Bolt tightening machine for automobile factory

A technology of automobile factory and screwing machine, which is applied in the field of automobile parts processing, and can solve the problems of laboriousness and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

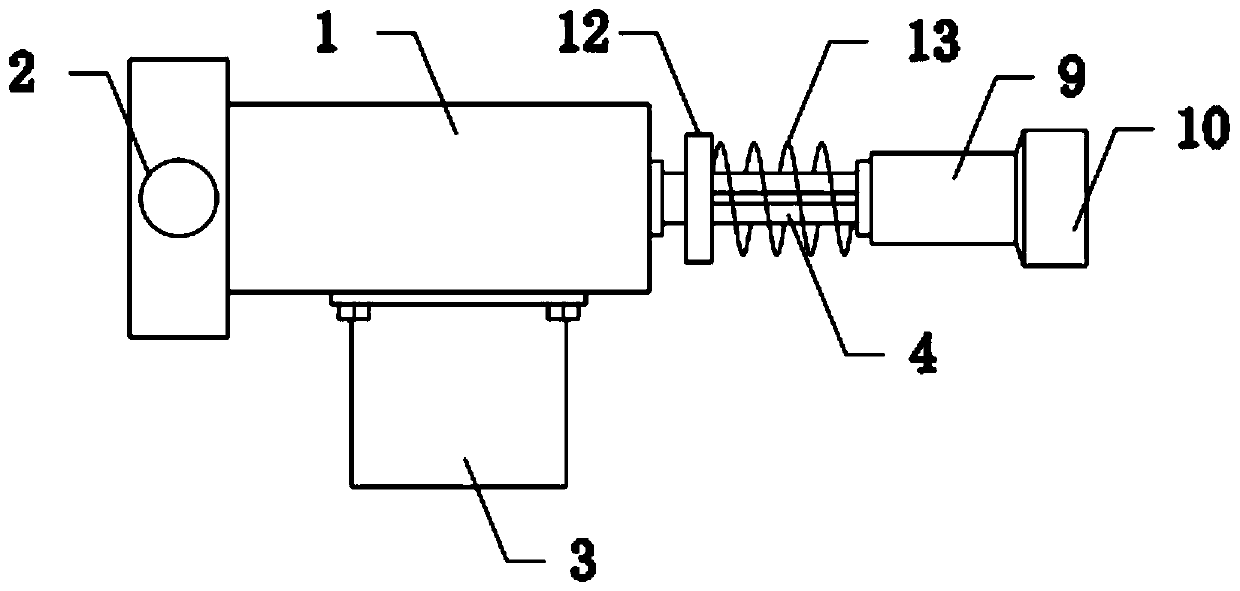

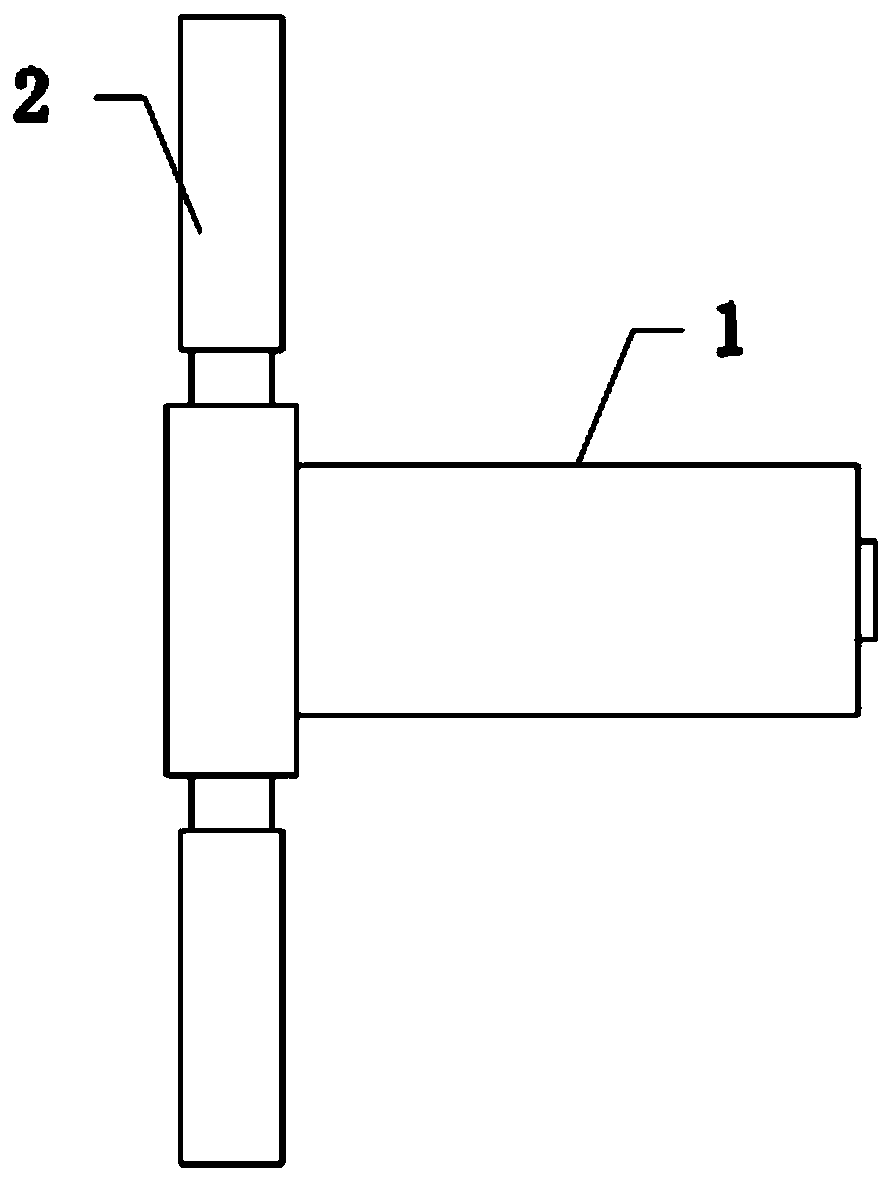

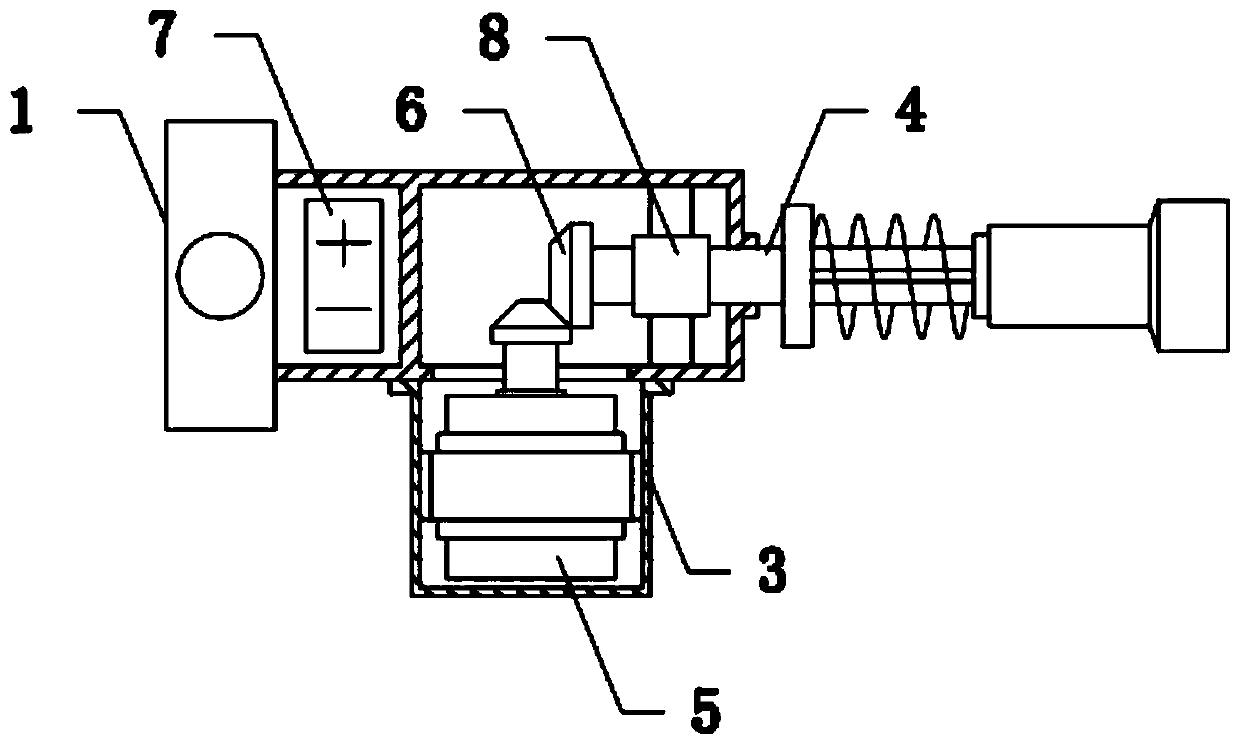

[0026] see Figure 1-4 , the present invention provides a technical solution: a bolt tightening machine for an automobile factory, comprising an outer casing 1 and a driving casing 3, the driving casing 3 is fixedly connected to the bottom of the outer casing 1 by screws, and the right side wall of the outer casing 1 is inserted transversely A rotating shaft 4 is connected, and a sliding sleeve 9 is sleeved on the right side of the outer wall of the rotating shaft 4;

[0027] The rotating shaft 4 can rotate on the outer casing 1, and a support bearing is installed at the connection between the outer casing 1 and the rotating shaft 4, and the supporting bearing is sleeved on the outer wall of the rotating shaft 4, so that the rotation of the rotating shaft 4 is stable;

[0028] The inner wall of the sliding sleeve 9 is provided with a slider, and the outer wall of the rotating shaft 4 is axially provided with a chute, and the slider is clamped in the chute;

[0029] Through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com