Helicopter rotor maintenance and detection device for aviation industry

A helicopter rotor and detection device technology, applied in the field of aviation maintenance, can solve the problems of inconvenient inspection and inspection of the rotor, lower inspection efficiency, time-consuming and laborious replacement of the rotor rubber strip, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

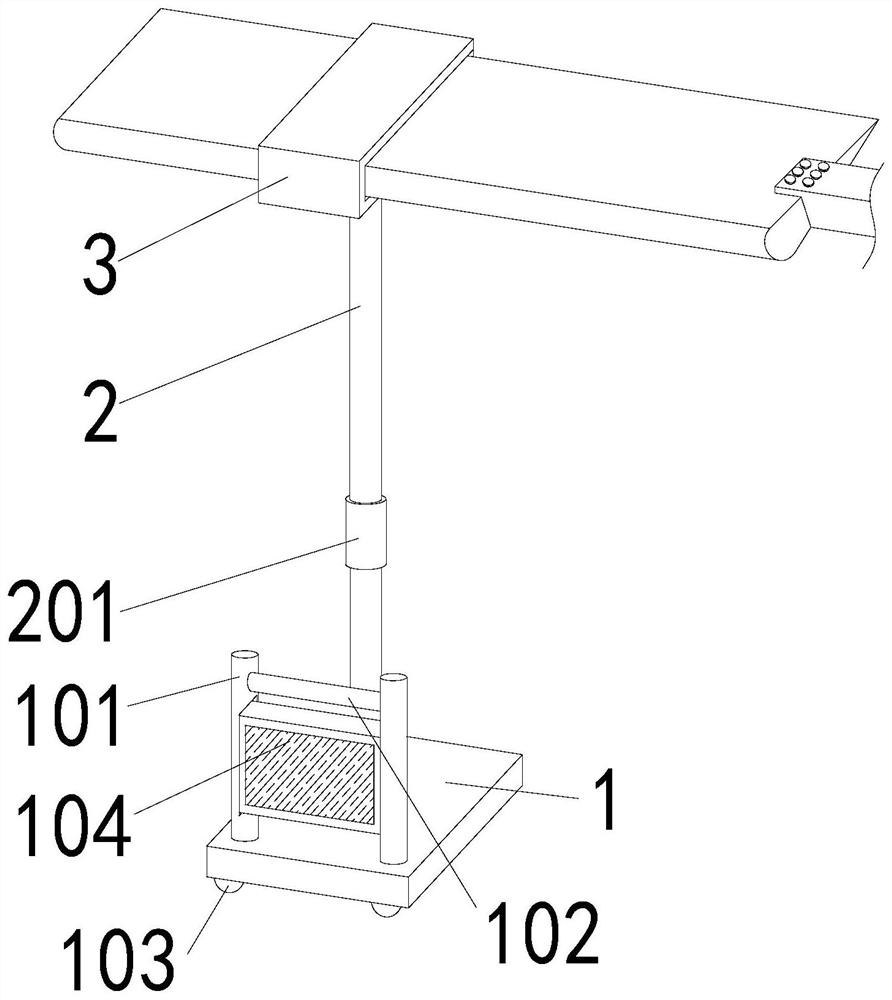

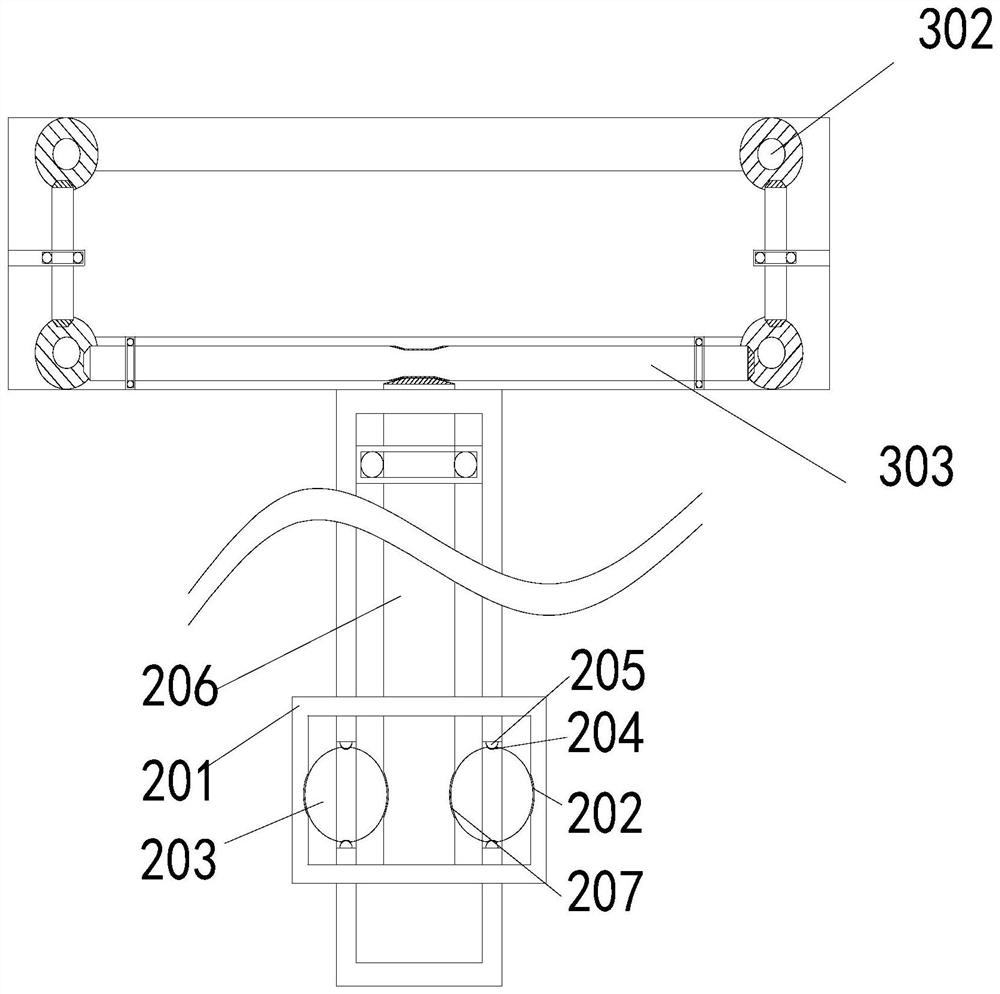

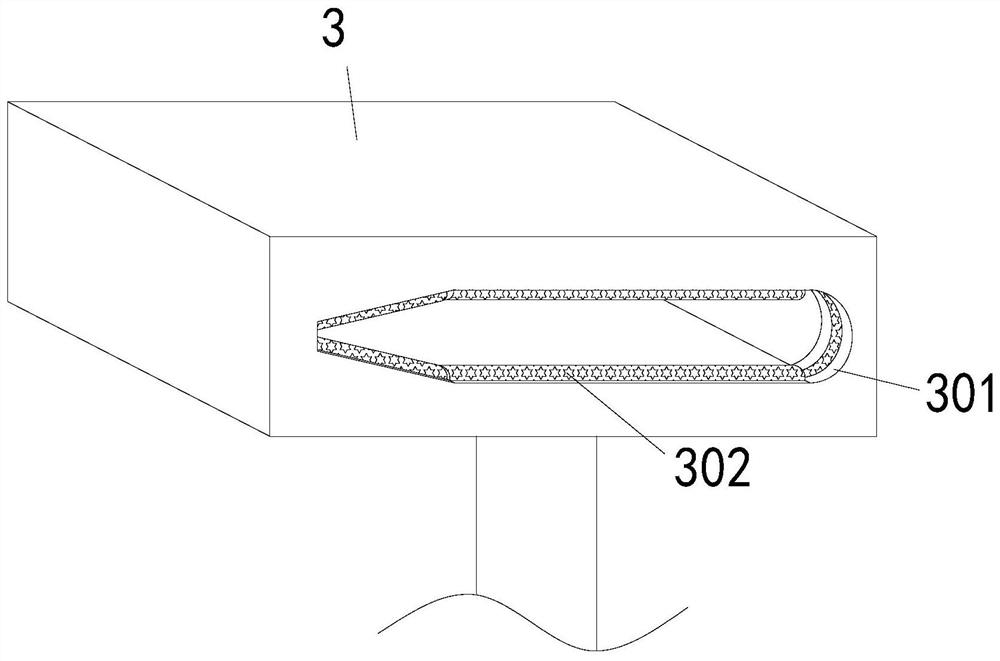

[0031] as attached figure 1 to attach Figure 8 Shown: a helicopter rotor maintenance detection device for the aviation industry, including a base 1, a support rod 2, and a detection device 3, wherein the support rod 2 is movably connected to the center of the top of the base 1, and the middle and lower parts of the support rod 2 are equipped with a drive Device 201, while the detection device 3 is movably connected to the top of the pole 2, the inner bearing of the pole 2 is connected to the driving rod 206, and the middle and lower section of the shaft of the driving rod 206 is provided with an engaging groove 207, and the inner walls of the two sides of the driving device 201 are provided with There is a driving ball groove 202, and a driving ball 203 is meshed and connected to the driving ball groove 202. The driving ball 203 extends to the inside of the pole 2 and engages with the engaging groove 207. The driving ball 203 penetrates the upper ends of the pole 2. A ball g...

Embodiment 2

[0045] When it is necessary to attach the rotor rubber strip to the windward side of the rotor, when the rubber strip in the right side plate 306 in the detection device 3 reaches the expected attachment position with the rotating shaft 324, the driving device 201 on the pole 2 is twisted, and the At this time, the internal drive ball 203 will rotate in the drive ball groove 202, and at the same time drive the drive rod 206 to rotate. At this time, the drive rod 206 will drive the drive shaft at the bottom of the right side plate 306 to rotate. When the drive shaft rotates, it will drive the rubber strip to take The rotating shaft 324 rotates, so that the rubber strip roll 323 engaged with the rubber strip taking rotating shaft 324 rotates, and at the same time, the rubber strip on the rubber strip rolling 323 is taken out under the action of the rotating shaft 324 and attached to the windward surface of the rotor. With the movement of the detection device 3, the rotor with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com