Automatic meat mincing machine for meat product processing

A product, automatic technology, applied in the direction of processed meat, meat processing equipment, applications, etc., to achieve the effect of improving the efficiency of meat chopping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] An automatic meat chopping machine for meat product processing, such as Figure 1-5 As shown, it includes a support foot 1, a base plate 2, a drive mechanism 3, a meat chopping mechanism 4 and a placement mechanism 5, the four corners of the bottom of the base plate 2 are connected with support feet 1, and the top of the base plate 2 is respectively equipped with a drive mechanism 3 and a chopping mechanism 5. The meat mechanism 4 is connected with the placement mechanism 5, and the driving mechanism 3 is connected with the meat chopping mechanism 4 in transmission.

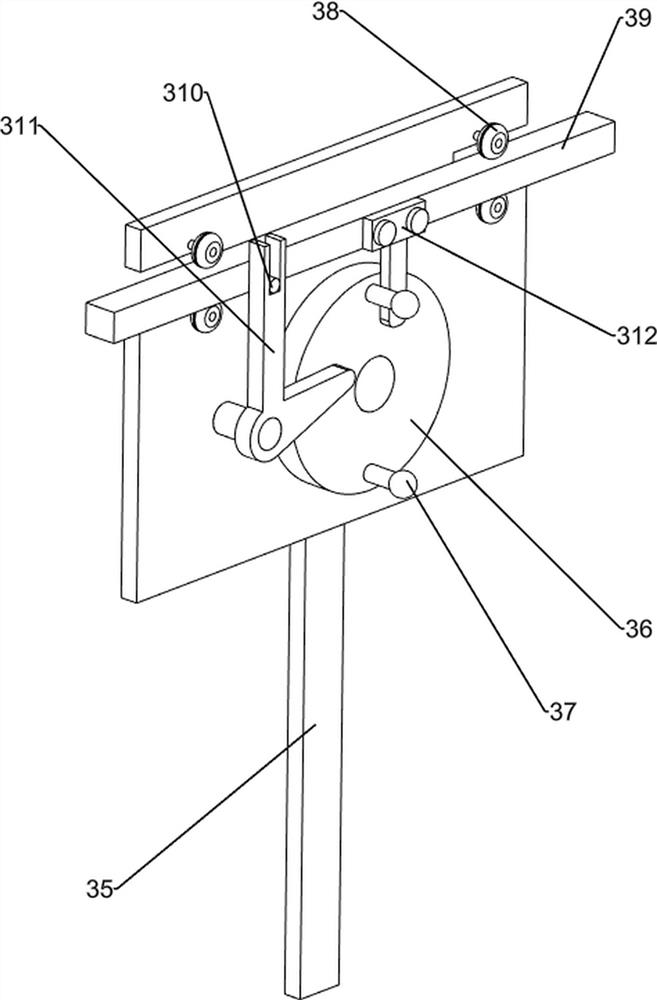

[0027] Drive mechanism 3 comprises mounting seat 31, motor 32, rotating shaft 33, first bevel gear set 34, fixed mount 35, disc 36, driving lever 37, pulley 38, movable lever 39, fixed lever 310, swing block 311, movable Block 312, connecting rod 313 and tooth bar 314, base plate 2 top right rear side is connected with mounting base 31, and the top of mounting base 31 is equipped with motor 32, and the out...

Embodiment 2

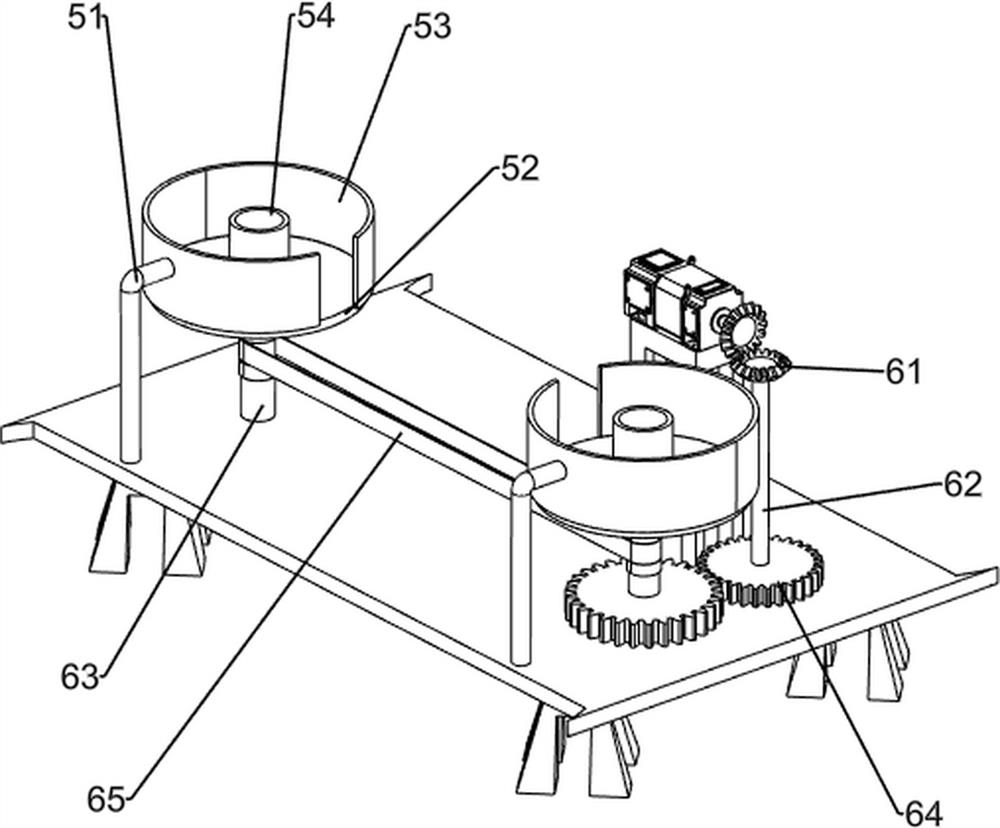

[0032] On the basis of Example 1, such as figure 1 , figure 2 and Figure 5Shown, also include rotating mechanism 6, and rotating mechanism 6 includes second bevel gear group 61, transmission rod 62, rotating rod 63, second gear 64 and transmission belt group 65, bottom plate 2 top right rear side rotation type is connected with Transmission rod 62, transmission rod 62 is positioned at the right side of mounting seat 31, is connected with the second bevel gear set 61 between transmission rod 62 and the output shaft on the right side of motor 32, is connected with rotating rod 63 at the bottom of circular plate 52, and rotating rod 63 Rotately connected with the top of the bottom plate 2, a transmission belt set 65 is connected between the two rotating rods 63, a second gear 64 is connected to the bottom of the right rotating rod 63 and the bottom of the transmission rod 62, and the two second gears 64 mesh.

[0033] The motor 32 rotates through the second bevel gear set 61 ...

Embodiment 3

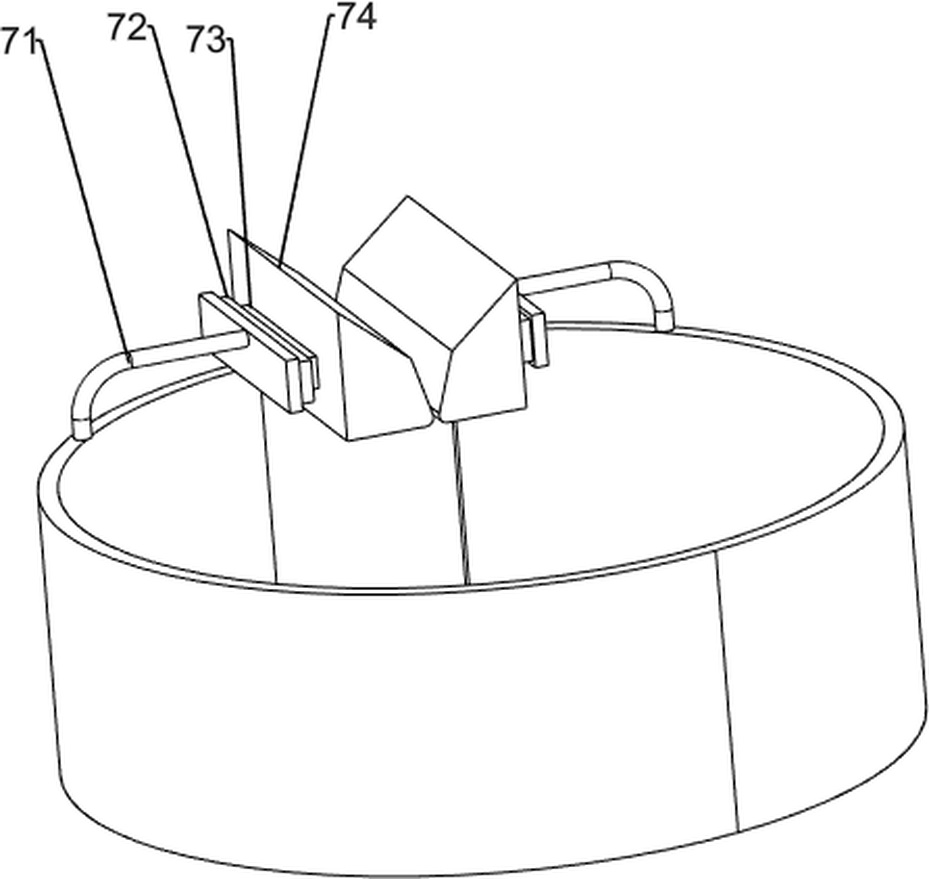

[0035] On the basis of Example 2, such as figure 1 and Figure 6 As shown, a wiping mechanism 7 is also included, and the wiping mechanism 7 includes a support frame 71, a first adhesive tape 72, a second adhesive tape 73 and a sponge block 74, and the top of the baffle plate 53 is symmetrically connected with two support frames. 71, the support frame 71 is connected with a first adhesive tape 72, the first adhesive tape 72 is bonded with a second adhesive tape 73, the second adhesive tape 73 is connected with a sponge block 74, and the sponge block 74 is in contact with the meat cleaver 43 Cooperate.

[0036] Chopper 43 can contact with sponge block 74 in the process of moving up and down, can wipe meat cutter 43 by sponge block 74, thereby can prevent minced meat from sticking on the meat chopper 43, after the work of chopping meat is finished, can The second adhesive tape 73 is torn off from the first adhesive tape 72, and then the sponge block 74 can be cleaned. After th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap