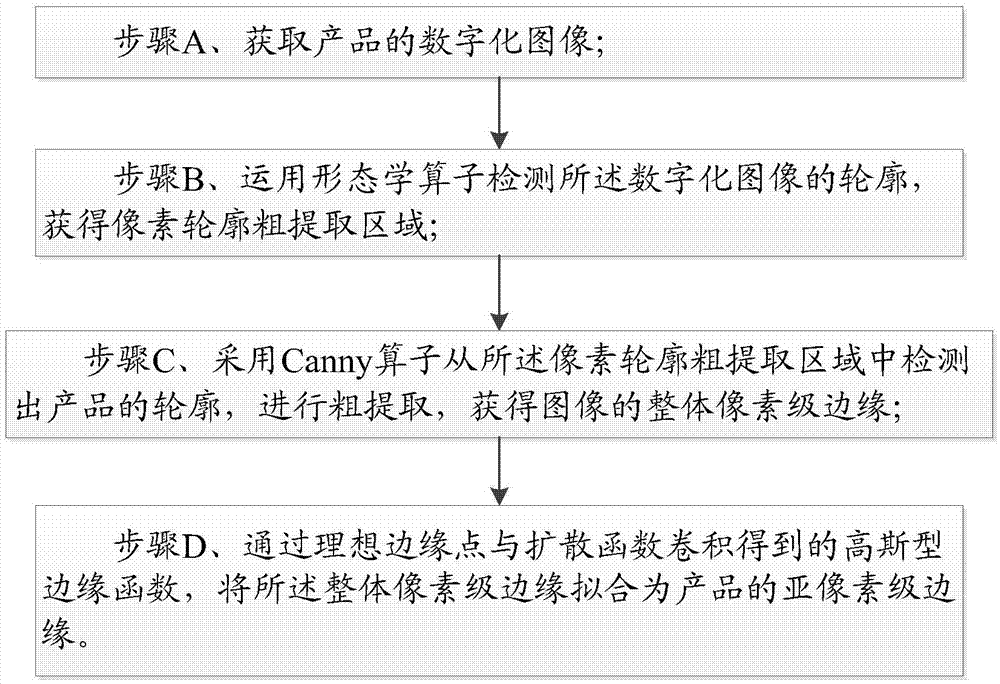

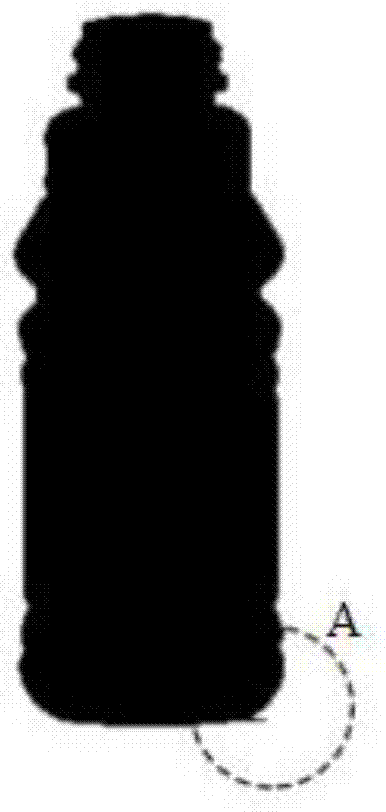

[0041] Such as figure 1 As shown in Figure 6, the sub-pixel edge detection method based on improved morphology includes:

[0042] Step A, obtaining the digitized image of the product;

[0043] Step B, using a morphological operator to detect the contour of the digitized image to obtain a rough extraction region of the pixel contour, the expression of which is

[0044]

[0045] Among them, Grad represents the rough extraction area of the pixel outline, f represents the digitized image, S 1 Represents the opening operation structure element, S 2 Indicate dilation and erosion of structural elements;

[0046] Step C, using the Canny operator to detect the outline of the product from the rough extraction area of the pixel outline, and perform rough extraction to obtain the overall pixel-level edge of the image;

[0047] Step D. Fitting the overall pixel-level edge to the sub-pixel-level edge of the product through the Gaussian edge function obtained by convolving the ide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com