Engine hood reinforcement

A technology of engine hood and strengthening structure, which is applied in the field of auto parts, can solve the problems of uneven stress on the inner plate of the engine hood, cracking of the solder joints and the inner plate, and high cost, so as to improve the overall durability and NVH performance, logistics and Cost reduction for management, etc., and the effect of improving rigidity and modalities

Active Publication Date: 2022-06-03

DONGFENG MOTOR GRP

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The thickness of the engine hood inner plate is usually 0.5-0.7mm, the thickness of the engine hood reinforcement plate is usually 1.0-1.5mm, and the connection between the hinge reinforcement plate and the gas strut reinforcement plate is the engine hood inner plate, which has poor rigidity

The force on the hinge of the inner panel of the hood is much greater than that on the gas strut. The force on the inner panel of the hood is uneven at the hinge and the gas strut. During the durability process, the two reinforcing plates are prone to relative displacement, resulting in cracking of the solder joints and the inner panel. And other issues

[0006] 2. Due to the limitation of the structure of the inner panel of the engine hood, the size of the hinge reinforcement plate and the gas strut reinforcement plate is small, and often only the self-positioning method can be used for positioning, and the accuracy is poor

[0007] 3. The hinge reinforcement plate and gas strut reinforcement plate are set as two parts, and the manufacturing, logistics and management costs are relatively high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0046] The basic principles and main structural features of the present invention have been shown and described above. The present invention is not limited by the above examples

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

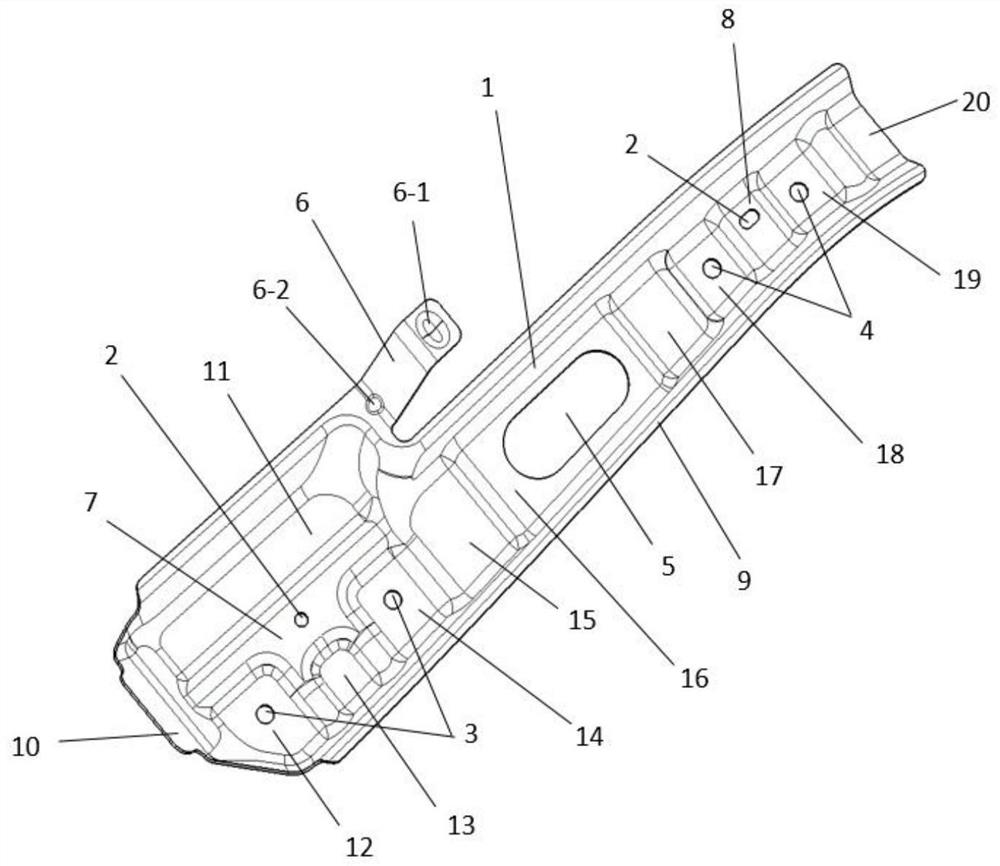

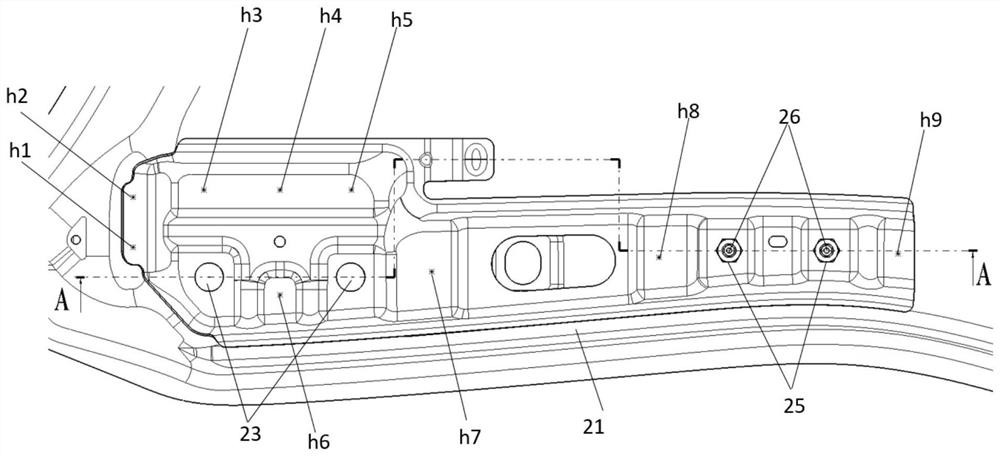

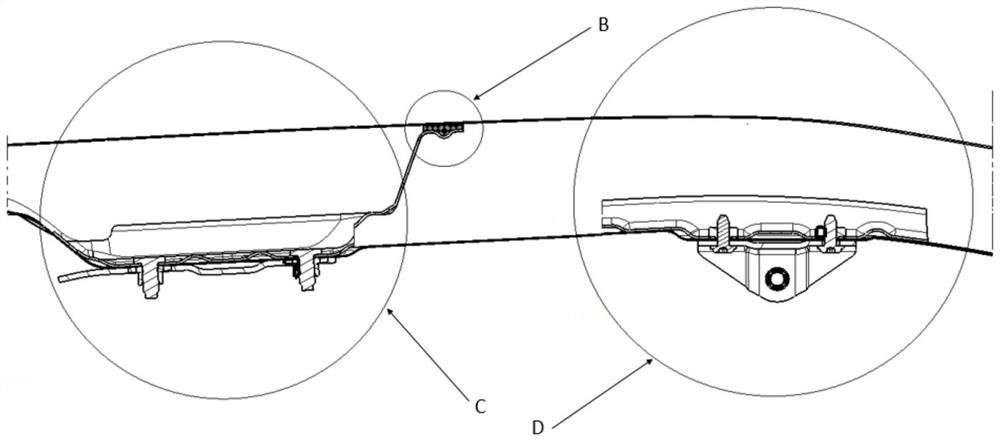

The invention relates to a hood reinforcement structure. The hood reinforcement structure comprises a hood reinforcement plate, and the hood reinforcement plate is provided with hinge installation holes for installing engine hood hinges and gas struts for installing gas strut brackets. The mounting holes of the bracket, the hood reinforcement plate are connected with the inner panel of the hood by spot welding. The hood reinforcement plate integrates the hinge reinforcement plate and the gas strut reinforcement plate, and the hinge shaft, the hood reinforcement plate and the gas strut body reinforcement plate form a triangular structure with good stability; after the hinge reinforcement plate and the gas strut reinforcement plate are integrated , the size of the reinforcement plate is large, and it is fixed on the inner panel of the engine hood through multiple welding points, so the rigidity is better; the double reinforcement structure is set at the hinge and the single reinforcement structure is set at the gas strut, so as to improve the overall rigidity and mode of the engine hood. Optimize the stress on the inner panel of the hood, prevent cracking of solder joints and the inner panel of the hood, and improve the overall durability and NVH performance of the hood.

Description

Engine hood reinforcement technical field [0001] The present invention relates to the technical field of auto parts, in particular to a hood reinforcement structure. Background technique In order to improve the use safety of user experience and engine cover, more and more automobiles begin to use gas struts to Replaces mechanical struts. The existing automobile hood is provided with two reinforcing plate parts for the reinforcement of the hinge and the gas strut respectively, wherein the hinge The chain reinforcement plate is located at the rear of the hood, and the gas strut reinforcement plate is located in the middle of the hood. The inner plate of the hood is connected; and the hinge reinforcement plate and gas strut reinforcement plate of the existing automobile hood are small in size, and most of them are customized Positioning and fixing in a bit manner. [0004] The existing engine cover has the following disadvantages: 1, under the closed state of the ho...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B62D25/12

CPCB62D25/12

Inventor 梁艳杨飘张玉刘颖文卢汉桥

Owner DONGFENG MOTOR GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com