Red date pitting device using barrel-shaped sawtooth opening for food processing

A food processing and pitting device technology, which is applied in fruit pitting devices, applications, food science, etc., can solve the problems of low efficiency of pitting, easy deformation of red dates, and low efficiency of pulp protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

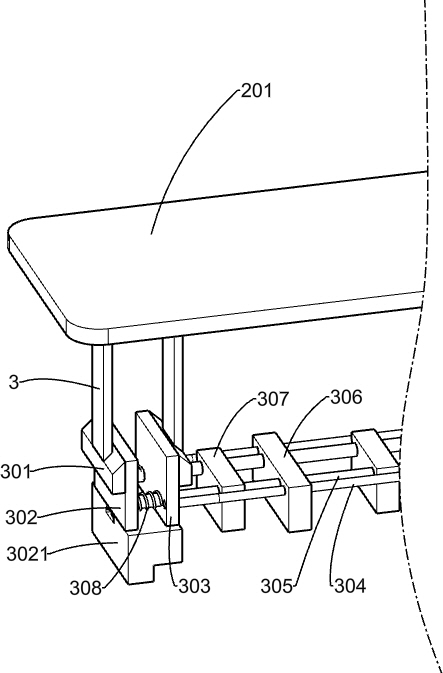

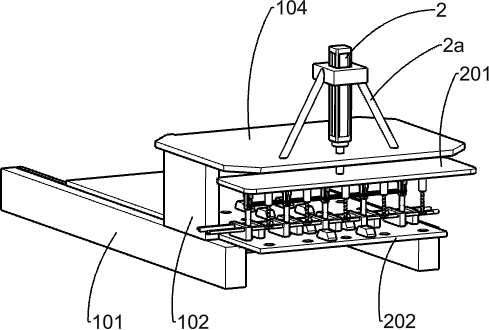

[0070] A kind of jujube pitting device for food processing using barrel-shaped sawtooth mouth, such as Figure 1-2 Shown in and 4-5, include vehicle frame 1, guide rail 101, connecting plate 1011, support plate 102, support frame 103, the first fixed plate 104, collecting frame 6 and denucleating mechanism, vehicle frame 1 is made of a flat plate and four Two guide rails 101 are fixedly installed on the front and rear sides of the upper part of the flat plate of the vehicle frame 1 near the left side, the front and rear sides of the connecting plate 1011 are fixedly connected to the inner side of the two guide rails 101 near the left end, and the two support plates 102 are respectively Fixedly installed on the right side of the upper part of the two guide rails 101, the front and rear ends of the support frame 103 are respectively fixedly installed on the top of the two guide rails 101 near the middle position, and the first fixed plate 104 is fixedly installed on the upper sid...

Embodiment 2

[0073] On the basis of Example 1, such as figure 2 and 4 As shown in -5, the denucleating mechanism includes a support 2a, a first cylinder 2, a second fixed plate 201, a material receiving plate 202, a first pole 203, a slide bar 204, a first spring 205, a sliding sleeve 206, and a sliding frame 207. Sawtooth tube 208 and clamping mechanism, the bracket 2a is fixedly installed in the upper right middle position of the first fixed plate 104, the first cylinder 2 is fixedly installed on the bracket 2a, and the telescopic rod of the first cylinder 2 passes through the first fixed plate 104, the second fixed plate 201 is fixedly installed on the lower end of the telescopic rod of the first cylinder 2, the front and rear sides of the material receiving plate 202 are slidingly connected with the inner sides of the two guide rails 101, there are five first support rods 203, five second A rod 203 is arranged and fixedly installed on the lower left side of the second fixed plate 201...

Embodiment 3

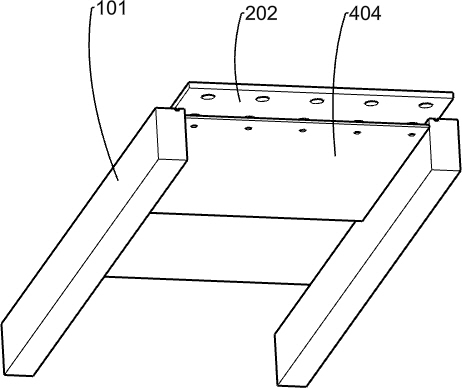

[0078] On the basis of Example 2, such as image 3 and 6 As shown, a pusher mechanism is also included, and the pusher mechanism includes a fixed cylinder 4, a sliding column 401, a push plate 403, a third spring 402 and a baffle plate 404, and five fixed cylinders 4 are evenly distributed in an array on the second fixed plate On the right side of the lower part of 201, five sliding columns 401 are slidingly connected with the lower sides of five fixed cylinders 4 respectively, each push plate 403 is fixedly installed on the lower end of each sliding column 401, and five third springs 402 are sleeved on the sliding On the column 401 , the third spring 402 is located between the fixed cylinder 4 and the push plate 403 , the baffle plate 404 is fixedly installed between the two guide rails 101 , and the guide plate is located in the middle below the material receiving plate 202 .

[0079] When the part of red dates with the pitting of the stock plate 202 is pushed to the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com