Chain belt-type variable transmission

A continuously variable transmission, chain-belt type technology, applied to components with teeth, belts/chains/gears, mechanical equipment, etc., can solve problems such as sliding, vibration and noise, and inability to transmit power to expand the contact area , Reduce vibration and noise, reduce vibration and noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

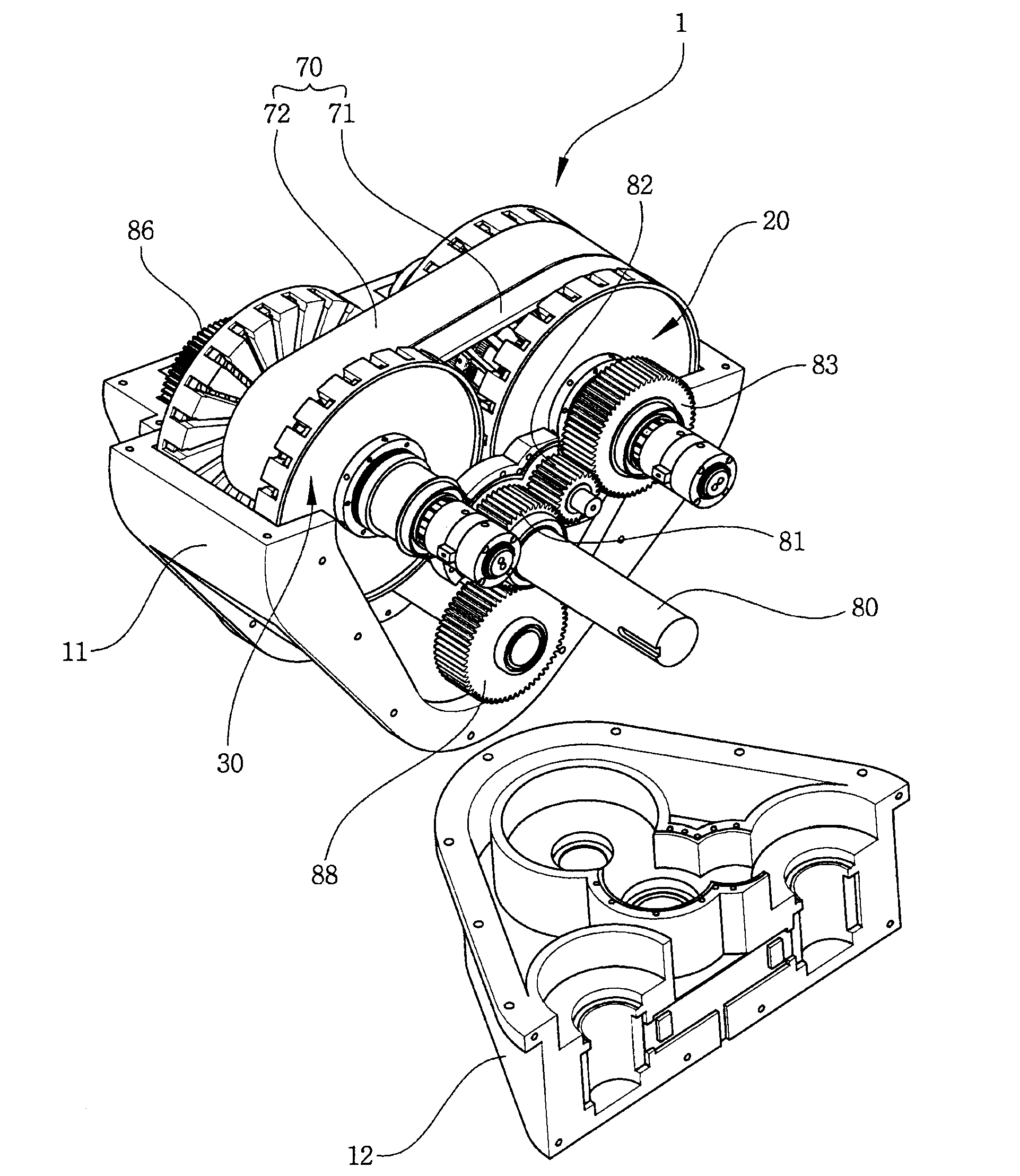

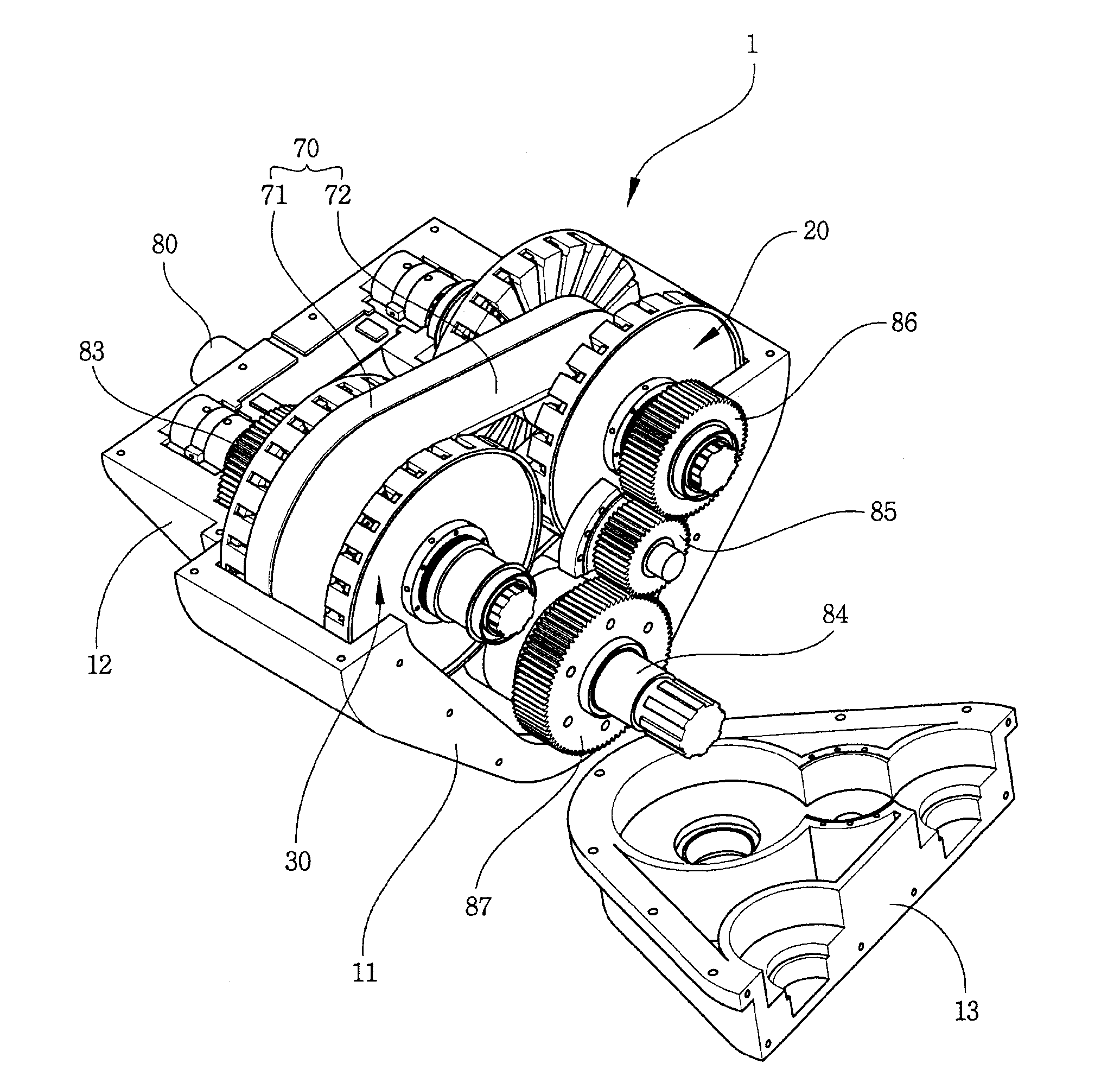

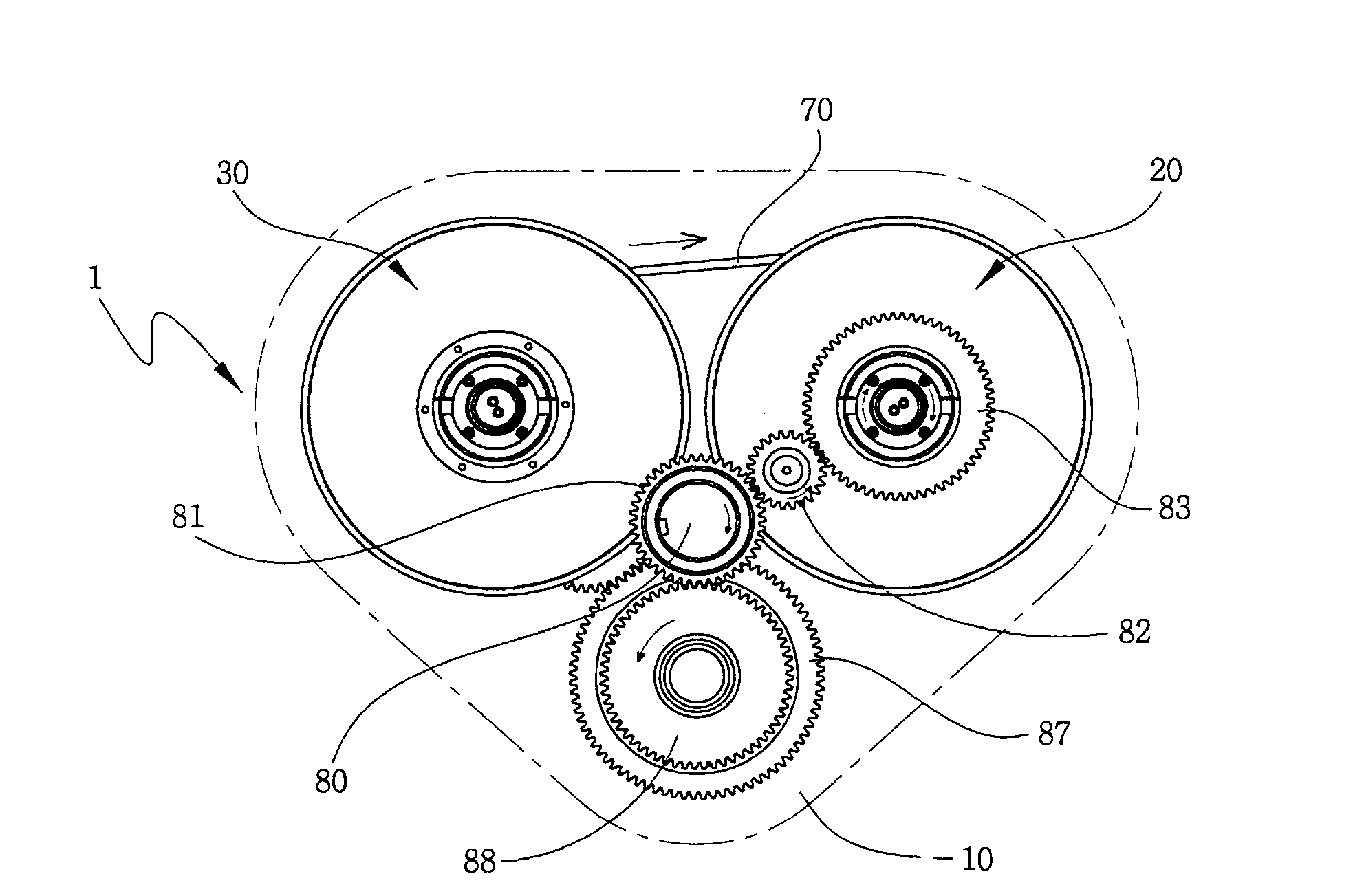

[0035] Below, refer to the attached Figure 1 to Figure 19 , the chain-belt type continuously variable transmission of the present invention will be described as follows.

[0036] figure 1 and figure 2It is a drawing showing a chain-belt type continuously variable transmission according to the present invention, and is a diagram showing a disassembled state in which each front case 12 and rear case 13 are exposed while omitting the illustration of the upper case and showing the gear connection mechanism of the power transmission process. The illustrated front perspective view and rear perspective view, while Figure 8 will be figure 1 The illustrated bottom perspective view of the illustrated transmission body 2 rotated 180 degrees in the clockwise direction.

[0037] This type of chain-belt type continuously variable transmission 1 based on the present invention is as figure 1 , figure 2 and Figure 8 As shown, it is composed of a case and a transmission body 2. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com