Scroll plate assembly, scroll compressor and air conditioner

A technology of scroll compressors and scroll disks, which is applied in the field of compressors and can solve problems affecting the energy efficiency of scroll compressors, gas flow loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

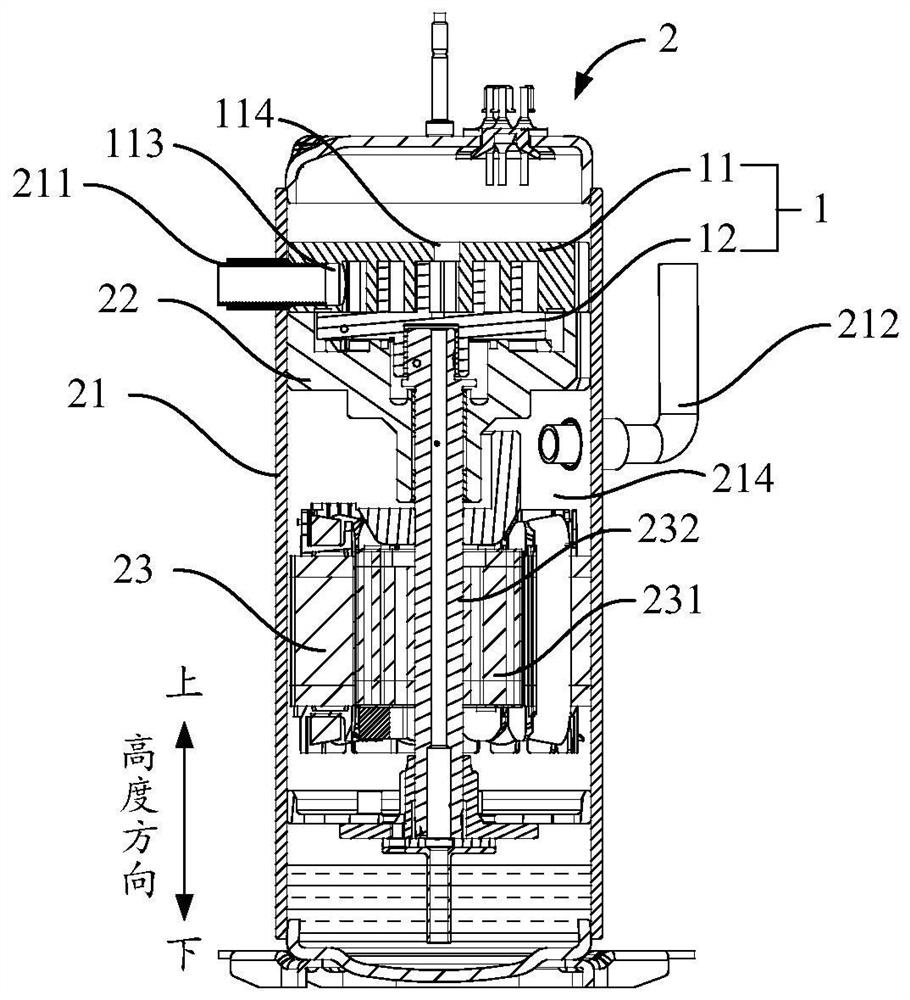

[0077] This embodiment provides a scroll assembly 1 that can be used in a scroll compressor 2 .

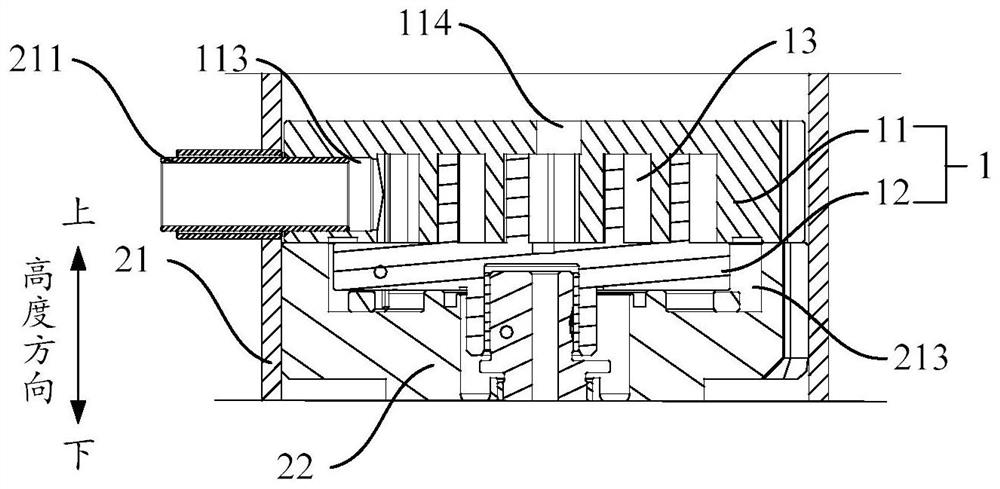

[0078] Such as figure 1 and figure 2As shown, the scroll assembly 1 includes a stationary disk 11 (ie, a fixed scroll) and a moving disk 12 (ie, a movable scroll). The moving disk 12 and the static disk 11 are engaged with each other, and a working chamber 13 is formed between the moving disk 12 and the static disk 11 .

[0079] The moving disk 12 can move in translation relative to the static disk 11 , and during the operation of the moving disk 12 , the shape and volume of the working chamber 13 change dynamically.

[0080] The static disc 11 is provided with an air inlet 113 and an air outlet 114; when assembled in the scroll compressor 2, the air inlet 113 communicates with the air inlet pipe 211 of the scroll compressor 2, and the air outlet 114 communicates with the air inlet pipe 211 of the scroll compressor. The exhaust chamber 214 of 2 communicates.

[0081] During t...

Embodiment 2

[0088] This embodiment provides a scroll assembly 1, which is further improved on the basis of the first embodiment.

[0089] Such as Figure 1 to Figure 4 As shown, as the pressure in the working chamber 13 changes, the oil injection channel 115 communicates with and disconnects with the oil injection groove 123 and the working chamber 13 alternately.

[0090] When the pressure of the working chamber 13 is greater than the pressure of the back pressure chamber 213, the pressure of the working chamber 13 is higher at this time, and the operation of the moving plate 12 disconnects the oil injection channel 115, the oil injection groove 123 and the working chamber 13. To prevent the gas in the working chamber 13 from entering the back pressure chamber 213 through the oil injection channel 115 and the oil injection groove 123, so as to reduce gas loss.

[0091] When the pressure of the working chamber 13 is lower than the pressure of the back pressure chamber 213, the pressure o...

Embodiment 3

[0094] This embodiment provides a scroll assembly 1, which is further improved on the basis of the second embodiment.

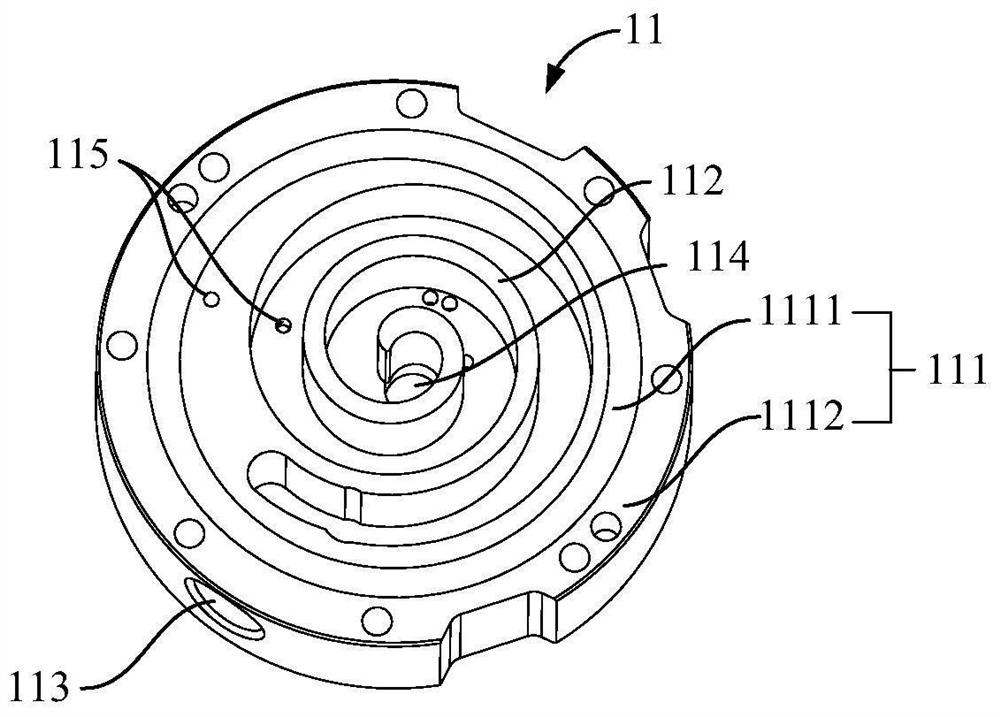

[0095] Such as Figure 1 to Figure 4 As shown, the stationary disk 11 specifically includes a stationary disk end plate 111 (ie, a first end plate) and a stationary disk scroll 112 (ie, a static scroll structure). The static disk scroll 112 is arranged on the bottom surface of the static disk end plate 111 and is arranged in a spiral shape. Exhaust holes 114 are located in the static disk scroll 112 to facilitate exhaust.

[0096] Such as Figure 5 and Figure 6 As shown, the oil injection channel 115 specifically includes an oil injection hole 1151, a connecting hole and a back pressure hole 1153. The back pressure hole 1153 is arranged on the bottom surface of the static disk end plate 111, the oil injection hole 1151 is arranged on the bottom surface of the static disk scroll 112, and the oil injection hole 1151 and the back pressure hole 1153 are blin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com